第十二章生产运作管理一、教学建议本章重点在理解生产运作管理的本质及其在企业经营中的作用,通过哪些具体运作内容的管理来实现生产运作的管理目标。因为篇幅所限,本章重点讲授生产运作的各种类型及其比较,通过各种生产类型的比较,使学生明确各种类型的运作的重点和关键。同时在各种类型比较的基础上能掌握其过程组织的特点和方式,从过程的角度审视生产运作过程,学会从过程分析中寻找解决问题的途径和方法。各种类型的探讨可以围绕制造和服务、MaketoStock和MaketoOrder、大量生产和多品种小批量生产的比较来展开。二、电子教案库已提供。三、知识点库生产运作的基本概念和本质:生产与运作的各种分类及各自的特点:·生产与运作的系统布置与系统运行阶段所涉及的各种主题及其作用:··选址决策所涉及的各种要素和选址决策方法:生产系统布置的原则和类型;.·各层次生产计划的特点和相互关系及各自的作用:综合计划和主生产计划的制定程序和方法;.物料需求计划的作用和制定程序及逻辑;四、案例库如使用本案例,需要更改案例名及部分数据为好!Case:ValentinValentin Inc. is a company who uses MRP to organize its production. The lot-sizingtechniquetheychoseforall references is lot-for-lot.Theyprovidepartof theproducttreestructurefor products A and B (the figures shown indicate the number ofcomponent required to produce aproduct of the next level)

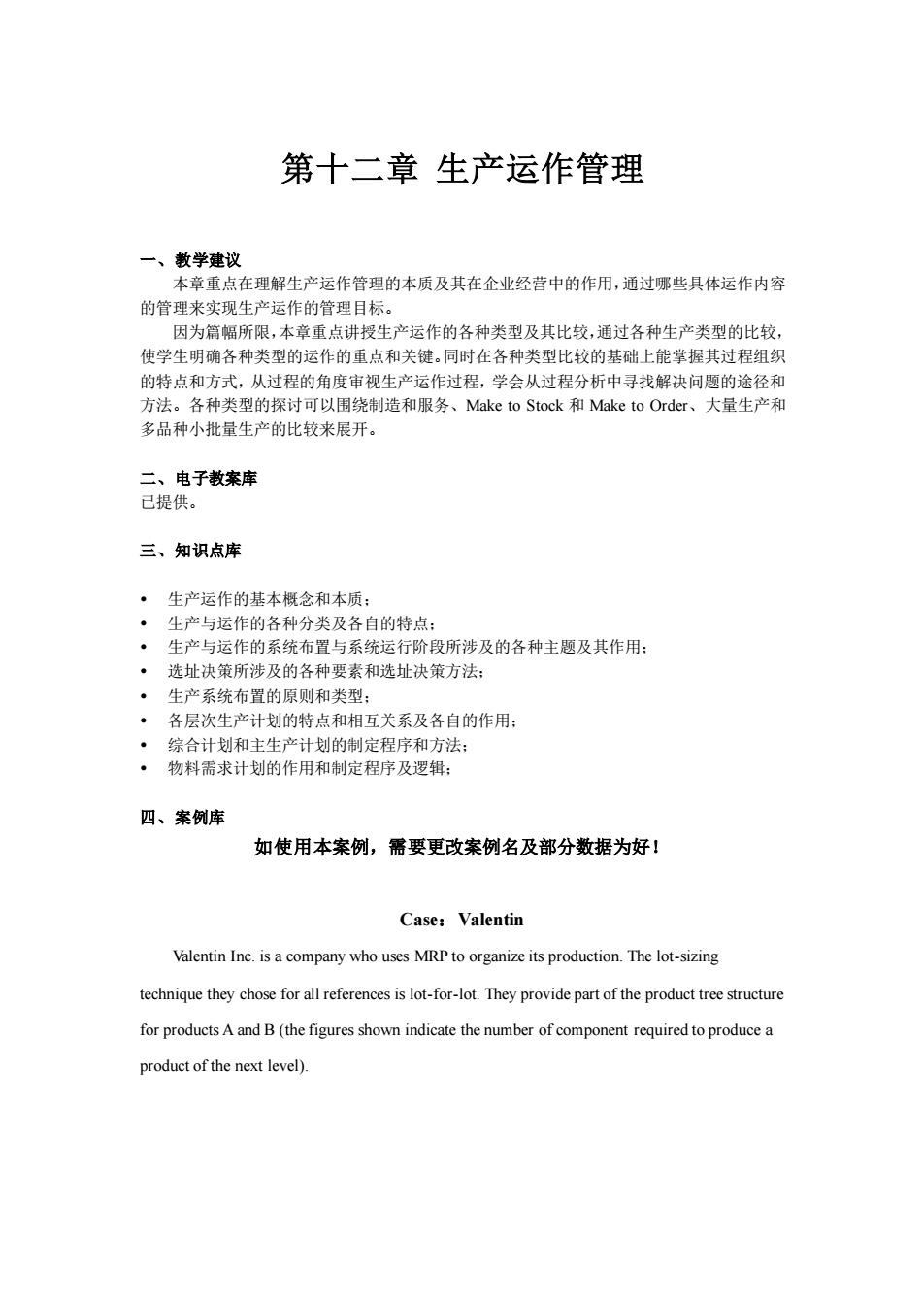

第十二章 生产运作管理 一、教学建议 本章重点在理解生产运作管理的本质及其在企业经营中的作用,通过哪些具体运作内容 的管理来实现生产运作的管理目标。 因为篇幅所限,本章重点讲授生产运作的各种类型及其比较,通过各种生产类型的比较, 使学生明确各种类型的运作的重点和关键。同时在各种类型比较的基础上能掌握其过程组织 的特点和方式,从过程的角度审视生产运作过程,学会从过程分析中寻找解决问题的途径和 方法。各种类型的探讨可以围绕制造和服务、Make to Stock 和 Make to Order、大量生产和 多品种小批量生产的比较来展开。 二、电子教案库 已提供。 三、知识点库 生产运作的基本概念和本质; 生产与运作的各种分类及各自的特点; 生产与运作的系统布置与系统运行阶段所涉及的各种主题及其作用; 选址决策所涉及的各种要素和选址决策方法; 生产系统布置的原则和类型; 各层次生产计划的特点和相互关系及各自的作用; 综合计划和主生产计划的制定程序和方法; 物料需求计划的作用和制定程序及逻辑; 四、案例库 如使用本案例,需要更改案例名及部分数据为好! Case:Valentin Valentin Inc. is a company who uses MRP to organize its production. The lot-sizing technique they chose for all references is lot-for-lot. They provide part of the product tree structure for products A and B (the figures shown indicate the number of component required to produce a product of the next level)

