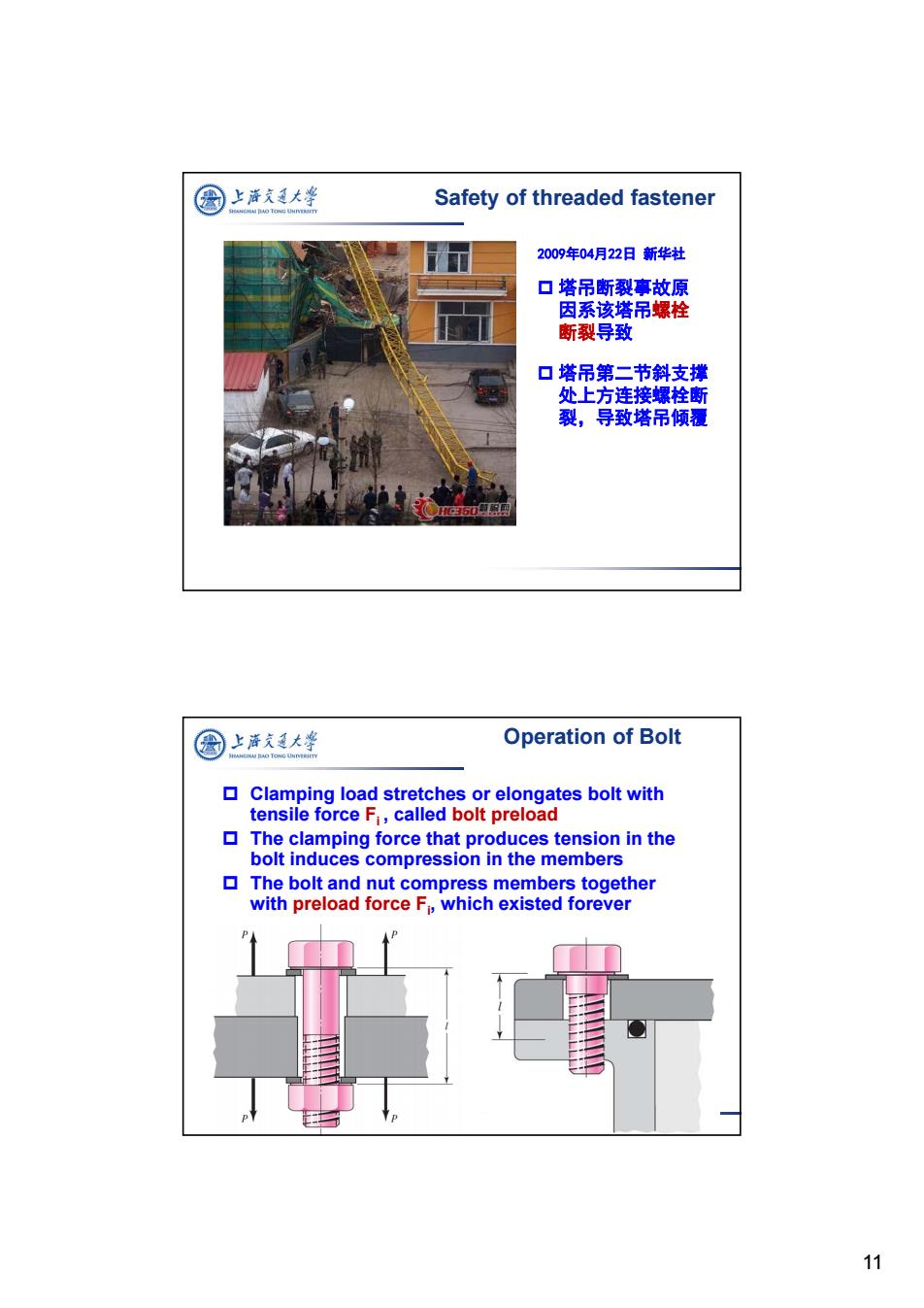

圈上序大峰 Safety of threaded fastener 2009年04月22日新华社 口塔吊断裂事故原 因系该塔吊螺栓 断裂导致 口塔吊第二节斜支撑 处上方连接螺栓断 裂,导致塔吊倾覆 圆上泽夫通大学 Operation of Bolt Clamping load stretches or elongates bolt with tensile force Fi,called bolt preload The clamping force that produces tension in the bolt induces compression in the members The bolt and nut compress members together with preload force Fi,which existed forever 11

11 塔吊断裂事故原 因系该塔吊螺栓 断裂导致 2009年04月22日 新华社 塔吊第二节斜支撑 处上方连接螺栓断 裂,导致塔吊倾覆 Safety of threaded fastener Operation of Bolt Clamping load stretches or elongates bolt with tensile force Fi , called bolt preload The clamping force that produces tension in the bolt induces compression in the members The bolt and nut compress members together with preload force Fi , which existed forever

