Heat pumping processes and systems Working fluids in Refrigeration and Heat Pump Systems Wednesday July 2nd 2014 Trygve M.Eikevik Professor Norwegian University of Science and Technology(NTNU) E-mails:trygve.m.eikevik@ntnu.no http://folk.ntnu.no/tme 髓 ONTNU ②SINTEF Topics of the lectures General about the refrigerants-history ·Working fluids HFC CFO -R404A 3 HeFC -R407C HC O2 -R410A -R134a -Ammonia -Hydrocarbons (example.propane) -Carbon dioxide(CO2) Choice of working fluid Refrigeration process with different working fluids Practical qualities for different working fluids ONTNU 2 ⑤SINTEF

1 Heat pumping processes and systems Working fluids in Refrigeration and Heat Pump Systems Wednesday July 2nd 2014 Trygve M. Eikevik Professor Norwegian University of Science and Technology (NTNU) E-mails: trygve.m.eikevik@ntnu.no http://folk.ntnu.no/tme 2 Topics of the lectures • General about the refrigerants - history • Working fluids – R404A – R407C – R410A – R134a – Ammonia – Hydrocarbons (example. propane) – Carbon dioxide (CO2 ) • Choice of working fluid • Refrigeration process with different working fluids • Practical qualities for different working fluids HFC NH3 HC CO2 CFC HCFC

Working fluid,refrigerant,process fluid Working fluid transports energy/heat from cold to warm side in the refrigeration system and through phase change between liquid and gas in a closed circle process(vapor compression process) Important factors on choice of working fluid -Temperature-/operation range -System solutions 一Place of operation -Availability and price -Locale environmental consequences(safety) -Global environmental consequences ONTNU ②SINTEF Working fluids -development Before 1930-"Natural fluids",example sulphuric ether,SO2,methyl chloride. ammonia,propane,isobutene etc. 1930/50-Synthetic fluids,example CFC-12 and HCFC-22 1987-Montreal protocol established.CFC and HCFC ozon destructive due to chloride and bromine.Phase out of CFC(1995)and HCFC(2010) .1988-HydrogenFluorcarbons introduced(HFC) .1997-Kyoto protocol established.HFC regulations due to high GWP-values. CO2-tax on HFc from 2003(the tax is depending in the GWP-value). 1990-now-Increased focus on use of NATURAL WORKING FLUIDS. special ammonia,CO,and hydro carbons 回NTNU SINTEF

3 Working fluid, refrigerant, process fluid • Working fluid transports energy/heat from cold to warm side in the refrigeration system and through phase change between liquid and gas in a closed circle process (vapor compression process) • Important factors on choice of working fluid – Temperature-/operation range – System solutions – Place of operation – Availability and price – Locale environmental consequences (safety) – Global environmental consequences 4 Working fluids – development • Before 1930 – ”Natural fluids”, example sulphuric ether , SO2 , methyl chloride, ammonia, propane, isobutene etc. • 1930/50 – Synthetic fluids, example CFC-12 and HCFC-22 • 1987 – Montreal protocol established . CFC and HCFC ozon destructive due to chloride and bromine. Phase out of CFC (1995) and HCFC (2010) • 1988 – HydrogenFluorcarbons introduced (HFC) • 1997 – Kyoto protocol established. HFC regulations due to high GWP-values. CO2 -tax on HFc from 2003 (the tax is depending in the GWP-value). • 1990 - now – Increased focus on use of NATURAL WORKING FLUIDS, special ammonia, CO2 and hydro carbons

Working fluids-important factors Physical-thermodynamic qualities -Normal boiling point(at 1,013 bar) -Vapor pressure curve-critical temperature(Tc)and pressure(Pc): Refrigeration process-process losses .Pressure level-pressure rating of components(21-23/38 bars operation pressure) .Pressure ratio-efficiencies of the compressor -Molecule weight: Heat of evaporation-mg pipe diameters Temperature in the exit of compressor -Volumetric refrigeration capacity-Ah.gas density [kJ/m3] .Gives necessary compressor volume [m] Thermo physical properties -Specific heat capacity,co [kJ/(kgK)] -Viscosity,v[mm2/s] -Thermal conductivity,[W/(mK)] ONTNU ②SINTEF Working fluids-important factors cont. 。Other factors -Chemical stability -Material compatibility(corrosion,reactions) 一Vater solubility -Miscibility with different types of oils/lubricants -Electric resistance Price and availability Environmental friendliness-safety Impact on ozone layer(ODP-Ozone Depleting Potential) -Contribution to the greenhouse effect(GWP-Globa/Warm -Toxicity,inflammability,odor etc. 回NTNU SINTEF

