Chapter 3 Hydraulic Pumps 妆 Chapter list 3.1 Introduction 3.2 Piston Pumps 3.3 Vane Pumps 3.4 Gear Pumps Homepage List Upwards Dowrwards Retumn Exit

Chapter 3 Hydraulic Pumps 1 Chapter list 3.1 Introduction 3.2 Piston Pumps 3.3 Vane Pumps 3.4 Gear Pumps

Chapter 3 Hydraulic Pumps 3.1 Introduction 3.1.1 Operating Principle 3.1.2 Main performance parameters in hydraulic pumps 3.1.3 Performance curves 3.1.4 Classification 3.1.5 Graphic symbols 2 Homepage List Upwards Downwards Retumn Exit

Chapter 3 Hydraulic Pumps 2 3.1 Introduction 3.1.1 Operating Principle 3.1.2 Main performance parameters in hydraulic pumps 3.1.3 Performance curves 3.1.4 Classification 3.1.5 Graphic symbols

Chapter 3 Hydraulic Pumps 3.1 Introduction Hydraulic pumps convert mechanical energy into hydraulic energy.They supply fluid to the components in the hydraulic system. 3.1.1 Operating principle 1,2-Non-return valve 3-Spring 4-Cylinder 5-Piston 6-Eccentric wheel Play y吧 Fig.3-1 Operating principle displacement pumps Homepage List Upwards Downwards Retumn Exit

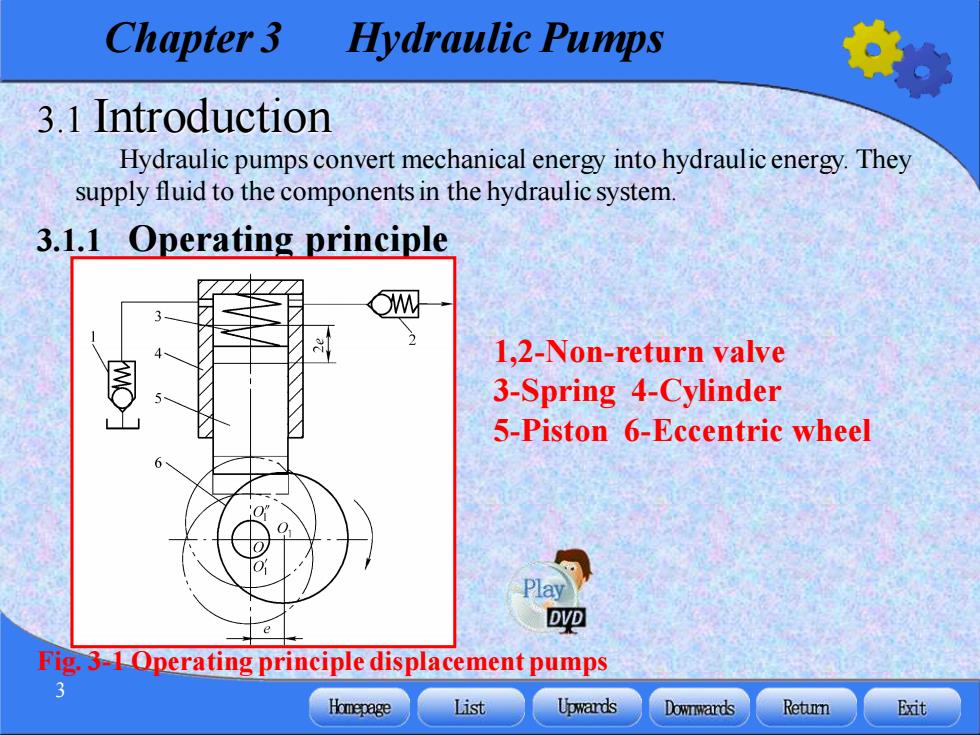

Chapter 3 Hydraulic Pumps 3 3.1 Introduction 3.1.1 Operating principle Hydraulic pumps convert mechanical energy into hydraulic energy. They supply fluid to the components in the hydraulic system. 1,2-Non-return valve 3-Spring 4-Cylinder 5-Piston 6-Eccentric wheel Fig. 3-1 Operating principle displacement pumps

