先进材料疑固实验室 Nucleation rate and its control Laboratory of Advanced Materials Solidification Grain refinement When fine solid particles are dispersed in the liquid,they can catalyse the nucleation to make it happen at small undercooling the nucleation rate is high. High nucleation rate a large number of crystals form within a given volume>smaller grain size in the cast structure>higher strength higher workability. This practice is grain refinement,and the additive in the form of solid particles is a "Grain Refiner". 上降充通大学 SHANGHAI JIAO TONG UNIVERSITY

Nucleation rate and its control Grain refinement • When fine solid particles are dispersed in the liquid, they can catalyse the nucleation to make it happen at small undercooling the nucleation rate is high. • High nucleation rate a large number of crystals form within a given volume smaller grain size in the cast structure higher strength + higher workability. • This practice is grain refinement, and the additive in the form of solid particles is a “Grain Refiner

先进材料疑固实验室 Nucleation rate and its control Laboratory of Advanced Materials Solidification Grain refinement N=N,P·A·B·exp(-△g/kT)·exp(-△G*kT) △g*=16m. 512 3 4g·f0, 103 R=,(D,)12 413 1O" R is the radius of embryo, As=f(s),S is a concentration c OO function,and can be calculated as: 2 28 SECS 32 36 8= -2(△T-△T.m (k-1[C4-(④T-△T./m Maxwell Hellawell 上降充通大学 SHANGHAI JIAO TONG UNIVERSITY

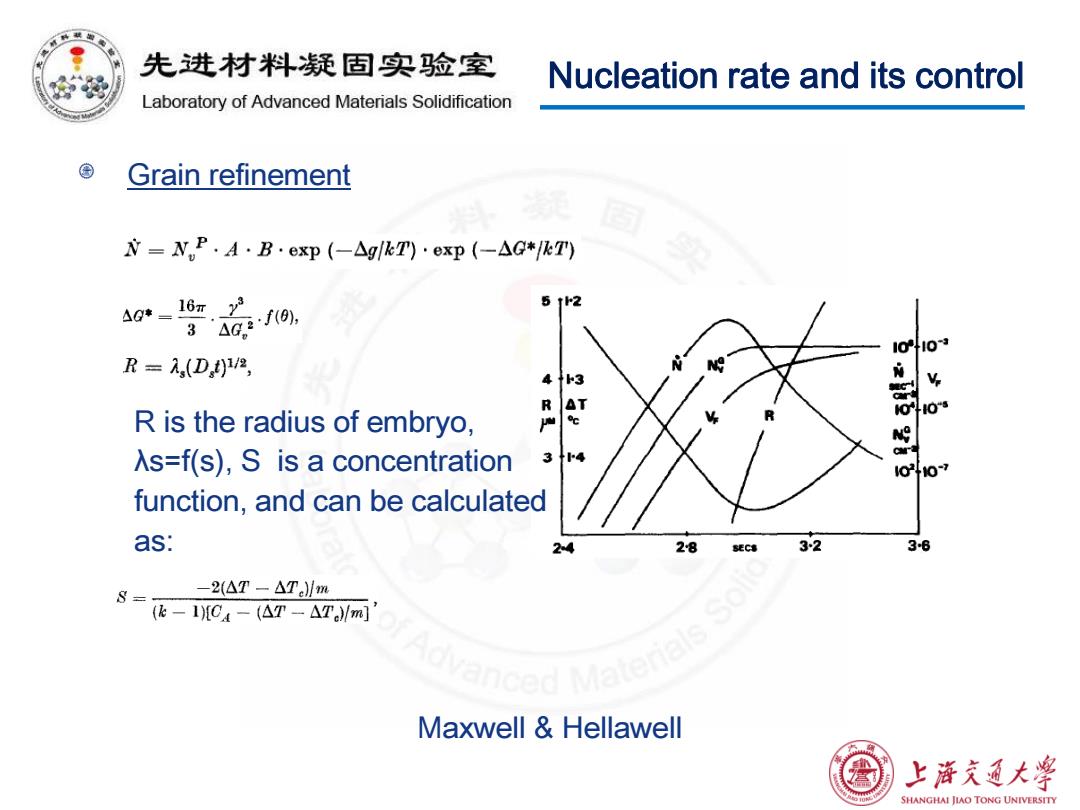

Nucleation rate and its control Grain refinement Maxwell & Hellawell R is the radius of embryo, λs=f(s), S is a concentration function, and can be calculated as:

先进材料疑固实验室 Nucleation rate and its control Laboratory of Advanced Materials Solidification Grain refinement Wetting angle Radius of nuclei 0=4 LOG.N LOG NO R,s52 R.=1m R53 g=11 LOGN! LOGN FIo.4.Plots of grain density No vs particle density Fia.7.N,o vs N,P in the Al-Ti system with P=0.5C N,P for Al-Ti with P0.5C/sec,Ro1 um,with s8c-1,0=7°,forR0=0.3,1,3.0um. 04,7,11°. Cooling speed Composition X=0-018 P=25 LOG.N X=01 LOG,N P=05 P=01 X=11 L0G。K LOGN Fo.6.N,FvgN,P for assumed values of0=4°,P= FIo.5.N0vgN,r for A1-Ti with9=7°,Rg=1m, 0.5C see-1,Ro -1 um,for three alloy systems,character- forP=0.1,0.5,2.6C/sec. ised by the value of I/X =mC(k -1)片X=0.018 (Al-Ti),X =0.1 (Al-Zr),X 1.1 (AL-Cr). 上产文通大学 SHANGHAI JIAO TONG UNIVERSITY

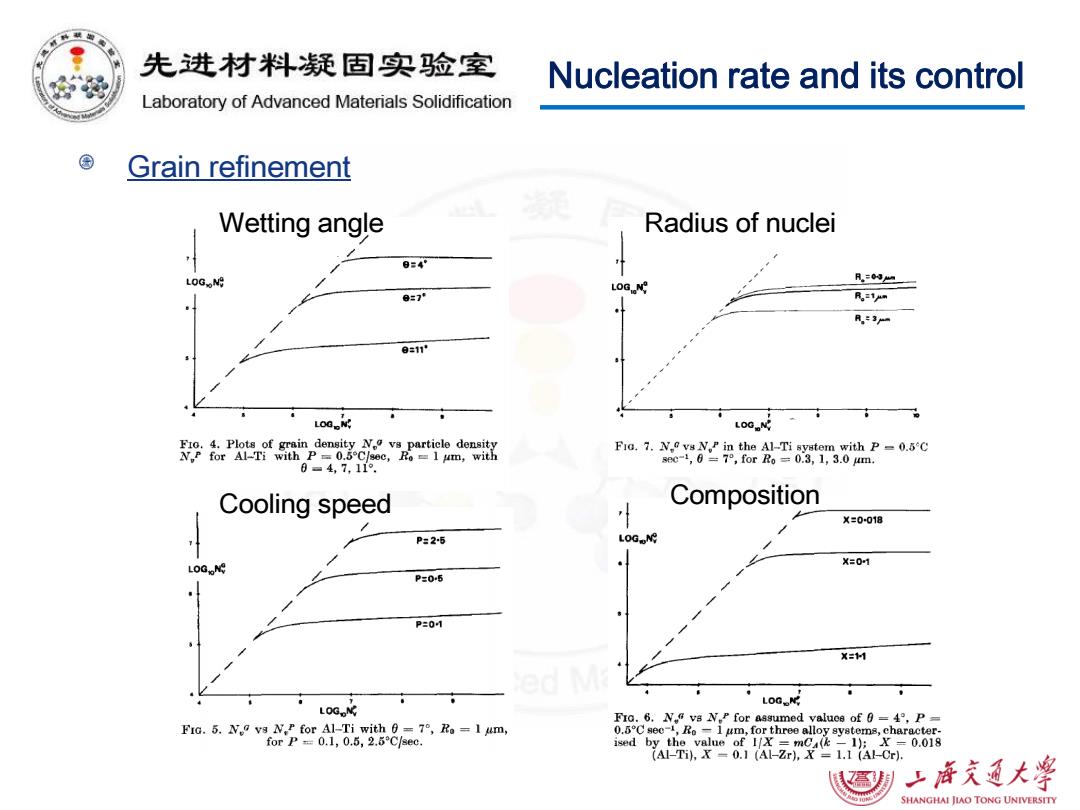

Nucleation rate and its control Wetting angle Radius of nuclei Cooling speed Composition Grain refinement