附件24.4 2What kinds of curves does the stator of vane pump consists of?Why could double-acting vane pumps be used for fixed displacement pumps? 3,Observe the single-acting and double-acting vane,what's the difference in the relation between the vane's obliquity in internal slot of rotor and the rotation direction?Why? 4Observe the vanes of the single-acting and double-acting pumps and motors,what's the difference in the relation between the vane's obliquity in internal slot of rotor and the rotation direction?Why? Experiment 3 Experiment of assembling YCY-IB type radial piston pumps 1.General description The oil suction and delivery action of a piston pump depend upon the size change of the chamber produced by reciprocating movement of the pistons within their cylinder bores.For piston pumps,the circular pistons and their corresponding cylinder bores can make high precise match-up and ensure good performance of seal High volumetric and overall efficiencies can be acquired even application under high pressure.The piston pumps can be divided into radial and axial types according to their pistons'arrangements and their different moving directions with respect to the transmission shafts.However,The piston pumps are sensitive to the oil contamination in hydraulic systems and composed of the complex construction.So it is higher costs than other pumps Parameter:Nominal Pressure:32MPa Nominal flow-rate:10~161/min Rated rotational Speed:1000~1500r/min 2.The purpose of the experiment (1)Make a more particular knowledge of the construction features and operating principle of YCY-IB typle radial piston pumps (2)To learn the knowledge of the construction features and operating principle of stroking mechanism of YCY-IB type radial piston pumps 6

附件 24.4 6 2、What kinds of curves does the stator of vane pump consists of ? Why could double-acting vane pumps be used for fixed displacement pumps ? 3、Observe the single-acting and double-acting vane, what’s the difference in the relation between the vane’s obliquity in internal slot of rotor and the rotation direction? Why ? 4、Observe the vanes of the single-acting and double-acting pumps and motors, what’s the difference in the relation between the vane’s obliquity in internal slot of rotor and the rotation direction? Why ? Experiment 3 Experiment of assembling YCY-IB type radial piston pumps 1. General description The oil suction and delivery action of a piston pump depend upon the size change of the chamber produced by reciprocating movement of the pistons within their cylinder bores. For piston pumps, the circular pistons and their corresponding cylinder bores can make high precise match-up and ensure good performance of seal .High volumetric and overall efficiencies can be acquired even application under high pressure. The piston pumps can be divided into radial and axial types according to their pistons’ arrangements and their different moving directions with respect to the transmission shafts. However, The piston pumps are sensitive to the oil contamination in hydraulic systems and composed of the complex construction. So it is higher costs than other pumps. Parameter: Nominal Pressure :32MPa Nominal flow-rate : 10~16l/min Rated rotational Speed : 1000~1500r/min 2. The purpose of the experiment (1) Make a more particular knowledge of the construction features and operating principle of YCY-IB typle radial piston pumps (2) To learn the knowledge of the construction features and operating principle of stroking mechanism of YCY-IB type radial piston pumps

附件24.4 (3)Understand how to regulate the P-Q characteristic curve of YCY-IB typle radial piston pumps (4)List the requirements of the main assembly technology and understand the assembly procedure of YCY-IB typle radial piston pumps 3.Equipment of experimental A YB-type Vane pump for assembly 4.The points for assembly and notes for attention (1)Pay attention to the location of the various parts when the pump is dismantled The parts which have been dismantled should be arranged regularly (2)As the high machining precision the parts of piston pumps is,especially with plunge. oil distribution shaft,servo spool valve,Set Plate,swash plate,the parts which have been dismantled should be arranged regularly and carefully.Surface finishing can not have a friction with a hard object in order to maintain the accuracy of surface roughness of parts. (3)All parts should be assembled as original request when the pump is assembled.Be sure to keep in mind that all parts must not be left out and keep the assembly direction and assembly location of parts correc (4)The parts must be carefully cleaned to ensure that it does not contain any cutting chip and other pollutants before assembling.The washed components which have relative motion should add the appropriate. (5)Must carefully check to make sure if the reciprocating movement of the pistons within their cylinder bores are flexible after the assembly (6)When tightening the Screw,force should be uniform.Note that the order of screw tightening should be symmetrical each other swirling (7)Laboratory report for assembling Vane pumps of YCY-IB type radial piston pumps >

