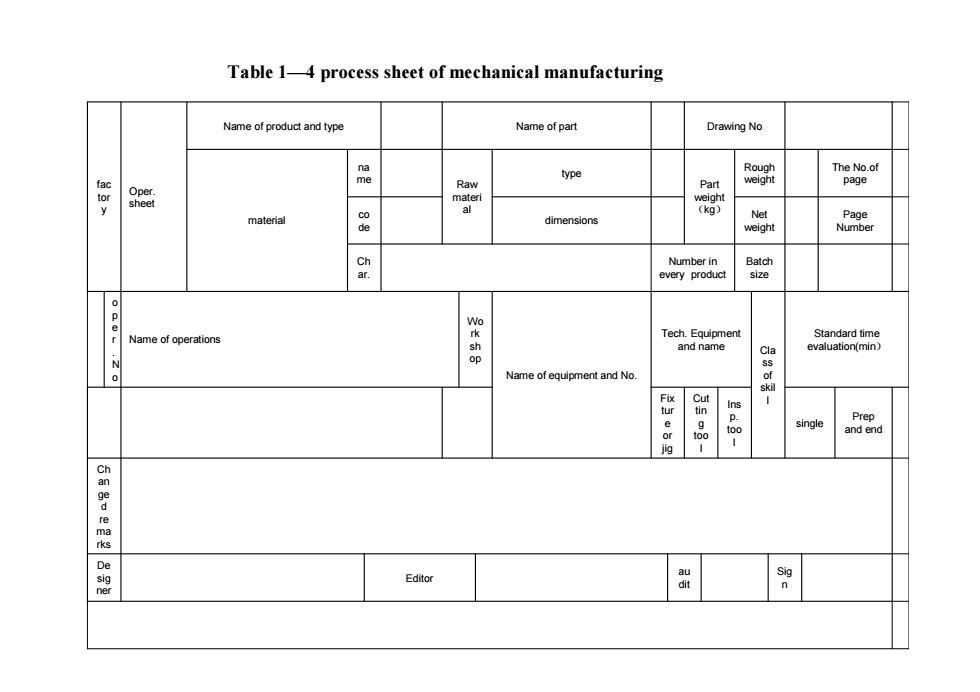

Table 14process sheet of mechanical manufacturingName of product and typeName of partDrawing NoRoughnaThe No.oftypemeweightpagefacRawPartOper.tormateriweightsheetaly(kg)NetPagecomaterialdimensionsdeNumberweightCh Number inBatchar.every productsize0Q@WorkTech. EquipmentStandard timeName ofoperationsshand nameevaluation(min)Cla:2opssof0Name ofequipmentand No.skilFixCut1Insturtinp.Prep1009singletooand endtoo11Chan80remarksDeauSigsigEditorditnner

Sig n au dit Editor De sig ner Ch an ge d re ma rks Prep and end single Ins p. too l Cut tin g too l Fix tur e or jig Standard time Cla evaluation(min) ss of skil l Tech. Equipment and name Name of equipment and No. Wo rk sh op Name of operations o p e r . N o Batch size Number in every product Ch ar. Page Number Net weight dimensions co de The No.of page Rough weight Part weight (kg) type Raw materi al na me material Name of product and type Name of part Drawing No Oper. sheet fac tor y Table 1—4 process sheet of mechanical manufacturing

1.2.2 The function of processplanning sheetThe function of the process planning sheet is as follows :(1) The main technique for giving regulations to guide the production(2) The basis of organization and management(3) The main information to guide the building, enlarging orrebuilding ofamechanicalfactory

1.2.2 The function of process planning sheet The function of the process planning sheet is as follows : (1)The main technique for giving regulations to guide the production (2) The basis of organization and management (3) The main information to guide the building, enlarging or rebuilding of a mechanical factory

1.2.3Designproceduresofprocessplanning(1)DesignproceduresofprocessplanningFirstly,the function,importance and working condition of thepartshouldbeclarified.If the design details are considered unreasonable or wrongduring inspection, suggestions to modify the design can be proposed

1.2.3 Design procedures of process planning (1)Design procedures of process planning Firstly, the function, importance and working condition of the part should be clarified. If the design details are considered unreasonable or wrong during inspection, suggestions to modify the design can be proposed