ProductBProductAZ(3)Y(2)Z(1)Y(1)W(2)The components Y and W are used exclusively in the production of products A and B. Theyare produced by the same company and could not be purchased from an other company: the leadtime is2months.Component Z ismanufactured bya subcontractor and its lead time is 1monthUsually,deliveries are received at thebeginning of themonthAt the end ofJanuary, the inventory for Y is 200 units ; a 400 units(Y) delivery is expectedat the beginning ofFebruary, and a 500 units (Y)delivery at the beginning of March.A safetystock is required on a month-basis: it should be as highas 1o%of thegross requirements of themonththat itisplannedfor.Production planning for products A and B is presented in the following table. Those productsare specific and demand that cannot be supplied is postponed (what has not been produced thismonth, will be required for the next month)We assume that there are no capacity constraints for the production of any of the products orcomponents.ProductAFeb.Mar.Jul.Aug.Jan.Apr.May.Jun.190220180150200240230Gross requirements A110Planned-order-receipts800000Lo00On-Hand Inventory0220180150200240230Net requirements220180150200240230Planned order receipt220150200240230180Planned order releaseJan.Feb.Mar.Apr.Jul.ProductAMay.Jun.Aug.709090120110120130Gross requirements A90Planned-order-receipts5000000050On-Hand Inventory0707012090110130Net requirements0707011012090130Planned order receipt907011070120130Planned order releaseQuestions:Determine the number for the planned-order releases for component Y, for the cominga)

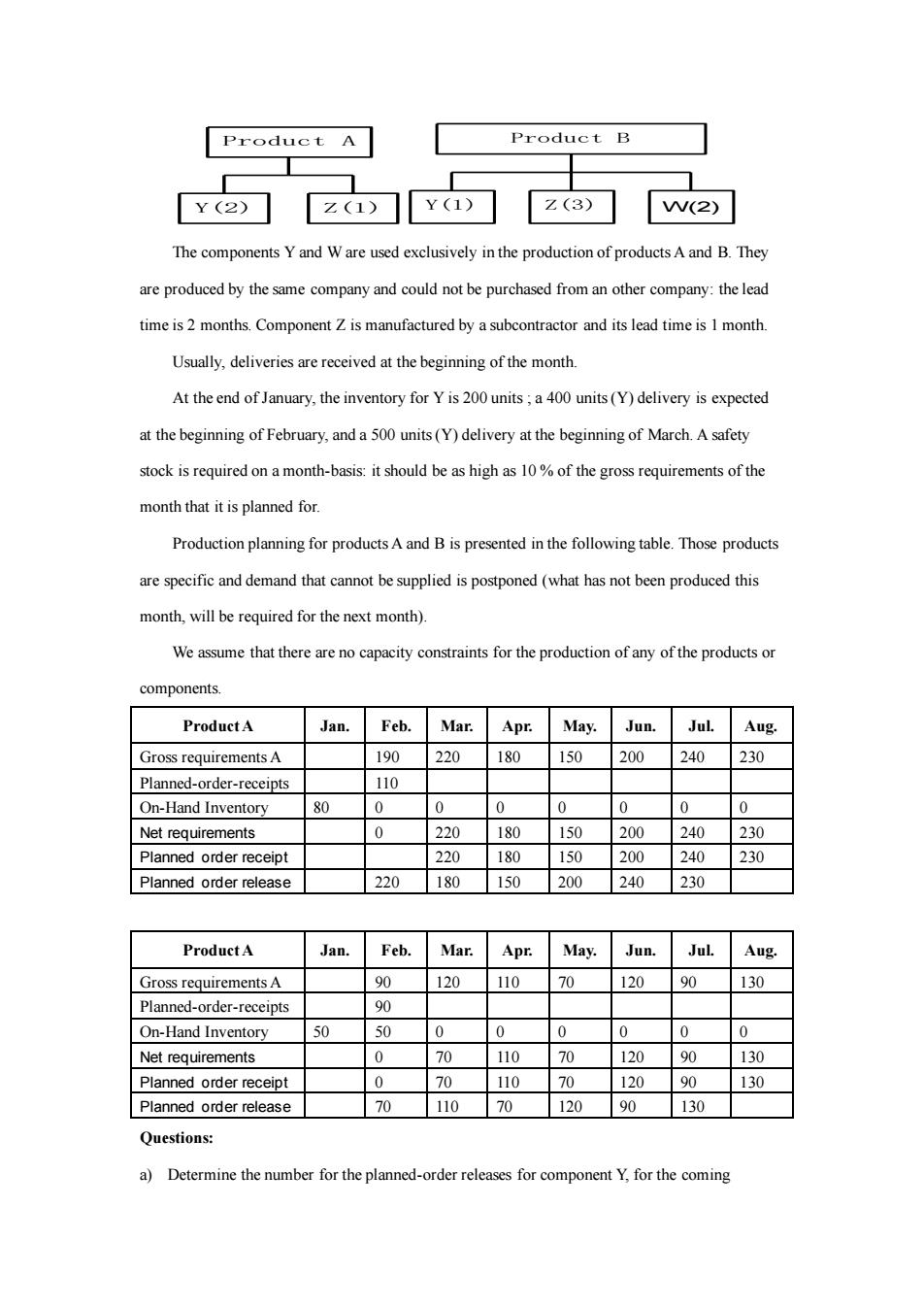

Y(2) Z(1) Product A Y(1) Z(3) W(2) Product B The components Y and W are used exclusively in the production of products A and B. They are produced by the same company and could not be purchased from an other company: the lead time is 2 months. Component Z is manufactured by a subcontractor and its lead time is 1 month. Usually, deliveries are received at the beginning of the month. At the end of January, the inventory for Y is 200 units ; a 400 units (Y) delivery is expected at the beginning of February, and a 500 units (Y) delivery at the beginning of March. A safety stock is required on a month-basis: it should be as high as 10 % of the gross requirements of the month that it is planned for. Production planning for products A and B is presented in the following table. Those products are specific and demand that cannot be supplied is postponed (what has not been produced this month, will be required for the next month). We assume that there are no capacity constraints