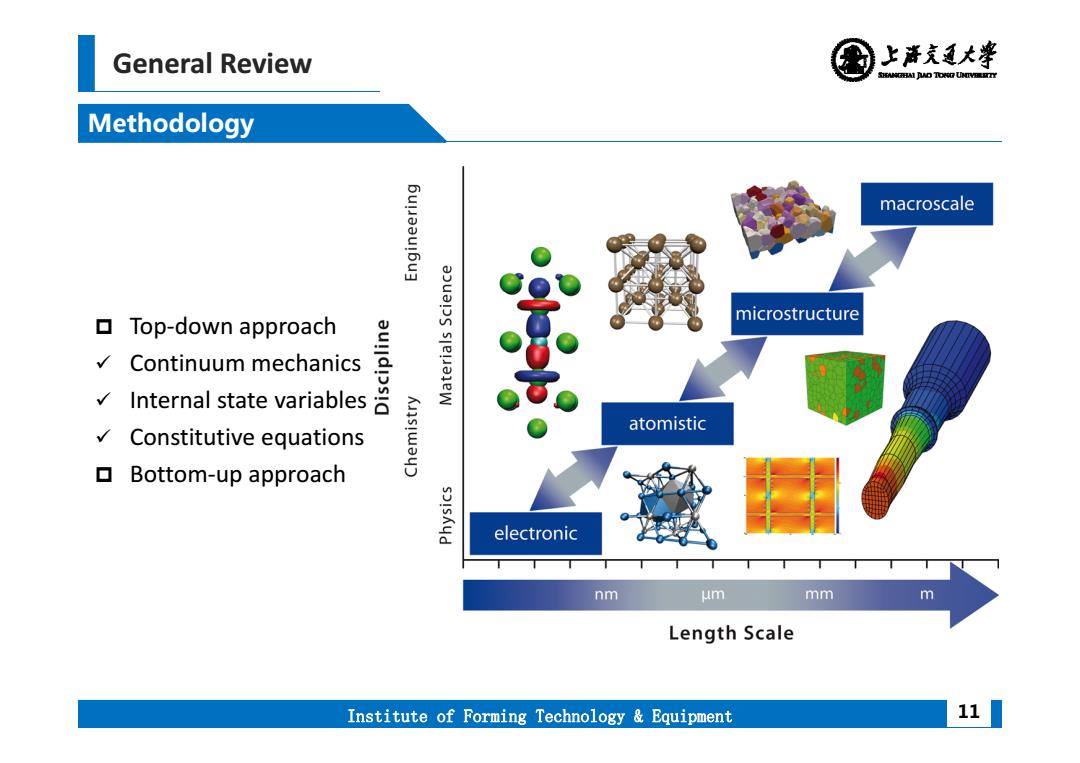

General Review 国上清充通大孝 SANCEAI JUO TO阳UY Methodology macroscale microstructure ▣Top-down approach astate vanic √Continuum mechanics atomistic Constitutive equations ▣Bottom-up approach electronic nm um mm Length Scale Institute of Forming Technology Equipment 11

General Review Institute of Forming Technology & Equipment Methodology 11 Top‐down approach Continuum mechanics Internal state variables Constitutive equations Bottom‐up approach

General Review 上清充通大¥ SANCEAI JUO TO阳UY Important points to be kept in mind ▣No volume change Shear stresses vs.Pure hydrostatic stresses ▣Fracture strain←hydrostatic stresses. slip vs.shear stresses at the slip plane. Plastic deformation<>permanent deformation without external constraints Phenomenological terms Plastic Deformation in Crystalline Materials Slip Twinning Phase Transformation Creep Mechanisms (Dislocation motion) Grain boundary sliding + Other Mechanisms Vacancy diffusion Grain rotation Dislocation climb Institute of Forming Technology Equipment 12

General Review Institute of Forming Technology & Equipment Important points to be kept in mind 12 Slip (Dislocation motion) Plastic Deformation in Crystalline Materials Twinning Phase Transformation Creep Mechanisms Grain boundary sliding Vacancy diffusion Dislocation climb + Other Mechanisms Grain rotation Phenomenological terms No volume change Shear stresses vs. Pure hydrostatic stresses Fracture strain ← hydrostaƟc stresses. slip vs. shear stresses at the slip plane. Plastic deformation ↔ permanent deformation without external constraints

