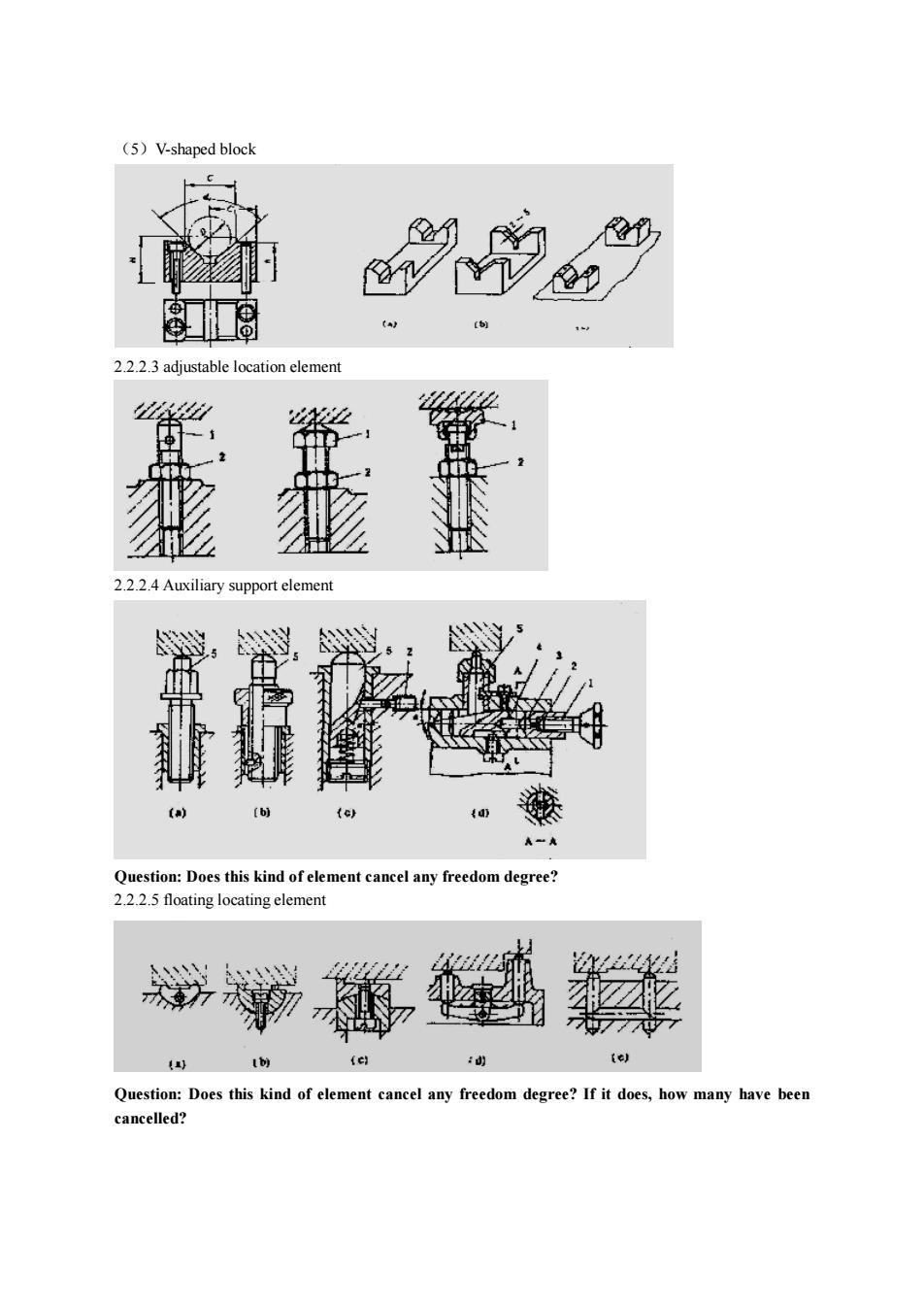

(5)V-shapedblock2.2.2.3adjustablelocationelement2.2.2.4Auxiliary supportelement(a)[b](c)Question: Does this kind ofelement cancel any freedom degree?2.2.2.5floatinglocatingelement(c)d1b)Question: Does this kind of element cancel any freedom degree? If it does, how many have beencancelled?

(5)V-shaped block 2.2.2.3 adjustable location element 2.2.2.4 Auxiliary support element Question: Does this kind of element cancel any freedom degree? 2.2.2.5 floating locating element Question: Does this kind of element cancel any freedom degree? If it does, how many have been cancelled?

