General Review 4 上清充通大学 SHEAMGRAI DUD TONO UHTVEREETTY Overview of processes Solidification processes Particulate processes Shaping processes Deformation processes Material removal Processing Property enhancing Heat treatment operations processes Cleaning surface treatments Surface processing Manufacturing operations Coating deposition processes processes Welding Permanent joining processes Brazing soldering Assembly operations Adhesive bonding Threaded fasteners Mechanical fastening Permanent fastening methods Institute of Forming Technology Equipment 6

General Review Institute of Forming Technology & Equipment Overview of processes 6 Solidification processes Particulate processes Deformation processes Material removal Heat treatment Cleaning & surface treatments Coating & deposition processes Welding Brazing & soldering Adhesive bonding Threaded fasteners Permanent fastening methods Manufacturing processes Shaping processes Property enhancing processes Surface processing operations Permanent joining processes Mechanical fastening Processing operations Assembly operations

General Review 上产克大睾 SHEAMGHAI DUD TONO UHTVEREETTY Overview of metal forming Metal forming:to change the shape of metal workpieces. Plastic deformation:a permanent change of shape,i.e.,the stress in materials is larger than its yield strength. Usually a die-to force deformed metal into the shape of the die. Metal forming is divided into: (1)Bulk forming:large strain,small displacement,surface area to volume of the work is small. (2)Sheet forming:small strain,large displacement;Surface area to volume of the work is large. Institute of Forming Technology Equipment 7

General Review Institute of Forming Technology & Equipment Overview of metal forming 7 Metal forming: to change the shape of metal workpieces. Plastic deformation: a permanent change of shape, i.e., the stress in materials is larger than its yield strength. Usually a die → to force deformed metal into the shape of the die. Metal forming is divided into: (1) Bulk forming: large strain, small displacement, surface area to volume of the work is small. (2) Sheet forming: small strain, large displacement; Surface area to volume of the work is large

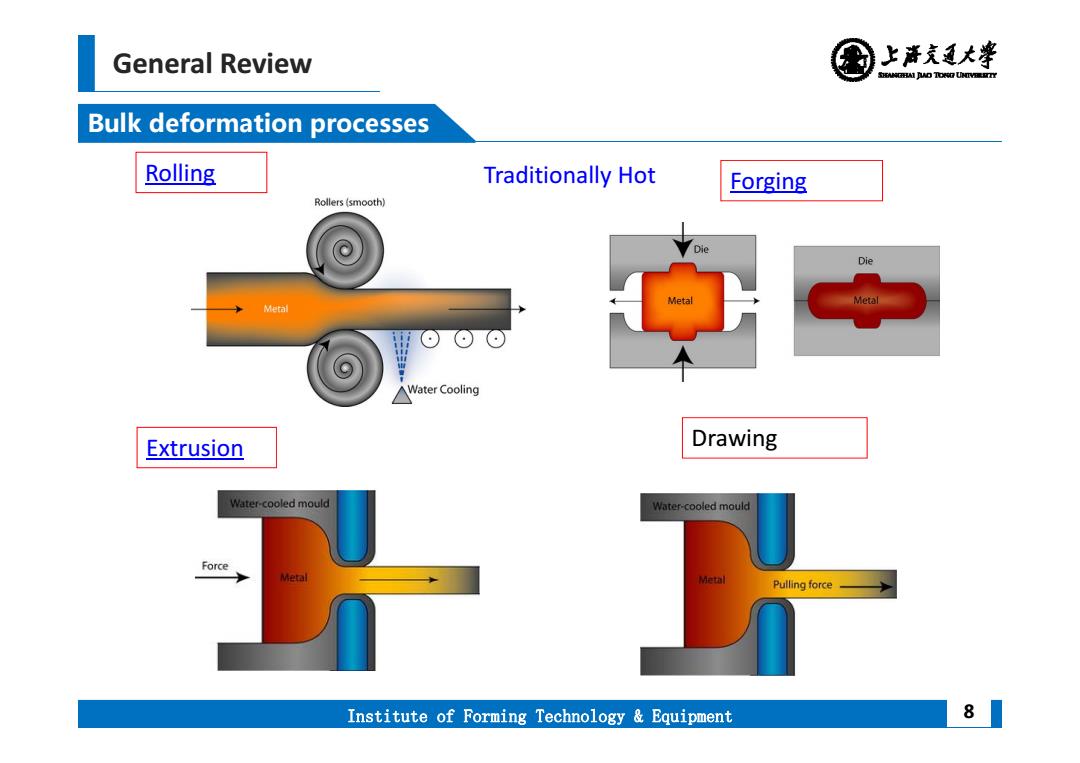

General Review 上清充通大学 SHEAMGRAI DUD TONO UHTVEREETTY Bulk deformation processes Rolling Traditionally Hot Forging Rollers(smooth) Die Metal Metal Metal △Water Cooling Extrusion Drawing Water-cooled mould Water-cooled mould Force Meta Metal Pulling force Institute of Forming Technology Equipment 8