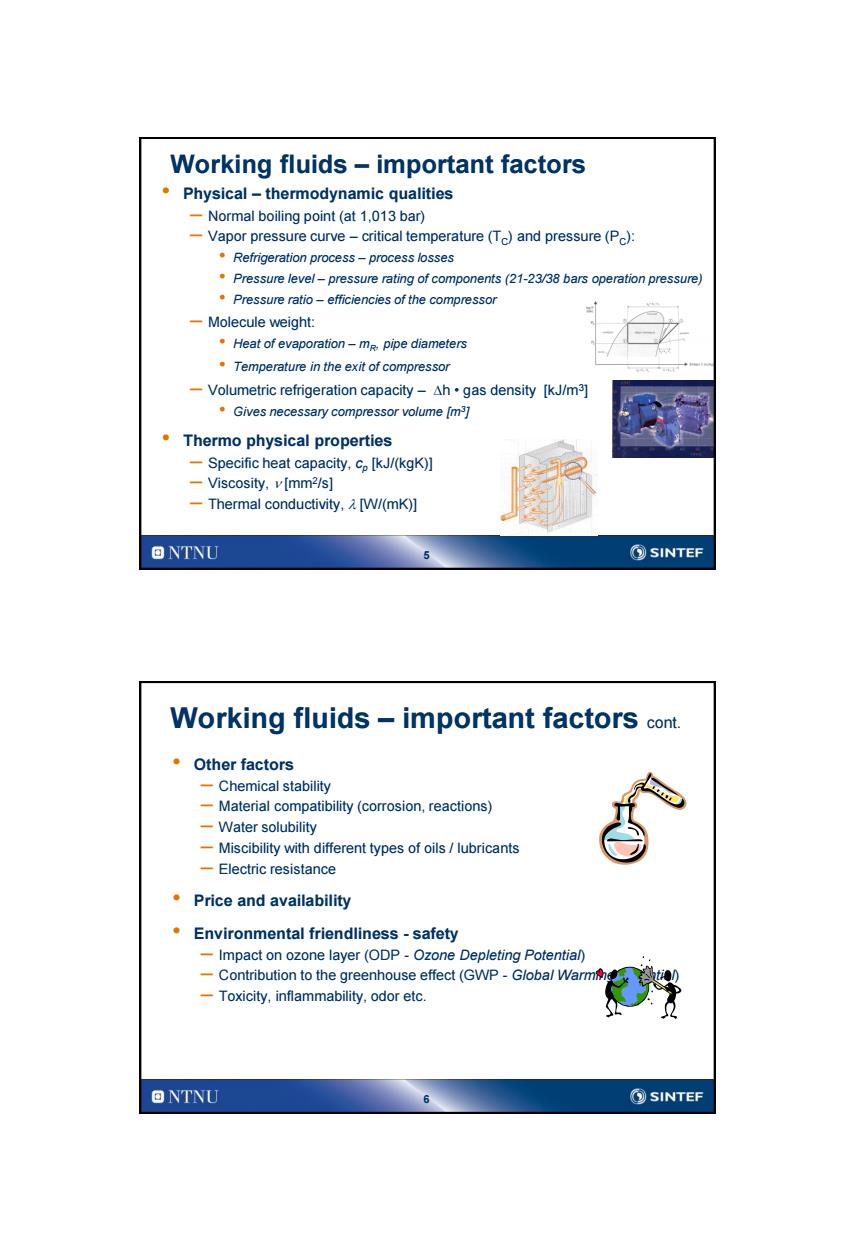

5 Working fluids – important factors • Physical – thermodynamic qualities – Normal boiling point (at 1,013 bar) – Vapor pressure curve – critical temperature (TC) and pressure (PC): • Refrigeration process – process losses • Pressure level – pressure rating of components (21-23/38 bars operation pressure) • Pressure ratio – efficiencies of the compressor – Molecule weight: • Heat of evaporation – mR , pipe diameters • Temperature in the exit of compressor – Volumetric refrigeration capacity – Dh • gas density [kJ/m3 ] • Gives necessary compressor volume [m3 ] • Thermo physical properties – Specific heat capacity, cp [kJ/(kgK)] – Viscosity, n [mm2 /s] – Thermal conductivity, l [W/(mK)] 6 • Other factors – Chemical stability – Material compatibility (corrosion, reactions) – Water solubility – Miscibility with different types of oils / lubricants – Electric resistance • Price and availability • Environmental friendliness - safety – Impact on ozone layer (ODP - Ozone Depleting Potential) – Contribution to the greenhouse effect (GWP - Global Warming Potential) – Toxicity, inflammability, odor etc. Working fluids – important factors cont

