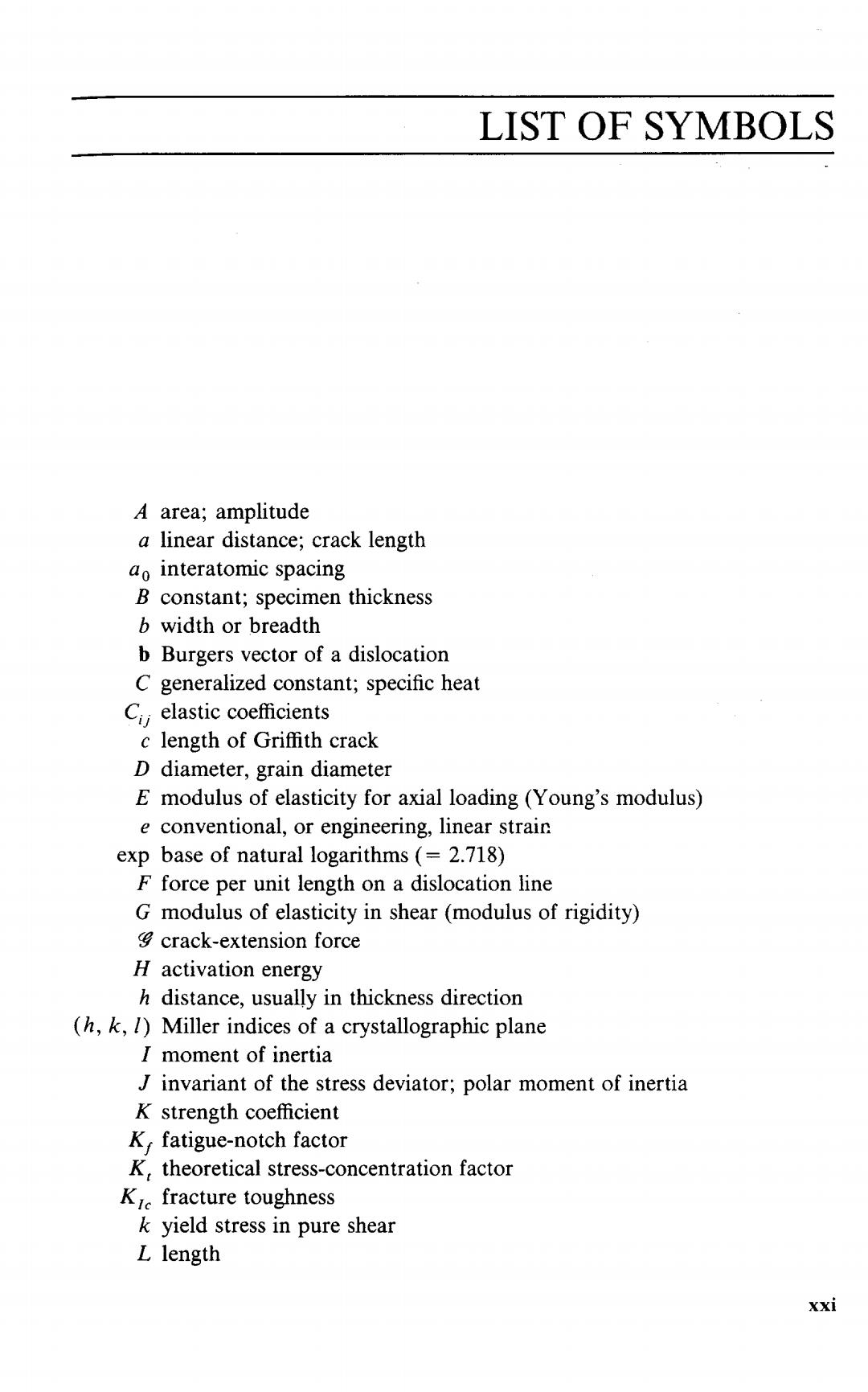

LIST OF SYMBOLS A area;amplitude a linear distance;crack length ao interatomic spacing B constant;specimen thickness b width or breadth b Burgers vector of a dislocation C generalized constant;specific heat Ci elastic coefficients c length of Griffith crack D diameter,grain diameter E modulus of elasticity for axial loading (Young's modulus) e conventional,or engineering,linear strain exp base of natural logarithms (2.718) F force per unit length on a dislocation line G modulus of elasticity in shear(modulus of rigidity) crack-extension force H activation energy h distance,usually in thickness direction (h,k,1)Miller indices of a crystallographic plane I moment of inertia J invariant of the stress deviator;polar moment of inertia K strength coefficient K,fatigue-notch factor K,theoretical stress-concentration factor KI fracture toughness k yield stress in pure shear L length xXi