附件 24.4 7 (3) Understand how to regulate the P-Q characteristic curve of YCY-IB typle radial piston pumps (4) List the requirements of the main assembly technology and understand the assembly procedure of YCY-IB typle radial piston pumps 3. Equipment of experimental A YB-type Vane pump for assembly 4. The points for assembly and notes for attention (1) Pay attention to the location of the various parts when the pump is dismantled .The parts which have been dismantled should be arranged regularly (2) As the high machining precision the parts of piston pumps is , especially with plunge、 oil distribution shaft、servo spool valve、Set Plate、swash plate, the parts which have been dismantled should be arranged regularly and carefully. Surface finishing can not have a friction with a hard object in order to maintain the accuracy of surface roughness of parts. (3) All parts should be assembled as original request when the pump is assembled. Be sure to keep in mind that all parts must not be left out and keep the assembly direction and assembly location of parts correct (4) The parts must be carefully cleaned to ensure that it does not contain any cutting chip and other pollutants before assembling .The washed components which have relative motion should add the appropriate hydraulic oil. (5) Must carefully check to make sure if the reciprocating movement of the pistons within their cylinder bores are flexible after the assembly. (6) When tightening the Screw ,force should be uniform. Note that the order of screw tightening should be symmetrical each other swirling (7) Laboratory report for assembling Vane pumps of YCY-IB type radial piston pumps

