HowAutomaticTransmissionsWorkAutomaticTransmissions:WhatMakesThemWorkIn thismonth's Tech Centercolumnwe'regoingtotakealookatthe innerworkings of thestandard automatictransmission.Thenwe'll discusssomewaystokeepyourtrannyhealthyandgiveit long life.Whatisan automatictransmission?Whatdoes itdo,andwhydoweneed it?First,a little history.Theearliestautomobilesofferedonlymanual transmissions.Similar inprincipleto today's stick-shiftvehicles,these cars,such as theFord Model T,sported twoforward gears and one reverse,coupledto the engine viaaseries of pedals.Butas cars grew largerand traffic got worse,engineers began searching foraway to havethe car"automatically"shift from onegeartoanother.Designers spent decades perfecting the modern automatic transmission.Althoughgroundworkhadbeenlaid intheearly1900sbyGemanmanufacturersofmarineengines,thefirstappearanceofanautomatictransmission inacar didnotoccuruntil 1938,whenGM invented"Hydra-maticDrive."Thefirstproductionautomobiletoofferthistransmission wasan Oldsmobile,whichrolled off the line in1940.ThiswasfollowedinclosesuccessionbyChrysler(theirspiesmusthavebeenworkingovertime),whichin1941introducedthree separatemodelswith"Vacamatic"(theychangedthenameto"FluidDrive"in1942)By1948,mostmajorAmericanautomakersofferedpassengercarswithoptionalfullyautomatictransmissions as an option.Thetechnologycamealongata propitioustimeinAmericanhistory.TheUnitedStates,rifewithvictoryfromWorld War ll and building up steam forthe post-war boom,produced scads of babies and cars (notnecessarily inthatorder).Intothosecars theydroppedthousands of automatictransmissions.It couldbefairlyarguedthattheautomatictransmission,with its simplicityandeaseofuse,offereduptheautomobiletothemasses,fulfillingthepromiseof President HerbertHoover,whomagenerationearlierhadpromised"acar in everygarageand a chicken in everypot."Atthevery least it widened the vistas of anincreasinglymobileworkforce,fedtheflowofmigrationtothesuburbs,andwelcomedwomenbackintotheeconomyfollowingthewareffort.Theautomatictransmissiondidthisbyofferinga"no-muss,no-fuss"formof shifting.Nomoremissedshiftgates.No engine lugging orracing.No torn-stocking,high-heel clutch-pedalingdramas.None of that. Justpressthegas andgoOkay,enoughwithhistory.Let'stakealook insideanautomatictransmission.TheTorque ConverterThe key to themodern automatic transmission is the torque converter. It takes the place of a clutch in amanualtransmissionAdirectdescendantofan earlier component calledafluid coupling.thetorqueconverterofferstheadvantageof multiplyingtheturningpowerprovidedbytheengine.It isconnectedtothemotorbymeansof ametal rodknownasthetransmissionshaft (sometimescalledtheinput shaft),whichfitsnexttobut does nottouchtheengine crankshaft.Repeat:there is no direct connection between the engine and the transmission.Instead, the engine turns the transmission bymeans of a process called hydraulic coupling.Think oftwo electric fans in a room.Line them up afewfeet apart, one in front of theother, bothfacing thesame direction.Nowtun on the rear fan.What happens? if you'veturned thefan up high enough,and if thefans are closeenoughtogether, the frontfan will begin to turn as well. In this same manner does the enginecrankshaft influencethe transmissionshaft,causing it to rotate

How Automatic Transmissions Work Automatic Transmissions: What Makes Them Work In this month's Tech Center column we're going to take a look at the inner workings of the standard automatic transmission. Then we'll discuss some ways to keep your tranny healthy and give it long life. What is an automatic transmission? What does it do, and why do we need it? First, a little history. The earliest automobiles offered only manual transmissions. Similar in principle to today's stick -shift vehicles, these cars, such as the Ford Model T, sported two forward gears and one reverse, coupled to the engine via a series of pedals. But as cars grew larger and traffic got worse, engineers began searching for a way to have the car "automatically" shift from one gear to another. Designers spent decades perfecting the modern automatic transmission. Although groundwork had been laid in the early 1900s by German manufacturers of marine engines, the first appearance of an automatic transmission in a car did not occur until 1938, when GM invented "Hydra-matic Drive." The first production automobile to offer this transmission was an Oldsmobile, which rolled off the line in 1940. This was followed in close succession by Chrysler (their spies must have been working overtime), which in 1941 introduced three separate models with "Vacamatic" (they changed the name to "Fluid Drive" in 1942). By 1948, most major American automakers offered passenger cars with optional fully automatic transmissions as an option. The technology came along at a