for the production of any of the products or components. Product A Jan. Feb. Mar. Apr. May. Jun. Jul. Aug. Gross requirements A 190 220 180 150 200 240 230 Planned-order-receipts 110 On-Hand Inventory 80 0 0 0 0 0 0 0 Net requirements 0 220 180 150 200 240 230 Planned order receipt 220 180 150 200 240 230 Planned order release 220 180 150 200 240 230 Product A Jan. Feb. Mar. Apr. May. Jun. Jul. Aug. Gross requirements A 90 120 110 70 120 90 130 Planned-order-receipts 90 On-Hand Inventory 50 50 0 0 0 0 0 0 Net requirements 0 70 110 70 120 90 130 Planned order receipt 0 70 110 70 120 90 130 Planned order release 70 110 70 120 90 130 Questions: a) Determine the number for the planned-order releases for component Y, for the coming

months.b)On January25thone ofthe main client calls and requires an extradelivery of 100 units ofproduct Afor the beginning of April (this extra demand is not part of the master productionschedule).You tell the client that you are going to do your best to accommodate his request,and that you will confirm the next day, what is really possible :-what number of product A will you be able to deliver at the beginning of April, if that ispossible considering the meantime andthe leadtimefor components,-and, in case it is not possible to fullfill his demand at the beginning of April (in total orpartof it), when will the remaining number be delivered (numbers and