Numbering of refrigerants Number of carbon(C)-1 Number of fluorine (F) R143a Number of hydrogen(H)+1 This gives the following: Letter code says that this is a Isomer. C=1+1=2 That means the refrigerant consist H=4-1=3 of the same number of atoms,but the F=3 molecule have a different composition Therefore:C2H,F3 ONTNU ②SINTEF Numbering of natural refrigerants Example: Carbon dioxide(CO2) R744 Ammonia(NHg) R717 Description is composed by the number 7 molar weight 回NTNU SINTEF

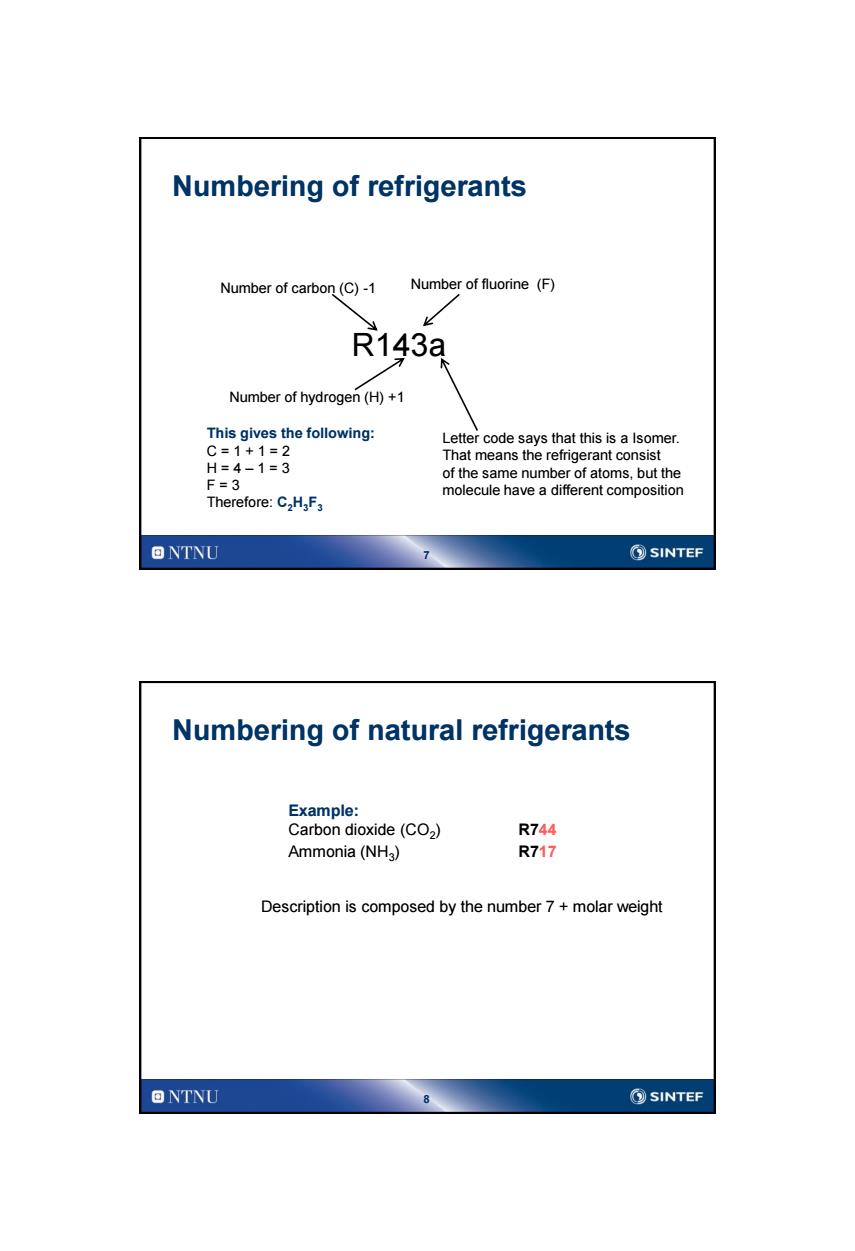

7 Numbering of refrigerants R143a Number of carbon (C) -1 Number of fluorine (F) Number of hydrogen (H) +1 This gives the following: C = 1 + 1 = 2 H = 4 – 1 = 3 F = 3 Therefore: C2H3F3 Letter code says that this is a Isomer. That means the refrigerant consist of the same number of atoms, but the molecule have a different composition 8 Numbering of natural refrigerants Example: Carbon dioxide (CO2 ) R744 Ammonia (NH3 ) R717 Description is composed by the number 7 + molar weight

Phase out program for HCFC(R22) Date EU's phase out Montreal protocol Stabilization from Stabilization from 01.01.1996 01.01.2001 01.012001 Reduction of 15%* 01.012003 Reduction of 55% 01.012004 Reduction of 70% Reduction of 35% 01.012008 Reduction of 75% 