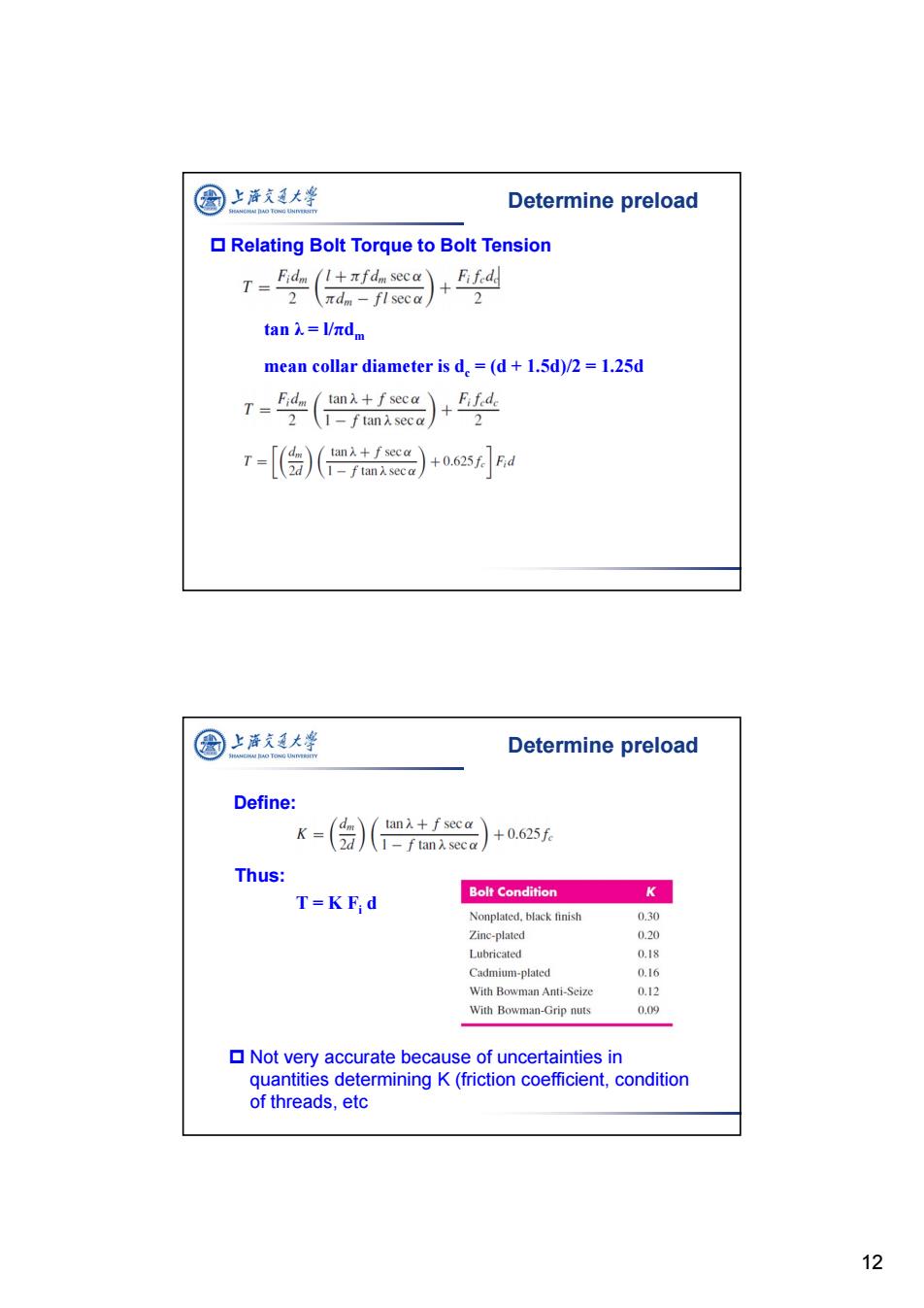

圈上泽文通大华 Determine preload Relating Bolt Torque to Bolt Tension T=Fid, I+πfdm seca Fifede πdm-fI seca 2 tan =I/ndm mean collar diameter is d,=(d 1.5d)/2 =1.25d Fifede TFidm(tan入+seca)+ i-ftan入seca/ 2 r-[()(巴 +0.625fFd 圆上泽夫道大峰 Determine preload Define: dm K=2a) tan入+f seca l-ftan入seca +0.625f Thus: Bolt Condition T=KFd K Nonplated,black finish 0.30 Zinc-plated 0.20 Lubricated 0.18 Cadmium-plated 0.16 With Bowman Anti-Seize 0.12 With Bowman-Grip nuts 0.09 Not very accurate because of uncertainties in quantities determining K(friction coefficient,condition of threads,etc 12

12 Relating Bolt Torque to Bolt Tension tan λ = l/πdm mean collar diameter is dc = (d + 1.5d)/2 = 1.25d Determine preload T = K Fi d Thus: Define: Determine preload Not very accurate because of uncertainties in quantities determining K (friction coefficient, condition of threads, etc

