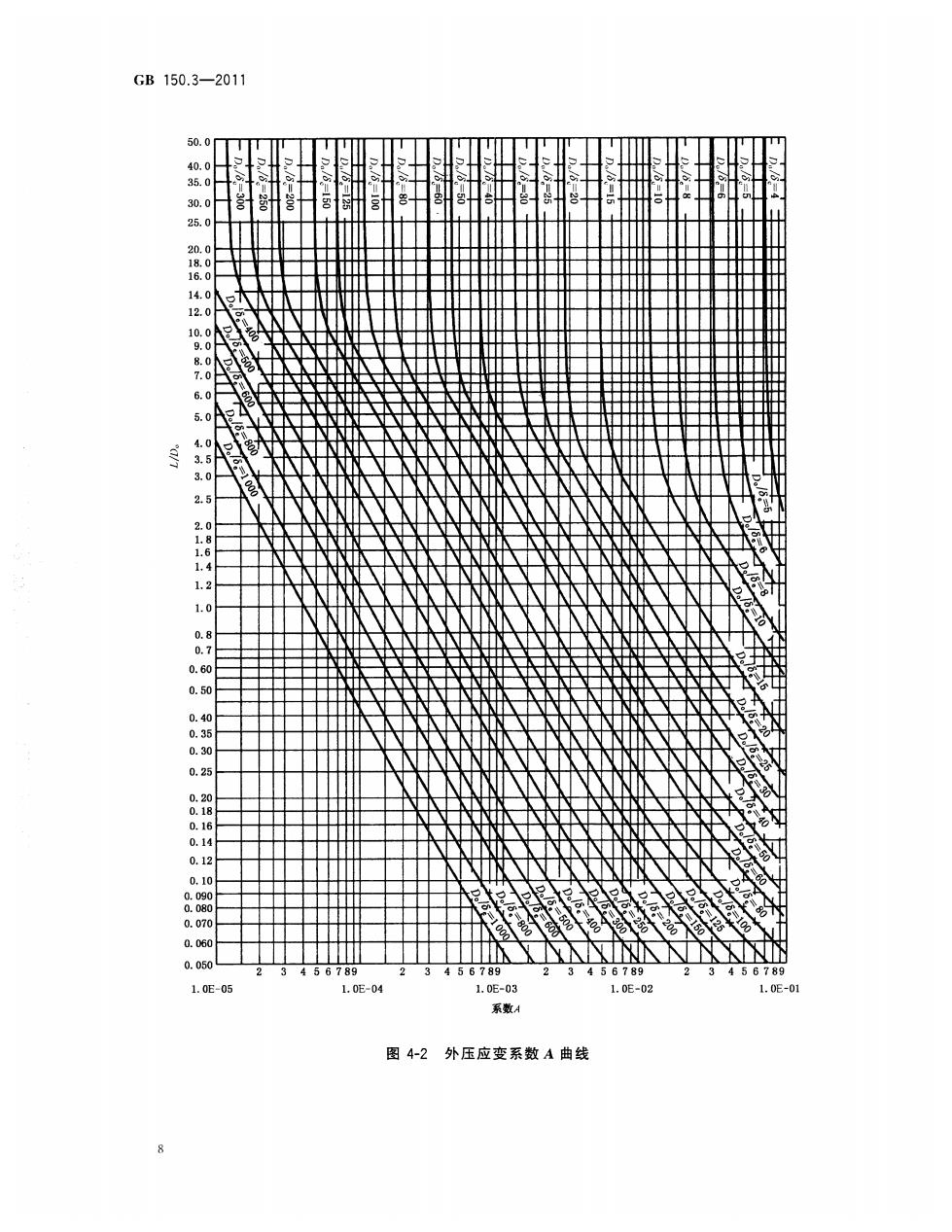

GB150.3201150.040.035. 030. 0025. 020.018.016.014.0P12.010.09. 08.07. 06.05. 04. 00"(/73.53. 02.52. 01.8161. 41.21.00. 80. 70. 600. 500. 400.350. 300.250.200.180.160.140. 120.100.0900.0800.0700. 060YNXN0.05034567893456789456789345678922221.0E051.0E-041.0E-031.0E-021.0E-01系数A图4-2外压应变系数A曲线8