dates -rememberthat delivery is organized at the beginning of each month)As this is your most important client, you are willing to use your safety stock to help himYour subcontractor is currently facing some underactivity and can deliver a maximum of 200 extraunitsofcomponentZatthebeginningofMarchifyouconfirmyourdemandtomorrowbyfax.You will have toreckon and justify the answer you intend to present to your client(numbersand dates ofdelivery),as well asforyour subcontractor (number and date of delivery)for thatadditionnal demand. You will also present the changes that your decision generates on planningforproductAandcomponentY,五、试题库一、简答题1、请解释,为什么在二战期间德军使用火车头厂生产坦克是犯了致命性的错误?(10)火车头生产企业采用的生产流程类型为工艺专业方式,这种方式的主要缺点为生产效率低、成本高,所以德军使用火车头生产企业生产坦克远没有美军使用汽车生产企业生产轻型坦克的效率高,生产数量上没有优势,所以说德军在坦克生产上犯了致命性的错误。2、采用小批量生产而非大批量生产的企业是否应该采取下列竞争重点?为什么?(10)(1)缩短生产周期;(2)低成本;(3)保持更大的生产能力缓冲;采用小批量生产的企业主要竞争优势在于生产的灵活性和柔性,而非大批量生产的成本和效率优势,所以,缩短生产周期和低成本不应该成为其竞争重点

months. b) On January 25th one of the main client calls and requires an extra delivery of 100 units of product A for the beginning of April (this extra demand is not part of the master production schedule). You tell the client that you are going to do your best to accommodate his request, and that you will confirm the next day, what is really possible : - what number of product A will you be able to deliver at the beginning of April, if that is possible considering