Recommended refrigerants for new refrigeration systems Types of system Natural refrigerants HFC-medias Freeze low (-40/+35C) C02.R717T(HC) R404A/R507 Freeze high(-30/+35C) C02,R717(HC) R404A/R507 Chilling low (-10/+35C) C02,R717(HC) R134A(R404A.R507, R407C) Chilling high(0/+35C) C02.R717(HC) R134A(R404A.R507. R407C,R410A*) Heat Pump (0/+55C) C02.R717(HC) R134A(R407C) Heat pump(0/+70C) C02,R717(HC) R134A Due to high temperature at exit of compressor:2 stage or extra cooling “2 stage,.40bar Due to high condenser pressure-have to use higher pressure classes for the components ONTNU 11 ②SINTEF Working fluids for refrigeration and heat pump systems Working tx) txm2 Piors3) t.23bae4) GWP5 Other fluid rcl C [barl PCI 日H R404A 46.5 74,4 373 50 3260 Mixture R407C -43.6 86,7 46.2 52 1530 Mixture R410A -50.5 72,1 49.3 38/5310 1730 Mixture R134a -26.1 101,1 40.7 74 1300 R7176) -33,1 132,3 113,3 55/761 0 Toxic R290) -42.1 96.7 42,5 63 3 Inflammabl e R7448) -78.49) 31,1 73.8 -15 0(1) Transcritic 1)Normal boiling point(1 bar)2)Critical temperature 3)Critical pressure 4) Condensing temperature at 23 bar 5)Global Warming Potential(GWP-verdi)6) Ammonia(NH 7)Propane 8))Tipple point-56.6"C/5,18 bar 10)23/35 bar 11)23/38 bar ONTNU SINTEF

