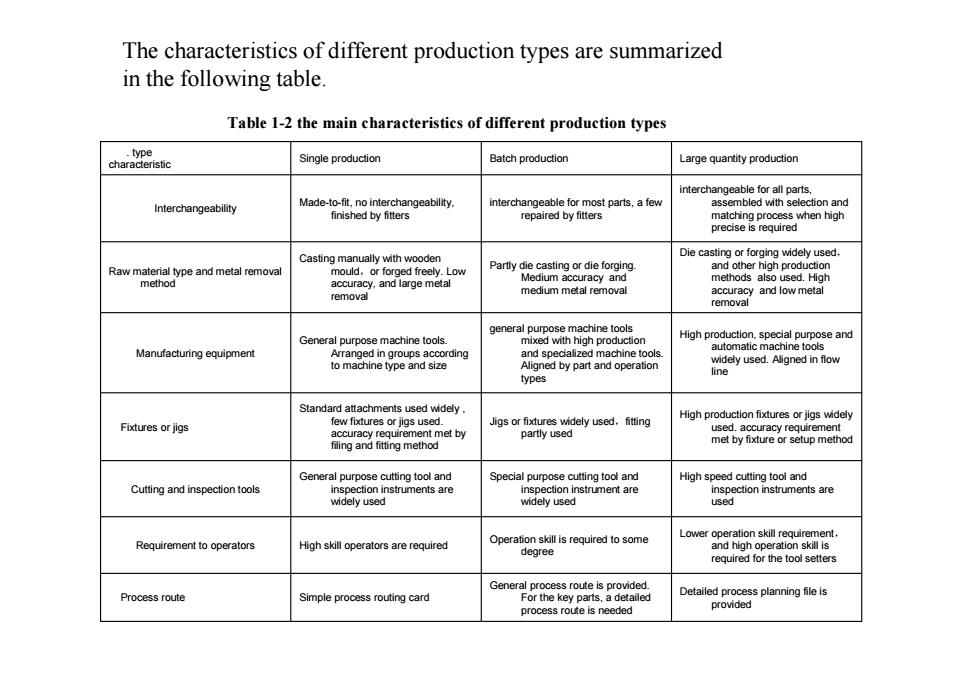

ThecharacteristicsofdifferentproductiontypesaresummarizedinthefollowingtableTable 1-2the main characteristics of different production types.typeSingle productionBatch productionLargequantityproductioncharacteristicinterchangeable for all parts,Made-tofit, no interchangeability.interchangeable for most parts, a fewassembled with selection andInterchangeabilityfinished by fittersrepaired by fittersmatching process when highprecise is requiredDie casting or forging widely used,Casting manually with woodenPartly die casting or die forgingand other high productionRawmaterial typeandmetal removalmould,or forged freely. LowMedium accuracy andmethods also used. Highmethodaccuracy, and large metalmedium metal removalaccuracy and low.metalremovalremovalgeneral purpose machine toolsHigh production, special purpose andGeneral purpose machine toolsmixed with high productionautomatic machine toolsManufacturing equipmentArranged in groups accordingand specialized machine toolswidely used. Aligned in flowto machine type and sizeAligned by part and operationlinetypesStandard attachments used widelyHighproductionfixtures orjigs widelyJigsorfixturs widelyuedftigfew fixtures or jigs used.Fixtures or jigsused. accuracy requirementaccuracy requirement met bypartly usedmet by fixture or setup methodfling and fitting methodGeneral purpose cutting tool andSpecial purpose cutting tool andHigh speed cutting tool andCutting and inspection toolsinspection instruments areinspection instrument areinspection instruments areusedwidely usedwidely usedLoweroperation skill requirement,Operation skill s required to someRequirement to operatorsHigh skill operators are requiredand high operation skill isdegreerequired for the tool settersGeneral process route is provided.Detailed process planning file isProcess routeSimple process routing cardFor the key parts,a detailedprovidedprocess route is needed

The characteristics of different production types are summarized in the following table. Table 1-2 the main characteristics of different production types Detailed process planning file is provided General process route is provided. For the key parts, a detailed process route is needed Process route Simple process routing card Lower operation skill requirement, and high operation skill is required for the tool setters Operation skill is required to some degree Requirement to operators High skill operators are required High speed cutting tool and inspection instruments are used Special purpose cutting tool and inspection instrument are widely used General purpose cutting tool and inspection instruments are widely used Cutting and inspection tools High production fixtures or jigs widely used. accuracy requirement met by fixture or setup method Jigs or fixtures widely used,fitting partly used Standard attachments used widely , few fixtures or jigs used. accuracy requirement met by filing and fitting method Fixtures or jigs High production, special purpose and automatic machine tools widely used. Aligned in flow line general purpose machine tools mixed with high production and specialized machine tools. Aligned by part and operation types General purpose machine tools. Arranged in groups according to machine type and size Manufacturing equipment Die casting or forging widely used, and other high production methods also used. High accuracy and low metal removal Partly die casting or die forging. Medium accuracy and medium metal removal Casting manually with wooden mould,or forged freely. Low accuracy, and large metal removal Raw material type and metal removal method interchangeable for all parts, assembled with selection and matching process when high precise is required interchangeable for most parts, a few repaired by fitters Made-to-fit, no interchangeability, finished by fitters Interchangeability Single production Batch production Large quantity production . type characteristic