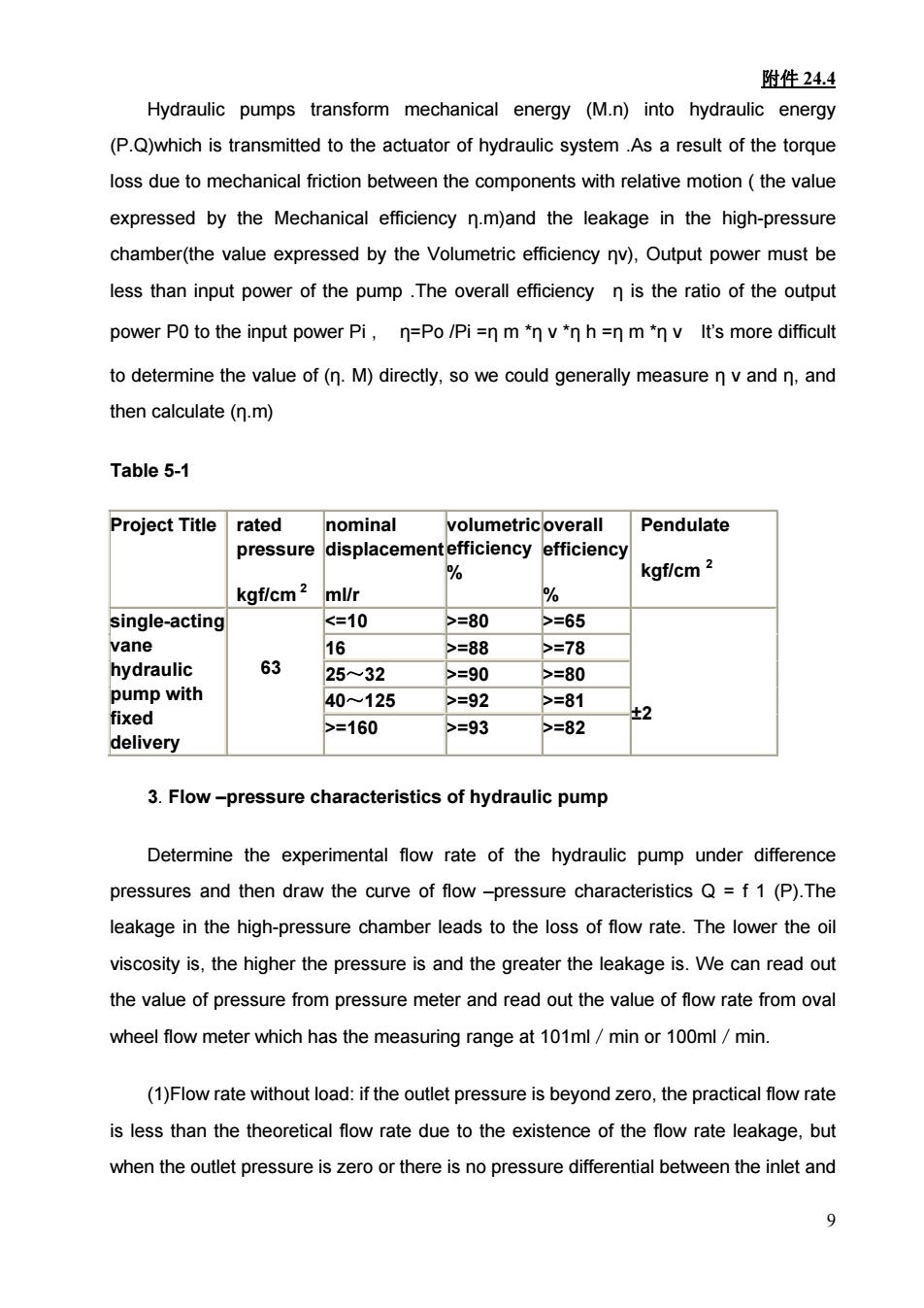

附件24.4 Experimental date Indoor temperature Major Class Group Name Ad小viso Model Number of experimental device: Substance of laboratory report 1.Description the operating principle of YCY-IB type radial piston pumps and then to explain the structure of the pump and what is the role of the various components. 2.Description the variable characteristic of YCY-IB type radial piston pumps.Do you have understood how to regulate the P-Q characteristic curve of YCY-IB type radial piston pumps: Draw its P-Q characteristic curves and Please specify it. Experiment 4 Performance parameters in hydraulic pump 1.The purpose of the experiment Hydraulic pumps conver mechanical energy into hydraulic energy.They supply fluid to the components in the hydraulic system.Acrossing this experiment,understand the main hydraulic pump performance and test methods and lay the initial foundation for the future design including the selection and the use of hydraulic pump. 2.The experiment contents and experimental program The performance of hydraulic pump experiment Include:the ability to achieve the rated pressure,nominal flow,volumetric efficiency,the value of pressure pulsation (pendulate),Noise,life-span,temperature rising,vibration and so on.The first three are the most important performance We use a single-acting vane hydraulic pump with fixed delivery in this experiment. It's technical indicators(from JB2146-77)is shown at Table 5-1

附件 24.4 8 Experimental date_._._ Indoor temperature_ Major_ Class _ Group_ Name_ Advisor_ Model Number of experimental device: Substance of laboratory report 1. Description the operating principle of YCY-IB type radial piston pumps and then to explain the structure of the pump and what is the role of the various components. 2、Description the variable characteristic of YCY-IB type radial piston pumps. Do you have understood how to regulate the P-Q characteristic curve of YCY-IB type radial piston pumps; Draw its P-Q characteristic curves and Please specify it. Experiment 4 Performance parameters in hydraulic pump 1. The purpose of the experiment Hydraulic pumps conver mechanical energy into hydraulic energy.They supply fluid to the components in the hydraulic system .Acrossing this experiment, understand the main hydraulic pump performance and test methods and lay the initial foundation for the future design including the selection and the use of hydraulic pump. 2. The experiment contents and experimental program The performance of hydraulic pump experiment Include : the ability to achieve the rated pressure, nominal flow, volumetric efficiency, the value of pressure pulsation (pendulate), Noise, life-span, temperature rising, vibration and so on . The first three are the most important performance. We use a single-acting vane hydraulic pump with fixed delivery in this experiment. It’s technical indicators ( from JB2146-77) is shown at Table 5-1

