Fourth Edition METAL FORMING MECHANICS AND METALLURGY William F.Hosford Robert M.Caddell CAMBRIDGE www.cambridge.org/9781107004528

Contents Preface to the Fourth Edition page xii 1 Stress and Strain.··.... 1 1.1 Stress 1 1.2 Stress transformation 2 1.3 Principal stresses 4 1.4 Mohr's circle equations 1.5 Strain 7 1.6 Small strains 9 1.7 The strain tensor 10 1.8 Isotropic elasticity 10 1.9 Strain energy 11 1.10 Force and moment balances 12 1.11 Boundary conditions 13 NOTES OF INTEREST.......·· 14 REFERENCES.·.······· 15 APPENDIX-EQUILIBRIUM EQUATIONS. 15 PROBLEMS.·············· 15 2 Plasticity........·· 17 2.1 Yield criteria 17 2.2 Tresca criterion 18 2.3 Von Mises criterion 20 2.4 Effective stress 21 2.5 Effective strain 22 2.6 Flow rules 23 2.7 Normality principle 24 2.8 Derivation of the von Mises effective strain 26 NOTES OF INTEREST.............................................. 27

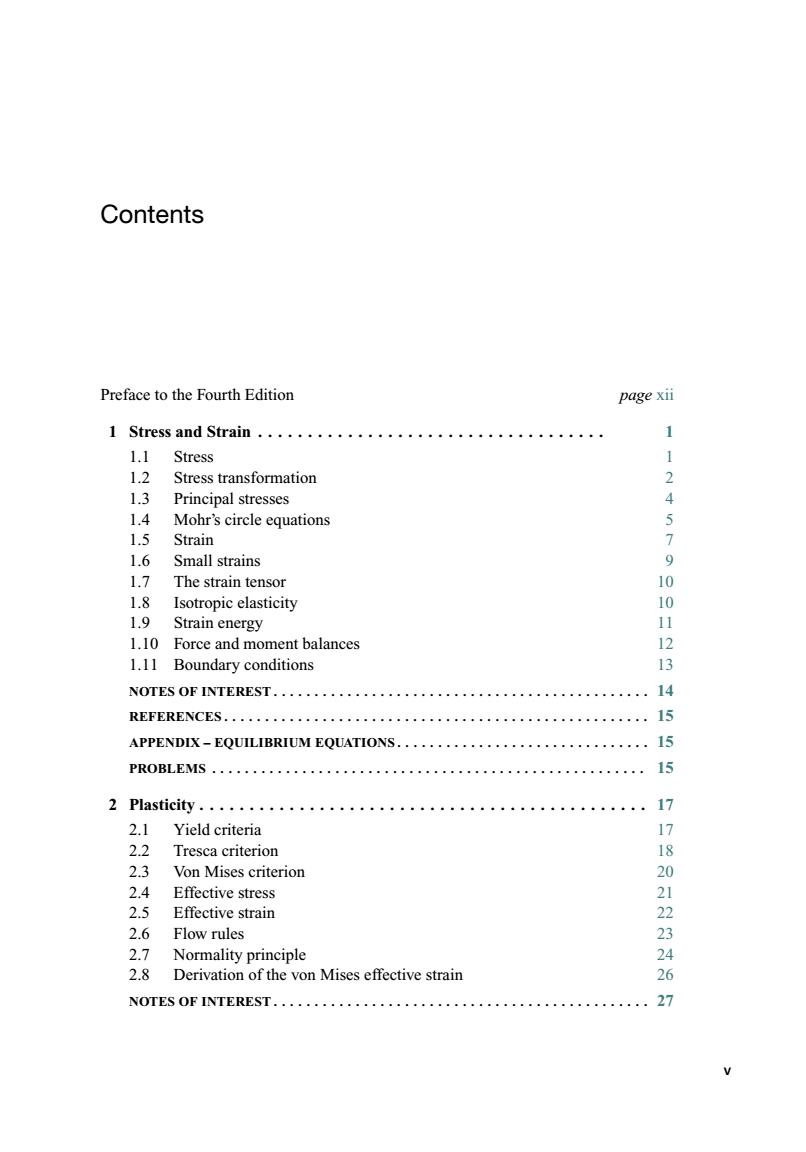

Contents Preface to the Fourth Edition page xii 1 Stress and Strain ................................... 1 1.1 Stress 1 1.2 Stress transformation 2 1.3 Principal stresses 4 1.4 Mohr’s circle equations 5 1.5 Strain 7 1.6 Small strains 9 1.7 The strain tensor 10 1.8 Isotropic elasticity 10 1.9 Strain energy 11 1.10 Force and moment balances 12 1.11 Boundary conditions 13 NOTES OF INTEREST .............................................. 14 REFERENCES .................................................... 15 APPENDIX – EQUILIBRIUM EQUATIONS ............................... 15 PROBLEMS ..................................................... 