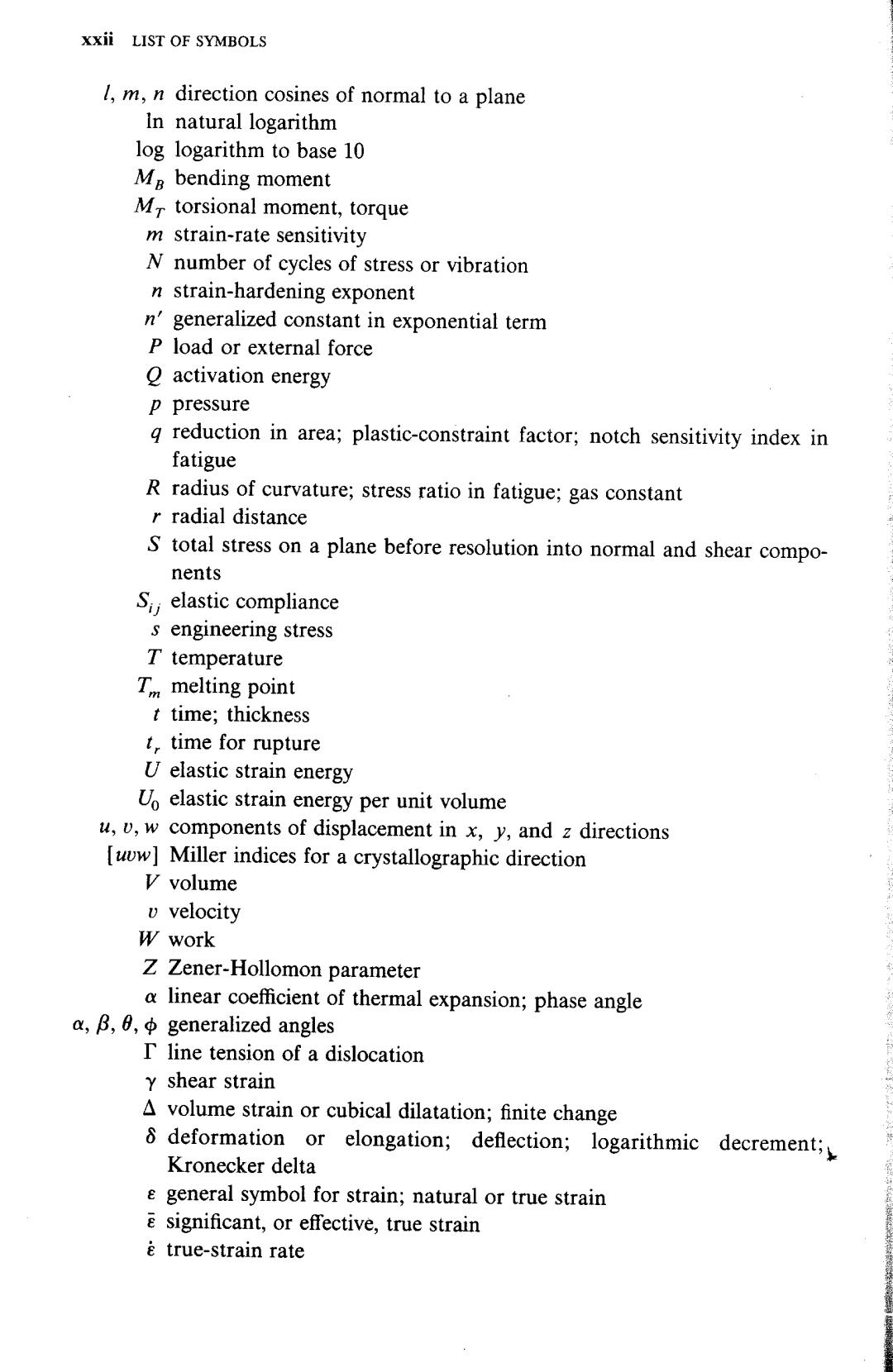

xxii LIST OF SYMBOLS 1,m,n direction cosines of normal to a plane In natural logarithm log logarithm to base 10 Ma bending moment M torsional moment,torque m strain-rate sensitivity N number of cycles of stress or vibration n strain-hardening exponent n'generalized constant in exponential term P load or external force O activation energy p pressure g reduction in area;plastic-constraint factor;notch sensitivity index in fatigue R radius of curvature;stress ratio in fatigue;gas constant r radial distance S total stress on a plane before resolution into normal and shear compo- nents S;elastic compliance s engineering stress T temperature T melting point t time;thickness t,time for rupture U elastic strain energy U elastic strain energy per unit volume u,v,w components of displacement in x,y,and z directions [wow]Miller indices for a crystallographic direction V volume v velocity W work Z Zener-Hollomon parameter a linear coefficient of thermal expansion;phase angle a,B,6,generalized angles I line tension of a dislocation y shear strain A volume strain or cubical dilatation;finite change 8 deformation or elongation;deflection;logarithmic decrement; Kronecker delta e general symbol for strain;natural or true strain E significant,or effective,true strain a true-strain rate