propitious time in American history. The United States, rife with victory from World War II and building up steam for the post-war boom, produced scads of babies and cars (not necessarily in that order). Into those cars they dropped thousands of automatic transmissions. It could be fairly argued that the automatic transmission, with its simplicity and ease of use, offered up the automobile to the masses, fulfilling the promise of President Herbert Hoover, whom a generation earlier had promised "a car in every garage and a chicken in every pot." At the very least it widened the vistas of an increasingly mobile workforce, fed the flow of migration to the suburbs, and welcomed women back into the economy following the war effort. The automatic transmission did this by offering a "no-muss, no-fuss" form of shifting. No more missed shift gates. No engine lugging or racing. No torn-stocking, high-heel clutch-pedaling dramas. None of that. Just press the gas and go. Okay, enough with history. Let's take a look inside an automatic transmission. The Torque Converter The key to the modern automatic transmission is the torque converter. It takes the place of a clutch in a manual transmission. A direct descendant of an earlier component called a fluid coupling, the torque converter offers the advantage of multiplying the turning power provided by the engine. It is connected to the motor by means of a metal rod known as the transmission shaft (sometimes called the input shaft), which fits next to but does not to uch the engine crankshaft. Repeat: there is no direct connection between the engine and the transmission. Instead, the engine turns the transmission by means of a process called hydraulic coupling. Think of two electric fans in a room. Line them up a few feet apart, one in front of the other, both facing the same direction. Now turn on the rear fan. What happens? If you've turned the fan up high enough, and if the fans are close enough together, the front fan will begin to turn as well. In this same manner does the engine crankshaft influence the transmission shaft, causing it to rotate

The identicalprocessoccurs in atorque converter,exceptthattransmissionfluidtakestheplaceofair.But there'smore.Insidethetorque converterareseveral componentsthat helpmultiplythepower.Thesearethe impeller (orpump),theturbine, and thestator(orguidewheel)A torque converter is like a giant doughnut. The impeller and the turbine (the two fans in the analogy above)face one another insidethe round metal casing.The impeller is on the engine side,the turbine on the trannyside.BothofthesecomponentshavebladesthatcatchthetransmissionfluidandcausethemtospinPicture two halves of a chambered nautilus, and this will perhaps give you a better image.As onefan begins to spin,theother will spinas well.Through centrifugalforce,thefluid moves totheoutsideof theblades,where it is redirected bya thirdfan, called a stator,back to theturbine side.This continual flowoffluidiswhatcausesthepowertobemultipliedTheLockupTorqueConverterBecausetheonlyconnectionbetweentwo sides ofatorque converteris afluid connection,thereis alwaysalittleslippage,runningfromabout2-8%.Toincreaseefficiencyandgasmileage,mostmodemautomatictransmissionsalsohavesomethingcalled a lockupclutch (aka,torqueconverterclutch).It works like this. As the speed of the car nears 40 miles per hour, the highly pressurized transmission fluid ischanneled throughthetransmissionshaftand activates aclutch piston.Thismetal pinlockstheturbinetotheimpeller,ineffectbypassingthetorque converter.It remains this wayuntil thevehicleslowsbelow40mph,atwhich pointthe clutchpistondisengages and the torqueconverterkicks in again.Simple,right?Planetary GearsetsNo,we're nottalking Mars and Venus here.These aredifferent-sized gears.just likethe ones onthebackofyourmountainbike.They're called planetary because they're circular and revolvearound a central gearknown as a sun gear.If it sounds likeour solar system,you're right --it's designed on the same model.Aplanetarygearsetsystemhasthreemajorelements:Sungear?Planet carrier, drum, and pistonsRinggear anddrumAithoughthere are differentvariations on theplanetary gearset theme (forinstance,sometrannies have twosets of planetarygears,two sun gears,etc.),the essentialdesignhas remained unchangedformorethan halfa century.OneexampleistheSimpsongeartrain.Inthisdesign,twosetsofplanetarygearsetsmeshwithtwosungearsThe two sun gears are in turn connected together to form what is called a common sun gear.The Simpsongeartrain is an older,three-speed designno longerin popularuse, but it will give us an idea oftheway anautomatictransmissionworks.Inneutral,withtheexceptionofthefree-turninginputshaft,thereisnomotionwithinthetransmissionIn firstgear,thefrontplanetarygearisengaged,lockingontothe input shaft.Think of thisasthe lowgear onyourbicycle.Thegearratiohere is2.46:1.Thisgetsthecarmoving.Oncethecarisrolling,thetransmissionshifts intosecond.Theintermediatebandisapplied,holdingstationary the high clutch drum, the reverse clutch, and the sun gear. The forward clutch is applied, lockingthe input shaft to the ring gear. The gear ratio here is 1.46:1.In high gear, the ratio goes to 1:1. All planetary gear members are locked to each other and to the output shaft.Inreversemode,thereverseandhigh clutchisapplied.The inputshaft is lockedtothereverseandhigh

