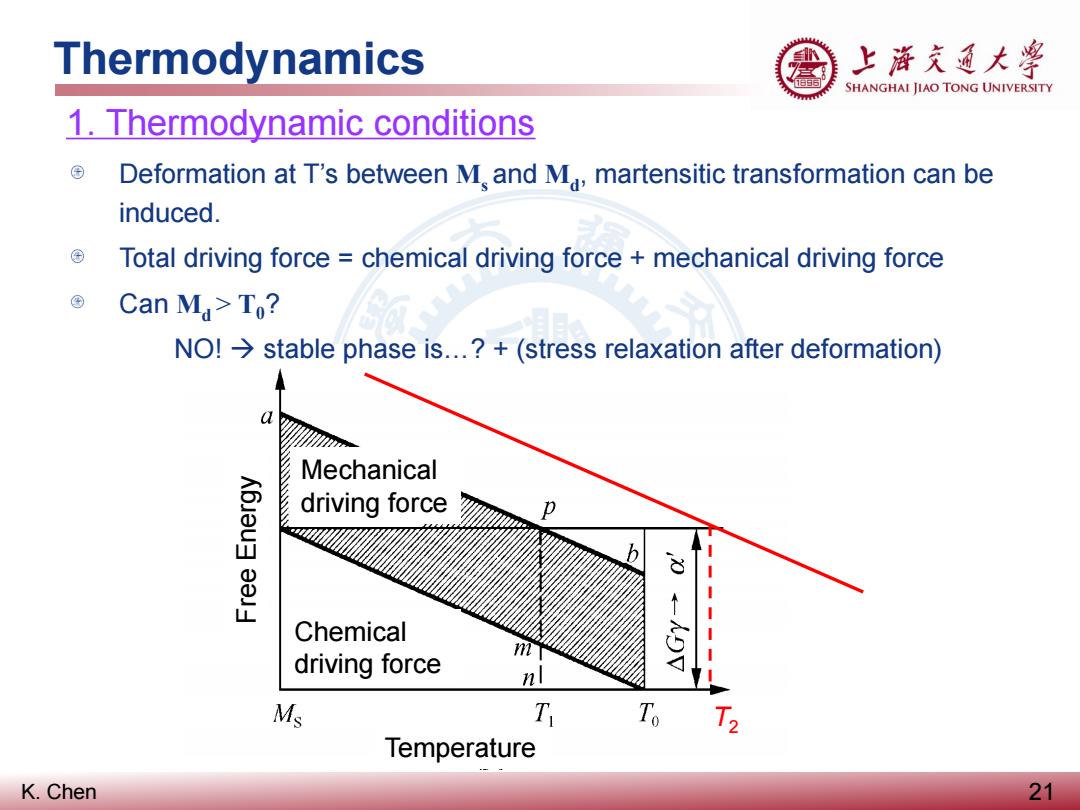

Thermodynamics 上游充通大兽 SHANGHAI JIAO TONG UNIVERSITY 1.Thermodynamic conditions Deformation at T's between M,and M,martensitic transformation can be induced. Total driving force chemical driving force mechanical driving force CanM>Tg? NO!>stable phase is...?+(stress relaxation after deformation) Mechanical driving force ↑ Chemical m driving force M T T T2 Temperature K.Chen 21

K. Chen Thermodynamics 21 1. Thermodynamic conditions Deformation at T’s between Ms and Md, martensitic transformation can be induced. Total driving force = chemical driving force + mechanical driving force Can Md > T0? NO! stable phase is…? + (stress relaxation after deformation) Temperature Free Energy Mechanical driving force Chemical driving force T2