Chapter 3 Hydraulic Pumps The operating principle of every pump in a hydraulic system depends upon the alternative change of their working volumes. Note:the piston diameter as d the offset of the eccentric wheel as e,the longest stroke the piston can reach as s and the discharged oil volume V then s 2e V=(πd2/4)s=(πd2/2)e As described above,the basic conditions that constitute a hydraulic pump can be concluded as follows: (1)Oil tight chamber. (2)Flow-deploying(separate the low pressure from the high one). (3)The absolute oil pressure in the reservoir should be equal or more than the atmospheric pressure. Homepage List Upwards Downwards Retumn Exit

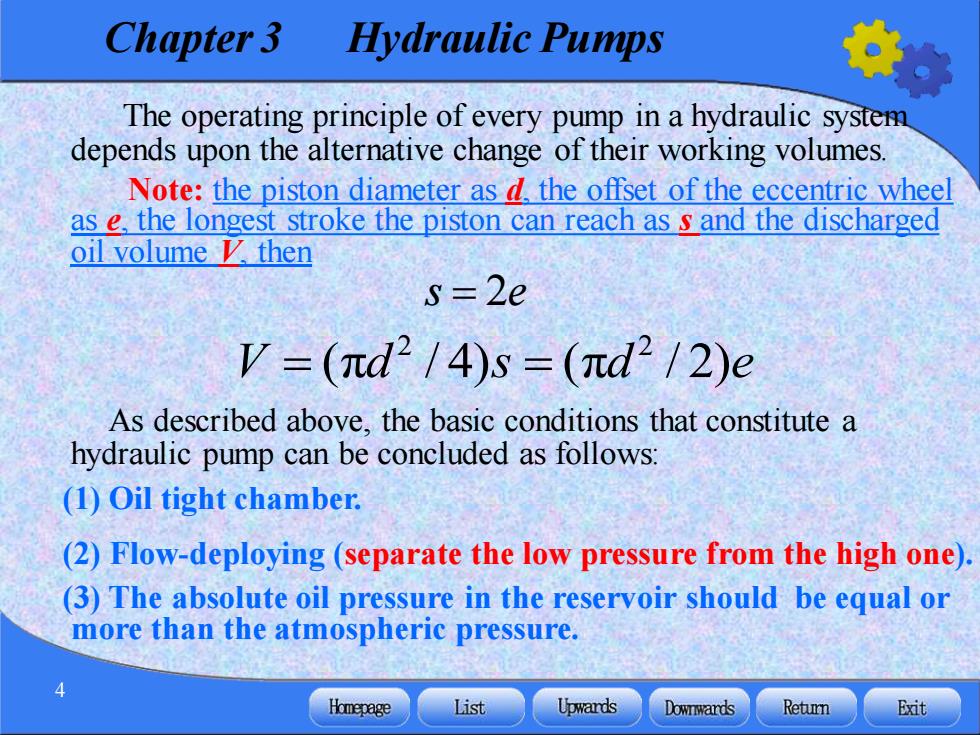

Chapter 3 Hydraulic Pumps 4 The operating principle of every pump in a hydraulic system depends upon the alternative change of their working volumes. Note: the piston diameter as d, the offset of the eccentric wheel as e, the longest stroke the piston can reach as s and the discharged oil volume V, then As described above, the basic conditions that constitute a hydraulic pump can be concluded as follows: (1) Oil tight chamber. (2) Flow-deploying (separate the low pressure from the high one). (3) The absolute oil pressure in the reservoir should be equal or more than the atmospheric pressure. s e = 2 2 2 V d s d e = = (π / 4) (π / 2)

Chapter 3 Hydraulic Pumps 3.1.2 Main performance parameters in hydraulic pumps 1.Pressure 1)Suction pressure-the pressure in the inlet port.For self-priming suction pumps,the suction pressure is lower than the atmospheric pressure 2)Working pressure P-the outlet pressure when the hydraulic pump is in operation,which depends upon the overall loads. 3)Rated pressure Ps-the highest pressure tested with standard method when the pump rotates continuously under common working conditions. 2.Delivery,flow rate and volumetric efficiency (1)Delivery V Homepage List Upwards Downwards Retumn Exit

Chapter 3 Hydraulic Pumps 5 3.1.2 Main performance parameters in hydraulic pumps 1. Pressure 1) Suction pressure —— the pressure in the inlet port. For self-priming suction pumps, the suction pressure is lower than the atmospheric pressure. 2)Working pressure P ——the outlet pressure when the hydraulic pump is in operation, which depends upon the overall loads. 3) Rated pressure PS —— the highest pressure tested with standard method when the pump rotates continuously under common working conditions. 2. Delivery,flow rate and volumetric efficiency (1) Delivery V