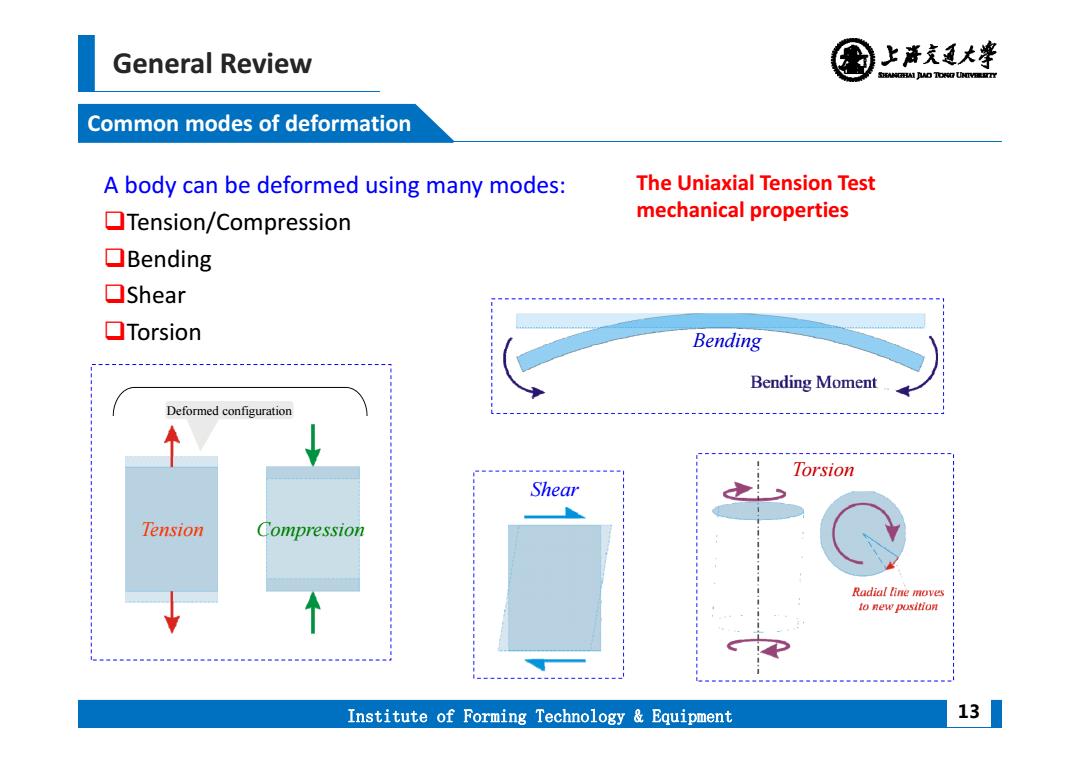

General Review 上清充通大半 SHEAMGRAI DUD TONO UHTVEREETTY Common modes of deformation A body can be deformed using many modes: The Uniaxial Tension Test Tension/Compression mechanical properties ▣Bending ▣Shear ▣Torsion Bending Bending Moment Deformed configuration Torsion Shear Tension Compression Radial line moves to new pusitio月 Institute of Forming Technology Equipment 13

General Review Institute of Forming Technology & Equipment Common modes of deformation 13 A body can be deformed using many modes: Tension/Compression Bending Shear Torsion Bending Tension Compression Deformed configuration Shear Torsion The Uniaxial Tension Test mechanical properties

Tensile Response of Materials 国上清充通大¥ SHEAMGRAI DUD TONO UHTVEREETTY The Uniaxial Tension Test(UTT) 个 Tensile specimen peol Note that Lo is NOT the length of the specimen,but Stroke→ the gauge length Gauge Length→Lo Possible axes e→ : Initial cross sectional areaAo ↑ b £→ Institute of Forming Technology Equipment 14

Tensile Response of Materials Institute of Forming Technology & Equipment The Uniaxial Tension Test (UTT) 14 Stroke → Load → e → s → → → Gauge Length → L0 Possible axes Tensile specimen Initial cross sectional area → A0 Note that L0 is NOT the length of the specimen, but the gauge length

Tensile Response of Materials 上清充通大¥ SANCEAI JUO TO阳UY Stress and strain Engineering Stress(s)and Engineering Strain(e) P←→the load;△L←change in length. D △L 0→initial e= L Subscript i→instantaneous Problems with the use of 's'and 'e'(as outlined in the coming slides). So,define True Stress(o)and True Strain(s) P △L 8= L Subscripts '0'refer to initial values and 'i'to instantaneous values. Institute of Forming Technology Equipment 15

Tensile Response of Materials Institute of Forming Technology & Equipment Stress and strain 15 Engineering Stress (s) and Engineering Strain (e) P ↔ the load; ΔL↔ change in length. Problems with the use of ‘s’ and ‘e’ (as outlined in the coming slides). So, define True Stress () and True Strain () A0 P s L0 L e 0 → iniƟal i → instantaneous Subscript i P A i L L Subscripts ‘0’ refer to initial values and ‘i’ to instantaneous values