Drivers of Supply Chain Performance Information data and analysis regarding inventory, transportation,facilities throughout the supply chain potentially the biggest driver of supply chain performance ■ Sourcing functions a firm performs and functions that are outsourced Pricing Price associated with goods and services provided by a firm to the supply chain SEIEE AU406 11

+ - SEIEE AU406 Information data and analysis regarding inventory, transportation, facilities throughout the supply chain potentially the biggest driver of supply chain performance Sourcing functions a firm performs and functions that are outsourced Pricing Price associated with goods and services provided by a firm to the supply chain 11 Drivers of Supply Chain Performance

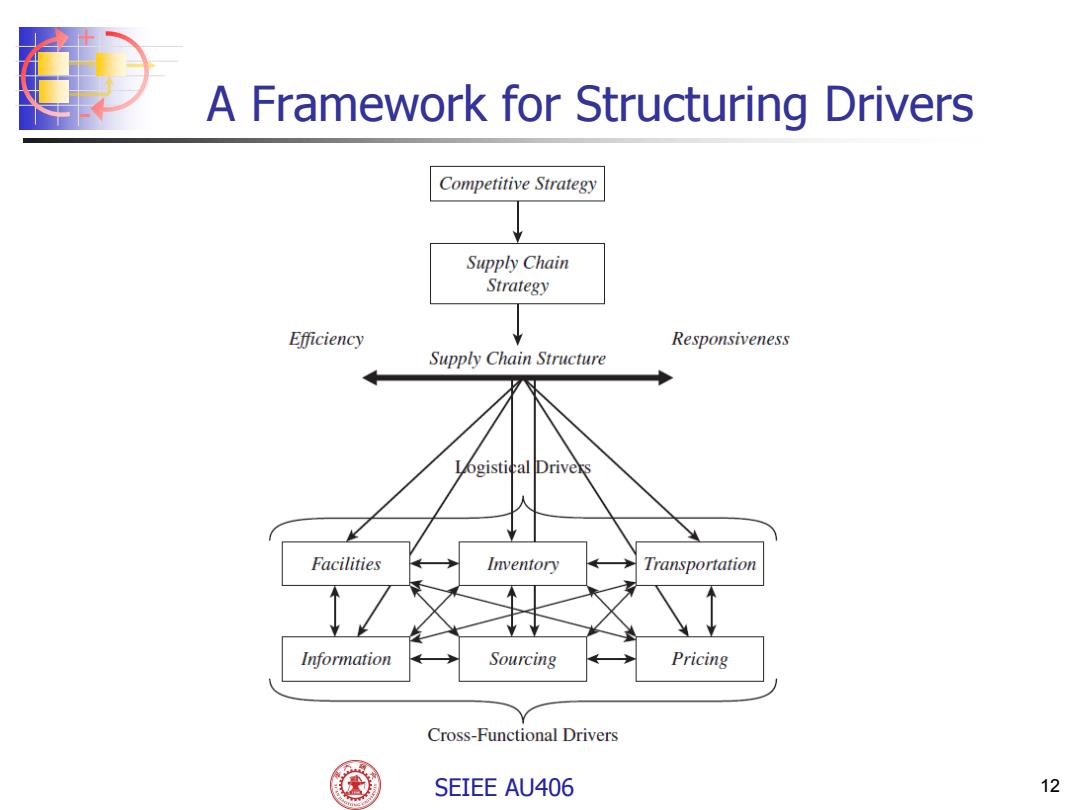

A Framework for Structuring Drivers Competitive Strategy Supply Chain Strategy Efficiency Responsiveness Supply Chain Structure Logistical Drivers Facilities Inventory Transportation Information Sourcing Pricing Cross-Functional Drivers SEIEE AU406 12

+ - SEIEE AU406 12 A Framework for Structuring Drivers

Facilities o b Role in the supply chain the "where"of the supply chain manufacturing or storage (warehouses) ■ Role in the competitive strategy economies of scale (efficiency priority) larger number of smaller facilities (responsiveness priority) Two major types of facilities are production sites and storage sites. SEIEE AU406 13

+ - SEIEE AU406 13 Facilities Role in the supply chain the “where” of the supply chain manufacturing or storage (warehouses) Role in the competitive strategy economies of scale (efficiency priority) larger number of smaller facilities (responsiveness priority) Two major types of facilities are production sites and storage sites

Components of Facilities Decisions Components of facilities decisions Location centralization (efficiency)vs.decentralization (responsiveness) s other factors to consider(e.g.,proximity to customers) Capacity (flexibility versus efficiency) Manufacturing methodology (product focused versus process focused) Warehousing methodology(SKU storage,job lot storage, cross-docking) Overall trade-off:Responsiveness versus efficiency SEIEE AU406 14

+ - SEIEE AU406 14 Components of Facilities Decisions Location centralization (efficiency) vs. decentralization (responsiveness) other factors to consider (e.g., proximity to customers) Capacity (flexibility versus efficiency) Manufacturing methodology (product focused versus process focused) Warehousing methodology (SKU storage, job lot storage, cross-docking) Overall trade-off: Responsiveness versus efficiency Components of facilities decisions

Facilities Example:Toyota and Honda Both Toyota and Honda use facilities decisions to be more responsive to their customers. These companies have an end goal of opening manufacturing facilities in every major market that they enter. While there are other benefits to opening local facilities,such as protection from currency fluctuation and trade barriers,the increase in responsiveness plays a large role in Toyota's and Honda's decision to place facilities in their local markets. The flexibility of Honda facilities to assemble both SUVs and cars in the same plant allowed the company to keep costs down in the downturn of 2008. While competitors'SUV production facilities were idle,Honda facilities maintained a high level of utilization. SEIEE AU406 15

+ - SEIEE AU406 15 Both Toyota and Honda use facilities decisions to be more responsive to their customers. These companies have an end goal of opening manufacturing facilities in every major market that they enter. While there are other benefits to opening local facilities, such as protection from currency fluctuation and trade barriers, the increase in responsiveness plays a large role in Toyota’s and Honda’s decision to place facilities in their local markets. The flexibility of Honda facilities to assemble both SUVs and cars in the same plant allowed the company to keep costs down in the downturn of 2008. While competitors’ SUV production facilities were idle, Honda facilities maintained a high level of utilization. Example: Toyota and Honda Facilities