Motorcycle Carburetor Theory 1olMotorcycle carburetors look very complex, but with a little theory, you can tuneyour bike for maximum performance. All carburetors work under the basic principleof atmospheric pressure. Atmospheric pressure is a powerful force which exertspressure on everything. It varies slightlybut is generally considered to be 15 poundsper square inch (PsI). This means that atmospheric pressure is pressing on everythingatl5PsI.Byvarying theatmospheric pressureinsidethe engine andcarburetor,wecan change the pressure and make fuel and air flow.Atmospheric pressure will force high pressure to low pressure. As the piston ona two stroke engine goes up (or goes down on a four stroke engine), a low pressureis formedinside the crankcase (above the piston on afour stroke).This low pressurealso causes a lowpressure inside the carburetor. Since the pressure is higher outsidethe engine and carburetor, air will rush inside the carburetor and engine until thepressure is equalized. The moving air going through the carburetor will pick up fuelandmixwiththeair.Inside a carburetor is a venturi, fig l.The venturi is a restriction inside thecarburetor that forces air to speed up to get through. A river that suddenly narrowscan be used to illustrate what happens inside a carb. The water in the river speedsup as it gets near the narrowed shores and will get faster if the river narrows evenmore. The same thing happens inside the carburetor. The air that is speeding up willcause atmospheric pressure to drop inside the carburetor. The faster the air moves,the lower the pressure inside the carburetor.AirVenturiSizeFlowHigh PressureFuelSupplyFIG 1Most motorcycle carburetor circuits are governed by throttle position and notby engine speed.There arefivemain metering systemsinside most motorcyclecarburetors.These metering circuits overlap each other and they are:

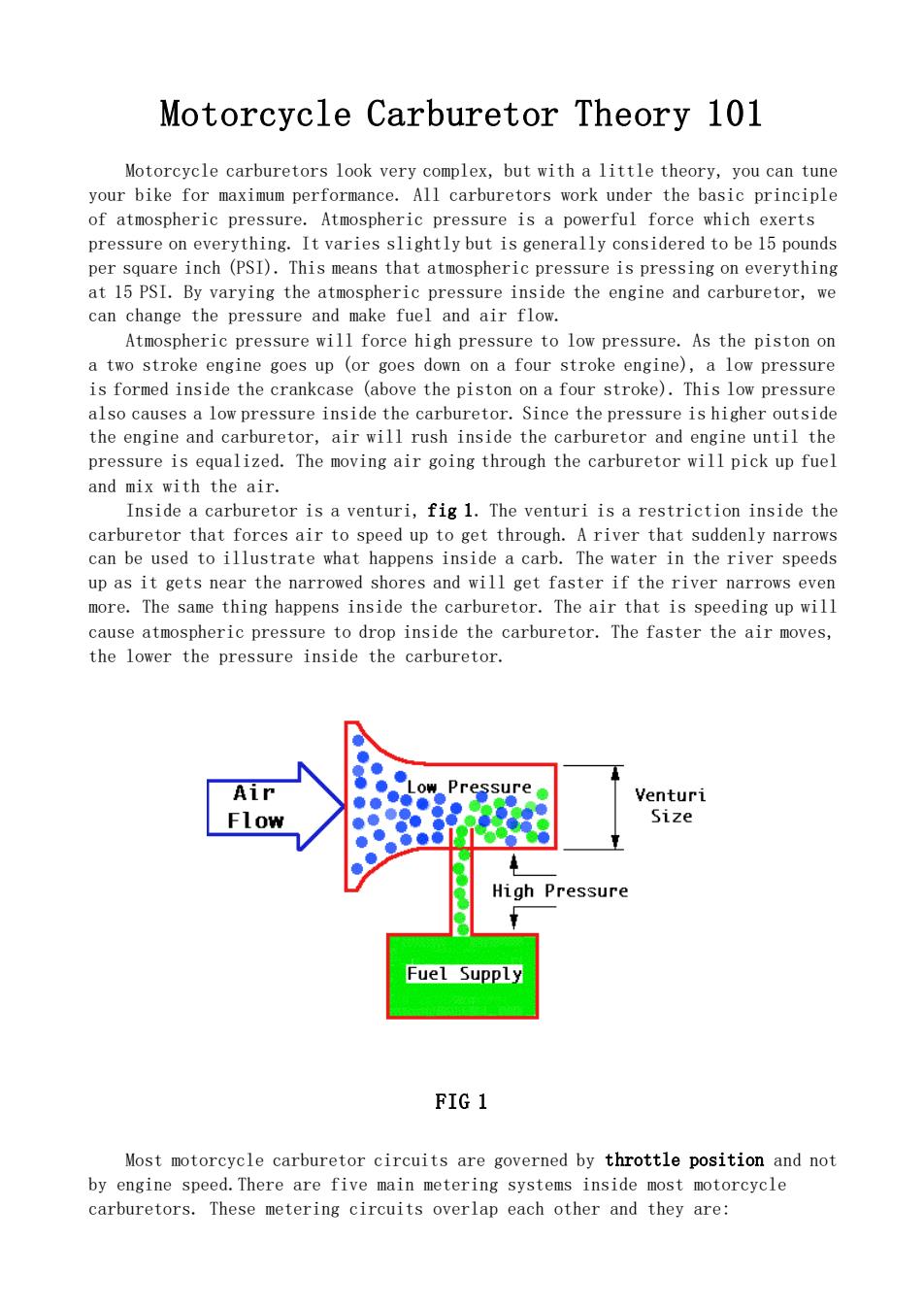

Motorcycle Carburetor Theory 101 Motorcycle carburetors look very complex, but with a little theory, you can tune your bike for maximum performance. All carburetors work under the basic principle of atmospheric pressure. Atmospheric pressure is a powerful force which exerts pressure on everything. It varies slightly but is generally considered to be 15 pounds per square inch (PSI). This means that atmospheric pressure is pressing on everything at 15 PSI. By varying the atmospheric pressure inside the engine and carburetor, we can change the pressure and make fuel and air flow. Atmospheric pressure will force high pressure to low pressure. As the piston on a two stroke engine goes up (or goes down on a four stroke engine), a low pressure is formed inside the crankcase (above the piston on a four stroke). This low pressure also causes a low pressure inside the carburetor. Since the pressure is higher outside the engine and carburetor, air will rush inside the carburetor and engine until the pressure is equalized. The moving air going through the carburetor will pick up fuel and mix with the air. Inside a carburetor is a venturi, fig 1. The venturi is a restriction inside the carburetor that forces air to speed up to get through. A river that suddenly narrows can be used to illustrate what happens inside a carb. The water in the river speeds up as it gets near the narrowed shores and will get faster if the river narrows even more. The same thing happens inside the carburetor. The