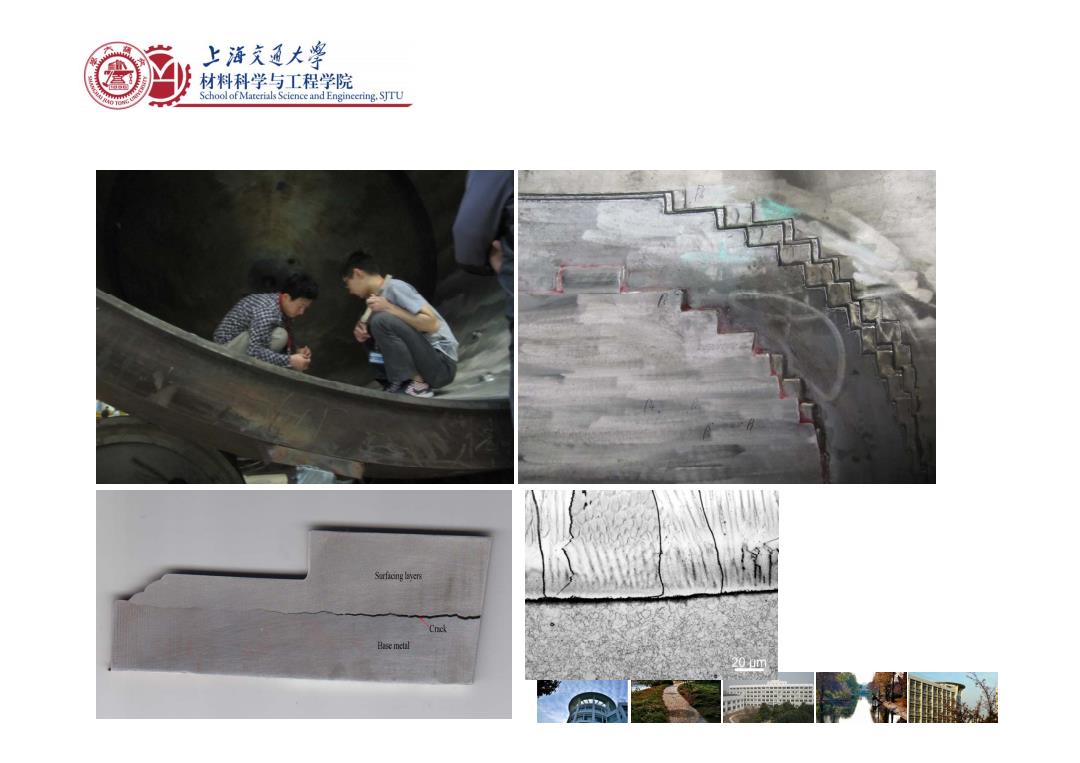

上游充通大学 材料科学与工程学院 School of Materials Science and Enginecring.SITU saficnglen Cnck Base mctal 20m