15 2 Plasticity ............................................. 17 2.1 Yield criteria 17 2.2 Tresca criterion 18 2.3 Von Mises criterion 20 2.4 Effective stress 21 2.5 Effective strain 22 2.6 Flow rules 23 2.7 Normality principle 24 2.8 Derivation of the von Mises effective strain 26 NOTES OF INTEREST .............................................. 27 v

vi CONTENTS REFERENCES.………………… 28 PROBLEMS 28 3 Strain Hardening.·· 30 3.1 The tension test 30 3.2 Elastic-plastic transition 32 3.3 Engineering vs.true stress and strain 32 3.4 Power-law expression 34 3.5 Other strain-hardening approximations 36 3.6 Behavior during necking 36 3.7 Compression testing 38 3.8 Bulge testing 38 3.9 Plane-strain compression 39 3.10 Torsion testing 40 NOTE OF INTEREST ......... 40 REFERENCES.···· 41 PROBLEMS 41 4 Plastic Instability.·········· 43 4.1 Uniaxial tension 43 4.2 Effect of inhomogeneities 44 4.3 Balanced biaxial tension 45 4.4 Pressurized thin-wall sphere 47 4.5 Significance of instability 48 N0 TE OF INTEREST,……………………·· 49 REFERENCES.………· 49 49 5 Temperature and Strain-Rate Dependence.·..··..··...··..···· 52 5.1 Strain rate 52 5.2 Superplasticity 55 5.3 Effect of inhomogeneities 58 5.4 Combined strain and strain-rate effects 62 5.5 Alternative description of strain-rate dependence 63 5.6 Temperature dependence of flow stress 65 5.7 Deformation mechanism maps 69 5.8 Hot working 69 5.9 Temperature rise during deformation 71 NOTES OF INTEREST...········ 72 REFERENCES.....··· 73 PROBLEMS............ 73 6 Vork Balance.······ 76 6.1 Ideal work 76