1.2 The function and design method ofprocessplanningfileThetermprocessroute(工艺规程)istheprocessplanningfile in which the process and operation method are specified. Inanother word, the aligned sequence of each operation, the partdimensions,tolerance and technical requirement, technicalequipment andmeasures,cuttingparameters,standardproductiontime,and levels of operators'skill are all included in the processplanning file

1.2 The function and design method of process planning file The term process route(工艺规程) is the process planning file in which the process and operation method are specified. In another word, the aligned sequence of each operation, the part dimensions, tolerance and technical requirement, technical equipment and measures, cutting parameters, standard production time, and levels of operators’ skill are all included in the process planning file

1-2.1TheformatofprocesssheetIn 1982, thepre-mechanical industry ministry issued the ministrystandard to regulate theformat ofprocess sheet (referred toJB/Z1187.382). Operation sheets vary greatly as to details:Name of part and type ;Name and No. of part ;Rawmaterial ;Name of operation ;Name of plant

1·2·1 The format of process sheet In 1982, the pre-mechanical industry ministry issued the ministry standard to regulate the format of process sheet (referred to JB/Z1 187.3- 82). Operation sheets vary greatly as to details: Name of part and type ; Name and No. of part ; Raw material ; Name of operation ; Name of plant

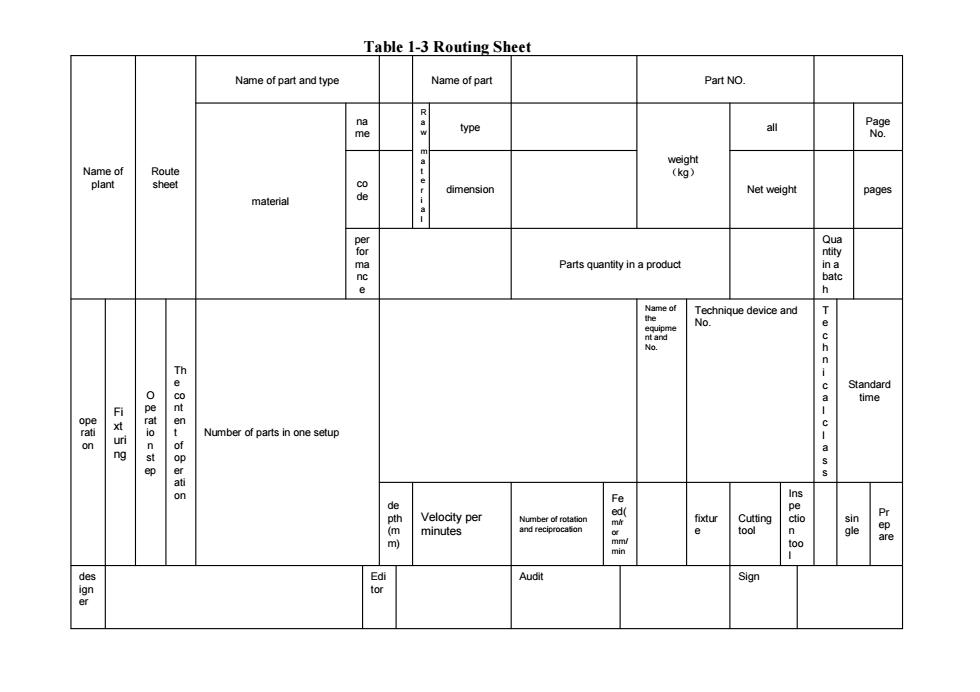

Table1-3Routing SheetName of partPart NOName of part and typeRna0Pagealltype3meNo.EEE-weightRouteName of(kg)COplantsheetdimensionNet weightpagesdematerialQuaperforntitymaParts quantity in a productinancbatcehName ofTTechnique device andtheeNo.equipmecntandhNo.nThiecStandard0coatimepent1Fioperatencxt tioratiNumberof parts in one setup1uriofnonangstopserepSatiInsonFedepeed(PrpthVelocity perfixturCuttingctiosinNumber of rotationmtep(menminutesand reciprocationtoolglearetoom)min1EdidesAuditSignigntorer

Edi Audit Sign tor des ign er Pr ep are sin gle Ins pe ctio n too l Cutting tool fixtur e Fe ed( m/r or mm/ min Number of rotation and reciprocation Velocity per minutes de pth (m m) Standard time T e c h n i c a l c l a s s Technique device and No. Name of the equipme nt and No. Number of parts in one setup Th e co nt en t of op er ati on O pe rat io n st ep Fi xt uri ng ope rati on Qua ntity in a batc h Parts quantity in a product per for ma nc e dimension Net weight pages co de Page No. all weight (kg) type R a w m a t e r i a l na me material Name of part and type Name of part Part NO. Route sheet Name of plant Table 1-3 Routing Sheet

Before products aremanufactured,technical and production preparation canTable1-4bemadebeforehandaccordingtothedemandsofprocessplanning sheet.According to the process planning sheet, the kinds, type and number ofmachinetools,theproduction areaneeded,theplanarrangement ofequipment,thenumber,typeandclassofoperators required canallbedecided. Then, the planning of factory preparation, enlarging or rebuildingwill be decided accordingly

Before products are manufactured, technical and production preparation can be made beforehand according to the demands of process planning sheet. According to the process planning sheet, the kinds, type and number of machine tools, the production area needed , the plan arrangement of equipment, the number, type and class of operators required can all be decided. Then, the planning of factory preparation, enlarging or rebuilding will be decided accordingly. Table 1-4