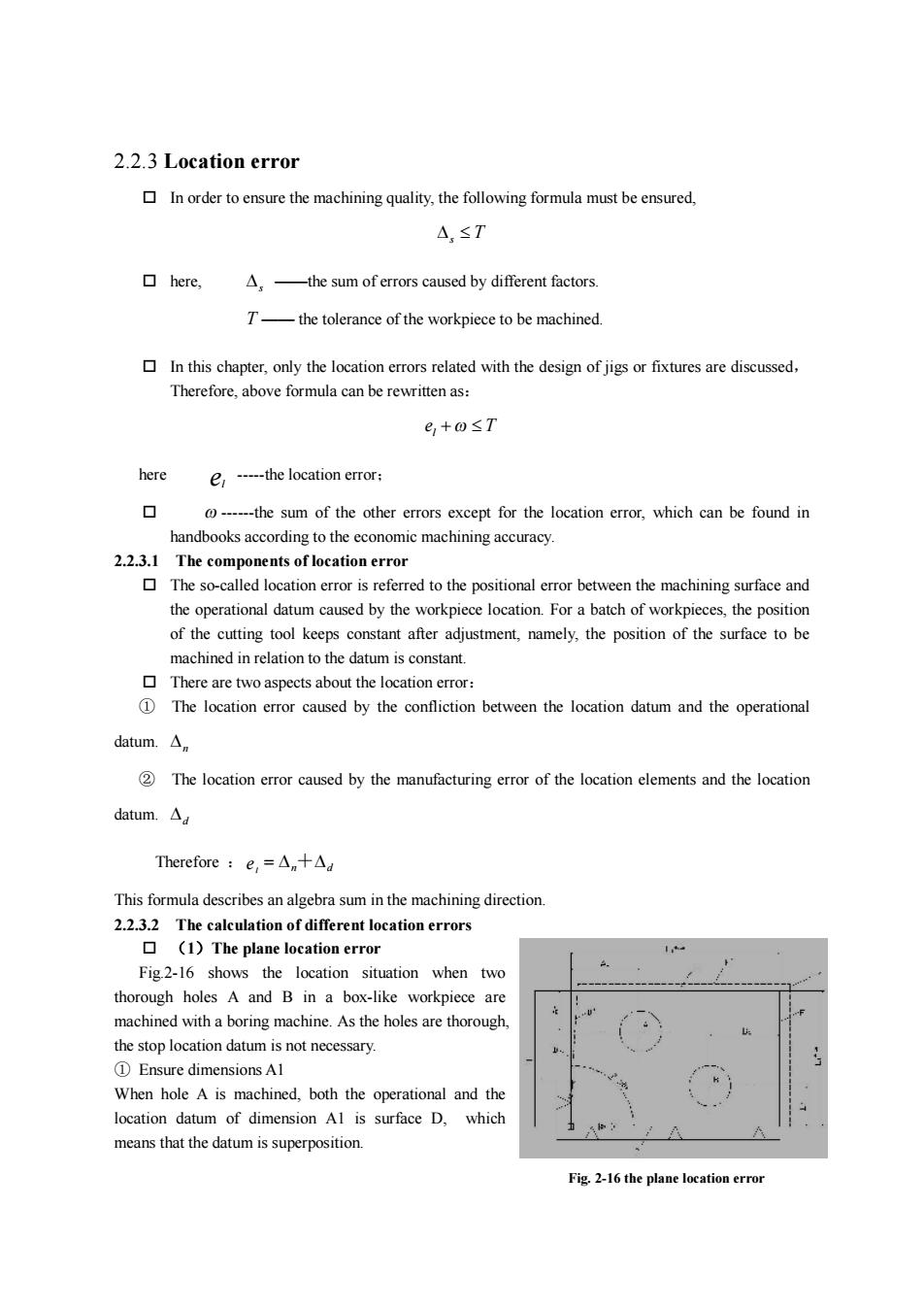

2.2.3 Location error In order to ensure the machining quality, the following formula must be ensured,4,≤There,△:thesumoferrorscausedbydifferentfactorsT-the tolerance ofthe workpiece to be machined. In this chapter, only the location errors related with the design of jigs or fixtures are discussed,Therefore, aboveformula can be rewritten as:e,+o≤Theree, ---the location error;口 ------the sum of the other errors except for the location error, which can be found inhandbooks according to the economic machining accuracy.2.2.3.1 The components of location error国The so-called location error is referred to thepositional error between themachining surface andthe operational datum caused by the workpiecelocation.Fora batch of workpieces, the positionof the cutting tool keepsconstantafter adjustment, namely,the position of the surfaceto bemachined in relationto thedatum is constant.Therearetwoaspects about thelocation error:@The location error caused by the confliction between the location datum and the operationaldatum. A,②The location error caused by the manufacturing error of the location elements and the locationdatum..AaTherefore:e,=,+dThisformula describes analgebra suminthemachiningdirection2.2.3.2The calculation of different location errors(1)TheplanelocationerrorFig.2-16shows thelocationsituationwhen twothorough holes A and B in a box-like workpiece aremachined with a boring machine. As the holes are thorough,the stop location datum is not necessary.EnsuredimensionsAlWhen hole A is machined,both the operational and thelocationdatumofdimensionAlissurfaceD,whichmeans that thedatum is superposition.Fig.2-16 the plane location error

2.2.3 Location error o In order to ensure the machining quality, the following formula must be ensured, Ds £ T o here, Ds ——the sum of errors caused by different factors. T —— the tolerance of the workpiece to be machined. o In this chapter, only the location errors related with the design of jigs or fixtures are discussed, Therefore, above formula can be rewritten as: el +w £ T here el -the location error; o w -the sum of the other errors except for the location error, which can be found in handbooks according to the economic machining accuracy. 2.2.3.1 The components of location error o The so-called location error is referred to the positional error between the machining surface and the operational datum caused by the workpiece location. For a batch of workpieces, the position of the cutting tool keeps constant after adjustment, namely, the position of the surface to be machined in relation to the datum is constant. o There are two aspects about the location error: ① The location error caused by the confliction between the location datum and the operational datum. Dn ② The location error caused by the manufacturing error of the location elements and the location datum. Dd Therefore :el = Dn+Dd This formula describes an algebra sum in the machining direction. 2.2.3.2 The calculation of different location errors o (1)The plane location error Fig.2-16 shows the location situation when two thorough holes A and B in a box-like workpiece are machined with a boring machine. As the holes are thorough, the stop location datum is not necessary. ① Ensure dimensions A1 When hole A is machined, both the operational and the location datum of dimension A1 is surface D, which means that the datum is superposition. Fig. 2-16 the plane location error