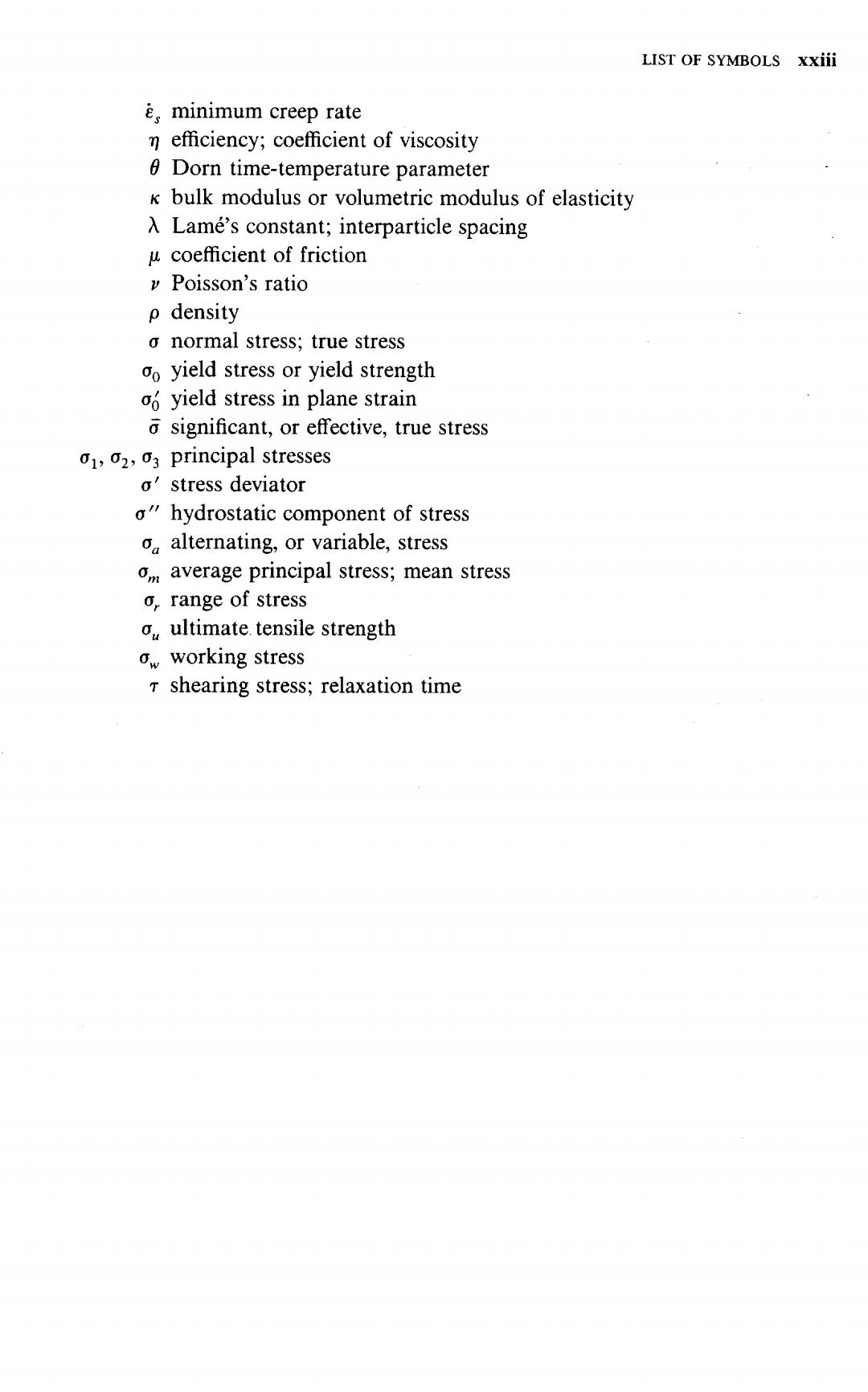

LIST OF SYMBOLS xxiii e,minimum creep rate n efficiency;coefficient of viscosity 6 Dorn time-temperature parameter k bulk modulus or volumetric modulus of elasticity A Lame's constant;interparticle spacing u coefficient of friction v Poisson's ratio p density o normal stress;true stress 0o yield stress or yield strength oo yield stress in plane strain o significant,or effective,true stress 01,02,03 principal stresses o'stress deviator o"hydrostatic component of stress o alternating,or variable,stress o average principal stress;mean stress o,range of stress o ultimate.tensile strength o working stress T shearing stress;relaxation time

PART ONE MECHANICAL FUNDAMENTALS

CHAPTER ONE INTRODUCTION 1-1 SCOPE OF THIS BOOK Mechanical metallurgy is the area of metallurgy which is concerned primarily with the response of metals to forces or loads.The forces may arise from the use of the metal as a member or part in a structure or machine,in which case it is necessary to know something about the limiting values which can be withstood without failure.On the other hand,the objective may be to convert a cast ingot into a more useful shape,such as a flat plate,and here it is necessary to know the conditions of temperature and rate of loading which minimize the forces that are needed to do the job. Mechanical metallurgy is not a subject which can be neatly isolated and studied by itself.It is a combination of many disciplines and many approaches to the problem of understanding the response of materials to forces.On the one hand is the approach used in strength of materials and in the theories of elasticity and plasticity,where a metal is considered to be a homogeneous material whose mechanical behavior can be rather precisely described on the basis of only a very few material constants.This approach is the basis for the rational design of structural members and machine parts.The topics of strength of materials, elasticity,and plasticity are treated in Part One of this book from a more generalized point of view than is usually considered in a first course in strength of materials.The material in Chaps.1 to 3 can be considered the mathematical framework on which much of the remainder of the book rests.For students of engineering who have had an advanced course in strength of materials or machine design,it probably will be possible to skim rapidly over these chapters.However, for most students of.metallurgy and for practicing engineers in industry,it is 3