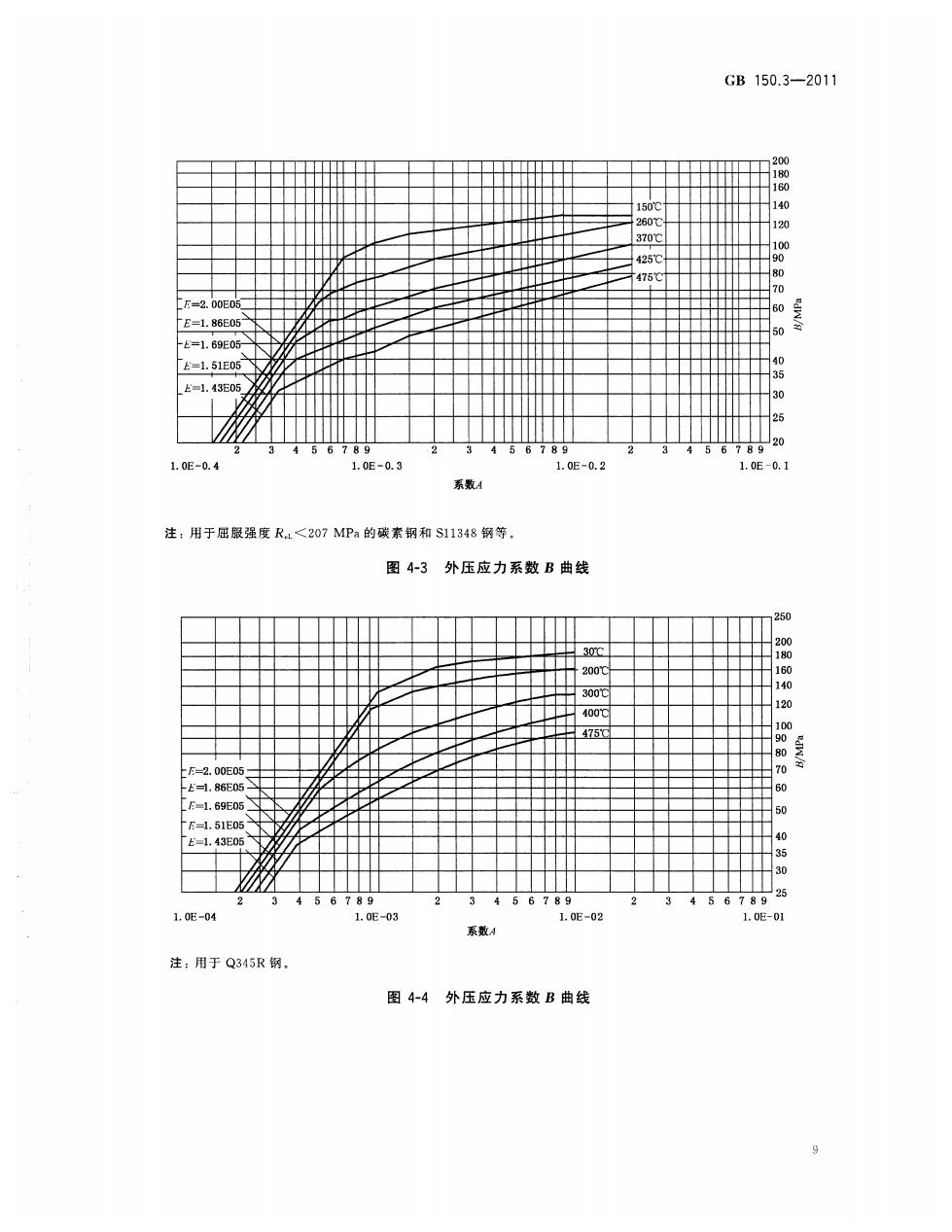

GB 150.3—2011200180160140150℃260℃120370'℃10090425℃80475℃70F=2.00E05CE=1.86E05~50E=1.69E05-40E=1.51E0535E=1.43E0530252045678945678945678921.0E0.41. 0E0. 31.0E0.21.0E-0.1系数A注:用于屈服强度R,<207MPa的碳素钢和S11348钢等图4-3外压应力系数B曲线25020030℃180160200℃140300℃1204000100475C70E=2.00E05160上=1.86E05=1.69E0550E=1.51E0540L=1.43E053530XIXa3567892A4567892567893421.0E041.0E031.0E021.0E01系数A注:用于Q345R钢。图4-4外压应力系数B曲线9