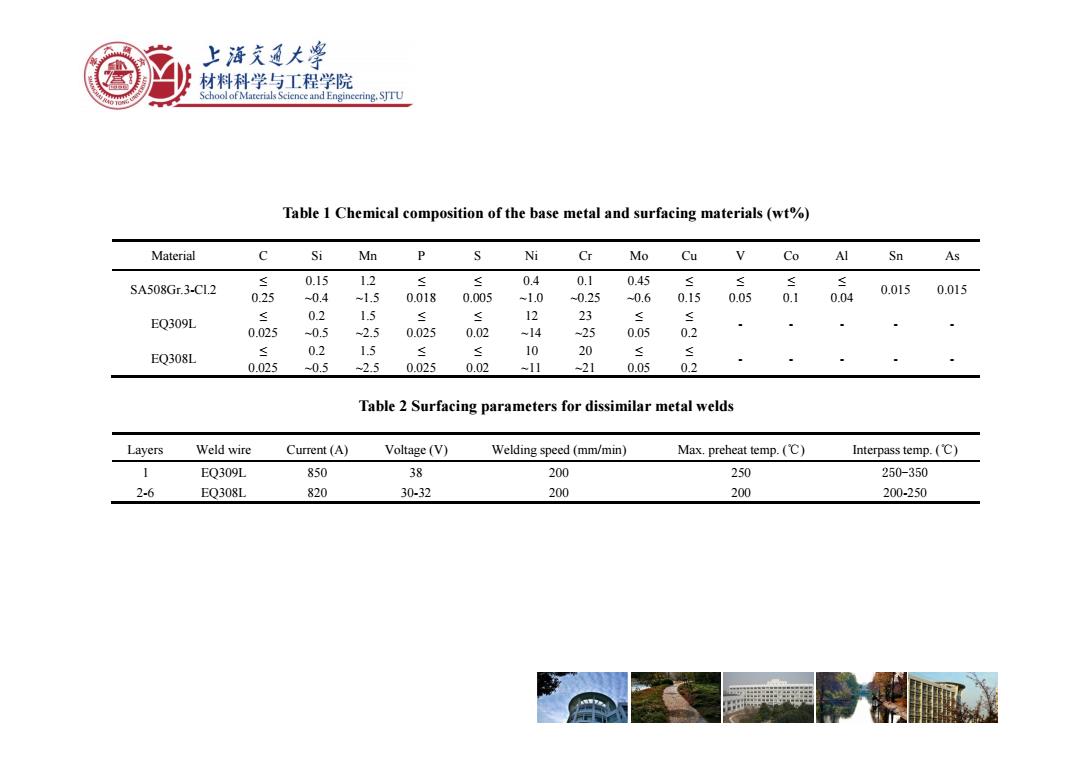

上海充通大学 材料科学与工程学院 School of Materials Science and Enginecring.SITU Table 1 Chemical composition of the base metal and surfacing materials(wt%) Material Si Mn P S Ni Cr Mo Cu Co Al Sn As 0.15 12 ≤ 0.4 0.1 0.45 ≤ ≤ SA508Gr.3-C1.2 0.018 0.015 0.25 0.4 1.5 0.005 -1.0 0.25 -0.6 0.15 0.05 0.1 0.04 0.015 0.2 1.5 23 EQ309L ≤ ≤ ≤ 12 ≤ 0.025 -0.5 -2.5 0.025 0.02 -14 25 0.05 0.2 EQ308L ≤ 0.2 1.5 ≤ 10 20 ≤ ≤ 0.025 0.5 2.5 0.025 0.02 ~11 -21 0.05 0.2 Table 2 Surfacing parameters for dissimilar metal welds Layers Weld wire Current(A) Voltage(V) Welding speed(mm/min) Max.preheat temp.(℃) Interpass temp.(C) EQ309L 850 38 200 250 250-350 2-6 EQ308L 820 30-32 200 200 200-250

T bl 1 Ch i l i i f h b l d f i i l ( %) Table 1 Chemical composition o f t he base metal an d sur facin g materials (wt%) Material C Si Mn P S Ni Cr Mo Cu V Co Al Sn As SA508Gr.3-Cl.2 ≤ 0 25 0.15 0 4 1.2 1 5 ≤ 0 018 ≤ 0 005 0.4 1 0 0.1 0 25 0.45 0 6 ≤ 0 15 ≤ 0 05 ≤ 0 1 ≤ 0 04 0.015 0.015 0.25 ~0.4 ~1.5 0.018 0.005 ~1.0 ~0.25 ~0.6 0.15 0.05 0.1 0.04 EQ309L ≤ 0.025 0.2 ~0.5 1.5 ~2.5 ≤ 0.025 ≤ 0.02 12 ~14 23 ~25 ≤ 0.05 ≤ 0.2 - - - - - EQ308L ≤ 0.025 0.2 ~0.5 1.5 ~2.5 ≤ 0.025 ≤ 0.02 10 ~11 20 ~21 ≤ 0.05 ≤ 0.2 - - - - - Table 2 Surfacing parameters for dissimilar metal welds Layers Weld wire Current (A) Voltage (V) Welding speed (mm/min) Max. preheat temp. ( ℃) Interpass temp. ( ℃) 1 EQ309L 850 38 200 250 250-350 2-6 EQ308L 820 30-32 200 200 200-250

