Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group 3.2 Cylinder gasket ④ ④®④ It is located between the cylinder head and liner,to ensure the cylinder head and jacket joints sealed to prevent gas leakage. There are two kinds of inder holetfin ter hole B-B rotation metal-asbestos gasket and pure steel or copper copper copper on pre metal gasket. (b steel wire 【 steel plate with pricking the tapes 【 core board face board 密 Figure 2.4 Cylinder gasket structure (a)(b)(c)(d)metal-asbestos plate (e)stamped plate (f)non-asbestos cylinder gasket 机械持电子工程膜 Automobile and Tractor Northwest A&F University

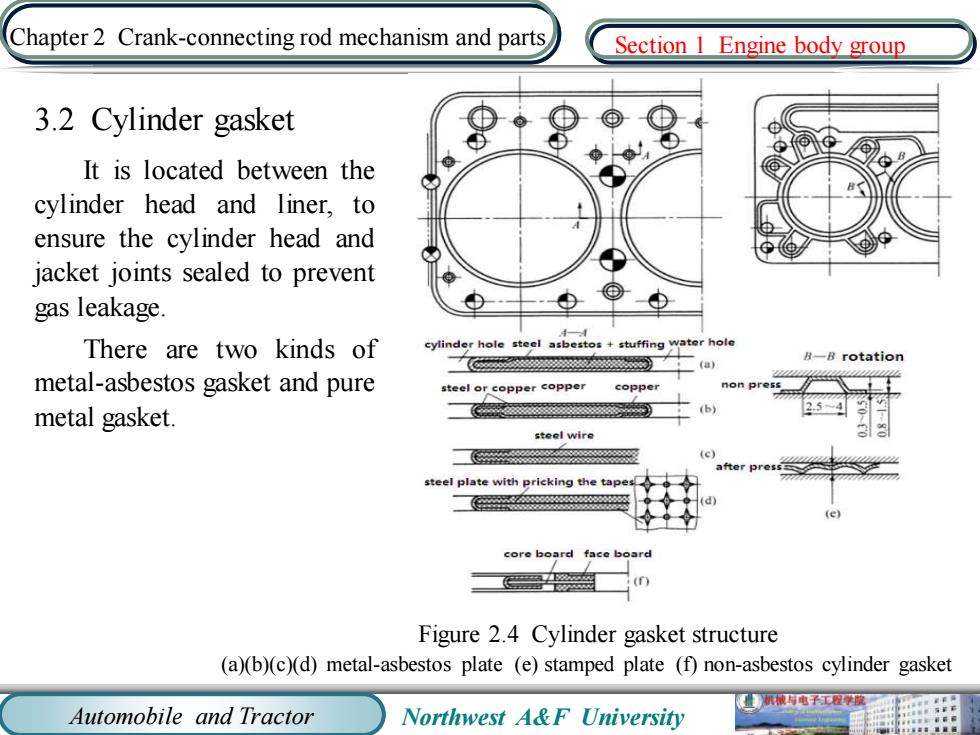

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 3.2 Cylinder gasket It is located between the cylinder head and liner, to ensure the cylinder head and jacket joints sealed to prevent gas leakage. There are two kinds of metal-asbestos gasket and pure metal gasket. Figure 2.4 Cylinder gasket structure (a)(b)(c)(d) metal-asbestos plate (e) stamped plate (f) non-asbestos cylinder gasket Section 1 Engine body group

Chapter 2 Crank-connecting rod mechanism and parts Section 1 Engine body group 3.3 Cylinder head bolt The number of bolts are as much as possible,and the diameter of bolt is appropriately smaller,which ensures uniform force.Preload of bolts should be 3-4 times larger than the maximum gas pressure in cylinder head.Screwing the bolts is symmetrically from the middle several times alternately to the surrounding. 8日。。8.88 19 02 1 03 o20o180120907011014o18 (a) (b) Figure 2.5 Cylinder head bolt tightening sequence (a)4125-type internal combustion engine (b)495-type internal combustion engine 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 3.3 Cylinder head bolt The number of bolts are as much as possible, and the diameter of bolt is appropriately smaller, which ensures uniform force. Preload of bolts should be 3-4 times larger than the maximum gas pressure in cylinder head. Screwing the bolts is symmetrically from the middle several times alternately to the surrounding. Figure 2.5 Cylinder head bolt tightening sequence (a) 4125-type internal combustion engine (b) 495-type internal combustion engine Section 1 Engine body group

Chapter 2 Crank-connecting rod mechanism and parts Section 2 Piston connecting rod group 1.Piston Group Piston group includes pistons,piston rings and piston pin and other parts.Piston group the cylinder and cylinder head constitute the working volume and combustion chamber volume.Piston bears and passes gas pressure to the crankshaft through the connecting rod,which also seal cylinder to prevent gas into the crankcase and oil into the cylinder. 1.1 Piston Most of pistons are made of aluminum alloy.There is also a small number of pistons that are made of cast iron and heat-resistant steel. (1)Piston Top:The shape of piston top and the size of the pit must meet the mixture formation and combustion. (2)Piston Leakproof:2-5 ring grooves with piston ring,mainly prevent from the seal,which also pass the heat to cylinder wall through the piston ring. (3)Piston Pin Seat:For the installation of piston pin. (4)Piston Skirt:Play a guiding role and bear lateral pressure. 业机被寿电子工程聚 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 2 Crank-connecting rod mechanism and parts 1. Piston Group Piston group includes pistons, piston rings and piston pin and other parts. Piston group 、 the cylinder and cylinder head constitute the working volume and combustion chamber volume.Piston bears and passes gas pressure to the crankshaft through the connecting rod,which also seal cylinder to prevent gas into the crankcase and oil into the cylinder. 1.1 Piston Most of pistons are made of aluminum alloy .There is also a small number of pistons that are made of cast iron and heat-resistantsteel. (1) Piston Top: The shape of piston top and the size of the pit must meet the mixture formation and combustion. (2) Piston Leakproof: 2-5 ring grooves with piston ring , mainly prevent from the seal, which also pass the heat to cylinder wall through the piston ring. (3) Piston Pin Seat: For the installation of piston pin. (4) Piston Skirt: Play a guiding role and bear lateral pressure. Section 2 Piston & connecting rod group