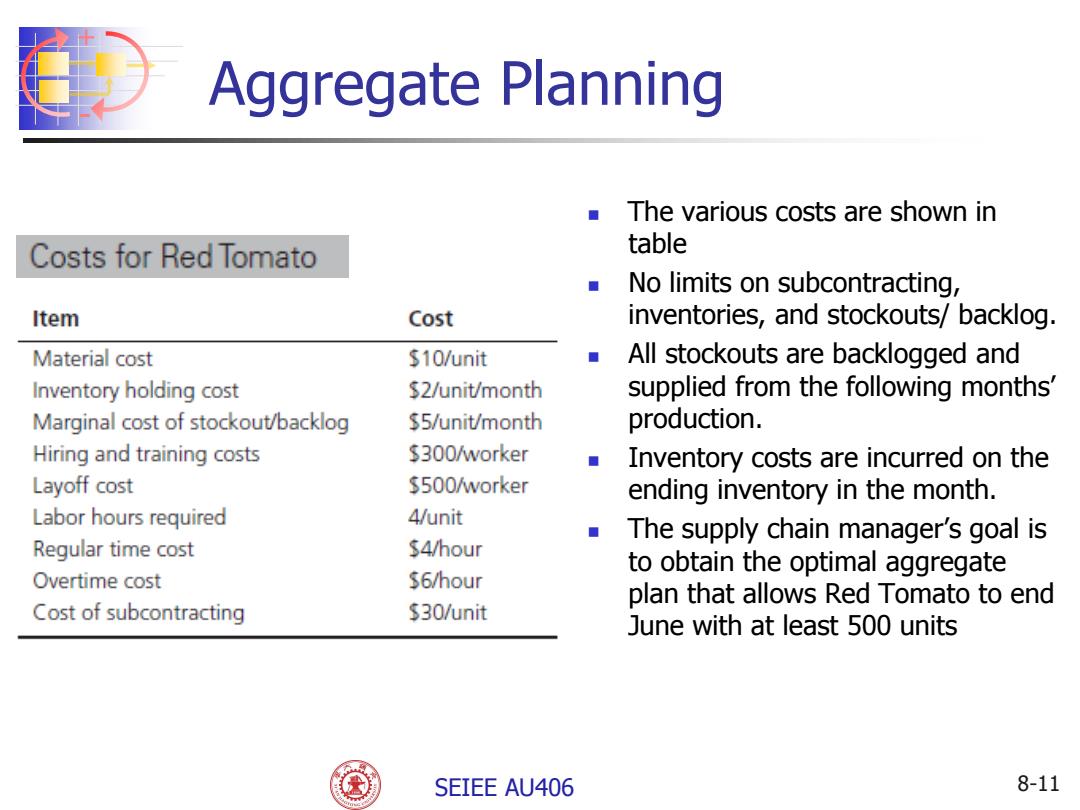

Aggregate Planning The various costs are shown in Costs for Red Tomato table No limits on subcontracting, Item Cost inventories,and stockouts/backlog. Material cost $10/unit All stockouts are backlogged and Inventory holding cost $2/unit/month supplied from the following months' Marginal cost of stockout/backlog $5/unit/month production. Hiring and training costs $300/worker Inventory costs are incurred on the Layoff cost $500/worker ending inventory in the month. Labor hours required 4/unit The supply chain manager's goal is Regular time cost $4/hour to obtain the optimal aggregate Overtime cost $6/hour plan that allows Red Tomato to end Cost of subcontracting $30/unit June with at least 500 units SEIEE AU406 8-11

+ - SEIEE AU406 8-11 Aggregate Planning The various costs are shown in table No limits on subcontracting, inventories, and stockouts/ backlog. All stockouts are backlogged and supplied from the following months’ production. Inventory costs are incurred on the ending inventory in the month. The supply chain manager’s goal is to obtain the optimal aggregate plan that allows Red Tomato to end June with at least 500 units

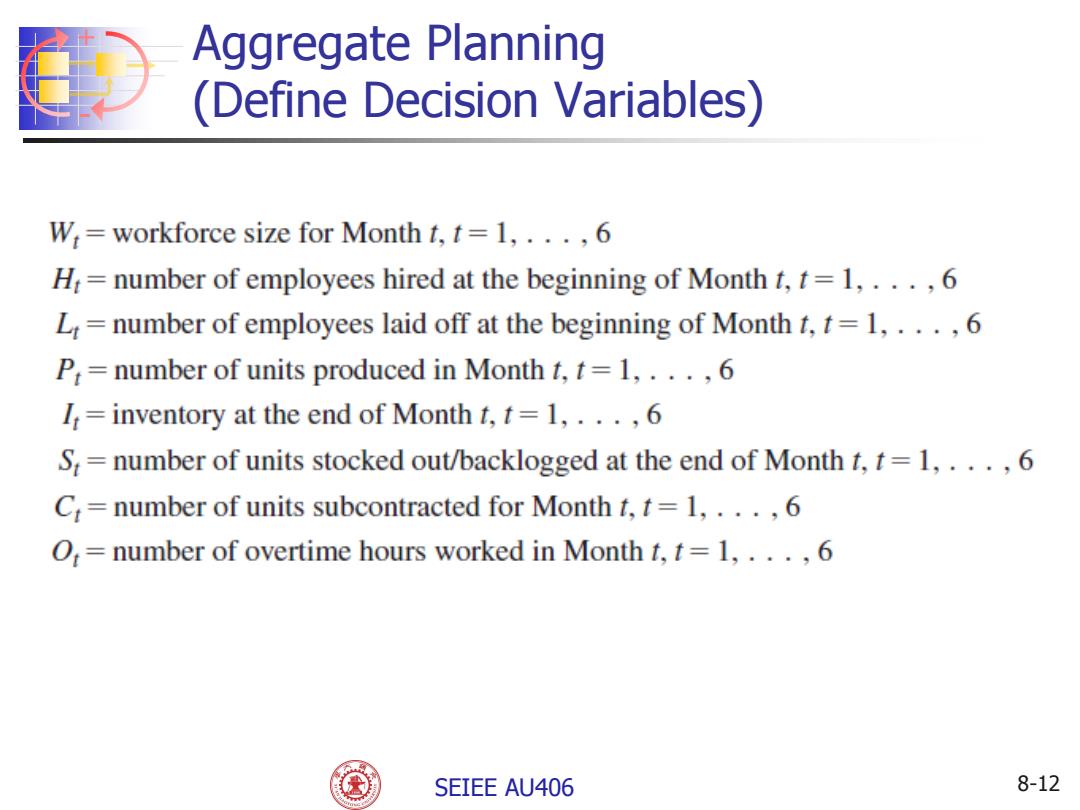

Aggregate Planning (Define Decision Variables) W workforce size for Month t,t=1,...6 H:=number of employees hired at the beginning of Month t,t=1,...,6 L=number of employees laid off at the beginning of Month t,t=1,...6 P,number of units produced in Month t,t=1,...6 I=inventory at the end of Month t,t=1,...,6 S=number of units stocked out/backlogged at the end of Month t,t=1,...,6 C.=number of units subcontracted for Month t,t=1,...,6 O,number of overtime hours worked in Month t,t=1,...6 SEIEE AU406 8-12

+ - SEIEE AU406 8-12 Aggregate Planning (Define Decision Variables)