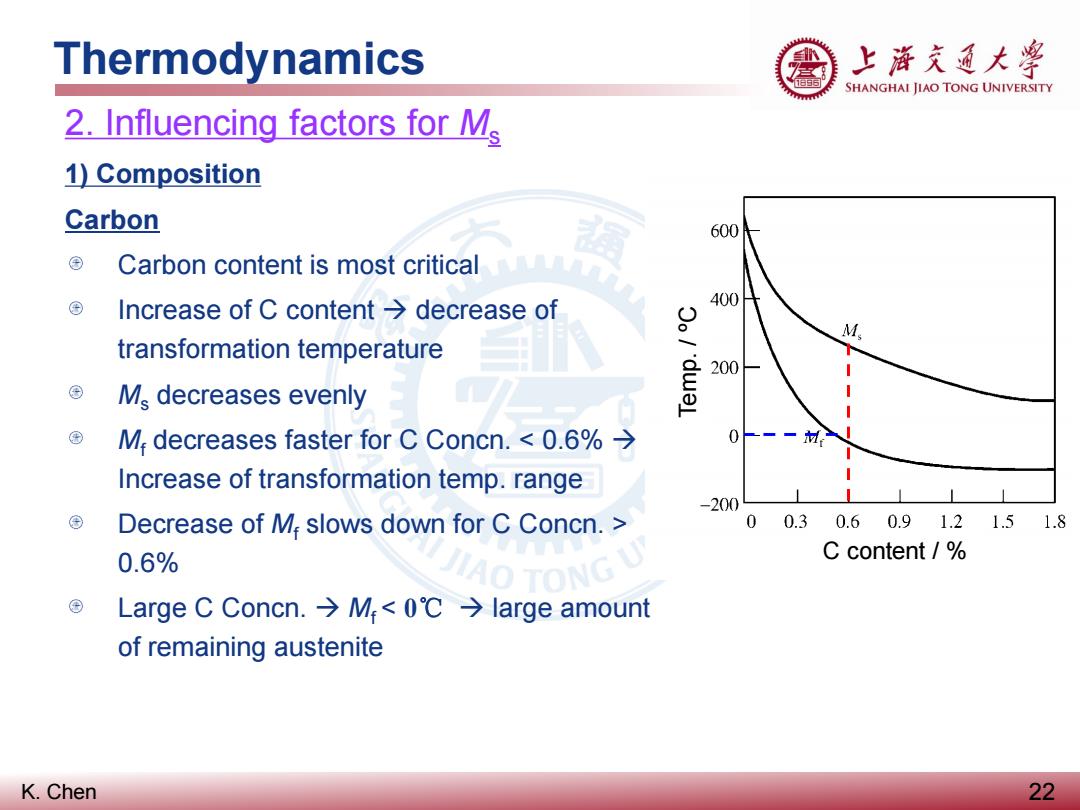

Thermodynamics 上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 2.Influencing factors for M 1)Composition Carbon 600 Carbon content is most critical Increase of C content decrease of 400 M transformation temperature 200- M decreases evenly ⊕ M:decreases faster for C Concn.<0.6%> Increase of transformation temp.range -200 ⊕ Decrease of M;slows down for C Concn. 00.30.60.91.21.51.8 0.6% C content / Large C Concn.→M<0℃→large amount of remaining austenite K.Chen 22

K. Chen Thermodynamics 22 2. Influencing factors for Ms 1) Composition Carbon Carbon content is most critical Increase of C content decrease of transformation temperature Ms decreases evenly Mf decreases faster for C Concn. < 0.6% Increase of transformation temp. range Decrease of Mf slows down for C Concn. > 0.6% Large C Concn. Mf < 0℃ large amount of remaining austenite C content / % Temp. / ºC

Thermodynamics 上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 2.Influencing factors for Ma 1)Composition Nitrogen Similar to C Solid-solution strengthening element in y and a.increase shear resistance>higher driving force needed C N are stabilizing elements for y phase>decrease To>strongly decrease M. ANG AI JIAO TONG UNIVE M K.Chen 23

K. Chen Thermodynamics 23 2. Influencing factors for Ms 1) Composition Nitrogen Similar to C Solid-solution strengthening element in γ and α. increase shear resistance higher driving force needed C & N are stabilizing elements for γ phase decrease T0 strongly decrease Ms