air that is speeding up will cause atmospheric pressure to drop inside the carburetor. The faster the air moves, the lower the pressure inside the carburetor. FIG 1 Most motorcycle carburetor circuits are governed by throttle position and not by engine speed.There are five main metering systems inside most motorcycle carburetors. These metering circuits overlap each other and they are:

* pilot circuit*throttlevalve* needle jet and jet needle*main jet*choke circuitThe pilot circuit has two adjustable parts, fig 2. The pilot air screw and pilotjet. The air screw can be located either near the back side of the carburetor or nearthe front of the carburetor.If the screw is located near the back,it regulates howmuch air enters the circuit. If the screwis turned in, it reduces the amount of airand richens the mixture. If it is turned out, it opens the passage more and allowsmore air into the circuit which results in a lean mixture.If the screw is locatednearthefront,it regulated fuelThe mixture will be leaner ifit isscrewed inand richer if screwed out.If theair screwhastobeturned morethan2turnsoutfor best idling,the next smaller size pilot jet will be needed.Air FlowFuelSupplyFIG 2Thepilot jetis the part which supplies most of thefuel at lowthrottle openings.Ithasasmallholeinitwhichrestrictsfuelflowthoughit.Boththepilotairscrew and pilot jet affects carburetion from idle to around 1/4 throttle.The slide valve affects carburetion between 1/8 thru 1/2 throttle. It especiallyaffects it between 1/8 and 1/4 and has a lesser affect up to 1/2. The slides comeinvarioussizesand the size isdetermined byhowmuch is cutawayfrom thebacksideof it,fig3.Thelargerthe cutaway,theleanerthemixture(sincemoreairisallowedthrough it) and the smaller the cutaway,the richer the mixture will be. Throttle