01.01.2010 Import stop of HCFC Reduction of 65% 01.012015 Reduction of 90% 01.01.2020 Reduction of 99.5% 01.012030 Import stop of HCFC *Compares to the level in 1989. Directive about ozone reduction mediums in Norway follows the EU's phase out plan. ONTNU ②SINTEF Important synthetic and natural refrigerates environmental properties Refrigerants Type Normal use ODP GWP Types of oils R22 HCFC Freeze/Chilling 0.055 1700 A.M.A/M R134a HFC Chilling/HP 0 1300 E R290(Propane) Natural Freeze/Chiling/HP 0 3 A.M.A/M R6ODa(lsobutene) Natural Freeze/Chilling 0 4 A.M.A/M R717 (Ammonia) Natural Freeze/Chilling/HP 0 0 A.M.A/M.PAO.(PAG) R744(C0) Natural Freeze/Chilling/HP 0 0 E(M above-10℃) HFK-blandinger Name Substitutes "Glide"C ODP GWP Types of oil R404AHP62,FX70) R502.R22 07 0 3750E R407A(KLEA60) R502.R22 6,6 0 1920 E R407B(KLEA61) R502 4.4 0 2560 E R407C(KLEA66,AC9000) R22 7.2 0 1610E R410(SUVA9100.AZ20) R22,R12 0.1 0 1890 E R507(AZ50 R502.R22 0 0 3800 E R413A(Isceon 49) R12 7.0 0 1770 A.(M.A/M) R417A(lsceon 59) R22 6,8 0 1950 A.(M.A/M) There is a lot more types of oils than listed below. Types of oil:A:Alkyd benzene oil,M:Mineral oil,A/M:Mixture of Alkyd benzene and Mineral oil,PAO:Polyalfa olefin oil, E:Ester oil,PAG:Polyalkylen glycol oil ONTNU 10 SINTEF