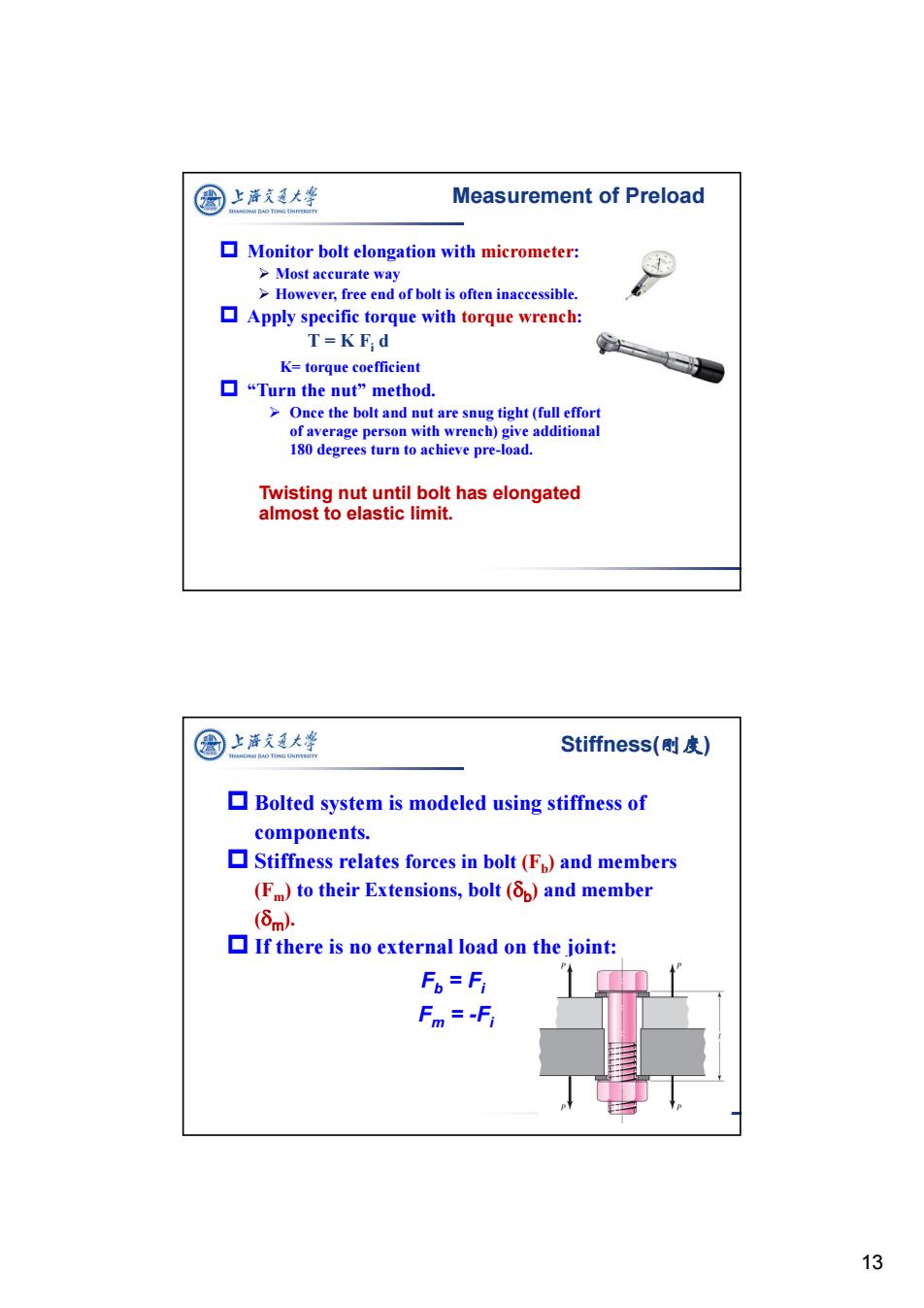

圈上海文通大华 Measurement of Preload Monitor bolt elongation with micrometer: >Most accurate way >However,free end of bolt is often inaccessible. Apply specific torque with torque wrench: T=KFd K=torque coefficient ▣“Turn the nut”method. >Once the bolt and nut are snug tight(full effort of average person with wrench)give additional 180 degrees turn to achieve pre-load. Twisting nut until bolt has elongated almost to elastic limit. 圈上泽夫道大学 Stiffness(则度) Bolted system is modeled using stiffness of components. Stiffness relates forces in bolt(Fp)and members (Fm)to their Extensions,bolt (p)and member (⑧m. If there is no external load on the joint: Fo=Fi Fm=-F1 13

13 Measurement of Preload Monitor bolt elongation with micrometer: Most accurate way However, free end of bolt is often inaccessible. Apply specific torque with torque wrench: T = K Fi d K= torque coefficient “Turn the nut” method. Once the bolt and nut are snug tight (full effort of average person with wrench) give additional 180 degrees turn to achieve pre-load. Twisting nut until bolt has elongated almost to elastic limit. Stiffness(刚度) Bolted system is modeled using stiffness of components. Stiffness relates forces in bolt (Fb) and members (Fm) to their Extensions, bolt (b) and member (m). If there is no external load on the joint: Fb = Fi Fm = -Fi