The identical process occurs in a torque converter, except that transmission fluid takes the place of air. But there's more. Inside the torque converter are several components that help multiply the power. These are the impeller (or pump), the turbine, and the stator (or guide wheel). A torque converter is like a giant doughnut. The impeller and the turbine (the two fans in the analogy above) face one another inside the round metal casing. The impeller is on the engine side, the turbine on the tranny side. Both of these components have blades that catch the transmission fluid and cause them to spin. Picture two halves of a chambered nautilus, and this will perhaps give you a better image. As one fan begins to spin, the other will spin as well. Through centrifugal force, the fluid moves to the outside of the blades, where it is redirected by a third fan, called a stator, back to the turbine side. This continual flow of fluid is what causes the power to be multiplied. The Lockup Torque Converter Because the only connection between two sides of a torque converter is a fluid connection, there is always a little slippage, running from about 2-8%. To increase efficiency and gas mileage, most modern automatic transmissions also have something called a lockup clutch (aka, torque converter clutch). It works like this. As the speed of the car nears 40 miles per hour, the highly pressurized transmission fluid is channeled through the transmission shaft and activates a clutch piston. This metal pin locks the turbine to the impeller, in effect bypassing the torque converter. It remains this way until the vehicle slows below 40 mph, at which point the clutch piston disengages and the torque converter kicks in again. Simple, right? Planetary Gearsets No, we're not talking Mars and Venus here. These are different-sized gears, just like the ones on the back of your mountain bike. They're called planetary because they're circular and revolve around a central gear known as a sun gear. If it sounds like our solar system, you're right - it's designed on the same model. A planetary gearset system has three major elements: • Sun gear • Planet carrier, drum, and pistons • Ring gear and drum Although there are different variations on the planetary gearset theme (for instance, some trannies have two sets of planetary gears, two sun gears, etc.), the essential design has remained unchanged for more than half a century. One example is the Simpson geartrain. In this design, two sets of planetary gearsets mesh with two sun gears. The two sun gears are in turn connected together to form what is called a common sun gear. The Simpson geartrain is an older, three-speed design no longer in popular use, but it will give us an idea of the way an automatic transmission works. In neutral, with the exception of the free-turning input shaft, there is no motion within the transmission. In first gear, the front planetary gear is engaged, locking onto the input shaft. Think of this as the low gear on your bicycle. The gear ratio here is 2.46:1. This gets the car moving. Once the car is rolling, the transmission shifts into second. The intermediate band is applied, holding stationary the high clutch drum, the reverse clutch, and the sun gear. The forward clutch is applied, locking the input shaft to the ring gear. The gear ratio here is 1.46:1. In high gear, the ratio goes to 1:1. All planetary gear members are locked to each other and to the output shaft. In reverse mode, the reverse and high clutch is applied. The input shaft is locked to the reverse and high