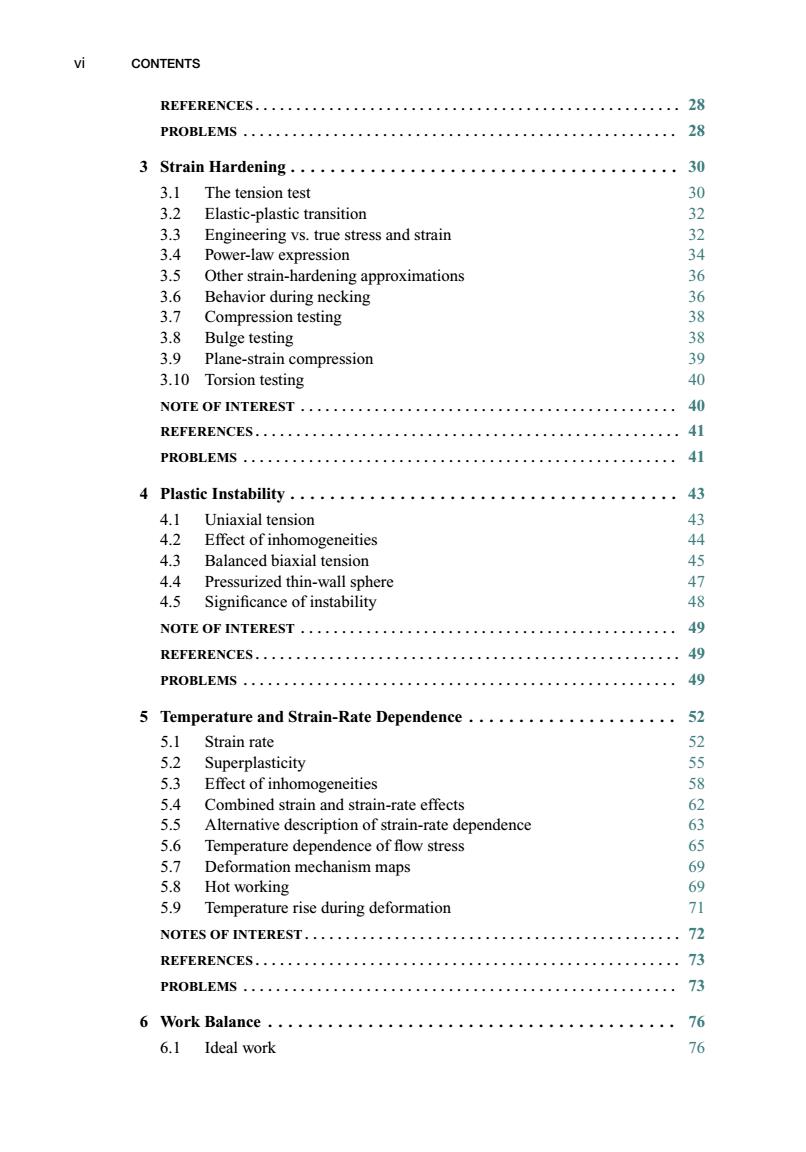

vi CONTENTS REFERENCES .................................................... 28 PROBLEMS ..................................................... 28 3 Strain Hardening ....................................... 30 3.1 The tension test 30 3.2 Elastic-plastic transition 32 3.3 Engineering vs. true stress and strain 32 3.4 Power-law expression 34 3.5 Other strain-hardening approximations 36 3.6 Behavior during necking 36 3.7 Compression testing 38 3.8 Bulge testing 38 3.9 Plane-strain compression 39 3.10 Torsion testing 40 NOTE OF INTEREST .............................................. 40 REFERENCES .................................................... 41 PROBLEMS ..................................................... 41 4 Plastic Instability ....................................... 43 4.1 Uniaxial tension 43 4.2 Effect of inhomogeneities 44 4.3 Balanced biaxial tension 45 4.4 Pressurized thin-wall sphere 47 4.5 Significance of instability 48 NOTE OF INTEREST .............................................. 49 REFERENCES .................................................... 49 PROBLEMS ..................................................... 49 5 Temperature and Strain-Rate Dependence ..................... 52 5.1 Strain rate 52 5.2 Superplasticity 55 5.3 Effect of inhomogeneities 58 5.4 Combined strain and strain-rate effects 62 5.5 Alternative description of strain-rate dependence 63 5.6 Temperature dependence of flow stress 65 5.7 Deformation mechanism maps 69 5.8 Hot working 69 5.9 Temperature rise during deformation 71 NOTES OF INTEREST .............................................. 72 REFERENCES .................................................... 73 PROBLEMS ..................................................... 73 6 Work Balance ......................................... 76 6.1 Ideal work 76

CONTENTS vii 6.2 Extrusion and drawing 77 6.3 Deformation efficiency 18 6.4 Maximum drawing reduction 6.5 Effects of die angle and reduction 80 6.6 Swaging 81 REFERENCES..... 82 PROBLEMS 82 7 Slab Analysis.......... 。。。 85 7.1 Sheet drawing 85 7.2 Wire and rod drawing 87 7.3 Friction in plane-strain compression 88 7.4 Sticking friction 90 7.5 Mixed sticking-sliding conditions 90 7.6 Constant shear stress interface 91 7.7 Axially symmetric compression 92 7.8 Sand-pile analogy 93 7.9 Flat rolling 93 7.10 Roll flattening 95 7.11 Roll bending 99 7.12 Coining 101 7.13 Reducing the area of contact 101 NOTES OF INTEREST....·...··.·· .102 REFERENCES..............,... ...102 PROBLEMS ....102 8 Friction and Lubrication....... ·····..106 8.1 General 106 8.2 Experimental findings 109 8.3 Ring friction test 110 8.4 Galling 111 8.5 Ultrasonics 111 NOTE OF INTEREST ....... ...111 REFERENCES....................................................112 PR0 BLEMS...........112 9 Upper-Bound Analysis.············· ….113 9.1 Upper bounds 113 9.2 Energy dissipation on plane of shear 114 9.3 Plane-strain frictionless extrusion 115 9.4 Plane-strain frictionless indentation 119 9.5 Plane-strain compression 119 9.6 Another approach to upper bounds 122 9.7 A combined upper-bound analysis 123 9.8 Plane-strain drawing 124

