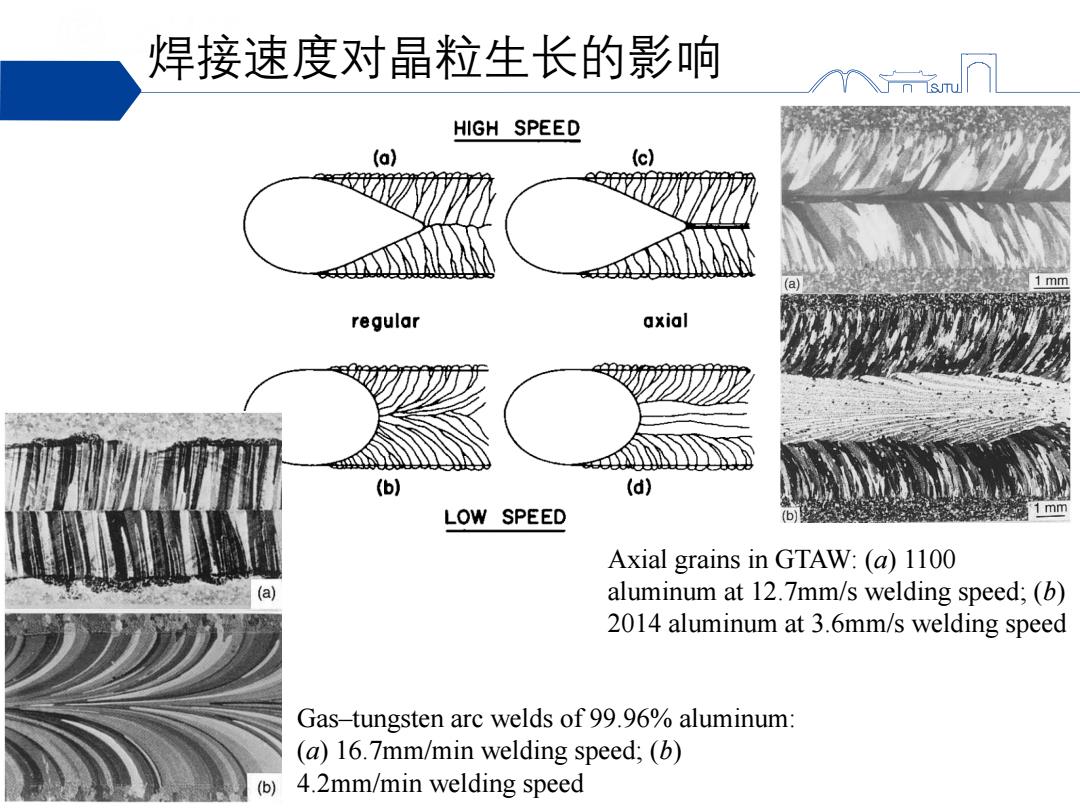

焊接速度对晶粒生长的影响 Ynsu HIGH SPEED (a) (c) (a) 1 mm regular axial (b) (d) LOW SPEED 6 mm Axial grains in GTAW:(a)1100 (a) aluminum at 12.7mm/s welding speed;(b) 2014 aluminum at 3.6mm/s welding speed Gas-tungsten arc welds of 99.96%aluminum: (a)16.7mm/min welding speed;(b) (b)4.2mm/min welding speed

焊接速度对晶粒生长的影响 Gas–tungsten arc welds of 99.96% aluminum: (a) 16.7mm/min welding speed; (b) 4.2mm/min welding speed Axial grains in GTAW: (a) 1100 aluminum at 12.7mm/s welding speed; (b) 2014 aluminum at 3.6mm/s welding speed

