Contents xiii CHAPTER 14 CONTINUOUS RECRYSTALLIZATION DURING AND AFTER LARGE STRAIN DEFORMATION 451 14.1 Introduction 451 14.2 Microstructural stability after large strains 452 14.3 Deformation at ambient temperatures 453 14.3.1 The development of stable microstructures by large strain deformation 453 14.3.2 The effect of the initial grain size 455 14.3.3 The effect of second-phase particles 457 14.3.4 The transition from discontinuous to continuous recrystallization 457 14.3.5 The mechanism of continuous recrystallization in aluminium 458 14.4 Deformation at elevated temperatures 461 14.4.1 Geometric dynamic recrystallization 461 14.4.2 The conditions for geometric dynamic recrystallization 462 14.4.3 The grain size resulting from geometric dynamic recrystallization 464 14.5 The stability of micron-grained microstructures against grain growth 465 14.5.1 Single-phase alloys 465 14.5.2 Two-phase alloys 466 CHAPTER 15 CONTROL OF RECRYSTALLIZATION 469 15.1 Introduction 469 15.2 Processing of some industrial aluminium alloys 469 15.2.1 Commercial purity aluminium 470 15.2.2 The production of aluminium beverage cans (AA3xxx) 472 15.2.3 Al-Mg-Si automotive sheet (AA6xxx) 476 15.3 Texture control in cold rolled and annealed sheet steel 478 15.3.1 Introduction 478 15.3.2 Background 480 15.3.3 Batch annealed.Al-killed,low carbon forming steels 482 15.3.4 Ultra-low carbon steels 485 15.3.5 Extra low carbon,high strength steels 487 15.4 Recent developments in grain oriented,silicon steel sheets 488 15.4.1 Introduction 488 15.4.2 Production of silicon steel sheets 489 15.4.3 The development of the Goss texture 491 15.4.4 Recent developments 492 15.5 Commercial superplastic aluminium alloys 495 15.5.1 Superplasticity and microstructure 495

CHAPTER 14 CONTINUOUS RECRYSTALLIZATION DURING AND AFTER LARGE STRAIN DEFORMATION 451 14.1 Introduction 451 14.2 Microstructural stability after large strains 452 14.3 Deformation at ambient temperatures 453 14.3.1 The development of stable microstructures by large strain deformation 453 14.3.2 The effect of the initial grain size 455 14.3.3 The effect of second-phase particles 457 14.3.4 The transition from discontinuous to continuous recrystallization 457 14.3.5 The mechanism of continuous recrystallization in aluminium 458 14.4 Deformation at elevated temperatures 461 14.4.1 Geometric dynamic recrystallization 461 14.4.2 The conditions for geometric dynamic recrystallization 462 14.4.3 The grain size resulting from geometric dynamic recrystallization 464 14.5 The stability of micron-grained microstructures against grain growth 465 14.5.1 Single-phase alloys 465 14.5.2 Two-phase alloys 466 CHAPTER 15 CONTROL OF RECRYSTALLIZATION 469 15.1 Introduction 469 15.2 Processing of some industrial aluminium alloys 469 15.2.1 Commercial purity aluminium 470 15.2.2 The production of aluminium beverage cans (AA3xxx) 472 15.2.3 Al–Mg–Si automotive sheet (AA6xxx) 476 15.3 Texture control in cold rolled and annealed sheet steel 478 15.3.1 Introduction 478 15.3.2 Background 480 15.3.3 Batch annealed, Al-killed, low carbon forming steels 482 15.3.4 Ultra-low carbon steels 485 15.3.5 Extra low carbon, high strength steels 487 15.4 Recent developments in grain oriented, silicon steel sheets 488 15.4.1 Introduction 488 15.4.2 Production of silicon steel sheets 489 15.4.3 The development of the Goss texture 491 15.4.4 Recent developments 492 15.5 Commercial superplastic aluminium alloys 495 15.5.1 Superplasticity and microstructure 495 Contents xiii