the meantime and the lead time for components, - and, in case it is not possible to fullfill his demand at the beginning of April (in total or part of it), when will the remaining number be delivered (numbers and dates - remember that delivery is organized at the beginning of each month). As this is your most important client, you are willing to use your safety stock to help him. Your subcontractor is currently facing some underactivity and can deliver a maximum of 200 extra units of component Z at the beginning of March if you confirm your demand tomorrow by fax.You will have to reckon and justify the answer you intend to present to your client(numbers and dates of delivery), as well as for your subcontractor (number and date of delivery) for that additionnal demand. You will also present the changes that your decision generates on planning for product A and component Y. 五、试题库 一、简答题 1、 请解释,为什么在二战期间德军使用火车头厂生产坦克是犯了致命性的错误?(10) 火车头生产企业采用的生产流程类型为工艺专业方式,这种方式的主要缺点为生产 效率低、成本高,所以德军使用火车头生产企业生产坦克远没有美军使用汽车生产企业 生产轻型坦克的效率高,生产数量上没有优势,所以说德军在坦克生产上犯了致命性的 错误。 2、 采用小批量生产而非大批量生产的企业是否应该采取下列竞争重点?为什么?(10) (1)缩短生产周期; (2)低成本; (3)保持更大的生产能力缓冲; 采用小批量生产的企业主要竞争优势在于生产的灵活性和柔性,而非大批量生产的 成本和效率优势,所以,缩短生产周期和低成本不应该成为其竞争重点