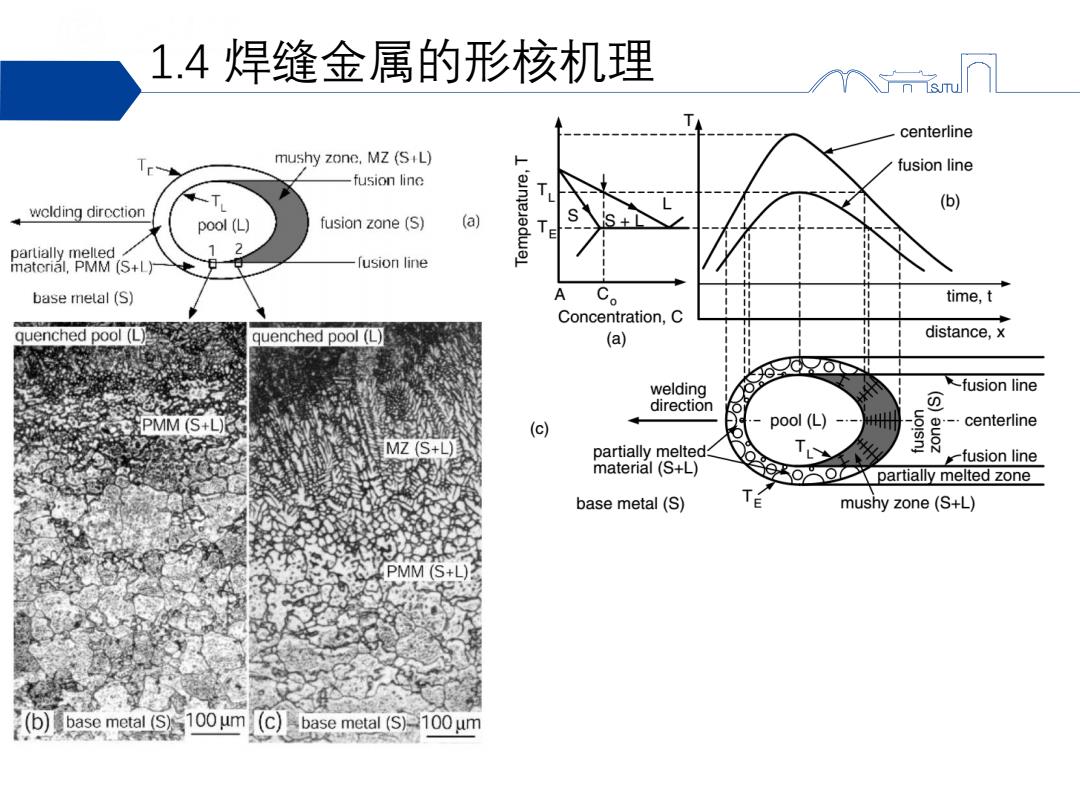

1.4焊缝金属的形核机理 centerline mushy zone,MZ (S+L) fusion line -fusion line T (b) welding dircction pool (L) fusion zone(S) (a) partially melted 1 2 matcrial,PMM(S+L) fusion line base metal(S) A time,t Concentration,C quenched pool (L quenched pool(L) (a) distance,x welding -fusion line direction 西 PMM(S+L) () pool (L) s centerline partially melted T uoz Q fusion line material (S+L) partially melted zone base metal(S) mushy zone(S+L) (b)asmetal(100 um (C)base metal (S)100 um

