Chapter 2 The design principle of jigs and fixturesabstractIn ordertofulfill the machining requirement ofa certain job,a relativelyaccurate position oftheworkpiece in a machine tool in relation to the cuttingtool during themetal cutting movement must beensured.Thefollowing threeconditionsmust besatisfied when fulfilling such a practical functionwhichare(1)theaccuratepositionofabatchofworkpieces in relation to the jigs or fixtures;(2)theaccurate position ofthejigs orfixtures inrelationtothe machine tool; (3)the accurate position ofthecutting tool in relation to the jigs or fixtures. In thischapter, themainattention is directed to theaccuratepositioningofworkpieces in jigsorfixturesThepositioningofworkpieces inmachinetoolsisindirectly achievedthrough jigs orfixtures

Chapter 2 The design principle of jigs and fixtures abstract In order to fulfill the machining requirement of a certain job, a relatively accurate position of the workpiece in a machine tool in relation to the cutting tool during the metal cutting movement must be ensured. The following three conditions must be satisfied when fulfilling such a practical function, which are (1)the accurate position of a batch of workpieces in relation to the jigs or fixtures;(2) the accurate position of the jigs or fixtures in relation to the machine tool;(3)the accurate position of the cutting tool in relation to the jigs or fixtures. In this chapter, the main attention is directed to the accurate positioning of workpieces in jigs or fixtures. The positioning of workpieces in machine tools is indirectly achieved through jigs or fixtures

8abstract2.1Introduction of jigs or fixtures2.2Thelocation of theworkpiece2.3 Clamping of the workpiece2.4 The basic requirement and designsteps for jigs or fixtures

abstract 2.1 Introduction of jigs or fixtures 2.2 The location of the workpiece 2.3 Clamping of the workpiece 2.4 The basic requirement and design steps for jigs or fixtures

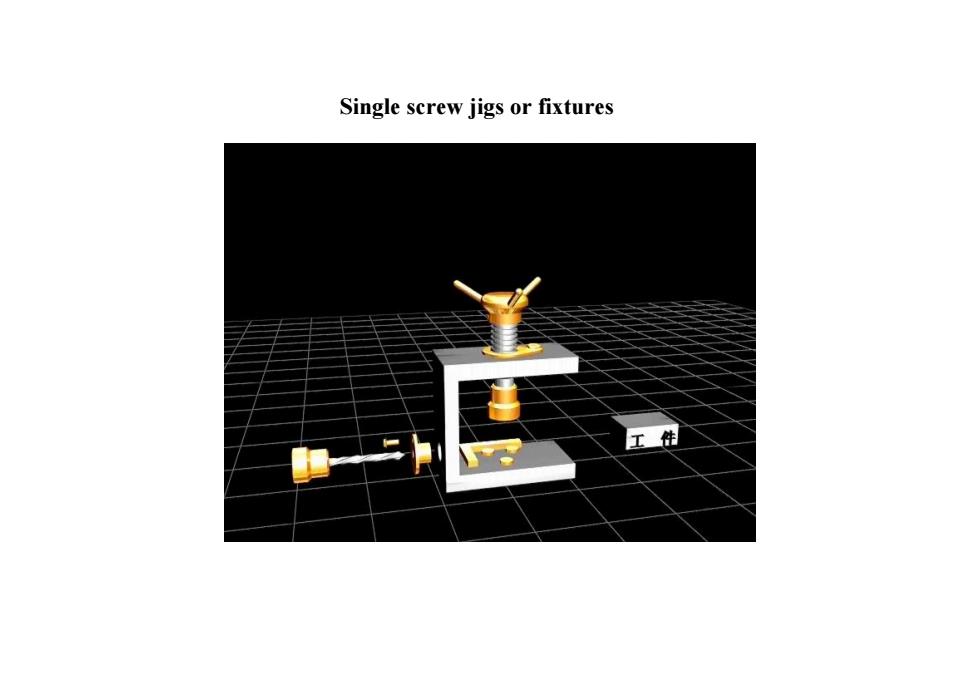

Single screw jigs or fixtures工件

Single screw jigs or fixtures

2.1 Introduction of jigs or fixturesPositioning:in orderto ensurethe accuracy and raisetheefficiency,jigs or fixtures should be used to ensure the accurate position of theworkpieceinrelationtothemachinetool.Clamping :In order to ensure the position of the location underexternalforce,aclampingforcemustbeimposedontheworkpieceSet up :The comprehensive procedure of positioning and clampingJigs or fixtures : The technological equipment to fulfill the procedureofsetup