clutch drum, theinput shell, and the sungear.Gear ratioforreverse is2.17:1.ThesearethebasicworkingsoraSimpsontransmissionClutches,Bands,and Servo PistonsGear shifting in an automatic transmission is very similar to the action taken while riding yourmountain bike -exceptthataseriesofvalves,sensors,andothercomponentstaketheplaceofyourbrain,decidingwhentoupshiftanddownshifttoalargerorsmallergearSome carsuse amultiple-disc clutchoperation.In this setup,a series offrictiondiscs areplaced betweensteelplates.Theclutchalsohasapistonandretumsprings.ThiswholeassemblyisknownasaclutchpackWhen fluid pressure is appliedto theclutch pack,the pistonengages,locking theassembly together anddriving thewheels.When pressure releases (forinstance, the engine goes to idle),thepistondisengages andthewheels stopturningOthercarsusetransmissionbands.Inthisdesign,aflexiblemetal ringfitsaroundtheoutsideoftheclutchhousing.It tightens to engagethegears,and loosens torelease them.This typeoftransmission also uses aservopistontoactivateand deactivatethebands.The transmission is connected to the wheels via an output shaft, which meshes to the axles in a variety ofways, depending on your car's design.The transmission turns the output shaft, which in turn spins the axles,which intum makethewheels go.There areamyriad ofwaystodo this.Sinceyoucan haveafront-orrear-wheel drive car,and since engines canbelocated in thefront,rear,oreven middleofthevehicle,theengineering choices are infinite.Suffice it to say,theaxles drivethe wheels.Manymodernfront-wheel-drivecarsusean assemblycalledatransaxle,which saves weight (therebyincreasing mileage)and space.Thetransaxlehouses thetransmissionand the axles ina singleunit thatweds totheengine.In Closing...Well, there you have it: an automatic transmission primer. We realize that this is a very generalized overview.Still,wewantedyoutohaveabasic understanding ofhowyourautomatictransmissionworks.ForotherEdmunds.com articles on the ins and outs of transmissions, both manual and automatic, please click on thelinksbelowIf you have ever driven a car with an automatic transmission, then you knowthat there are two bigdifferences betweenan automatic transmission and a manual transmissionThereisnoclutchpedal inanautomatictransmissioncarThereisnogear shift inanautomatictransmissioncar.Onceyouputthetransmission intodriveeverything else is automatic.Boththeautomatictransmission(plusitstorqueconverter)andamanualtransmission(withitsclutch)accomplishexactlythe samething,buttheydo it intotallydifferentways.Itturnsoutthatthewayanautomatictransmissiondoesitisabsolutelyamazing!

clutch drum, the input shell, and the sun gear. Gear ratio for reverse is 2.17:1. These are the basic workings or a Simpson transmission. Clutches, Bands, and Servo Pistons Gear shifting in an automatic transmission is very similar to the action taken while riding your mountain bike - except that a series of valves, sensors, and other components take the place of your brain, deciding when to upshift and downshift to a larger or smaller gear. Some cars use a multiple-disc clutch operation. In this setup, a series of friction discs are placed between steel plates. The clutch also has a piston and return springs. This whole assembly is known as a clutch pack. When fluid pressure is applied to the clutch pack, the piston engages, locking the assembly together and driving the wheels. When pressure releases (for instance, the engine goes to idle), the piston disengages and the wheels stop turning. Other cars use transmission bands. In this design, a flexible metal ring fits around the outside of the clutch housing. It tightens to engage the gears, and loosens to release them. This type of transmission also uses a servo piston to activate and deactivate the bands. The transmission is connected to the wheels via an output shaft, which meshes to the axles in a variety of ways, depending on your car's design. The transmission turns the output shaft, which in turn spins the axles, which in turn make the wheels go. There are a myriad of ways to do this. Since you can have a front- or rear-wheel drive car, and since engines can be located in the front, rear, or even middle of the vehicle, the engineering choices are infinite. Suffice it to say, the axles drive the wheels. Many modern front-wheel-drive cars use an assembly called a transaxle, which saves weight (thereby increasing mileage) and space. The transaxle houses the transmission and the axles in a single unit that weds to the engine. In Closing. Well, there you have it: an automatic transmission primer. We realize that this is a very generalized overview. Still, we wanted you to have a basic understanding of how your automatic transmission works. For other Edmunds.com articles on the ins and outs of transmissions, both manual and automatic, please click on the links below: If you have ever driven a car with an automatic transmission, then you know that there are two big differences between an automatic transmission and a manual transmission: • There is no clutch pedal in an automatic transmission car. • There is no gear shift in an automatic transmission car. Once you put the transmission into drive, everything else is automatic. Both the automatic transmission (plus its torque converter) and a manual transmission (with its clutch) accomplish exactly the same thing, but they do it in totally different ways. It turns out that the way an automatic transmission does it is absolutely amazing!