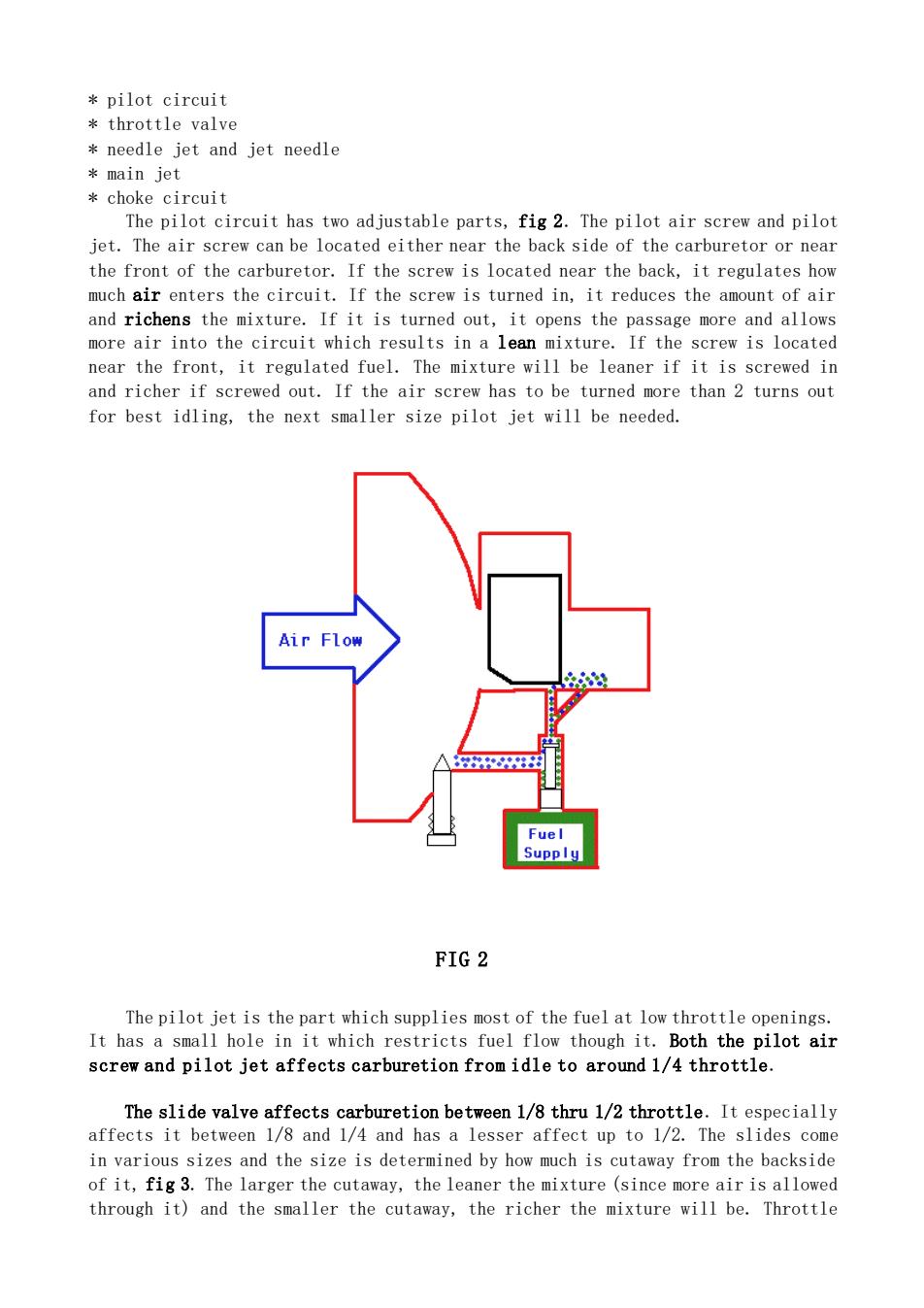

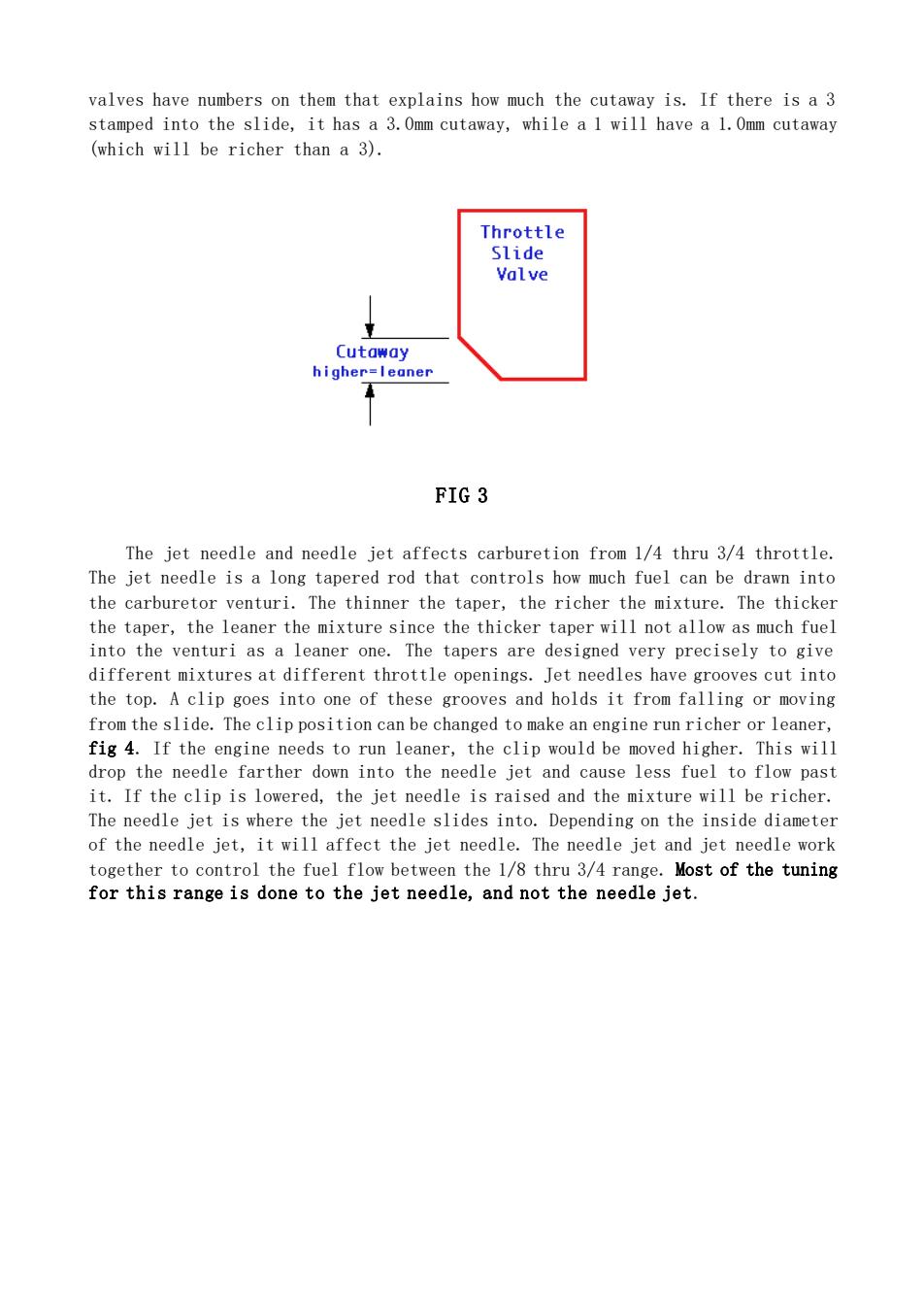

* pilot circuit * throttle valve * needle jet and jet needle * main jet * choke circuit The pilot circuit has two adjustable parts, fig 2. The pilot air screw and pilot jet. The air screw can be located either near the back side of the carburetor or near the front of the carburetor. If the screw is located near the back, it regulates how much air enters the circuit. If the screw is turned in, it reduces the amount of air and richens the mixture. If it is turned out, it opens the passage more and allows more air into the circuit which results in a lean mixture. If the screw is located near the front, it regulated fuel. The mixture will be leaner if it is screwed in and richer if screwed out. If the air screw has to be turned more than 2 turns out for best idling, the next smaller size pilot jet will be needed. FIG 2 The pilot jet is the part which supplies most of the fuel at low throttle openings. It has a small hole in it which restricts fuel flow though it. Both the pilot air screw and pilot jet affects carburetion from idle to around 1/4 throttle. The slide valve affects carburetion between 1/8 thru 1/2 throttle. It especially affects it between 1/8 and 1/4 and has a lesser affect up to 1/2. The slides come in various sizes and the size is determined by how much is cutaway from the backside of it, fig 3. The larger the cutaway, the leaner the mixture (since more air is allowed through it) and the smaller the cutaway, the richer the mixture will be. Throttle