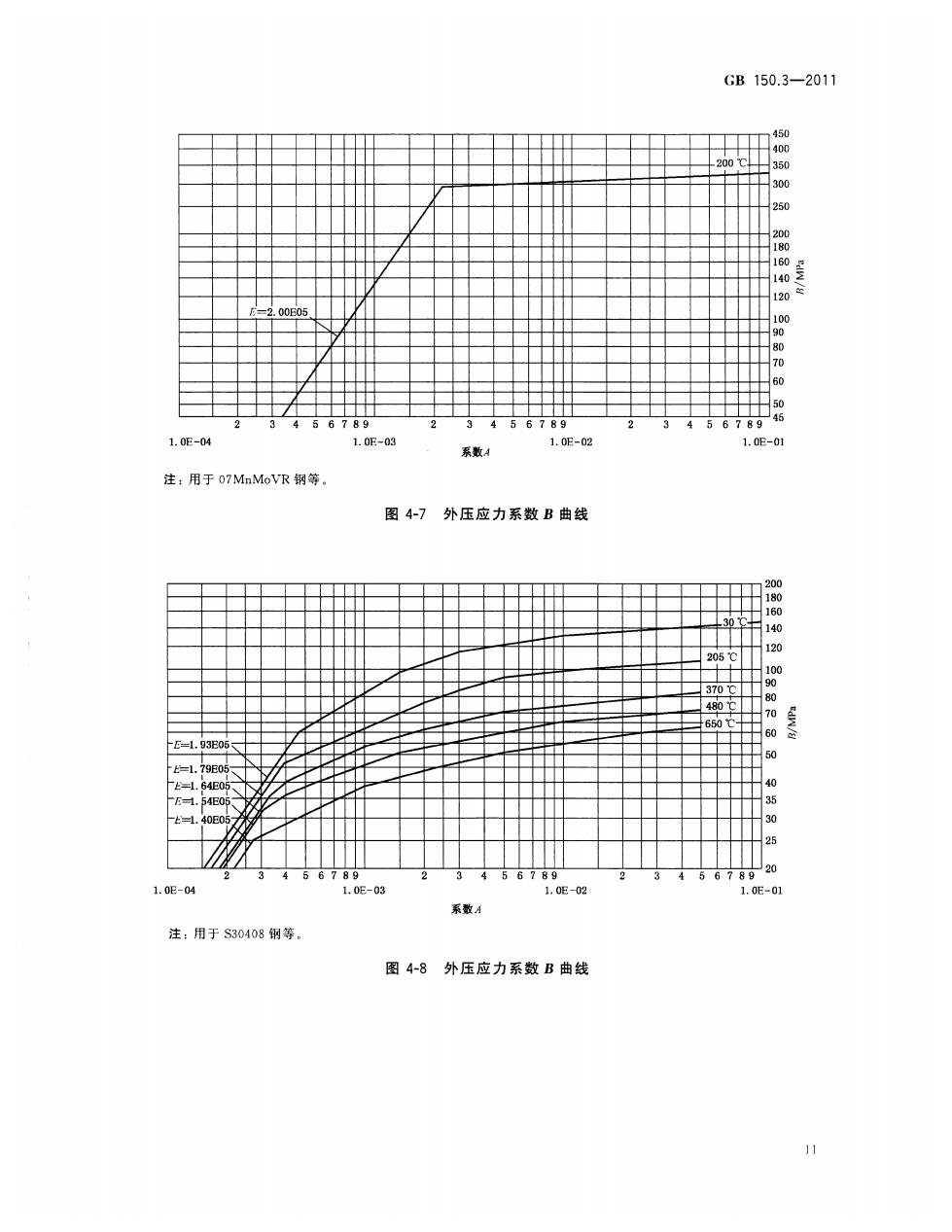

GB150.32011250200180150℃160260℃140370℃门120425C100475℃+90EoToF=2.00E05H60F1.86E05-160E=1.69E05E=1.57E05AO上=1.43E05XD252456789245678923456789331.0E041.0E031.0E-021.0E-01系数A注:用于除图4-4注明的材料外,材料的屈服强度R>207MPa的碳钢、低合金钢和S11306钢等图.4-5外压应力系数B曲线450400350300R=380~R-415+R-345250H200180Z160+140R=310Rq=260-275V12010090上=2.00E0580T605045345678934567892234567891.0E041.0E031.0E021.0E01系数A注:用于除图4-4注明的材料外.材料的屈服强度RL>260MPa的碳钢、低合金钢等。图4-6外压应力系数B曲线10

GB150.3—2011450400200℃3503002502001801601408120-2.00E051009080106050政452345678923456789234567891.0E041.0E031.0E021.0E01系数A注:用于07MnMoVR钢等。图4-7外压应力系数B曲线20018016030C+140120205℃10090370°℃80480EdW/70650160E=1.93E0550上=1.79E0540二1.64E053554E030E=1.40E02520234567893456789456789221.0E~041. 0E031. 0E021. 0E01系数A注:用于S30408钢等。图4-8外压应力系数B曲线11

