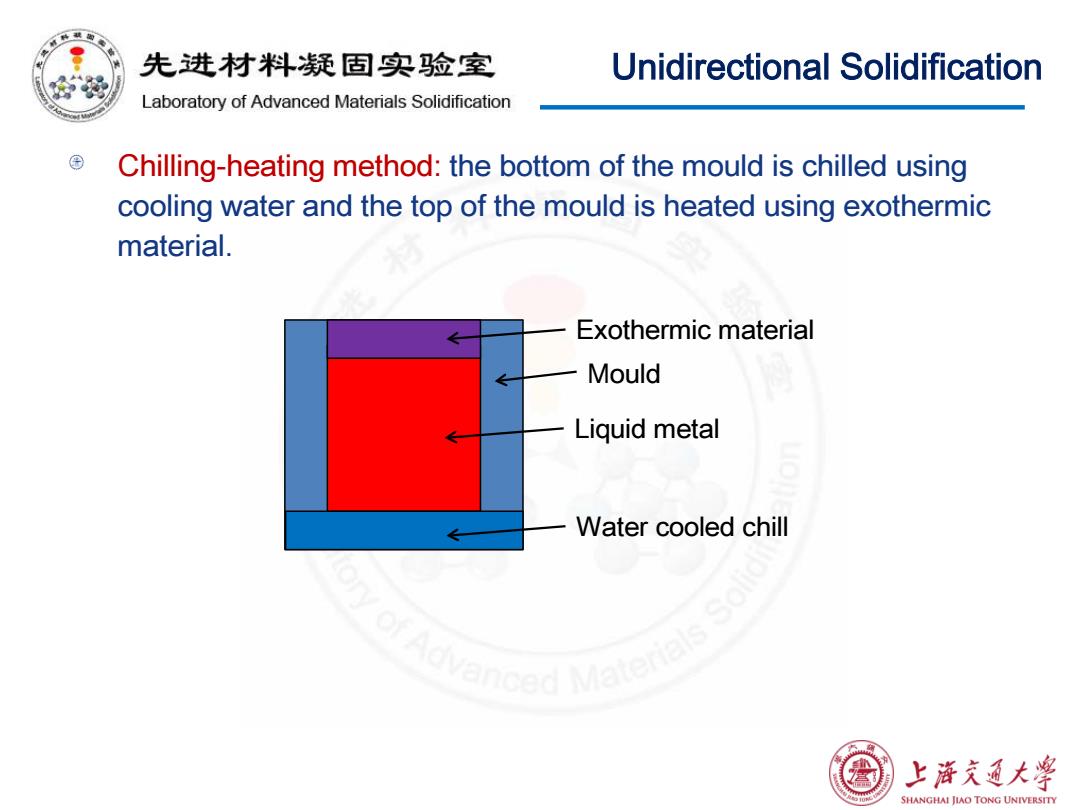

先进材料疑固实验室 Unidirectional Solidification Laboratory of Advanced Materials Solidification Chilling-heating method:the bottom of the mould is chilled using cooling water and the top of the mould is heated using exothermic material. Exothermic material Mould Liquid metal Water cooled chill 上浒充通大 SHANGHAI JIAO TONG UNIVERSITY

Chilling-heating method: the bottom of the mould is chilled using cooling water and the top of the mould is heated using exothermic material. Exothermic material Water cooled chill Liquid metal Mould Unidirectional Solidification

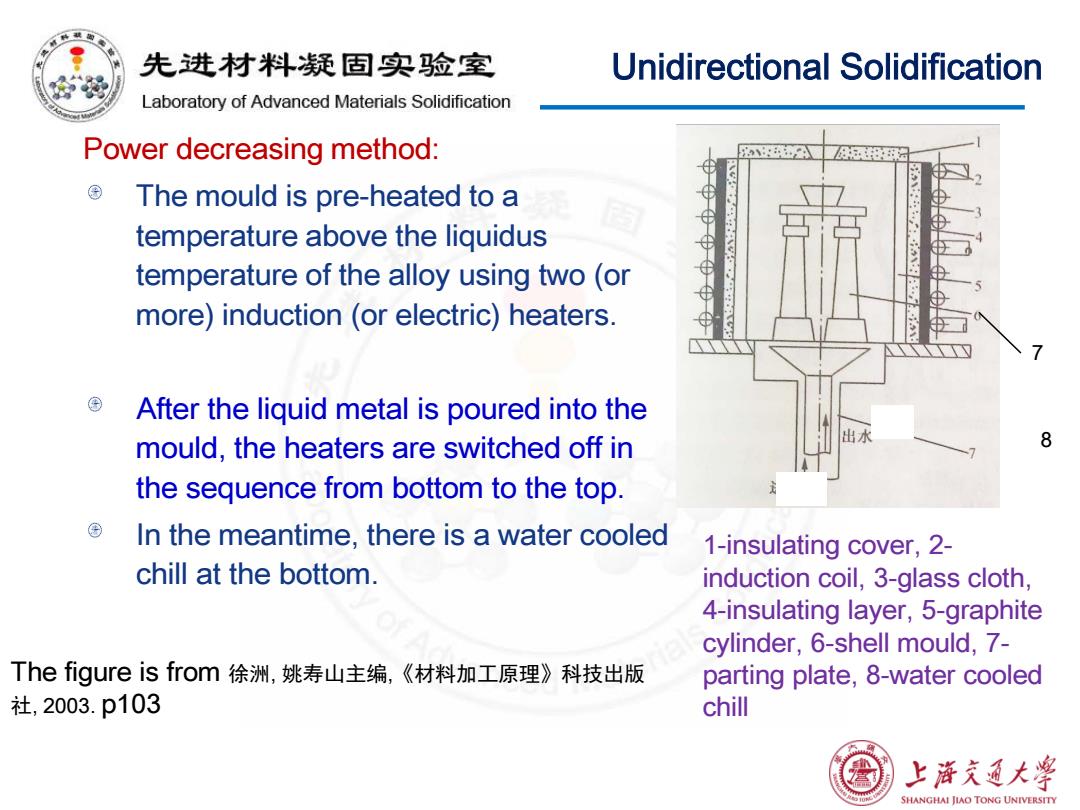

先进材料疑固实验室 Unidirectional Solidification Laboratory of Advanced Materials Solidification Power decreasing method: 88 The mould is pre-heated to a temperature above the liquidus temperature of the alloy using two(or more)induction(or electric)heaters. After the liquid metal is poured into the mould,the heaters are switched off in 8 the sequence from bottom to the top. In the meantime,there is a water cooled 1-insulating cover,2- chill at the bottom. induction coil,3-glass cloth, 4-insulating layer,5-graphite cylinder,6-shell mould,7- The figure is from徐洲,姚寿山主编,《材料加工原理》科技出版 parting plate,8-water cooled 社,2003.p103 chill 上浒充通大 SHANGHAI JIAO TONG UNIVERSITY

Power decreasing method: The mould is pre-heated to a temperature above the liquidus temperature of the alloy using two (or more) induction (or electric) heaters. After the liquid metal is poured into the mould, the heaters are switched off in the sequence from bottom to the top. In the meantime, there is a water cooled chill at the bottom. The figure is from 徐洲, 姚寿山主编,《材料加工原理》科技出版 社, 2003. p103 1-insulating cover, 2- induction coil, 3-glass cloth, 4-insulating layer, 5-graphite cylinder, 6-shell mould, 7- parting plate, 8-water cooled chill 7 8 Unidirectional Solidification