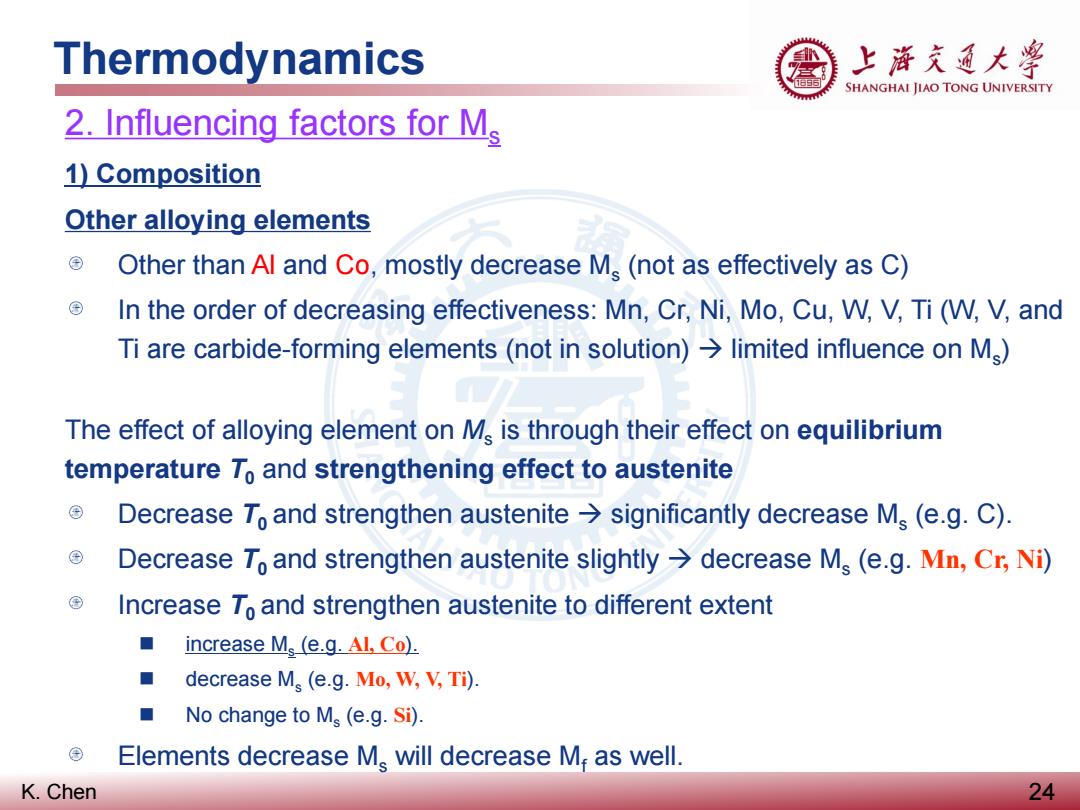

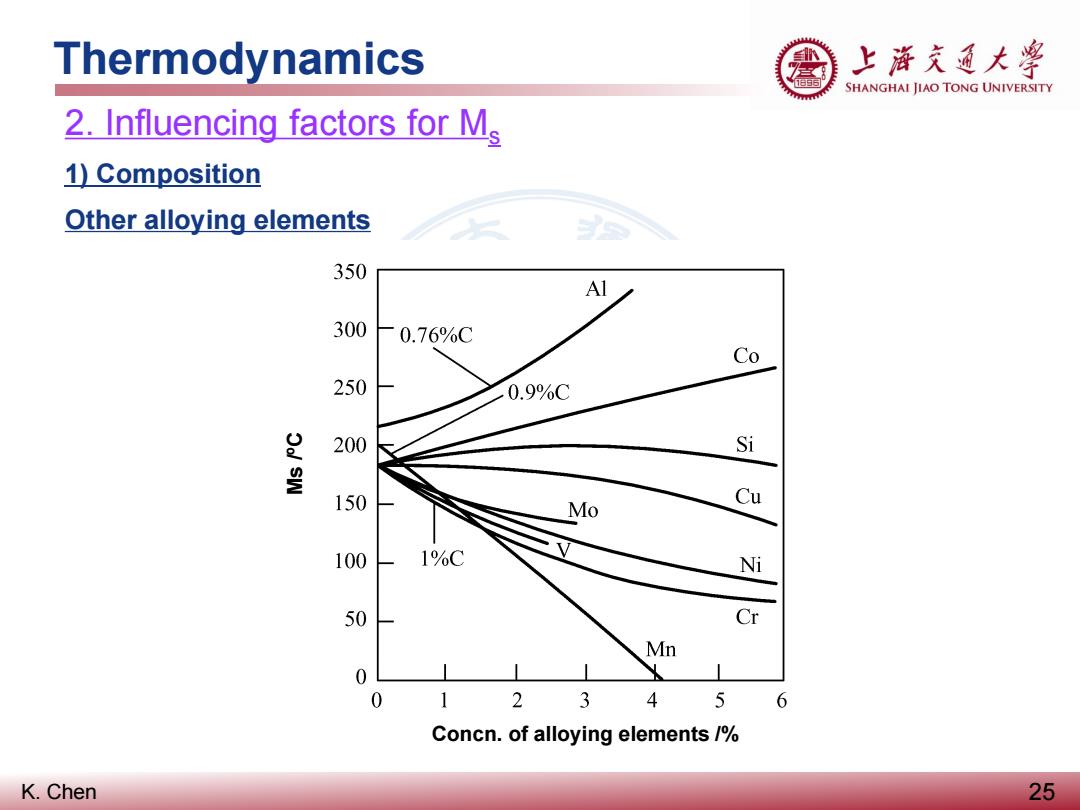

Thermodynamics 上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 2.Influencing factors for Ms 1)Composition Other alloying elements Other than Al and Co,mostly decrease M(not as effectively as C) In the order of decreasing effectiveness:Mn,Cr,Ni,Mo,Cu,W,V,Ti(W,V,and Ti are carbide-forming elements(not in solution)>limited influence on M) The effect of alloying element on Ms is through their effect on equilibrium temperature To and strengthening effect to austenite Decrease To and strengthen austenite>significantly decrease M(e.g.C). Decrease To and strengthen austenite slightly decrease Ms(e.g.Mn,Cr,Ni) Increase To and strengthen austenite to different extent ■ increase Ms (e.g.Al,Co). ■ decrease Ms(e.g.Mo,W,V,Ti). No change to M (e.g.Si). ⊕ Elements decrease M.will decrease M;as well K.Chen 24