1.4 焊缝金属的形核机理

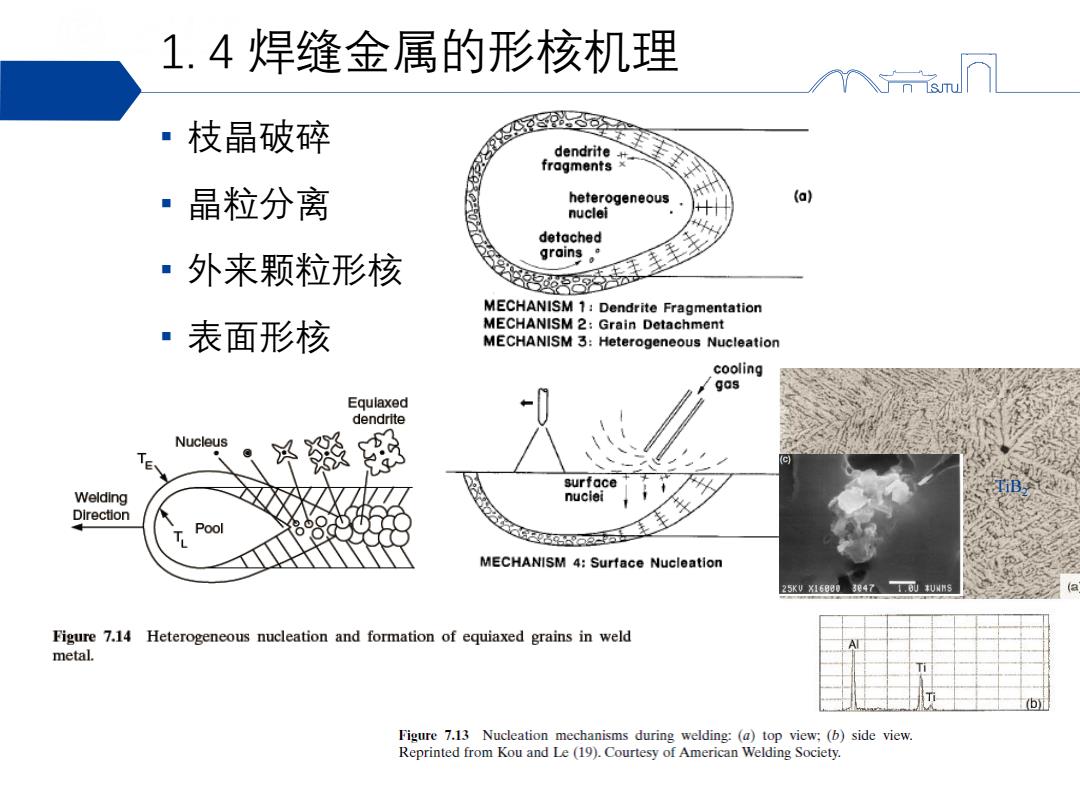

1.4焊缝金属的形核机理 枝晶破碎 2✉8 dendrite+ fragments x 晶粒分离 heterogeneous (a) nuclei detached ·外来颗粒形核 grains,° MECHANISM 1:Dendrite Fragmentation ·表面形核 MECHANISM 2:Grain Detachment MECHANISM 3:Heterogeneous Nucleation cooling gas Equlaxed dendrite Nucleus 兴磁柔 9 surface Welding nuciei Direction Pool MECHANISM 4:Surtace Nucleation 25KVX1680030471可0Un9 Figure 7.14 Heterogeneous nucleation and formation of equiaxed grains in weld metal. (b Figure 7.13 Nucleation mechanisms during welding:(a)top view;(b)side view. Reprinted from Kou and Le(19).Courtesy of American Welding Society

1. 4 焊缝金属的形核机理 ▪ 枝晶破碎 ▪ 晶粒分离 ▪ 外来颗粒形核 ▪ 表面形核 TiB2

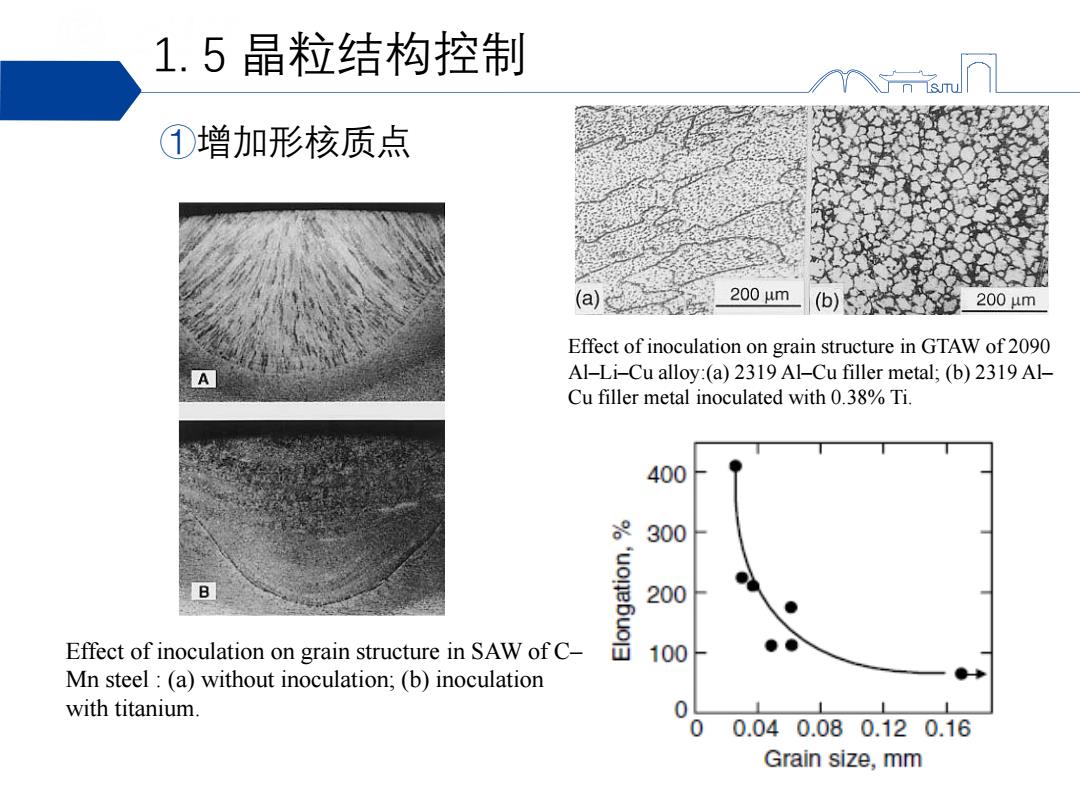

1.5晶粒结构控制 Y了nsu ①增加形核质点 (a) 200um (b) 200um Effect of inoculation on grain structure in GTAW of 2090 Al-Li-Cu alloy:(a)2319 Al-Cu filler metal;(b)2319 Al- Cu filler metal inoculated with 0.38%Ti 400 9 300 B 200 Effect of inoculation on grain structure in SAW of C- 100 Mn steel:(a)without inoculation;(b)inoculation with titanium. 00 0.040.080.120.16 Grain size,mm

