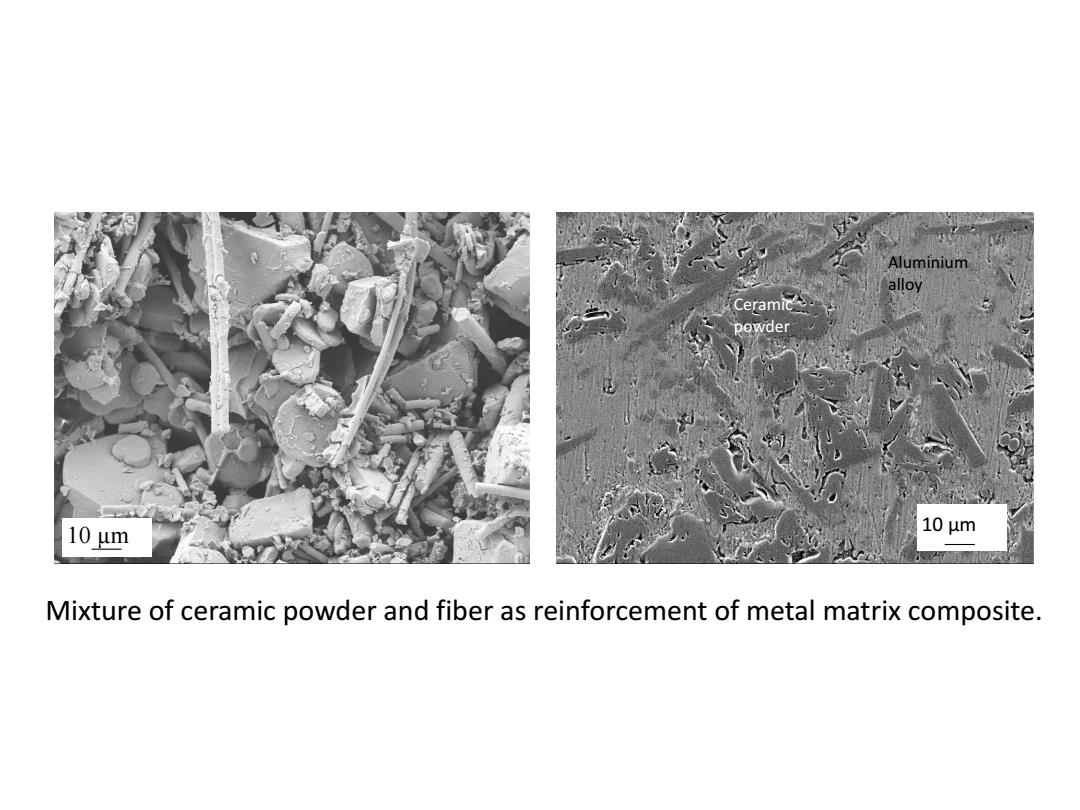

Aluminium alloy powder 10m 10μm Mixture of ceramic powder and fiber as reinforcement of metal matrix composite

10 µm Aluminium alloy Ceramic powder 10 µm Mixture of ceramic powder and fiber as reinforcement of metal matrix composite