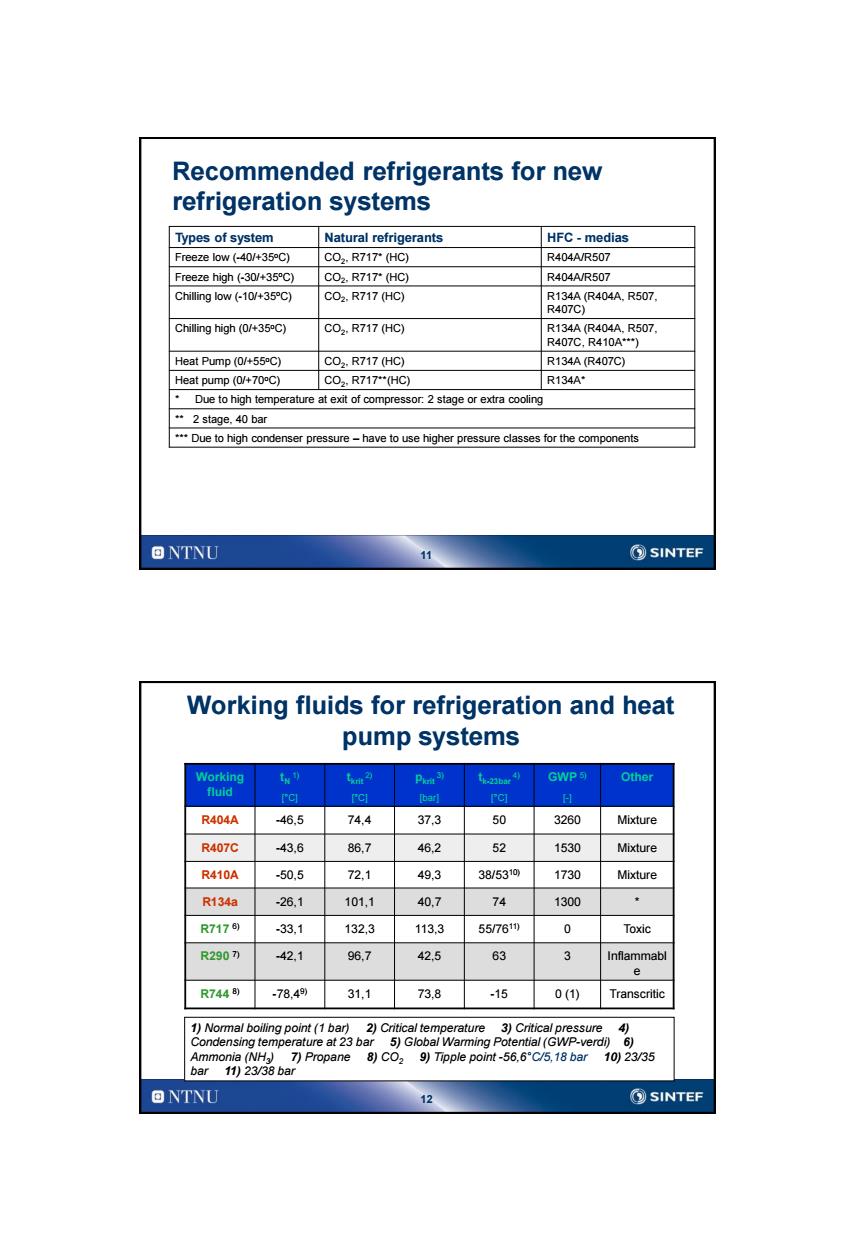

11 Recommended refrigerants for new refrigeration systems Types of system Natural refrigerants HFC - medias Freeze low (-40/+35oC) CO2 , R717* (HC) R404A/R507 Freeze high (-30/+35oC) CO2 , R717* (HC) R404A/R507 Chilling low (-10/+35oC) CO2 , R717 (HC) R134A (R404A, R507, R407C) Chilling high (0/+35oC) CO2 , R717 (HC) R134A (R404A, R507, R407C, R410A***) Heat Pump (0/+55oC) CO2 , R717 (HC) R134A (R407C) Heat pump (0/+70oC) CO2 , R717**(HC) R134A* * Due to high temperature at exit of compressor: 2 stage or extra cooling ** 2 stage, 40 bar *** Due to high condenser pressure – have to use higher pressure classes for the components 12 Working fluids for refrigeration and heat pump systems Working fluid tN 1) [°C] tkrit 2) [°C] pkrit 3) [bar] tk-23bar 4) [°C] GWP 5) [-] Other R404A -46,5 74,4 37,3 50 3260 Mixture R407C -43,6 86,7 46,2 52 1530 Mixture R410A -50,5 72,1 49,3 38/5310) 1730 Mixture R134a -26,1 101,1 40,7 74 1300 * R717 6) -33,1 132,3 113,3 55/7611) 0 Toxic R290 7) -42,1 96,7 42,5 63 3 Inflammabl e R744 8) -78,49) 31,1 73,8 -15 0 (1) Transcritic 1) Normal boiling point (1 bar) 2) Critical temperature 3) Critical pressure 4) Condensing temperature at 23 bar 5) Global Warming Potential (GWP-verdi) 6) Ammonia (NH3 ) 7) Propane 8) CO2 9) Tipple point -56,6°C/5,18 bar 10) 23/35 bar 11) 23/38 bar

Vapor pressure for different refrigerants 100 .R717 R290 R407C ,R744 R718 R719 ---.R502 R507 R508B .-.R1270-….…R600 ----R600a---.R500 ▣▣▣.R141b 10 -80 -60 .40 20 60 80 100 120 140 160 Temperatur,t['c] ONTNU SINTEF Volumetric refrigeration capacity for different medias qy=VRC=Aho'Pv 30000 -。-R-744 -R-410A NH 25D00 R-22 R-407C 20D00 -R-12 C02 15000 R410A/ R407 10D0D0 R290 R134a 5000 0 20 0 60 80 100 TIC] ONTNU ⑤SINTEF