valves have numbers on them that explains howmuch the cutaway is.If there is a 3stamped into the slide,it has a 3.Omm cutaway, while a l will have a l.Omm cutaway(which will bericher than a3).ThrottleslideValveCutawayhigher=leanerFIG3The jet needle and needle jet affects carburetion from 1/4 thru 3/4 throttle.The jet needle is a long tapered rod that controls how much fuel can be drawn intothe carburetor venturi.The thinner the taper, the richer the mixture. The thickerthe taper,theleaner themixturesince thethicker taperwill not allowasmuchfuelinto the venturi as a leaner one.The tapers are designed very precisely to givedifferentmixtures at different throttle openings.Jet needles have grooves cut intothe top. A clip goes into one of these grooves and holds it from falling or movingfrom the slide. The clip position can be changed to make an engine run richer or leaner,fig4.If theengineneeds torunleaner,theclip wouldbemovedhigher.This willdrop the needlefarther down intothe needlejet and cause lessfuelto flowpastit.If theclip islowered,the jet needle is raised and themixturewill bericher.Theneedle jet is wherethe jet needle slides into.Depending on the inside diameterof theneedle jet,itwill affect the jet needle.The needle jetand jetneedleworktogether to control the fuel flow between the1/8 thru 3/4range. Most of the tuningfor this range is done to the jet needle, and not the needle jet

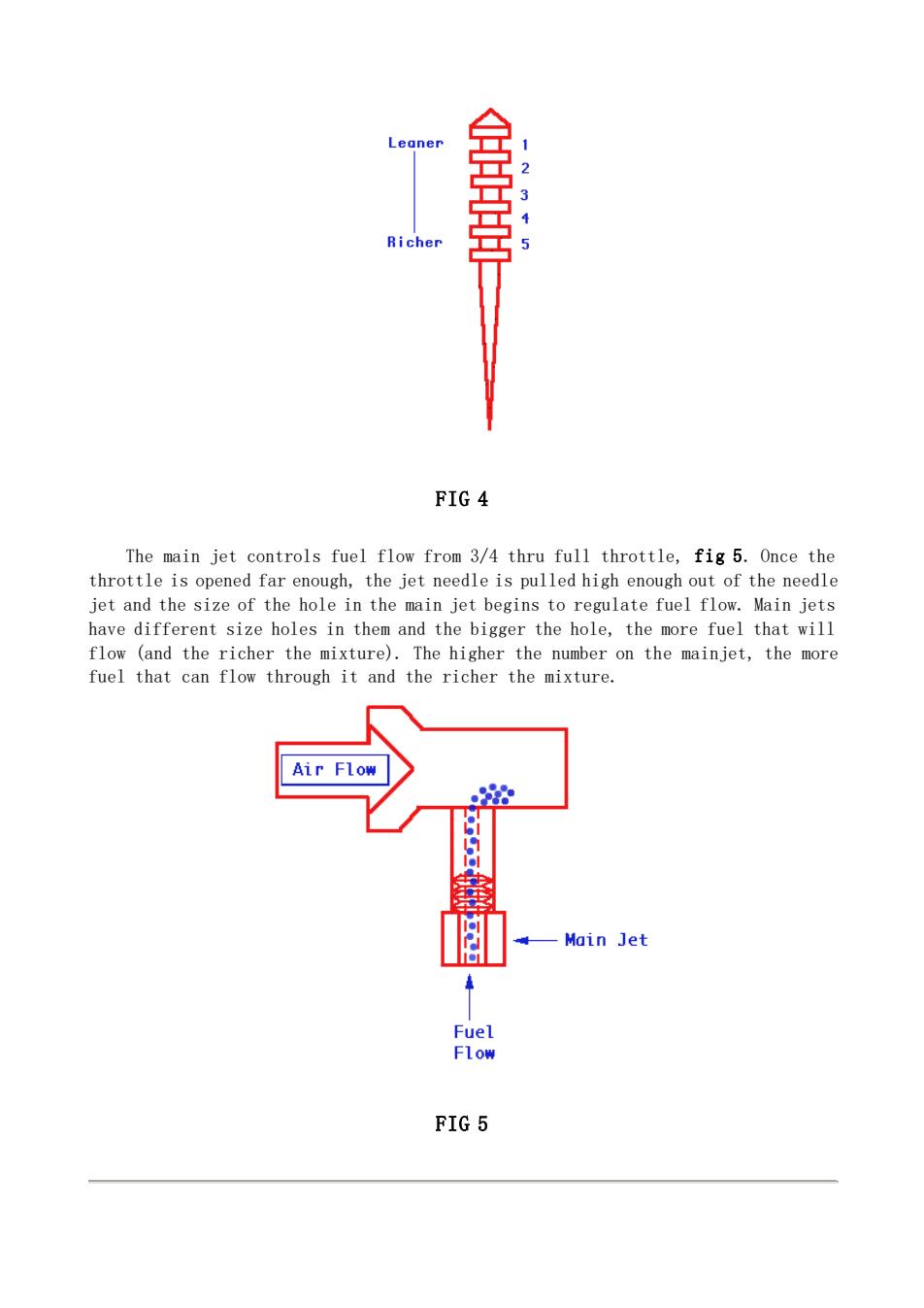

valves have numbers on them that explains how much the cutaway is. If there is a 3 stamped into the slide, it has a 3.0mm cutaway, while a 1 will have a 1.0mm cutaway (which will be richer than a 3). FIG 3 The jet needle and needle jet affects carburetion from 1/4 thru 3/4 throttle. The jet needle is a long