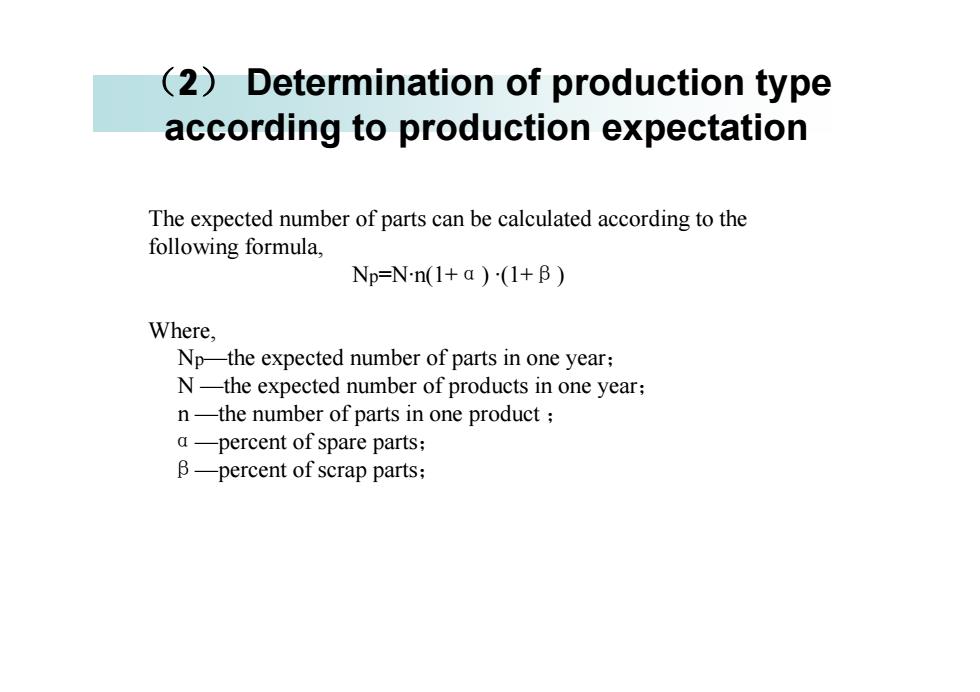

(2)Determinationof productiontypeaccordingtoproductionexpectationTheexpectednumberofpartscanbecalculatedaccordingtothefollowing formula,Np=N·n(1+ α) -(1+ β)Where,Nptheexpectednumberofpartsinoneyear;Ntheexpectednumberofproductsinoneyear;n -the number of parts in one product ;apercentof spareparts;βpercent of scrapparts;

(2) Determination of production type according to production expectation The expected number of parts can be calculated according to the following formula, Np=N·n(1+α) ·(1+β) Where, Np—the expected number of parts in one year; N —the expected number of products in one year; n —the number of parts in one product ; α—percent of spare parts; β—percent of scrap parts;

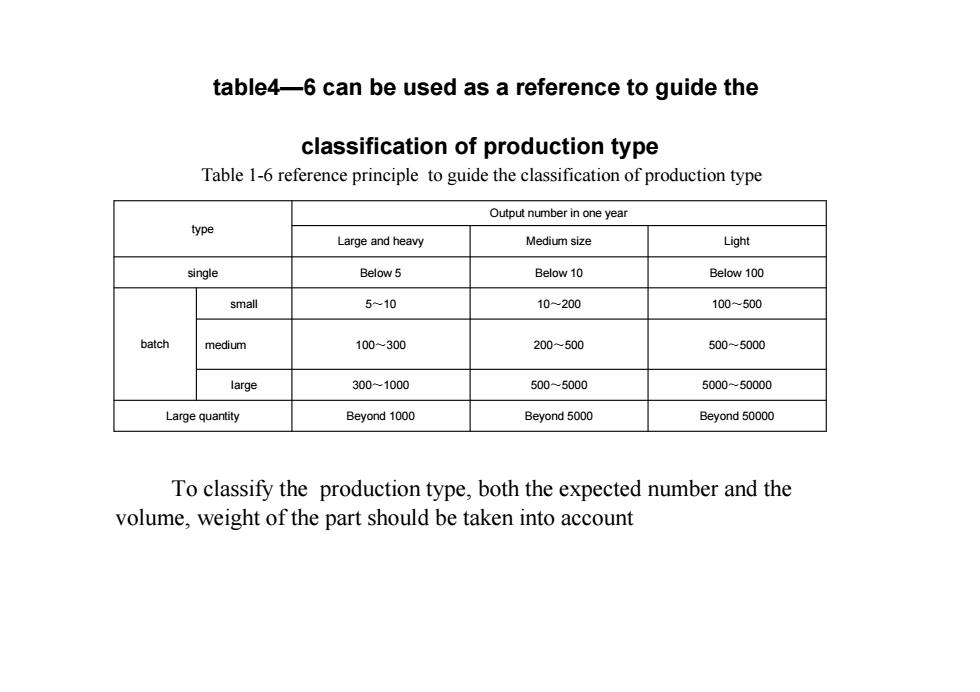

table46canbeusedasareferencetoguidetheclassificationofproductiontypeTable1-6referenceprincipleto guide the classificationofproductiontypeOutput numberinoneyeartypeMedium sizeLightLargeand heavysingleBelow5Below10Below100small5~1010~200100~500batch100~300200~500500~5000mediumlarge300~1000500~50005000~50000Beyond 1000Beyond 5000Beyond 50000Large quantityTo classify the production type, both the expected number and thevolume,weightofthepartshouldbetaken intoaccount

table4—6 can be used as a reference to guide the classification of production type To classify the production type, both the expected number and the volume, weight of the part should be taken into account Large quantity Beyond 1000 Beyond 5000 Beyond 50000 large 300~1000 500~5000 5000~50000 medium 100~300 200~500 500~5000 small 5~10 10~200 100~500 batch single Below 5 Below 10 Below 100 Large and heavy Medium size Light Output number in one year type Table 1-6 reference principle to guide the classification of production type