Outline Introduction Processing maps Elements of plastic theory Plastic deformation mechanism Recovery recrystallization

Outline Processing maps Plastic deformation mechanism Elements of plastic theory Recovery & recrystallization Introduction

国上泽充大李 BRANCHAI JIAO TONQ UNTPERSTTY Introduction Processing maps Elements of plastic theory Plastic deformation of crystal Outline and terminology Recovery recrystallization Recovery Recrystallization DRV DRX

Introduction Elements of plastic theory 1 Recovery & recrystallization 1 1 Outline and terminology Recovery Recrystallization DRV & DRX 1 Plastic deformation of crystal Processing maps 1

上清充通大¥ Outline and terminology SHEAMGRAI DUD TONO UHTVEREETTY Main annealing processes -microstructure (a)Deformed state (b)Recovered state (c)Partially recrystallized state (d)Fully recrystallized state (e)Grain growth (f )Abnormal grain growth Schematic diagram of the main annealing processes Institute of Forming Technology Equipment 4

Outline and terminology Institute of Forming Technology & Equipment 4 Main annealing processes ‐ microstructure Schematic diagram of the main annealing processes (a) Deformed state (b) Recovered state (c) Partially recrystallized state (d) Fully recrystallized state (e) Grain growth (f ) Abnormal grain growth

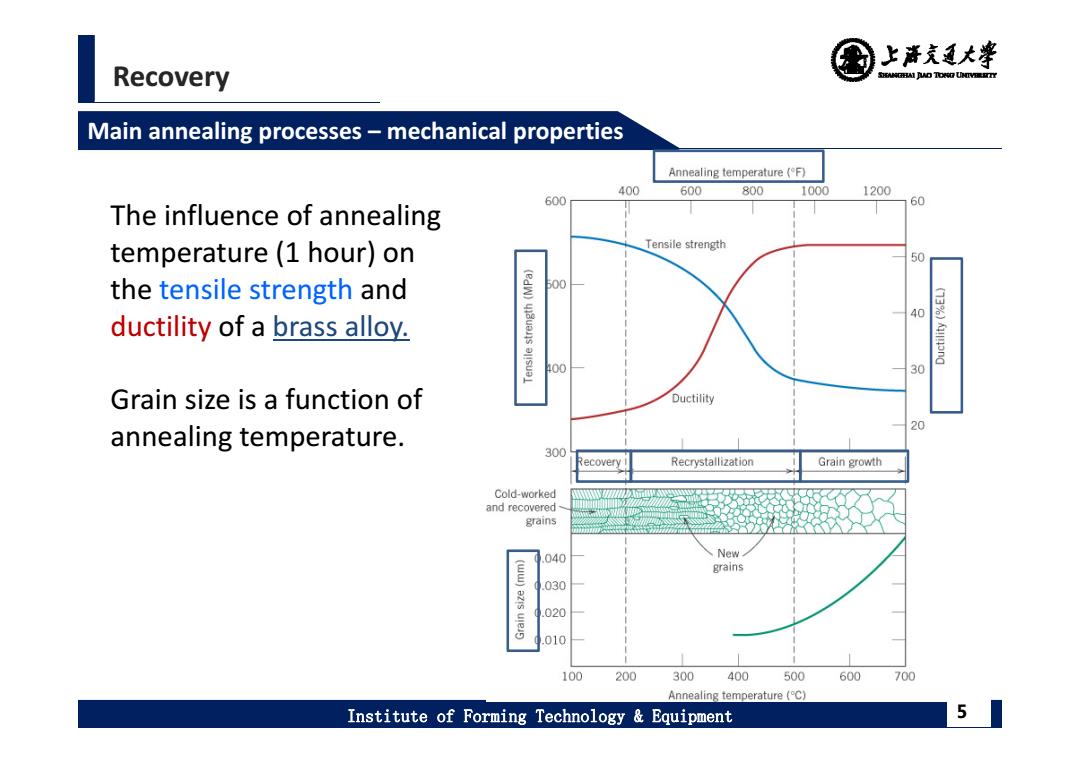

上清充通大¥ Recovery SHEAMGHAI DUD TONO UHTVEREETTY Main annealing processes-mechanical properties Annealing temperature(F) 400 600 800 1000 1200 600 60 The influence of annealing temperature(1 hour)on Tensile strength 50 the tensile strength and 500 40 ductility of a brass alloy. 00 30 Grain size is a function of Ductility 20 annealing temperature. 300 ecovery Recrystallization Grain growth Cold-worked and recovered grains 040 New grains 030 020 010 100 200 300 400 500 600 700 Annealing temperature(C) Institute of Forming Technology Equipment 5

Recovery Institute of Forming Technology & Equipment 5 Main annealing processes – mechanical properties The influence of annealing temperature (1 hour) on the tensile strength and ductility of a brass alloy. Grain size is a function of annealing temperature

Outline and terminology 上清充通大学 SHEAMGRAI DUD TONO UHTVEREETTY Terminology Why can discovery and recrystallization occur in deformed material? The increases in stored energy are a result of deformation. The dislocations provide the driving force for the annealing phenomena. Thermodynamically Lower energy unstable conditions conditions Temperature,time,the nature of material Institute of Forming Technology Equipment 6

Outline and terminology Institute of Forming Technology & Equipment 6 Terminology Why can discovery and recrystallization occur in deformed material? Temperature, time, the nature of material Thermodynamically unstable conditions Lower energy conditions • The increases in stored energy are a result of deformation. • The dislocations provide the driving force for the annealing phenomena