General Review Institute of Forming Technology & Equipment Bulk deformation processes 8 Rolling Forging Extrusion Drawing Traditionally Hot

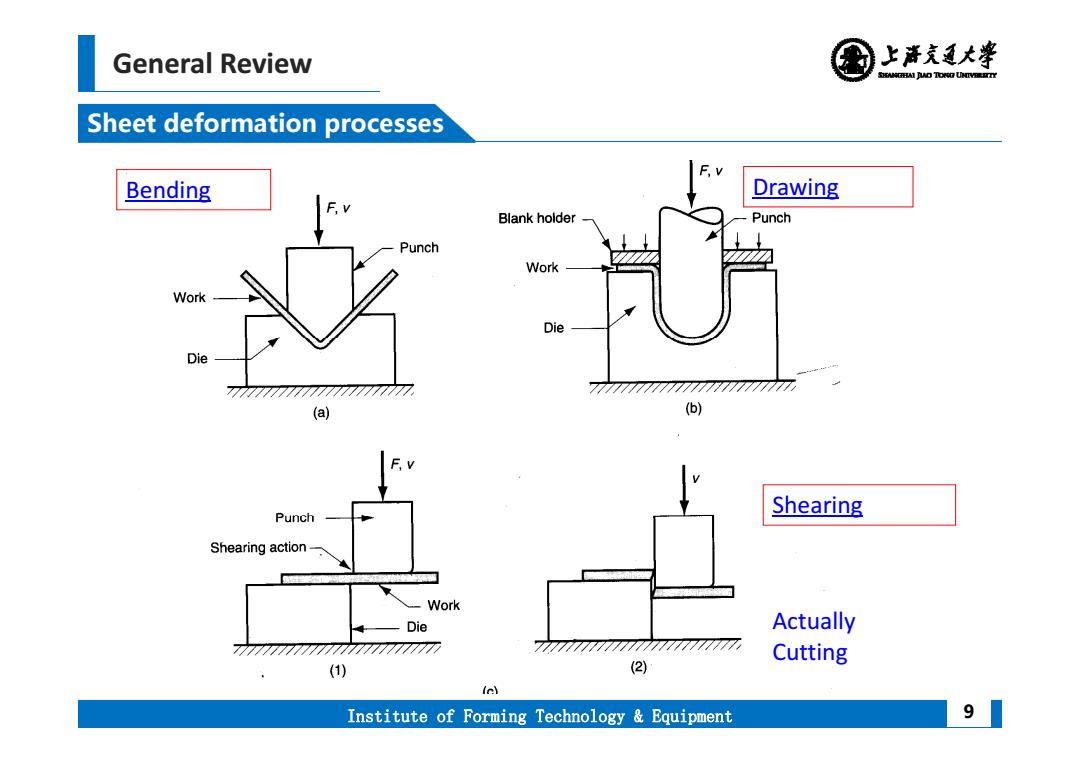

General Review 上清充通大学 SHEAMGRAI DUD TONO UHTVEREETTY Sheet deformation processes Bending Drawing Blank holder Punch Punch Work Work Die Die 777777777777777777777 7777777777777777777 (a) (b) Punch Shearing Shearing action- Work Die Actually 7777777777777777元 7777 Cutting (1) (2) (e) Institute of Forming Technology Equipment 9

General Review Institute of Forming Technology & Equipment Sheet deformation processes 9 Bending Drawing Shearing Actually Cutting

General Review 上产克大睾 SHEAMGHAI DUD TONO UHTVEREETTY Methodology Two methods to study the strength,deformation and failure of materials (a)Engineering Mechanics or Continuum approach Assuming that materials are isotropic and homogeneous Applying mathematical methods,using global parameters to determine stress state and material's response to external forces. (b)Materials Science or Microscopic approach Understanding of the mechanical properties based on the atomic/mesoscopic scale. Institute of Forming Technology Equipment 10

General Review Institute of Forming Technology & Equipment Methodology 10 Two methods to study the strength, deformation and failure of materials : (a) Engineering Mechanics or Continuum approach ‐ Assuming that materials are isotropic and homogeneous ‐ Applying mathematical methods, using global parameters to determine stress state and material’s response to external forces. (b) Materials Science or Microscopic approach ‐ Understanding of the mechanical properties based on the atomic/mesoscopic scale