2.1 Introduction of jigs or fixtures v Positioning : in order to ensure the accuracy and raise the efficiency, jigs or fixtures should be used to ensure the accurate position of the workpiece in relation to the machine tool. v Clamping :In order to ensure the position of the location under external force , a clamping force must be imposed on the workpiece. v Set up :The comprehensive procedure of positioning and clamping v Jigs or fixtures :The technological equipment to fulfill the procedure of set up

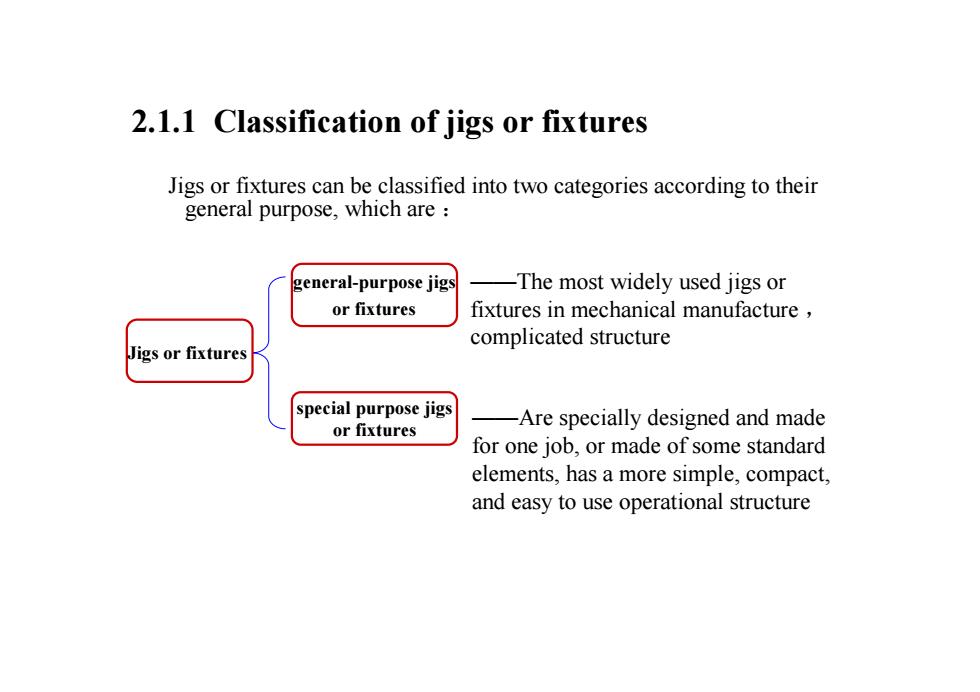

2.1.1 Classification of jigs or fixturesJigsorfixtures canbeclassified intotwocategoriesaccordingtotheirgeneral purpose, which are :-Themostwidelyused jigsorgeneral-purposejigsorfixturesfixtures inmechanical manufacturecomplicated structureJigsorfixturesspecial purpose jigsArespeciallydesignedandmadeorfixturesfor one job, or made of some standardelements,hasamoresimple,compactandeasytouseoperational structure

2.1.1 Classification of jigs or fixtures Jigs or fixtures can be classified into two categories according to their general purpose, which are : general-purpose jigs or fixtures special purpose jigs or fixtures Jigs or fixtures ——Are specially designed and made for one job, or made of some standard elements, has a more simple, compact, and easy to use operational structure ——The most widely used jigs or fixtures in mechanical manufacture , complicated structure