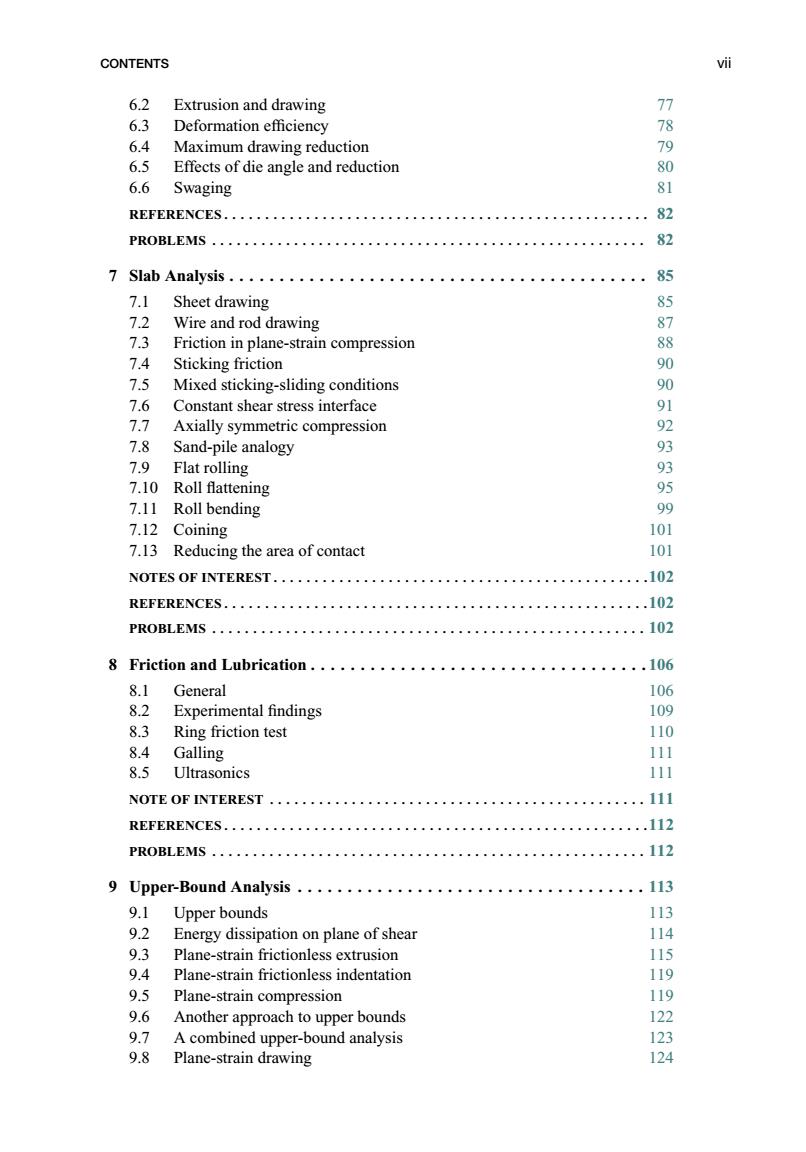

CONTENTS vii 6.2 Extrusion and drawing 77 6.3 Deformation efficiency 78 6.4 Maximum drawing reduction 79 6.5 Effects of die angle and reduction 80 6.6 Swaging 81 REFERENCES .................................................... 82 PROBLEMS ..................................................... 82 7 Slab Analysis .......................................... 85 7.1 Sheet drawing 85 7.2 Wire and rod drawing 87 7.3 Friction in plane-strain compression 88 7.4 Sticking friction 90 7.5 Mixed sticking-sliding conditions 90 7.6 Constant shear stress interface 91 7.7 Axially symmetric compression 92 7.8 Sand-pile analogy 93 7.9 Flat rolling 93 7.10 Roll flattening 95 7.11 Roll bending 99 7.12 Coining 101 7.13 Reducing the area of contact 101 NOTES OF INTEREST ..............................................102 REFERENCES ....................................................102 PROBLEMS ..................................................... 102 8 Friction and Lubrication .................................. 106 8.1 General 106 8.2 Experimental findings 109 8.3 Ring friction test 110 8.4 Galling 111 8.5 Ultrasonics 111 NOTE OF INTEREST .............................................. 111 REFERENCES ....................................................112 PROBLEMS ..................................................... 112 9 Upper-Bound Analysis ................................... 113 9.1 Upper bounds 113 9.2 Energy dissipation on plane of shear 114 9.3 Plane-strain frictionless extrusion 115 9.4 Plane-strain frictionless indentation 119 9.5 Plane-strain compression 119 9.6 Another approach to upper bounds 122 9.7 A combined upper-bound analysis 123 9.8 Plane-strain drawing 124

vili CONTENTS 9.9 Axisymmetric drawing 124 REFERENCES..…·· .126 PROBLEMS.,,...,,.······ 126 10 Slip-Line Field Analysis ...... ...132 10.1 Introduction 132 10.2 Governing stress equations 132 10.3 Boundary conditions 136 10.4 Plane-strain indentation 137 10.5 Hodographs for slip-line fields 138 10.6 Plane-strain extrusion 139 10.7 Energy dissipation in a slip-line field 141 10.8 Metal distortion 141 10.9 Indentation of thick slabs 142 10.10 Plane-strain drawing 146 10.11 Constant shear stress interfaces 150 10.12 Pipe formation 151 NOTES OF INTEREST................. REFERENCES..·· ..154 APPENDIX.......