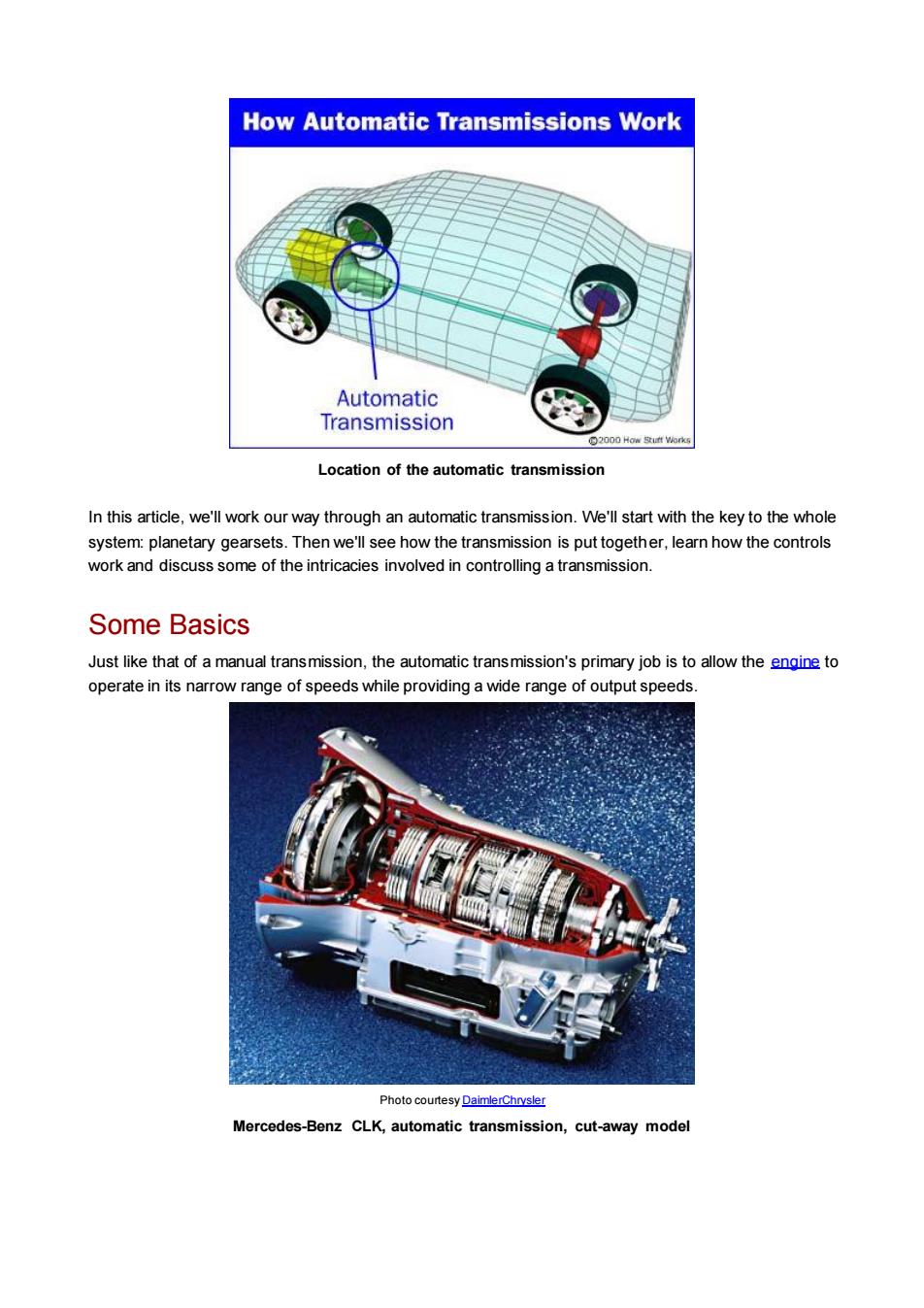

How Automatic Transmissions WorkAutomaticTransmissionLocationoftheautomatictransmissionInthisarticle,we'llworkourwaythroughanautomatictransmission.We'll startwiththekeytothewholesystem:planetarygearsets.Thenwe'llseehowthetransmissionisputtogether,learnhowthecontrolsworkanddiscusssomeoftheintricaciesinvolved incontrollingatransmission.SomeBasicsJustlikethatofamanual transmission,theautomatictransmission'sprimaryjobisto allowtheenginetooperate in its narrow rangeof speeds while providinga widerange of output speeds.PhotocourtesyDaimlerChrvslerMercedes-BenzCLK,automatictransmission,cut-awaymodel

Location of the automatic transmission In this article, we'll work our way through an automatic transmission. We'll start with the key to the whole system: planetary gearsets. Then we'll see how the transmission is put together, learn how the controls work and discuss some of the intricacies involved in controlling a transmission. Some Basics Just like that of a manual transmission, the automatic transmission's primary job is to allow the engine to operate in its narrow range of speeds while providing a wide range of output speeds. Photo courtesy DaimlerChrysler Mercedes-Benz CLK, automatic transmission, cut-away model

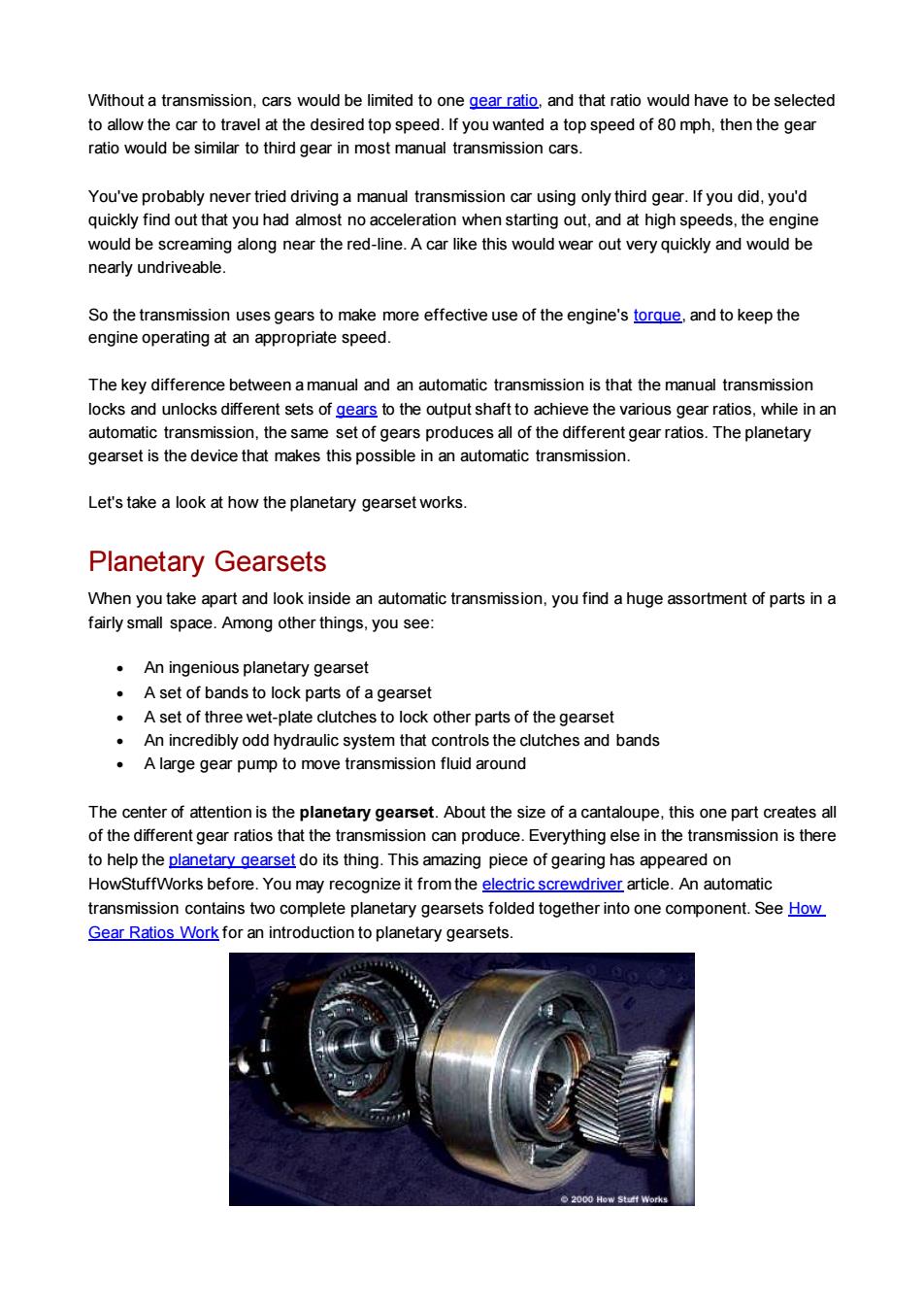

Withoutatransmission,cars wouldbe limitedto onegearratio,andthatratio wouldhavetobeselectedtoallowthecartotravelatthedesiredtopspeed.If youwanted atopspeed of8omph,thenthegealratiowould besimilartothirdgearinmostmanual transmission cars.You'veprobablynevertrieddrivinga manual transmission car usingonlythird gear.Ifyoudid,you'dquicklyfind out that you had almost no acceleration when starting out, and at high speeds,the enginewould be screaming along near the red-line. A car like this would wear out very