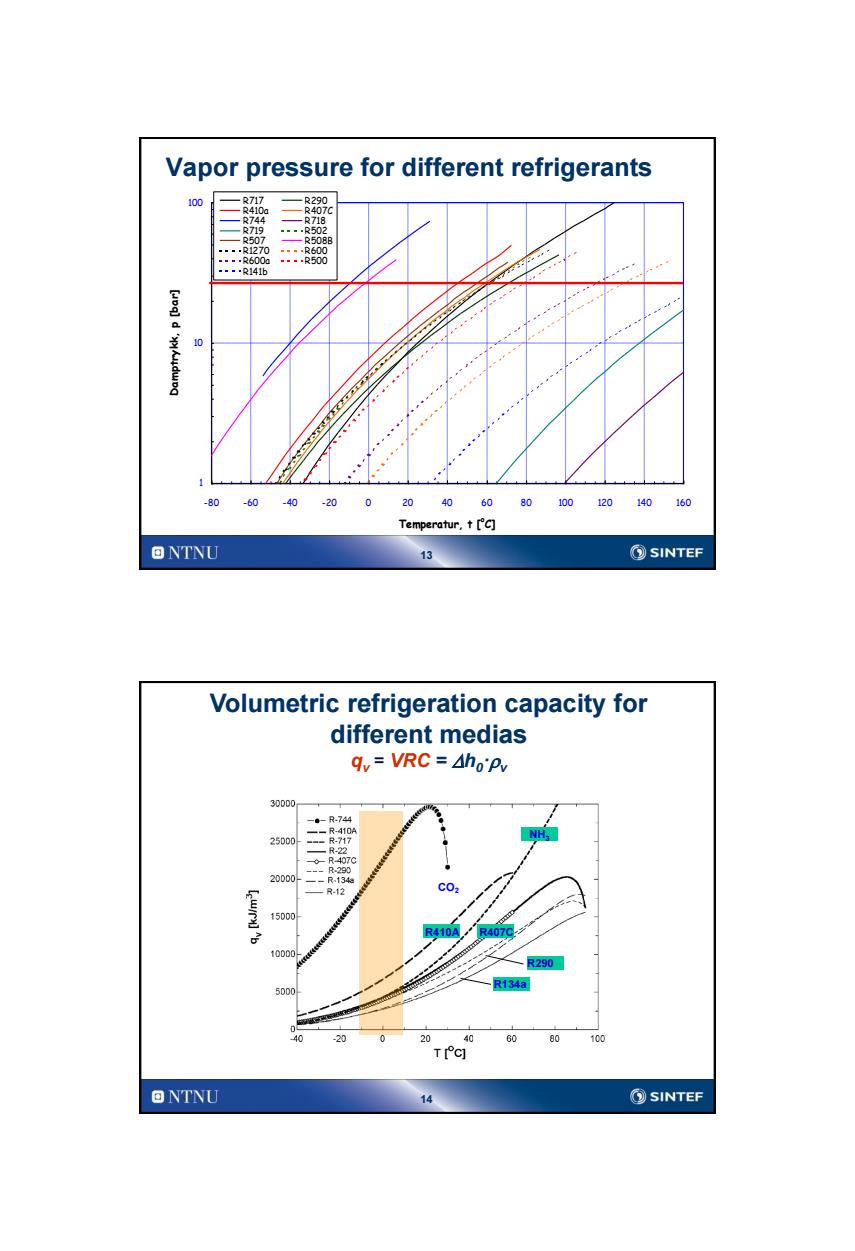

13 Vapor pressure for different refrigerants 1 10 100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160 Temperatur, t [oC] Damptrykk, p [bar] R717 R290 R410a R407C R744 R718 R719 R502 R507 R508B R1270 R600 R600a R500 R141b 14 Volumetric refrigeration capacity for different medias qv = VRC = Dh0·v CO2 R134a R407C R290 R410A NH3