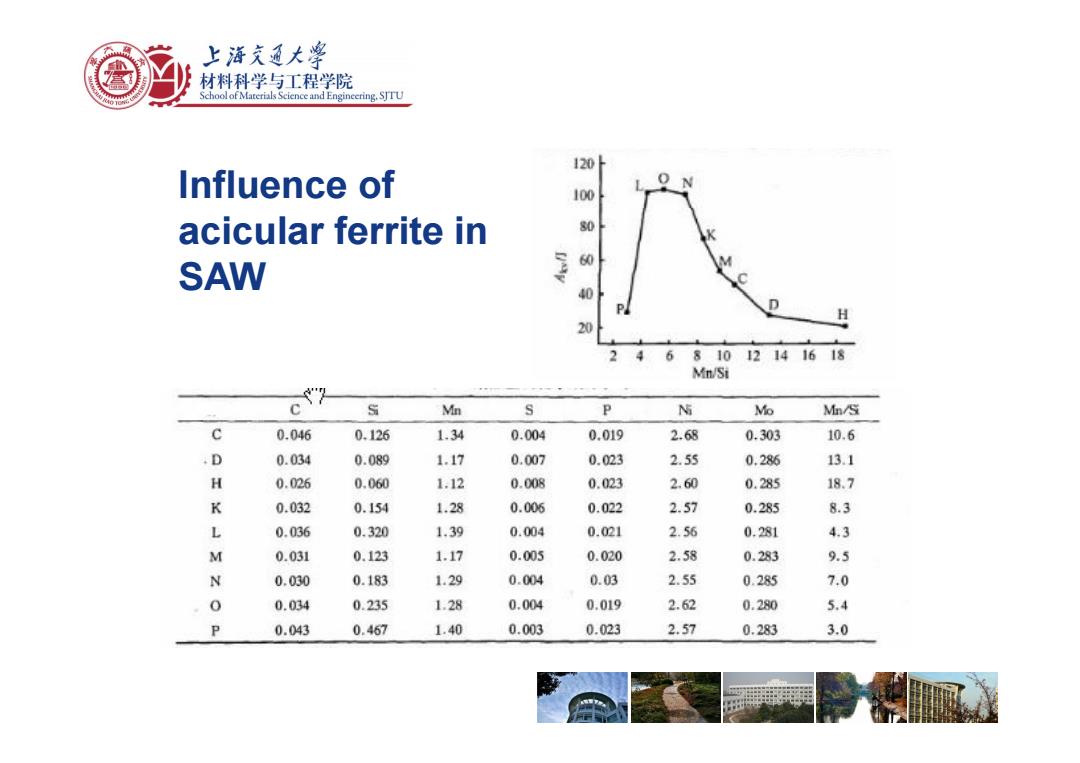

上海充通大学 材料科学与工程学院 School of Materials Science and Enginecring.SITU 120 Influence of 100 acicular ferrite in 80 60 SAW 40 20 246810 12141618 Mn/Si C久 S M s P S Mo Mn/S C 0.046 0.126 1.34 0.004 0.019 2.68 0.303 10.6 0 0.034 0.089 1.17 0.007 0.023 2.55 0.286 13.1 H 0.026 0.060 1.12 0.008 0.023 2.60 0.285 18.7 K 0.032 0.154 1.28 0.006 0.022 2.57 0.285 8.3 L 0.036 0.320 1.39 0.004 0.021 2.56 0.281 4.3 M 0.03 0.123 1.17 0.005 0.020 2.58 0.283 9.5 N 0.030 0.183 1.29 0.004 0.03 2.55 0.285 7.0 0 0.034 0.235 1.28 0.004 0.019 2.62 0.280 5.4 P 0.043 0.467 1.40 0.003 0.023 2.57 0.283 3.0

Influence of acicular ferrite in SAW

上海充通大学 材料科学与工程学院 School of Materials Science and Enginecring.SITU dissimi ar meta weld Necessity- V.C.Summer-USA(2000) Crack(SCC,FCP) Tsuruga 2-Japan(2003) ·Carbon diffusion Palisades-wall crack in Precipitate evolution HAZ,USA(1993) e Ringhals 3 and 4-Sweden ·Fluidity(UMZ) (2000) Grain boundary migration Three Mile Island 1-USA (2003) HEAT AND STRESS Tihange 2-Belgium (2002) Calvert Cliffs 2-USA Special microstructure (2005) of FCC/BCC interface Biblis-A-Germany (2000) LEAKS AND BREAKAGES

dissimilar metal weld Necessity… • V C Summer – USA (2000) • Crack (SCC FCP) Concern… V.C. Summer USA (2000) • Tsuruga 2– Japan (2003) • Palisades – wall crack in Crack (SCC, FCP) • Carbon diffusion • Precipitate evolution HAZ, USA (1993) • Ringhals 3 and 4 – Sweden (2000) • Precipitate evolution • Fluidity (UMZ) G i b d i ti (2000) • Three Mile Island 1 – USA (2003) • Grain boun dary migration HEAT AND STRESS • Tihange 2 – Belgium (2002) • Calvert Cliffs 2 – USA (2005) Special microstructure f FCC/BCC i f • Biblis-A – Germany (2000) LEAKS AND BREAKAGES of FCC/BCC inter face LEAKS AND BREAKAGES