quickly and would benearlyundriveable.Sothetransmissionusesgearstomakemoreeffectiveuseoftheengine'storgue.andtokeeptheengineoperatingatanappropriatespeed.Thekeydifferencebetweenamanualandanautomatictransmissionisthatthemanualtransmissionlocksandunlocksdifferentsetsofgearstotheoutputshafttoachievethevariousgearratios,while inanautomatic transmission, the same set of gears produces all of the different gear ratios. The planetarygearsetisthedevicethatmakesthispossibleinanautomatictransmission.Let's takea look at howthe planetary gearset works.PlanetaryGearsetsWhenyoutakeapart andlookinsideanautomatictransmission,youfindahugeassortment of parts inafairly small space. Among other things, you see:AningeniousplanetarygearsetA set of bands to lock parts of a gearsetAsetof threewet-plateclutchestolock otherpartsof thegearsetAnincrediblyoddhydraulicsystemthatcontrolstheclutchesandbands。A large gear pump to move transmission fluid aroundThe center of attention is the planetary gearset. About the size of a cantaloupe, this one part creates allofthedifferentgearratiosthatthetransmissioncanproduce.Everythingelseinthetransmissionistheretohelptheplanetarygearsetdo itsthing.Thisamazingpieceofgearinghas appearedonHowStuffWorks before.Youmay recognize it fromthe electric screwdriverarticle.An automatictransmissioncontainstwocompleteplanetarygearsetsfoldedtogetherintoonecomponent.SeeHowGearRatiosWorkforanintroductiontoplanetarygearsets

Without a transmission, cars would be limited to one gear ratio, and that ratio would have to be selected to allow the car to travel at the desired top speed. If you wanted a top speed of 80 mph, then the gear ratio would be similar to third gear in most manual transmission cars. You've probably never tried driving a manual transmission car using only third gear. If you