小批量生产为保证足够的柔性和不确定的生产任务,应该保持更大的生产能力缓冲。3、在MRP系统中,为什么还需要安全库存?在使用MRP系统之后,你还可以考虑如何进一步降低系统中的原材料和零部件的安全库存?请至少给出三种可操作性的方法。(10分)答:在MRP系统中使用安全库存的目的同样是为了防止各种不确定性情况的出现,比如,供应商供货的延迟、设备的故障以及需求的不确定性增加等要素。可以降低安全库存的方法有多种途径,比如,缩短提前期、使提前期的变化程度降低、缩短生产准备时间、减少设备故障时间等。二、计算题:65分1.某一产品的日需求量为20单位,标准差为5单位。盘点周期为20天,提前期为15天。管理部门已经制定了满足95%的政策。在盘点周期期初,库存中有150单位产品。问最高库存量有多大?订购量为多少?平均库存水平为多大?(15分)OT+L=/(15+20)×5=29.58最高库存量=d(T+L)+zOT+L=20×(20+15)+1.64×(29.58)=748.5单位订购量q=d(T+L)+zOT+L-I=748.5-150=598.5单位dxT20×20+1.64×29.58=248.5单位平均库存量:+ ZOT+L =222.公司的有一台专门制作水果蛋糕的机器。它每天可以生产1500份水果蛋糕。公司以往每周只需生产一天,生产的数量就可以满足一周的需求。公司在全年50周中均销售这种水果蛋糕。机器每次准备需要400元。生产出来的水果蛋糕必须在温度很低而且非常卫生的环境下储存,因此每份水果蛋糕每储存一天要花费公司0.8元。请问,公司是采取每周一次性生产1500份水果蛋糕的策略呢?还是应该采用经济制造批量(EOQ)方法?请比较两种方案(你可以自已做出认为合理的假设)?(15)答:首先确定采用EOQ方法下的成本:

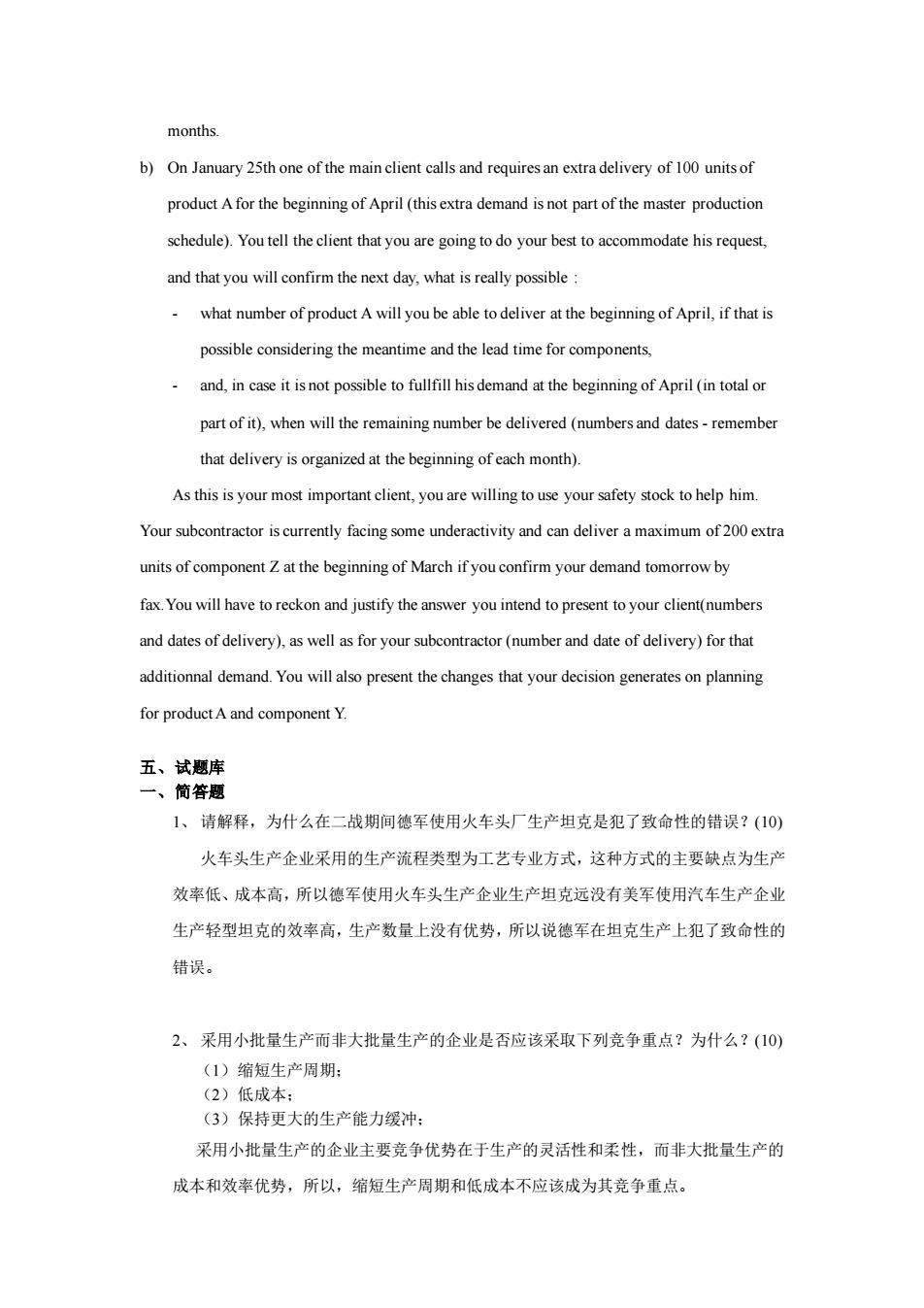

小批量生产为保证足够的柔性和不确定的生产任务,应该保持更大的生产能力缓冲。 3、 在 MRP 系统中,为什么还需要安全库存?在使用 MRP 系统之后,你还可以考虑如 何进一步降低系统中的原材料和零部件的安全库存?请至少给出三种可操作性的 方法。(10 分) 答:在 MRP 系统中使用安全库存的目的同样是为了防止各种不确定性情况的出现,比 如,供应商供货的延迟、设备的故障以及需求的不确定性增加等要素。 可以降低安全库存的方法有多种途径,比如,缩短提前期、使提前期的变化程度降低、 缩短生产准备时间、减少设备故障时间等。 二、计算题: 65 分 1.某一产品的日需求量为 20 单位,标准差为 5 单位。盘点周期为 20 天,提前期为 15 天。 管理部门已经制定了满足 95%的政策。在盘点周期期初,库存中有 150 单位产品。问最高 库存量有多大?订购量为多少?平均库存水平为多大?(15 分) 平均库存量 单位 订购量 单位 最高库存量 单位 1.64 29.58 248.5 2 20 20 2 ( ) 748.5 150 598.5 ( ) 20 (20 15) 1.64 (29.58) 748.5 (15 20) 5 29.58 _ _ _ + = + = = = + + − = − = = + + = + + = + = + + + + T L T L T L T L z d T q d T L z I d T L z 2. 公司的有一台专门制作水果蛋糕的机器。它每天可以生产 1500 份水果蛋糕。公司以往 每周只需生产一天,生产的数量就可以满足一周的需求。公司在全年 50 周中均销售这 种水果蛋糕。机器每次准备需要 400 元。生产出来的水果蛋糕必须在温度很低而且非常 卫生的环境下储存,因此每份水果蛋糕每储存一天要花费公司 0.8 元。请问,公司是采 取每周一次性生产 1500 份水果蛋糕的策略呢?还是应该采用经济制造批量(EOQ)方 法?请比较两种方案(你可以自己做出认为合理的假设)?(15) 答: 首先确定采用 EOQ 方法下的成本:

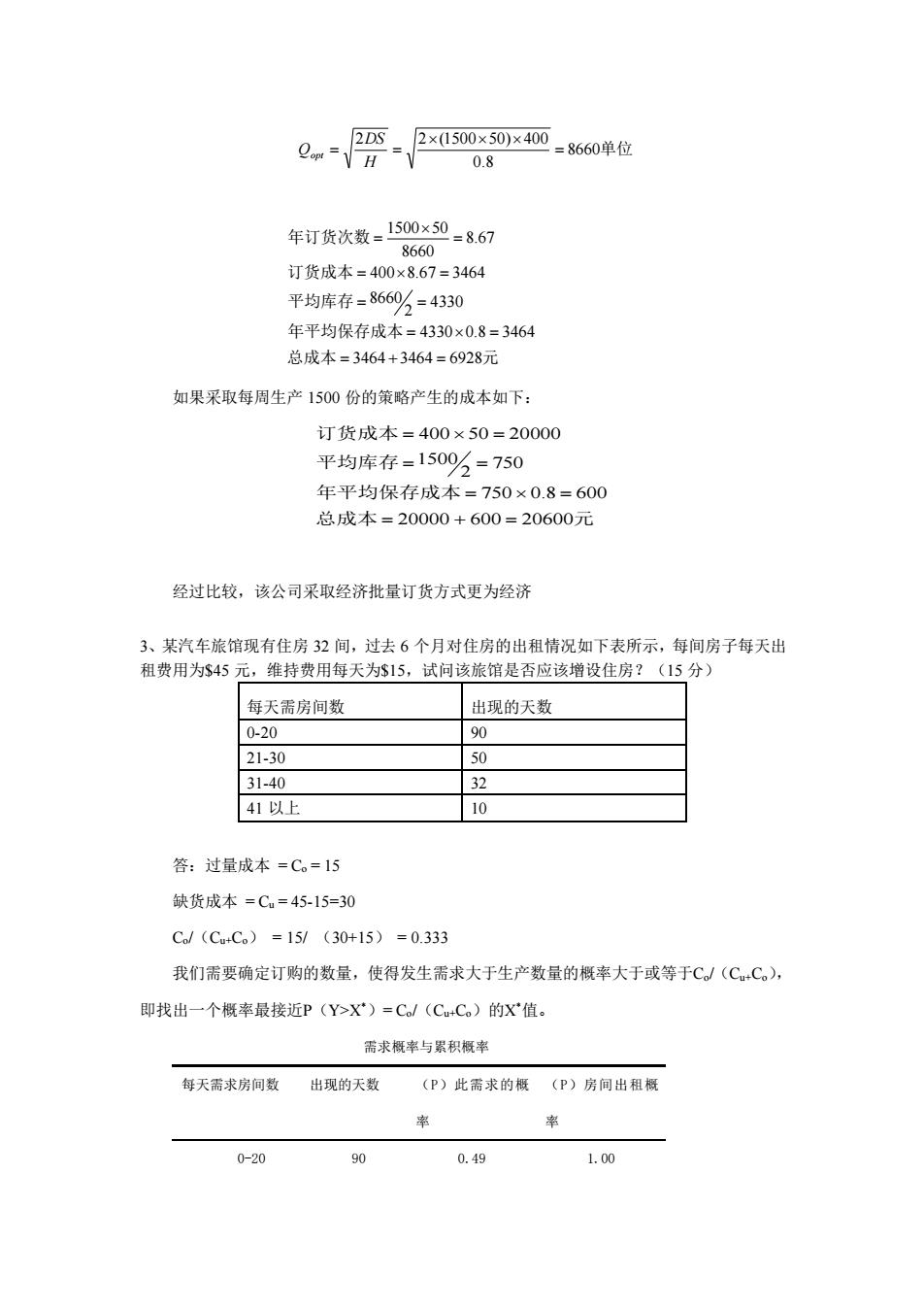

2DS2×(1500×50)×400=8660单位Qopr=H0.8年订货次数=1500×50=8.678660订货成本=400×8.67=3464平均库存=866%=4330/2年平均保存成本=4330×0.8=3464总成本=3464+3464=6928元如果采取每周生产1500份的策略产生的成本如下:订货成本=400×50=20000平均库存=150%=750/2年平均保存成本=750×0.8=600总成本=20000+600=20600元经过比较,该公司采取经济批量订货方式更为经济3、某汽车旅馆现有住房32间,过去6个月对住房的出租情况如下表所示,每间房子每天出维持费用每天为$15,试问该旅馆是否应该增设住房?(15分)租费用为S455元,每天需房间数出现的天数0-20905021-303231-4041以上10答:过量成本=C。=15缺货成本 =Cu=45-15=30Co/(Cu+Co)=15/(30+15)=0.333我们需要确定订购的数量,使得发生需求大于生产数量的概率大于或等于C/(Cu+C),即找出一个概率最接近P(Y>X*)=Co/(Cu+C。)的X值。需求概率与累积概率每天需求房间数出现的天数(P)此需求的概(P)房间出租概率率900. 491. 000-20

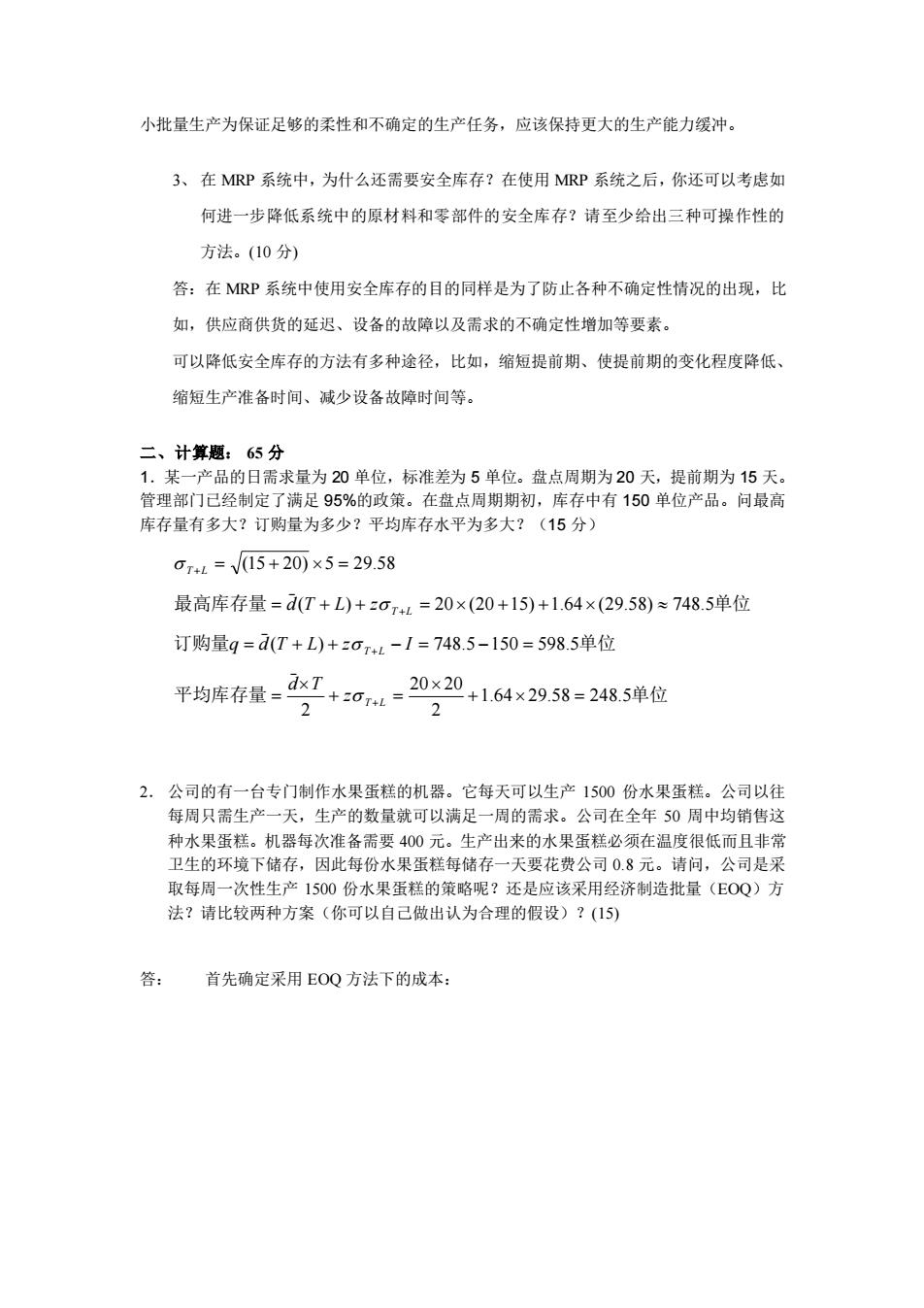

总成本 元 年平均保存成本 平均库存 订货成本 年订货次数 单位 3464 3464 6928 4330 0.8 3464 4330 2 8660 400 8.67 3464 8.67 8660 1500 50 8660 0.8 2 2 (1500 50) 400 = + = = = = = = = = = = = = H DS Qopt 如果采取每周生产 1500 份的策略产生的成本如下: 总成本 元 年平均保存成本 平均库存 订货成本 20000 600 20600 750 0.8 600 750 2 1500 400 50 20000 = + = = = = = = = 经过比较,该公司采取经济批量订货方式更为经济 3、某汽车旅馆现有住房 32 间,过去 6 个月对住房的出租情况如下表所示,每间房子每天出 租费用为$45 元,维持费用每天为$15,试问该旅馆是否应该增设住房?(15 分) 每天需房间数 出现的天数 0-20 90 21-30 50 31-40 32 41 以上 10 答:过量成本 = Co = 15 缺货成本 = Cu = 45-15=30 Co/(Cu+Co) = 15/ (30+15) = 0.333 我们需要确定订购的数量,使得发生需求大于生产数量的概率大于或等于Co/(Cu+Co), 即找出一个概率最接近P(Y>X*)= Co/(Cu+Co)的X*值。 需求概率与累积概率 每天需求房间数 出现的天数 (P)此需求的概 率 (P)房间出租概 率 0-20 90 0.49 1.00