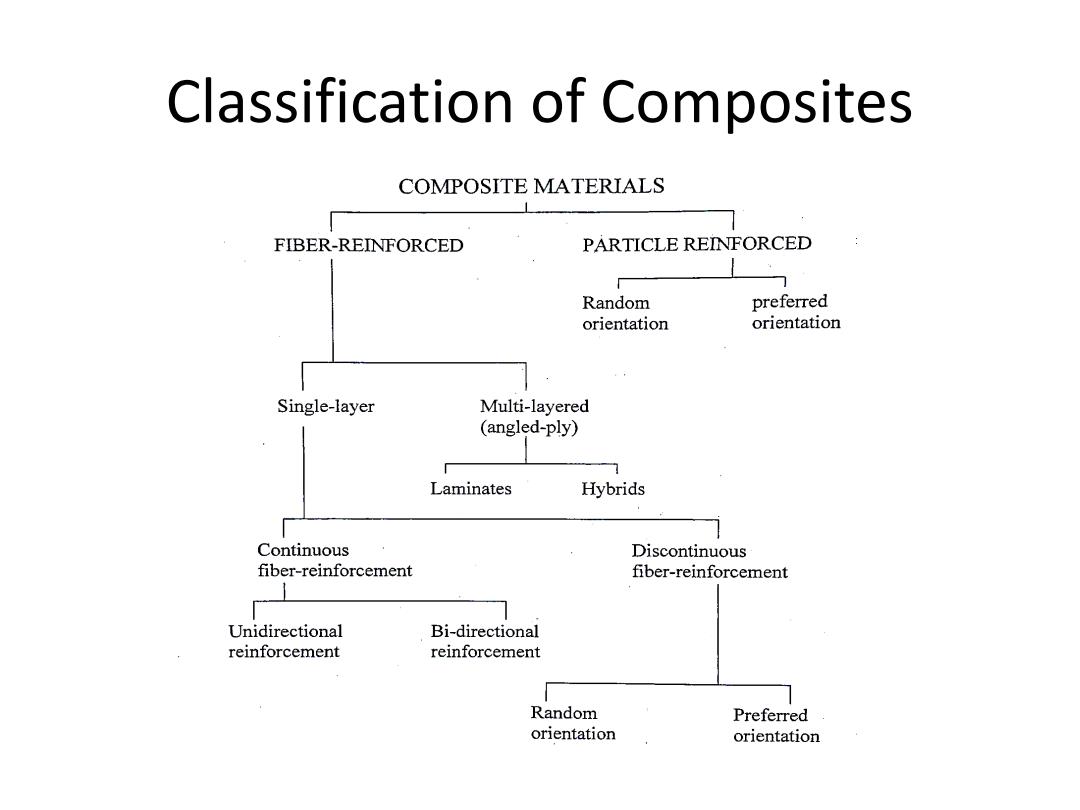

Classification of Composites COMPOSITE MATERIALS FIBER-REINFORCED PARTICLE REINFORCED Random preferred orientation orientation Single-layer Multi-layered (angled-ply) Laminates Hybrids Continuous Discontinuous fiber-reinforcement fiber-reinforcement Unidirectional Bi-directional reinforcement reinforcement Random Preferred orientation orientation

Classification of Composites

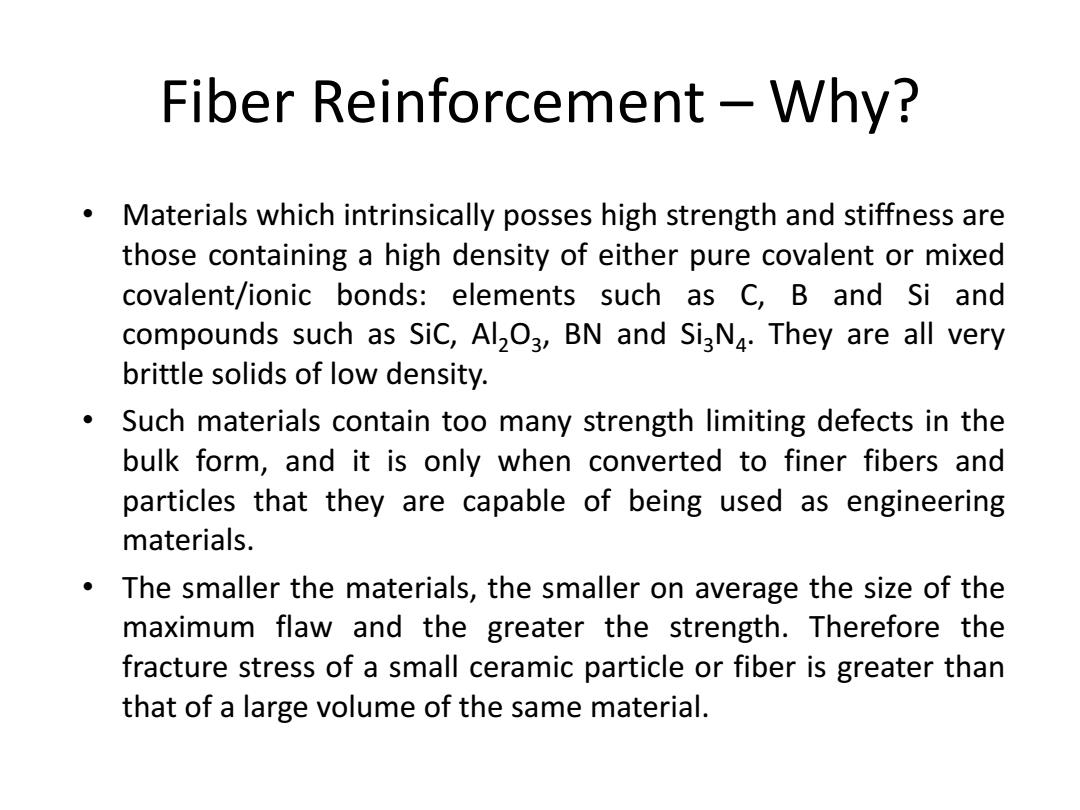

Fiber Reinforcement -Why? ● Materials which intrinsically posses high strength and stiffness are those containing a high density of either pure covalent or mixed covalent/ionic bonds:elements such as C,B and Si and compounds such as SiC,Al2O3,BN and SigN4.They are all very brittle solids of low density. ● Such materials contain too many strength limiting defects in the bulk form,and it is only when converted to finer fibers and particles that they are capable of being used as engineering materials. The smaller the materials,the smaller on average the size of the maximum flaw and the greater the strength.Therefore the fracture stress of a small ceramic particle or fiber is greater than that of a large volume of the same material