xiv Contents 15.5.2 Development of the microstructure by static recrystallization 496 15.5.3 Development of the microstructure by dynamic recrystallization 497 15.6 Sub-micron-grained alloys 499 15.6.1 Background 499 15.6.2 Processing methods 500 15.6.3 Properties and applications or SMG alloys 504 15.6.4 Summary 505 CHAPTER 16 COMPUTER MODELLING AND SIMULATION OF ANNEALING 507 16.1 Introduction 507 16.1.1 The role of computer simulation 507 16.1.2 The status of computer simulation 508 16.2 Micro models 509 16.2.1 Monte Carlo simulations 509 16.2.2 Cellular automata 514 16.2.3 Molecular dynamics 515 16.2.4 Vertex simulations 516 16.2.5 Computer Avrami models 522 16.2.6 Neural network modelling 522 16.3 Coupled models 524 16.3.1 The annealing of'real'microstructures 524 16.3.2 The annealing of computer generated deformation microstructures 524 16.3.3 Modelling an industrial thermomechanical process 524 APPENDIX I TEXTURE 527 Al.1 Representation of texture 527 A1.1.1 Pole figures 528 A1.1.2 Inverse pole figures 528 A1.1.3 Orientation distribution functions and Euler space 529 A1.1.4 Rodrigues-Frank space 531 Al.1.5 Misorientations 533 A1.2 Measurement of macrotexture 533 A1.2.1 X-ray diffraction 533 A1.2.2 Neutron diffraction 535 A1.3 Measurement of microtexture 535 A1.3.1 Optical methods 535 A1.3.2 Deep etching 536

15.5.2 Development of the microstructure by static recrystallization 496 15.5.3 Development of the microstructure by dynamic recrystallization 497 15.6 Sub-micron-grained alloys 499 15.6.1 Background 499 15.6.2 Processing methods 500 15.6.3 Properties and applications or SMG alloys 504 15.6.4 Summary 505 CHAPTER 16 COMPUTER MODELLING AND SIMULATION OF ANNEALING 507 16.1 Introduction 507 16.1.1 The role of computer simulation 507 16.1.2 The status of computer simulation 508 16.2 Micro models 509 16.2.1 Monte Carlo simulations 509 16.2.2 Cellular automata 514 16.2.3 Molecular dynamics 515 16.2.4 Vertex simulations 516 16.2.5 Computer Avrami models 522 16.2.6 Neural network modelling 522 16.3 Coupled models 524 16.3.1 The annealing of ‘real’ microstructures 524 16.3.2 The annealing of computer generated deformation microstructures 524 16.3.3 Modelling an industrial thermomechanical process 524 APPENDIX 1 TEXTURE 527 A1.1 Representation of texture 527 A1.1.1 Pole figures 528 A1.1.2 Inverse pole figures 528 A1.1.3 Orientation distribution functions and Euler space 529 A1.1.4 Rodrigues-Frank space 531 A1.1.5 Misorientations 533 A1.2 Measurement of macrotexture 533 A1.2.1 X-ray diffraction 533 A1.2.2 Neutron diffraction 535 A1.3 Measurement of microtexture 535 A1.3.1 Optical methods 535 A1.3.2 Deep etching 536 xiv Contents