tapered rod that controls how much fuel can be drawn into the carburetor venturi. The thinner the taper, the richer the mixture. The thicker the taper, the leaner the mixture since the thicker taper will not allow as much fuel into the venturi as a leaner one. The tapers are designed very precisely to give different mixtures at different throttle openings. Jet needles have grooves cut into the top. A clip goes into one of these grooves and holds it from falling or moving from the slide. The clip position can be changed to make an engine run richer or leaner, fig 4. If the engine needs to run leaner, the clip would be moved higher. This will drop the needle farther down into the needle jet and cause less fuel to flow past it. If the clip is lowered, the jet needle is raised and the mixture will be richer. The needle jet is where the jet needle slides into. Depending on the inside diameter of the needle jet, it will affect the jet needle. The needle jet and jet needle work together to control the fuel flow between the 1/8 thru 3/4 range. Most of the tuning for this range is done to the jet needle, and not the needle jet

LeanerRicherFIG 4Themainjet controlsfuelflowfrom3/4thrufullthrottle,fig5.Oncethethrottle is opened far enough,the jet needleis pulledhigh enough out of the needlejet and the size of the hole in the main jet begins to regulate fuel flow.Main jetshave different size holes in them and the bigger the hole, the more fuel that willflow (and the richer the mixture).Thehigher the number on the mainjet,the morefuel that can flow through it and the richer the mixture.AirFlowMainJet01-FuelFlowFIG5

