Chapter 10 Engine working conditions and features Section 1 Working conditions &rated powe 1.Working Conditions of Engine The actual working conditions of the engine is abbreviated to working conditions.Working conditions of engine can be described by a set of its parameters to characterize certain performance,in which the main parameters are the speed n and the effective power Pe(or torque Te). P.=T.·n/9550[kW] P Although the engine operating conditions are varied,the work area of one engine on the Pe-n working conditions map is limited,as shown. Figure 10.1 A variety of engine working conditions 业机械与电子工程学原 Automobile and Tractor Northwest A&F University

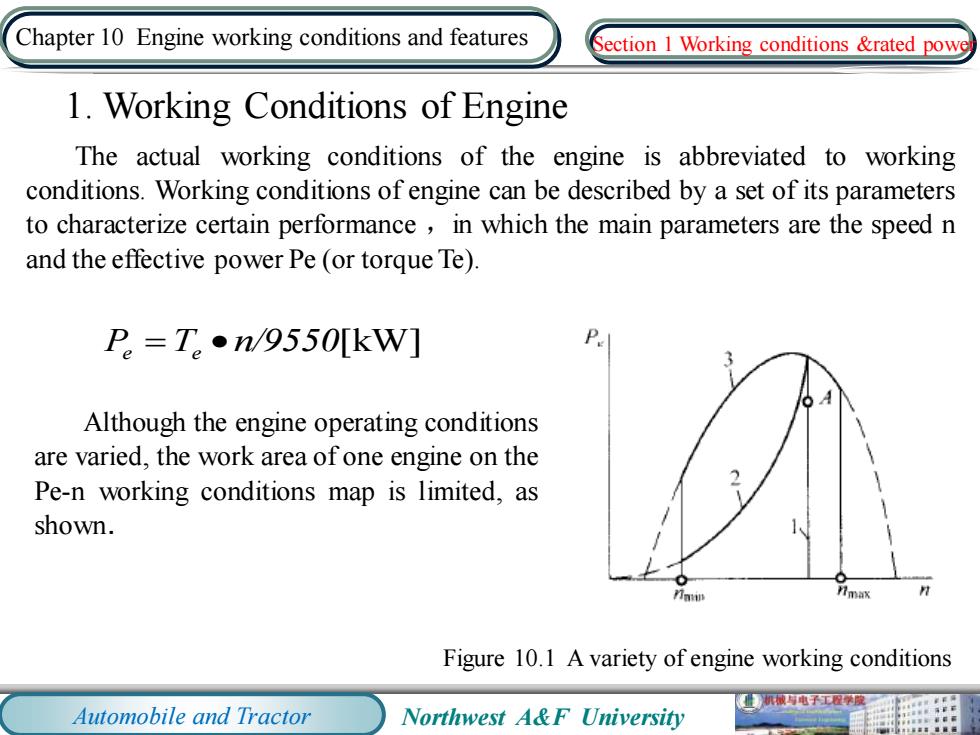

Automobile and Tractor Northwest A&F University Chapter 10 Engine working conditions and features 1. Working Conditions of Engine The actual working conditions of the engine is abbreviated to working conditions. Working conditions of engine can be described by a set of its parameters to characterize certain performance ,in which the main parameters are the speed n and the effective power Pe (or torque Te). P T n/9550[kW] e = e • Although the engine operating conditions are varied, the work area of one engine on the Pe-n working conditions map is limited, as shown. Section 1 Working conditions &rated power Figure 10.1 A variety of engine working conditions

Chapter 10 Engine working conditions and features Section 1 Working conditions &rated powe According to different conditions,working conditions of engine can be roughly divided into three categories 1.1 Constant speed(fixed)working conditions Changes in engine power,but the crankshaft speed is almost unchanged.Such as driven generators,pumps and other engines. 1.2 Fluid resistance (propeller)working conditions Between engine power and speed is certainly a function,a common power function close to three,namely: Pe≈kn3 Such as the propeller driven by marine engine is such a case.Power absorbed by the propeller and propeller speed to the cube is proportional. 1.3 Surface working conditions Engine power and speed is independent of changes in a wide range,and both have no particular relationship.Cars tractors and other land transport vehicles use such engine. 械电子工程学 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 10 Engine working conditions and features According to different conditions, working conditions of engine can be roughly divided into three categories : 1.1 Constant speed (fixed) working conditions Changes in engine power, but the crankshaft speed is almost unchanged. Such as driven generators, pumps and other engines. 1.2 Fluid resistance (propeller) working conditions Between engine power and speed is certainly a function, a common power function close to three, namely: Pe≈kn3 Such as the propeller driven by marine engine is such a case. Power absorbed by the propeller and propellerspeed to the cube is proportional. 1.3 Surface working conditions Engine power and speed is independent of changes in a wide range, and both have no particular relationship. Cars、tractors and other land transport vehicles use such engine. Section 1 Working conditions &rated power