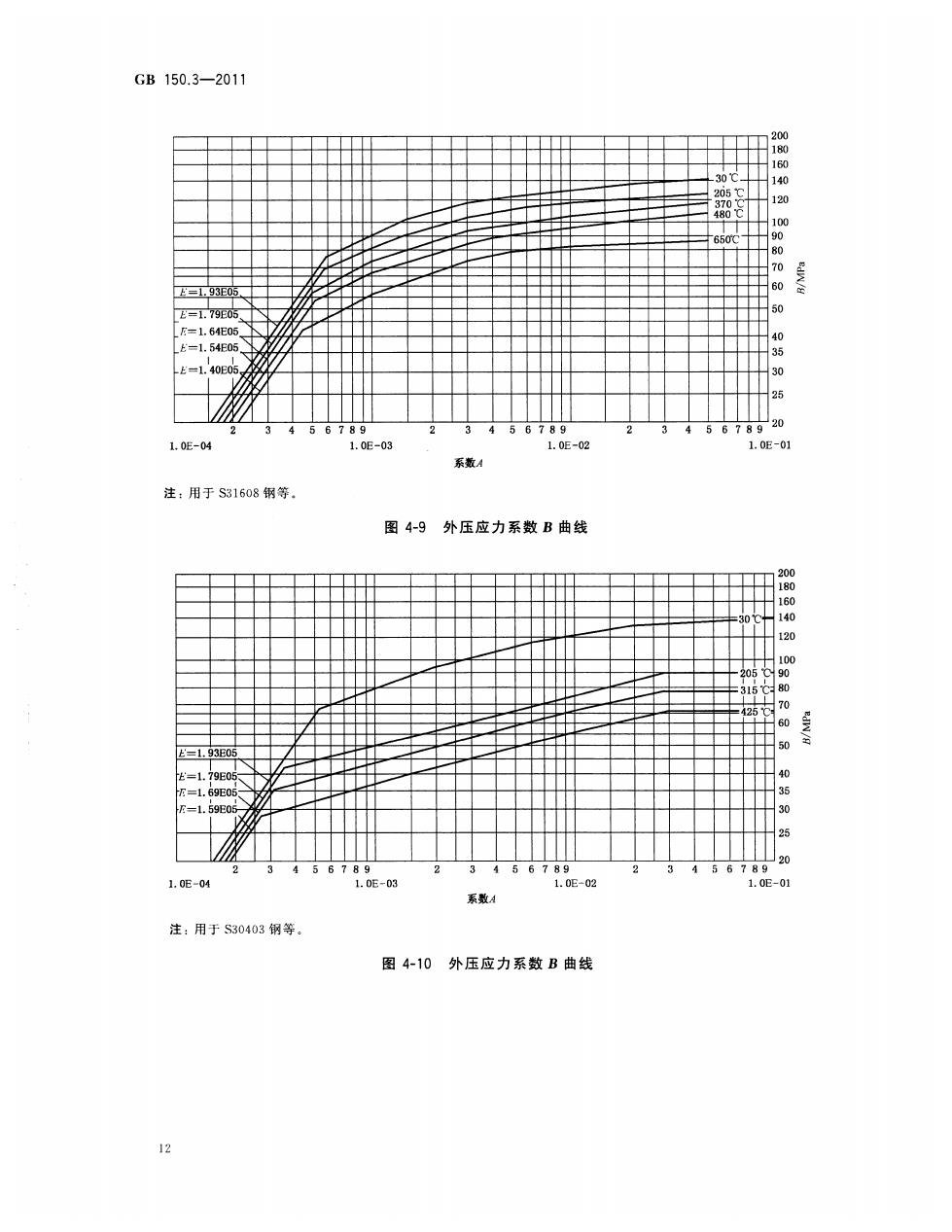

GB150.3201120018016030℃140205℃C120370480℃10090650℃+67060RE-193E05160E=1.79E05、811F=1.64E0540=1.54E055E=1.40E053025N203456789456789345678922321.0E-011. 0E041.0E031.0E02系数A注:用于S31608钢等。图4-9外压应力系数B曲线200180160140120100205903158042570501.93E0540=1.79E0535F=1.69E05F=1.59E0530X25203456789234567892345678921.0E041.0E031. 0E021. 0E01系数A注:用于S30403钢等图4-10外压应力系数B曲线12