Contents XV A1.3.3 Transmission electron microscopy (TEM) 536 A1.3.4 Electron backscatter diffraction (EBSD) 537 APPENDIX 2 THE MEASUREMENT OF RECRYSTALLIZATION 541 A2.1 Techniques for measuring recrystallization 541 A2.1.1 Optical microscopy 542 A2.1.2 Transmission electron microscopy 542 A2.1.3 Scanning electron microscopy 542 A2.1.4 Electron backscatter diffraction 542 A2.1.5 X-ray diffraction 543 A2.1.6 Ultrasonics 543 A2.1.7 Property measurements 543 A2.2 Driving pressure for recrystallization 544 A2.2.1 Calorimetry 544 A2.2.2 X-ray diffraction 544 A2.2.3 Electron microscopy and diffraction 544 A2.3 Fraction recrystallized 545 A2.3.1 Microscopical methods 545 A2.3.2 EBSD methods 546 A2.4 Nucleation and growth rates 546 A2.4.1 Nucleation of recrystallization 546 A2.4.2 Growth rates 547 A2.5 Grain and subgrain size 547 A2.5.1 EBSD measurement 548 A2.5.2 Calculation of size 549 A2.5.3 Precision of measurement 550 A2.6 Grain boundary character distribution 550 A2.6.1 Misorientation angle 550 A2.6.2 Misorientation axis 552 A2.6.3 Boundary plane 552 A2.7 Grain boundary properties 552 A2.7.1 Boundary energy 552 A2.7.2 Boundary mobility 553 A2.8 Parameters of two-phase alloys 555 A2.8.1 Particle size 555 A2.8.2 Volume fraction 555 A2.8.3 Interparticle spacing 555 A2.8.4 Particle distribution 556 REFERENCES 557 SUBJECT INDEX 617

A1.3.3 Transmission electron microscopy (TEM) 536 A1.3.4 Electron backscatter diffraction (EBSD) 537 APPENDIX 2 THE MEASUREMENT OF RECRYSTALLIZATION 541 A2.1 Techniques for measuring recrystallization 541 A2.1.1 Optical microscopy 542 A2.1.2 Transmission electron microscopy 542 A2.1.3 Scanning electron microscopy 542 A2.1.4 Electron backscatter diffraction 542 A2.1.5 X-ray diffraction 543 A2.1.6 Ultrasonics 543 A2.1.7 Property measurements 543 A2.2 Driving pressure for recrystallization 544 A2.2.1 Calorimetry 544 A2.2.2 X-ray diffraction 544 A2.2.3 Electron microscopy and diffraction 544 A2.3 Fraction recrystallized 545 A2.3.1 Microscopical methods 545 A2.3.2 EBSD methods 546 A2.4 Nucleation and growth rates 546 A2.4.1 Nucleation of recrystallization 546 A2.4.2 Growth rates 547 A2.5 Grain and subgrain size 547 A2.5.1 EBSD measurement 548 A2.5.2 Calculation of size 549 A2.5.3 Precision of measurement 550 A2.6 Grain boundary character distribution 550 A2.6.1 Misorientation angle 550 A2.6.2 Misorientation axis 552 A2.6.3 Boundary plane 552 A2.7 Grain boundary properties 552 A2.7.1 Boundary energy 552 A2.7.2 Boundary mobility 553 A2.8 Parameters of two-phase alloys 555 A2.8.1 Particle size 555 A2.8.2 Volume fraction 555 A2.8.3 Interparticle spacing 555 A2.8.4 Particle distribution 556 REFERENCES 557 SUBJECT INDEX 617 Contents xv