Fiber Reinforcement – Why? • Materials which intrinsically posses high strength and stiffness are those containing a high density of either pure covalent or mixed covalent/ionic bonds: elements such as C, B and Si and compounds such as SiC, Al2O3 , BN and Si3N4 . They are all very brittle solids of low density. • Such materials contain too many strength limiting defects in the bulk form, and it is only when converted to finer fibers and particles that they are capable of being used as engineering materials. • The smaller the materials, the smaller on average the size of the maximum flaw and the greater the strength. Therefore the fracture stress of a small ceramic particle or fiber is greater than that of a large volume of the same material

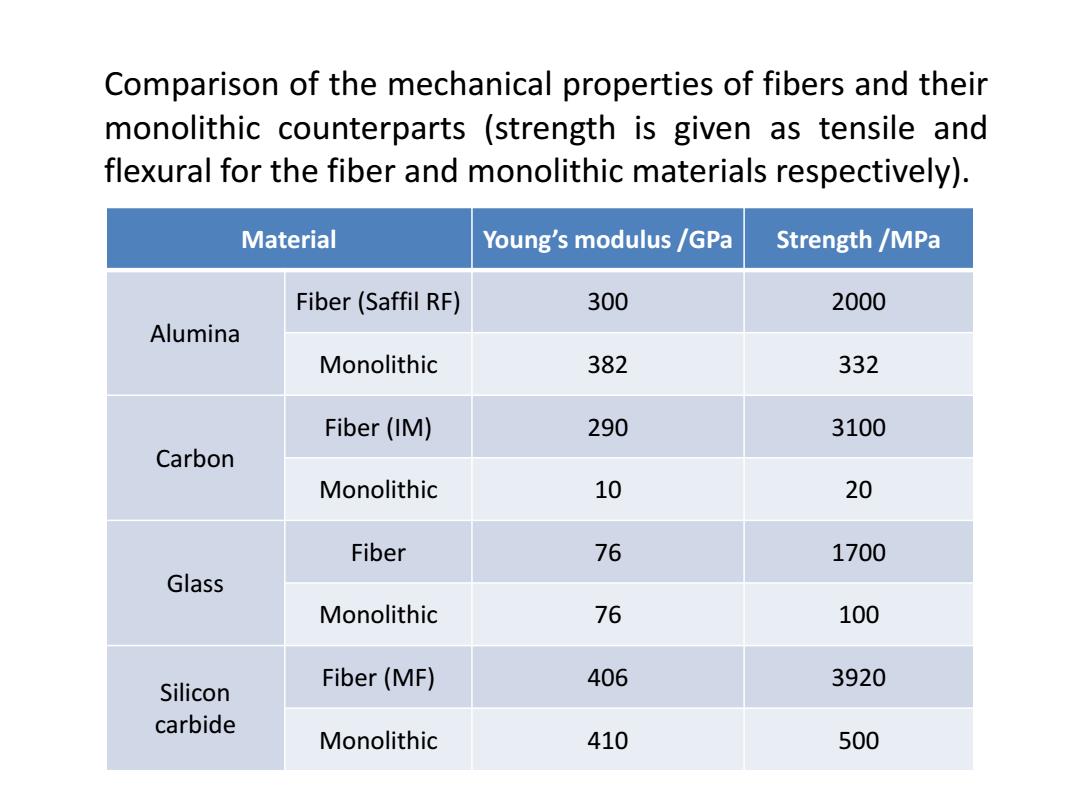

Comparison of the mechanical properties of fibers and their monolithic counterparts (strength is given as tensile and flexural for the fiber and monolithic materials respectively). Material Young's modulus/GPa Strength /MPa Fiber(Saffil RF) 300 2000 Alumina Monolithic 382 332 Fiber(IM) 290 3100 Carbon Monolithic 10 20 Fiber 76 1700 Glass Monolithic 76 100 Silicon Fiber(MF) 406 3920 carbide Monolithic 410 500

Material Young’s modulus /GPa Strength /MPa Alumina Fiber (Saffil RF) 300 2000 Monolithic 382 332 Carbon Fiber (IM) 290 3100 Monolithic 10 20 Glass Fiber 76 1700 Monolithic 76 100 Silicon carbide Fiber (MF) 406 3920 Monolithic 410 500 Comparison of the mechanical properties of fibers and their monolithic counterparts (strength is given as tensile and flexural for the fiber and monolithic materials respectively)

Fiber Reinforcement -Why? A small diameter with respect to its grain size allows a higher fraction of the theoretical strength to be attained than that possible in a bulk form.The smaller the size,the lower the probability of having imperfections in the materials. 3.0 GPa 2.5 2.0 1.5 6 8 10 12μm14 d Decrease in strength(o;)of a carbon fiber with increase in diameter

Fiber Reinforcement – Why? • A small diameter with respect to its grain size allows a higher fraction of the theoretical strength to be attained than that possible in a bulk form. The smaller the size, the lower the probability of having imperfections in the materials. Decrease in strength (σf ) of a carbon fiber with increase in diameter