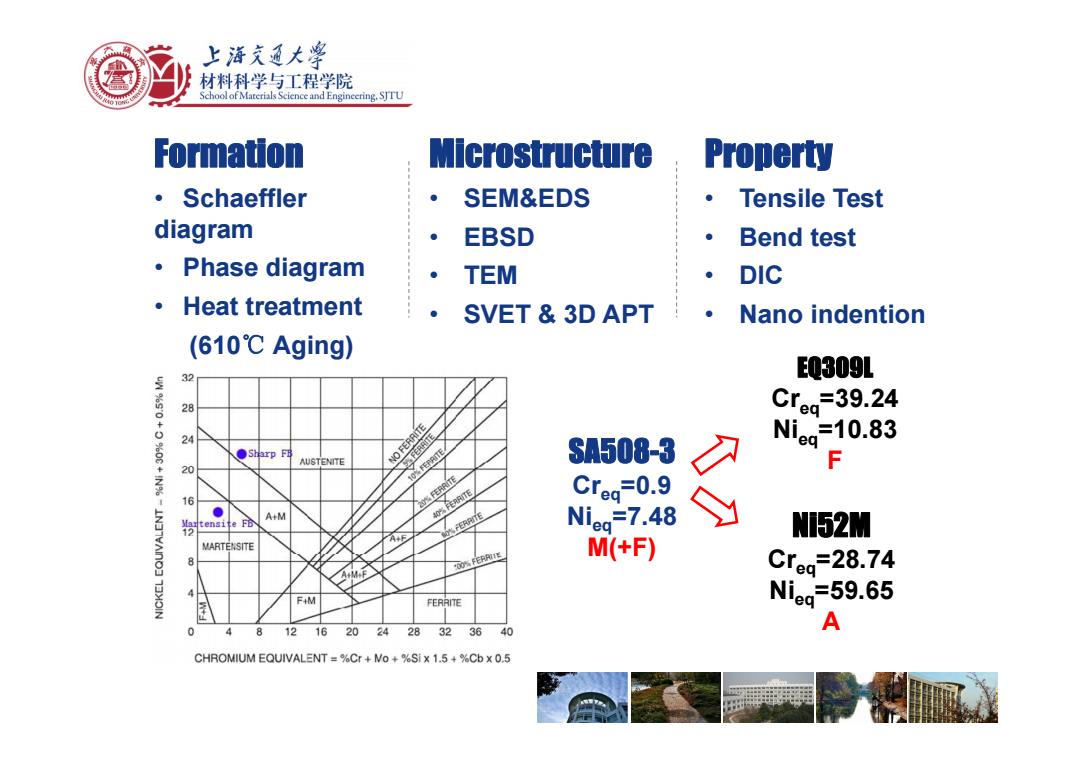

上游充通大学 材料科学与工程学院 School of Materials Science and Enginecring.SITU Formation Microstructure Property 。Schaeffler SEM&EDS Tensile Test diagram EBSD Bend test 。Phase diagram TEM DIC ·Heat treatment SVET 3D APT Nano indention (610℃Aging) 0309L Crea=39.24 24 Nie0=10.83 ●srpF AUSTENITE NO FER F丽 SA508-3 F 20 16 20%FERRITE Creq=0.9 A+M 12 tensite F Niea=7.48 Ni52M A+5 M(+F) A+M+F Cre-28.74 F+M FERRITE Nieg=59.65 A 0 12 16 20 24 28 32 3640 CHROMIUM EQUIVALENT =%Cr+No+%Si x 1.5+%Cb x 0.5

Formation • Schaeffler Microstructure • SEM&EDS Property • Tensile Test diagram • Phase diagram • EBSD • TEM • Bend test • DIC • Heat treatment (610℃ Aging) • SVET & 3D APT • Nano indention EQ309L SA508-3 Creq=39.24 Nieq=10.83 F Creq=0.9 Nieq=7.48 M(+F) F Ni52M C 28 74 M( F) req=28.74 Nieq=59.65 A