FIG 4 The main jet controls fuel flow from 3/4 thru full throttle, fig 5. Once the throttle is opened far enough, the jet needle is pulled high enough out of the needle jet and the size of the hole in the main jet begins to regulate fuel flow. Main jets have different size holes in them and the bigger the hole, the more fuel that will flow (and the richer the mixture). The higher the number on the mainjet, the more fuel that can flow through it and the richer the mixture. FIG 5

The choke system is used tostart cold engines.Sincethefuel in a cold engineis sticking to the cylinder walls due to condensation, the mixture is too lean forthe engine to start. The choke system will add fuel to the engine to compensate forthe fuel that is stuck to the cylinder walls. Once the engine is warmed up,condensationisnotaproblem,andthechokeisnotneeded.Theair/fuelmixturemustbechanges tomeet thedemandsof theneedsof theengine.The ideal air/fuel ratiois l4.7 grams of air to l gram of fuel. This ideal ratiois only achieved for a very short period while the engine is running.Due to theincomplete vaporization of fuel at slow speeds or the additional fuel required athigh speeds, the actual operational air/fuel ratio is usually richer.Figure6 showsthe actual air/fuel ratio for any given throttle opening.Lean18:116:114.7:114:1Air/Fuel12: 1Ratio10:18:16: 1Rich·FullStartIdleCruiseThrottleFIG 6Carburetor Jetting TroubleshootingCarburetor troubleshooting is simple once the basic principles are known.Thefirst step is to find where the engine is running poorly, fig 7.It must be rememberedthatcarburetor jettingisdetermined bythe throttleposition,not enginespeedIftheengineishavingtroublesatlowrpm(idletol/4throttle),thepilotsystemorslidevalveisthelikelyproblem.Iftheenginehasproblemsbetween1/4and3/4throttle,the jet needle and needlejet (most likelythe jet needle) islikelytheproblem. If the engine is running poorly at 3/4 to full throttle, the main jet isthe likely problem