Chapter 10 Engine working conditions and features Section 1 Working conditions &rated powe 2.Engine Rated Power Operation of the engine maximum power allowed is a certain limit.According to the characteristics,application,use features and life requirements of the engine,on the basis of repeated experiments,the power is determined by man. The same type of engine,in different conditions and life requirements,the rated power and corresponding speed on the nameplate can be different.The rated engine power on the nameplate,is allowed to use maximum power called the rated power. China's national standard sets the engine rated power that is divided into the following four grades: (1)15min power:In standard environmental conditions,the maximum effective power allows the engine to operate continuously for 15min. (2)Ih power:In standard environmental conditions,the maximum effective power allows the engine to operate continuously for 1h. (3)12h power:In standard environmental conditions,the maximum effective power allows the engine to operate continuously for 12h. (4)continuous power:In standard environmental conditions,the maximum effective power allows the engine to operate continuously for a long time 机械电子工程学刀 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 10 Engine working conditions and features 2. Engine Rated Power Operation of the engine maximum power allowed is a certain limit. According to the characteristics, application, use features and life requirements of the engine,on the basis of repeated experiments, the power is determined by man. The same type of engine, in different conditions and life requirements, the rated power and corresponding speed on the nameplate can be different. The rated engine power on the nameplate, is allowed to use maximum power called the rated power. China's national standard sets the engine rated power that is divided into the following four grades: (1) 15min power: In standard environmental conditions, the maximum effective power allows the engine to operate continuously for 15min. (2) 1h power: In standard environmental conditions, the maximum effective power allows the engine to operate continuously for 1h. (3) 12h power: In standard environmental conditions, the maximum effective power allows the engine to operate continuously for 12h. (4) continuous power: In standard environmental conditions, the maximum effective power allows the engine to operate continuously for a long time. Section 1 Working conditions &rated power

Chapter 10 Engine working conditions and features Section 2 Adjustment feature The relationship that engine performance indicator changes with the adjustment is known as the adjustment feature of the engine.Such as the fuel supply advance angle adjustment feature of diesel engine,the fuel adjustment feature,the ignition advance angle adjustment feature of gasoline engine,and the fuel (carburetor) adjustment feature. 1.Adjustment Feature of Diesel Engine 1.1 The purpose and method of the fuel supply advance angle adjustment feature of diesel engine When diesel engine fuel supply adjusting mechanism fixed and maintaining a certain speed,we can measure the relationship of effective power Pe,lh fuel consumption Gf the fuel consumption rate ge with the changes in fuel supply advance angle 0,ie Pe=f(0),Gf=f(0),ge =f0),are known as the fuel supply advance angle adjustment feature. 机械电子工程学度 Automobile and Tractor Northwest A&F University

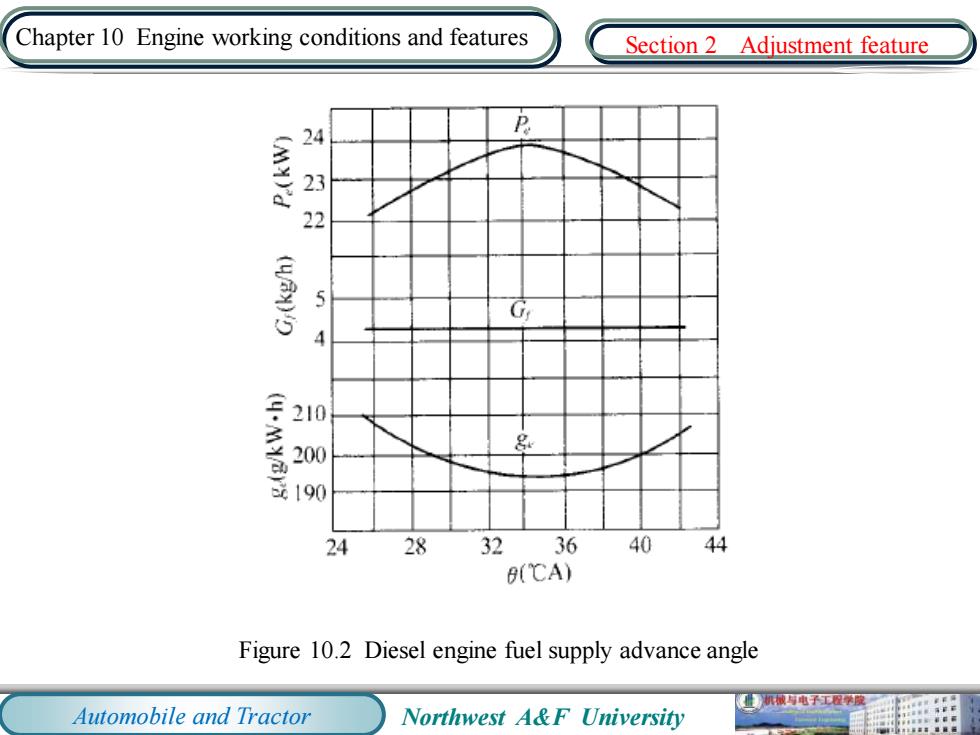

Automobile and Tractor Northwest A&F University Chapter 10 Engine working conditions and features 1. Adjustment Feature of Diesel Engine 1.1 The purpose and method of the fuel supply advance angle adjustment feature of diesel engine When diesel engine fuel supply adjusting mechanism fixed and maintaining a certain speed, we can measure the relationship of effective power Pe,1h fuel consumption Gf, the fuel consumption rate ge with the changes in fuel supply advance angle θ, ie Pe = f (θ), Gf = f (θ ), ge =f(θ) , are known as the fuel supply advance angle adjustment feature. The relationship that engine performance indicator changes with the adjustment is known as the adjustment feature of the engine. Such as the fuel supply advance angle adjustment feature of diesel engine, the fuel adjustment feature, the ignition advance angle adjustment feature of gasoline engine, and the fuel (carburetor) adjustment feature. Section 2 Adjustment feature

Chapter 10 Engine working conditions and features Section 2 Adjustment feature 24 P 2 5 G 210 200 g 24 28 32 36 40 44 (℃A) Figure 10.2 Diesel engine fuel supply advance angle 业机械电子工学度 Automobile and Tractor Northwest A&F University

Automobile and Tractor Northwest A&F University Chapter 10 Engine working conditions and features Figure 10.2 Diesel engine fuel supply advance angle Section 2 Adjustment feature