ThisPageIntentionally LeftBlank

This Page Intentionally Left Blank

5um Fig.2.12(b).See p.33. RD ND Sum (a) (b) Fig.2.38.See p.64

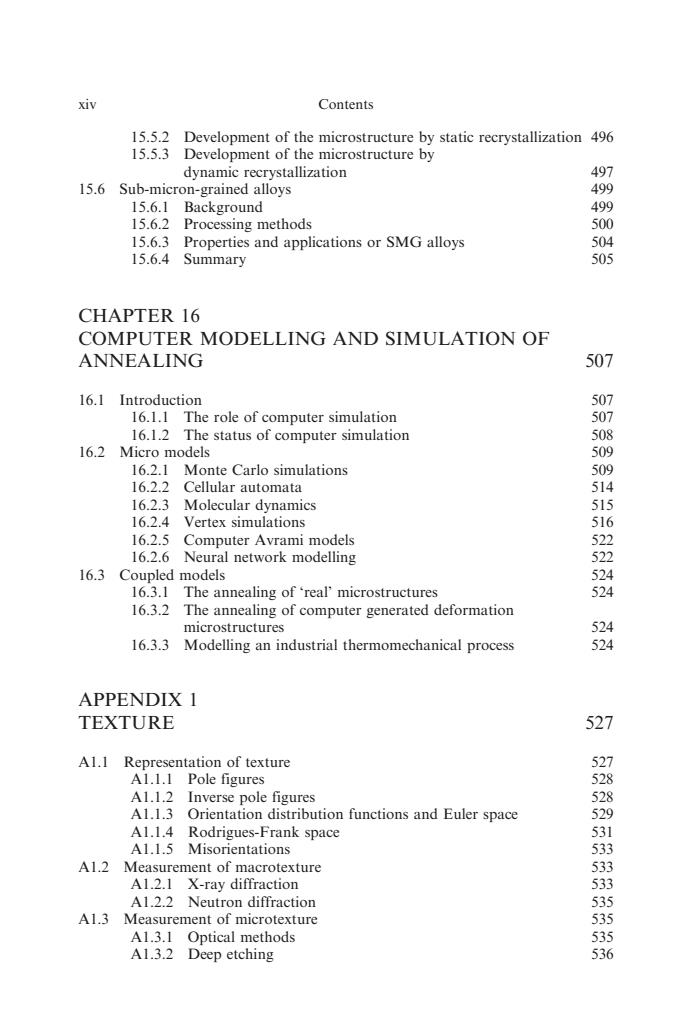

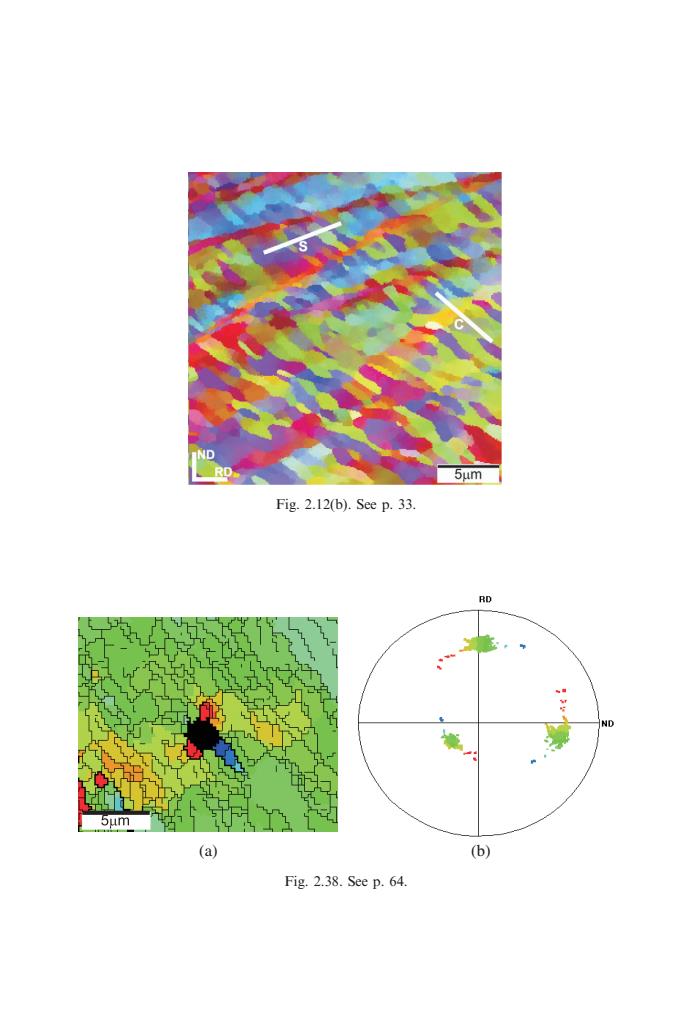

Fig. 2.12(b). See p. 33. (a) (b) Fig. 2.38. See p. 64