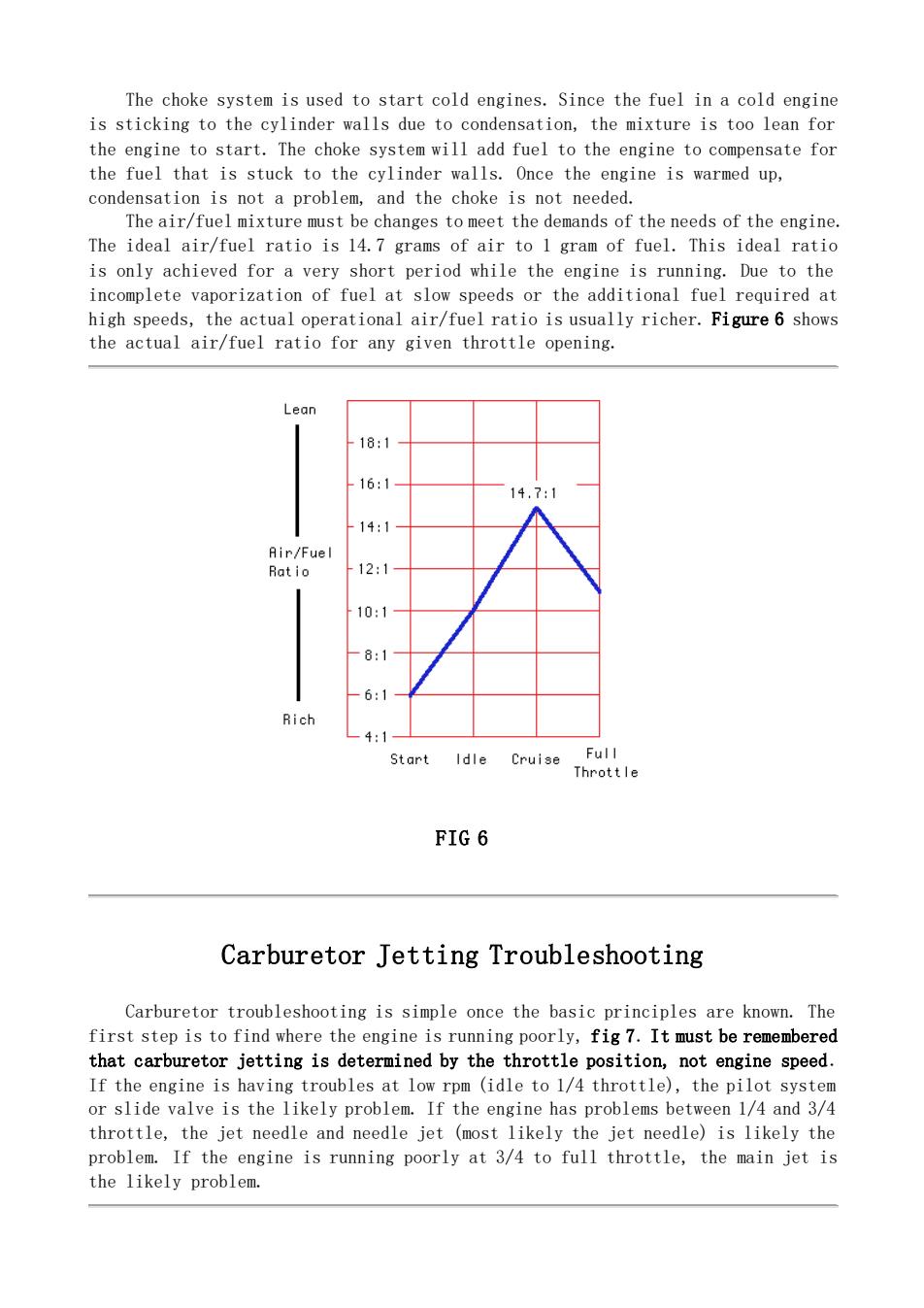

The choke system is used to start cold engines. Since the fuel in a cold engine is sticking to the cylinder walls due to condensation, the mixture is too lean for the engine to start. The choke system will add fuel to the engine to compensate for the fuel that is stuck to the cylinder walls. Once the engine is warmed up, condensation is not a problem, and the choke is not needed. The air/fuel mixture must be changes to meet the demands of the needs of the engine. The ideal air/fuel ratio is 14.7 grams of air to 1 gram of fuel. This ideal ratio is only achieved for a very short period while the engine is running. Due to the incomplete vaporization of fuel at slow speeds or the additional fuel required at high speeds, the actual operational air/fuel ratio is usually richer. Figure 6 shows the actual air/fuel ratio for any given throttle opening. FIG 6 Carburetor Jetting Troubleshooting Carburetor troubleshooting is simple once the basic principles are known. The first step is to find where the engine is running poorly, fig 7. It must be remembered that carburetor jetting is determined by the throttle position, not engine speed. If the engine is having troubles at low rpm (idle to 1/4 throttle), the pilot system or slide valve is the likely problem. If the engine has problems between 1/4 and 3/4 throttle, the jet needle and needle jet (most likely the jet needle) is likely the problem. If the engine is running poorly at 3/4 to full throttle, the main jet is the likely problem