did, you'd quickly find out that you had almost no acceleration when starting out, and at high speeds, the engine would be screaming along near the red-line. A car like this would wear out very quickly and would be nearly undriveable. So the transmission uses gears to make more effective use of the engine's torque, and to keep the engine operating at an appropriate speed. The key difference between a manual and an automatic transmission is that the manual transmission locks and unlocks different sets of gears to the output shaft to achieve the various gear ratios, while in an automatic transmission, the same set of gears produces all of the different gear ratios. The planetary gearset is the device that makes this possible in an automatic transmission. Let's take a look at how the planetary gearset works. Planetary Gearsets When you take apart and look inside an automatic transmission, you find a huge assortment of parts in a fairly small space. Among other things, you see: • An ingenious planetary gearset • A set of bands to lock parts of a gearset • A set of three wet-plate clutches to lock other parts of the gearset • An incredibly odd hydraulic system that controls the clutches and bands • A large gear pump to move transmission fluid around The center of attention is the planetary gearset. About the size of a cantaloupe, this one part creates all of the different gear ratios that the transmission can produce. Everything else in the transmission is there to help the planetary gearset do its thing. This amazing piece of gearing has appeared on HowStuffWorks before. You may recognize it from the electric screwdriver article. An automatic transmission contains two complete planetary gearsets folded together into one component. See How Gear Ratios Work for an introduction to planetary gearsets