··· ....154 PROBLEMS··· .157 11 Deformation-Zone Geometry...............................167 ll.lThe△parameter 167 11.2 Friction 168 11.3 Redundant deformation 168 11.4 Inhomogeneity 170 11.5 Internal damage 175 11.6 Residual stresses 179 11.7 Comparison of plane-strain and axisymmetric deformation 182 NOTE OF INTEREST ....... 184 REFERENCES ...184 PROBLEMS.····· .184 12 Formability........ ···..186 12.1 Ductility I86 12.2 Metallurgy 186 12.3 Ductile fracture 190 12.4 Hydrostatic stress 191 12.5 Bulk formability tests 195 12.6 Formability in hot working 196 NOTE OF INTEREST.··· ..197 REFERENCES.·.··· ...197 PROBLEMS 197

viii CONTENTS 9.9 Axisymmetric drawing 124 REFERENCES ....................................................126 PROBLEMS ..................................................... 126 10 Slip-Line Field Analysis .................................. 132 10.1 Introduction 132 10.2 Governing stress equations 132 10.3 Boundary conditions 136 10.4 Plane-strain indentation 137 10.5 Hodographs for slip-line fields 138 10.6 Plane-strain extrusion 139 10.7 Energy dissipation in a slip-line field 141 10.8 Metal distortion 141 10.9 Indentation of thick slabs 142 10.10 Plane-strain drawing 146 10.11 Constant shear stress interfaces 150 10.12 Pipe formation 151 NOTES OF INTEREST ..............................................152 REFERENCES ....................................................154 APPENDIX ...................................................... 154 PROBLEMS ..................................................... 157 11 Deformation-Zone Geometry ............................... 167 11.1 The parameter 167 11.2 Friction 168 11.3 Redundant deformation 168 11.4 Inhomogeneity 170 11.5 Internal damage 175 11.6 Residual stresses 179 11.7 Comparison of plane-strain and axisymmetric deformation 182 NOTE OF INTEREST .............................................. 184 REFERENCES ....................................................184 PROBLEMS ..................................................... 184 12 Formability ........................................... 186 12.1 Ductility 186 12.2 Metallurgy 186 12.3 Ductile fracture 190 12.4 Hydrostatic stress 191 12.5 Bulk formability tests 195 12.6 Formability in hot working 196 NOTE OF INTEREST .............................................. 197 REFERENCES ....................................................197 PROBLEMS ..................................................... 197