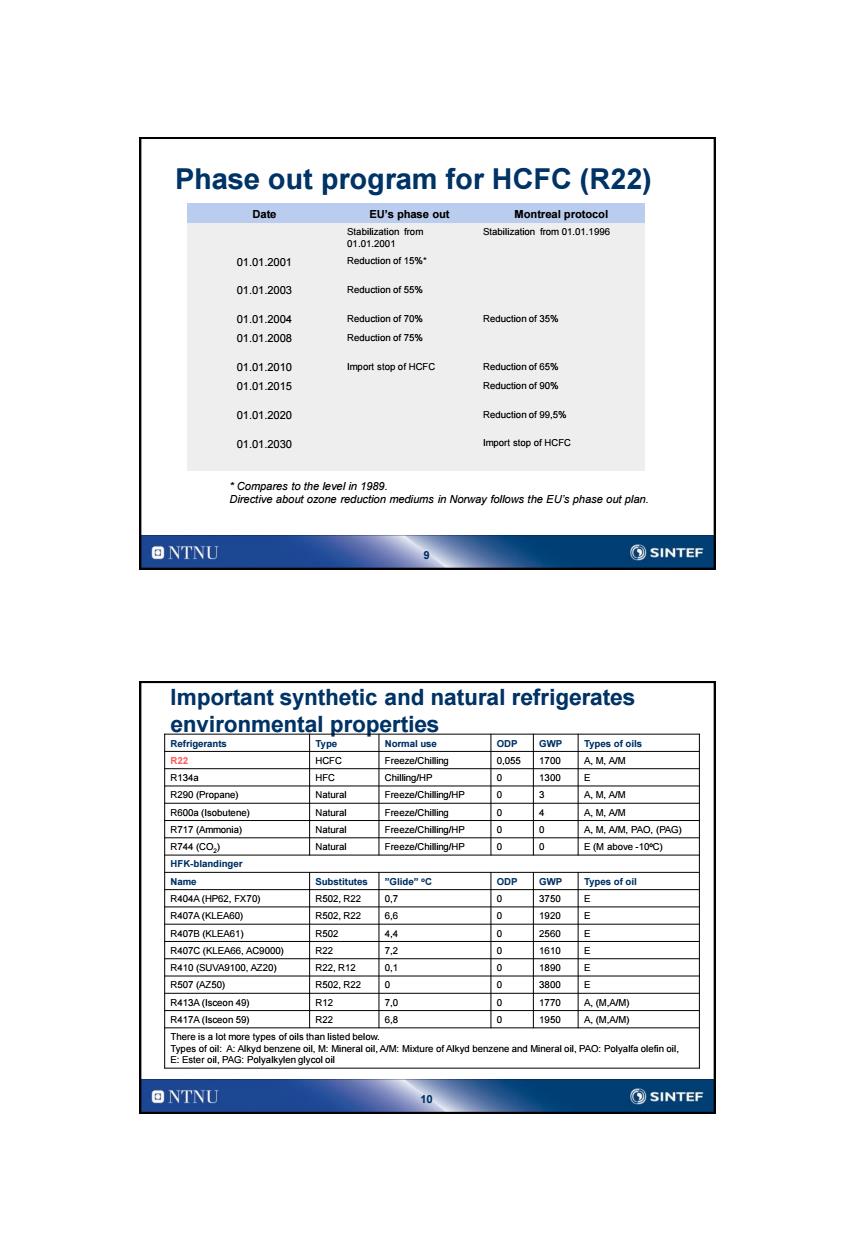

9 Phase out program for HCFC (R22) Date EU’s phase out Montreal protocol Stabilization from 01.01.2001 Stabilization from 01.01.1996 01.01.2001 Reduction of 15%* 01.01.2003 Reduction of 55% 01.01.2004 Reduction of 70% Reduction of 35% 01.01.2008 Reduction of 75% 01.01.2010 Import stop of HCFC Reduction of 65% 01.01.2015 Reduction of 90% 01.01.2020 Reduction of 99,5% 01.01.2030 Import stop of HCFC * Compares to the level in 1989. Directive about ozone reduction mediums in Norway follows the EU’s phase out plan. 10 Important synthetic and natural refrigerates environmental properties Refrigerants Type Normal use ODP GWP Types of oils R22 HCFC Freeze/Chilling 0,055 1700 A, M, A/M R134a HFC Chilling/HP 0 1300 E R290 (Propane) Natural Freeze/Chilling/HP 0 3 A, M, A/M R600a (Isobutene) Natural Freeze/Chilling 0 4 A, M, A/M R717 (Ammonia) Natural Freeze/Chilling/HP 0 0 A, M, A/M, PAO, (PAG) R744 (CO2 ) Natural Freeze/Chilling/HP 0 0 E (M above -10oC) HFK-blandinger Name Substitutes ”Glide” oC ODP GWP Types of oil R404A (HP62, FX70) R502, R22 0,7 0 3750 E R407A (KLEA60) R502, R22 6,6 0 1920 E R407B (KLEA61) R502 4,4 0 2560 E R407C (KLEA66, AC9000) R22 7,2 0 1610 E R410 (SUVA9100, AZ20) R22, R12 0,1 0 1890 E R507 (AZ50) R502, R22 0 0 3800 E R413A (Isceon 49) R12 7,0 0 1770 A, (M,A/M) R417A (Isceon 59) R22 6,8 0 1950 A, (M,A/M) There is a lot more types of oils than listed below. Types of oil: A: Alkyd benzene oil, M: Mineral oil, A/M: Mixture of Alkyd benzene and Mineral oil, PAO: Polyalfa olefin oil, E: Ester oil, PAG: Polyalkylen glycol oil