K. Chen Thermodynamics 24 2. Influencing factors for Ms 1) Composition Other alloying elements Other than Al and Co, mostly decrease Ms (not as effectively as C) In the order of decreasing effectiveness: Mn, Cr, Ni, Mo, Cu, W, V, Ti (W, V, and Ti are carbide-forming elements (not in solution) limited influence on Ms) The effect of alloying element on Ms is through their effect on equilibrium temperature T0 and strengthening effect to austenite Decrease T0 and strengthen austenite significantly decrease Ms (e.g. C). Decrease T0 and strengthen austenite slightly decrease Ms (e.g. Mn, Cr, Ni) Increase T0 and strengthen austenite to different extent increase Ms (e.g. Al, Co). decrease Ms (e.g. Mo, W, V, Ti). No change to Ms (e.g. Si). Elements decrease Ms will decrease Mf as well

Thermodynamics 上游充通大粤 SHANGHAI JIAO TONG UNIVERSITY 2.Influencing factors for Ms 1)Composition Other alloying elements 350 Al 300 0.76%C Co 250 0.9%C ol SW 200 Si 150 Mo Cu 100 1%C Ni 50 Cr Mn 0 0 1 2 3 4 5 6 Concn.of alloying elements/% K.Chen 25

K. Chen Thermodynamics 25 2. Influencing factors for Ms 1) Composition Other alloying elements Concn. of alloying elements /% Ms /ºC