1. 5 晶粒结构控制 ①增加形核质点 Effect of inoculation on grain structure in GTAW of 2090 Al–Li–Cu alloy:(a) 2319 Al–Cu filler metal; (b) 2319 Al– Cu filler metal inoculated with 0.38% Ti. Effect of inoculation on grain structure in SAW of C– Mn steel : (a) without inoculation; (b) inoculation with titanium

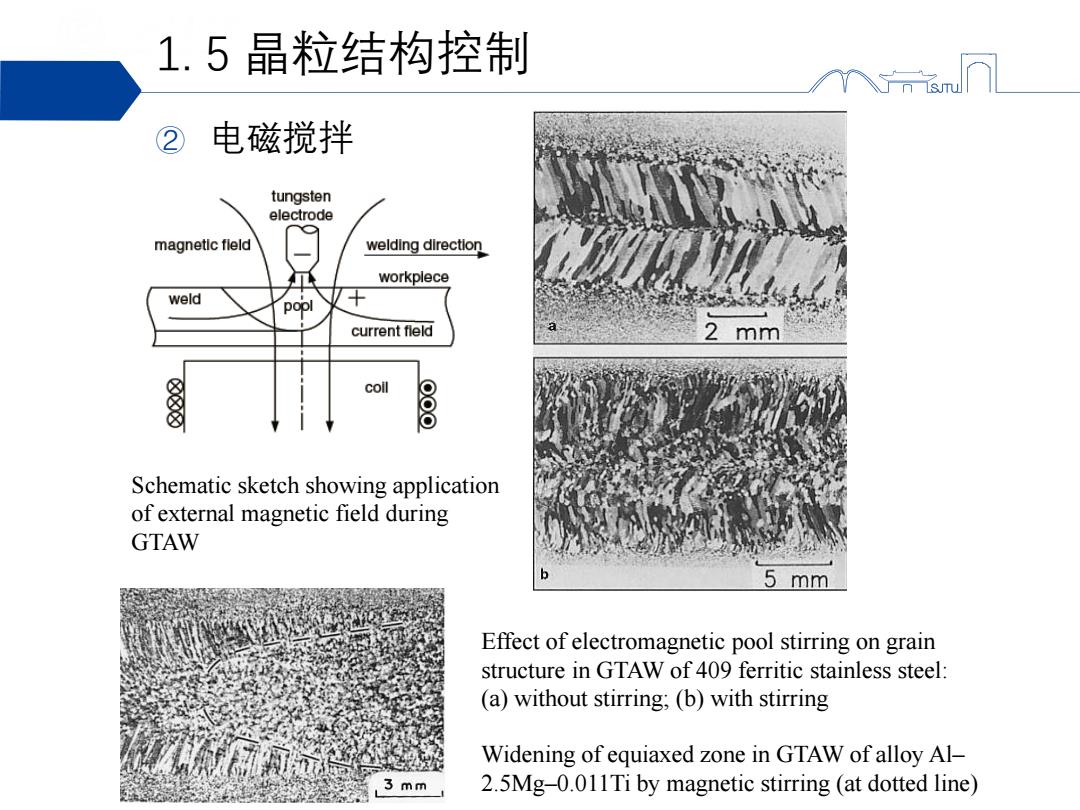

1.5晶粒结构控制 2 电磁搅拌 tungsten electrode magnetic fleld welding direction workplece weld popl current fleld 2 mm coll Schematic sketch showing application of external magnetic field during GTAW 5 mm Effect of electromagnetic pool stirring on grain structure in GTAW of 409 ferritic stainless steel: (a)without stirring;(b)with stirring Widening of equiaxed zone in GTAW of alloy Al- 3 mm 2.5Mg-0.011Ti by magnetic stirring (at dotted line)

② 电磁搅拌 Widening of equiaxed zone in GTAW of alloy Al– 2.5Mg–0.011Ti by magnetic stirring (at dotted line) Effect of electromagnetic pool stirring on grain structure in GTAW of 409 ferritic stainless steel: (a) without stirring; (b) with stirring Schematic sketch showing application of external magnetic field during GTAW 1. 5 晶粒结构控制