附件24.4 Hydraulic pumps transform mechanical energy (M.n)into hydraulic energy (P.Q)which is transmitted to the actuator of hydraulic system.As a result of the torque loss due to mechanical friction between the components with relative motion(the value expressed by the Mechanical efficiency n.m)and the leakage in the high-pressure chamber(the value expressed by the Volumetric efficiency nv),Output power must be less than input power of the pump.The overall efficiency n is the ratio of the output power P0 to the input power Pi.n=Po /Pi =n m*n v*n h =n m*n v It's more difficult to determine the value of(n.M)directly,so we could generally measure n v and n,and then calculate(n.m) Table 5-1 Project Title rated nominal volumetricoverall Pendulate pressure lisplacemen t effic ciency efficiency kgf/cm2 kgf/cm2 single-acting <=10 >=80 >=65 vane 16 >=88 >=78 hydraulic 63 25-32 >=90 >=80 pump with 40~125 >=92 >=81 fixed =160 =93 82 delivery 3.Flow-pressure characteristics of hydraulic pump Determine the experimental flow rate of the hydraulic pump under difference pressures and then draw the curve of flow-pressure characteristics Q=f1(P).The leakage in the high-pressure chamber leads to the loss of flow rate.The lower the oil viscosity is,the higher the pressure is and the greater the leakage is.We can read out the value of pressure from pressure meter and read out the value of flow rate from oval wheel flow meter which has the measuring range at 101ml/min or 100ml/min (1)Flow rate without load:if the outlet pressure is beyond zero,the practical flow rate is less than the theoretical flow rate due to the existence of the flow rate leakage,but when the outlet pressure is zero or there is no pressure differential between the inlet and 9

附件 24.4 9 Hydraulic pumps transform mechanical energy (M.n) into hydraulic energy (P.Q)which is transmitted to the actuator of hydraulic system .As a result of the torque loss due to mechanical friction between the components with relative motion ( the value expressed by the Mechanical efficiency η.m)and the leakage in the high-pressure chamber(the value expressed by the Volumetric efficiency ηv), Output power must be less than input power of the pump .The overall efficiency η is the ratio of the output power P0 to the input power Pi , η=Po /Pi =η m *η v *η h =η m *η v It’s more difficult to determine the value of (η. M) directly, so we could generally measure η v and η, and then calculate (η.m) Table 5-1 Project Title rated pressure kgf/cm 2 nominal displacement volumetric efficiency % ml/r overall efficiency % Pendulate kgf/cm 2 <=10 >=80 >=65 16 >=88 >=78 25~32 >=90 >=80 40~125 >=92 >=81 single-acting vane hydraulic pump with fixed delivery 63 >=160 >=93 >=82 ±2 3. Flow –pressure characteristics of hydraulic pump Determine the experimental flow rate of the hydraulic pump under difference pressures and then draw the curve of flow –pressure characteristics Q = f 1 (P).The leakage in the high-pressure chamber leads to the loss of flow rate. The lower the oil viscosity is, the higher the pressure is and the greater the leakage is. We can read out the value of pressure from pressure meter and read out the value of flow rate from oval wheel flow meter which has the measuring range at 101ml/min or 100ml/min. (1)Flow rate without load: if the outlet pressure is beyond zero, the practical flow rate is less than the theoretical flow rate due to the existence of the flow rate leakage, but when the outlet pressure is zero or there is no pressure differential between the inlet and

附件24.4 outlet pressure,the pump leakage is zero.The flow rate under this condition is considered equal to the theoretical flow rate in industrial production.We should determine the Flow rate without load of pump under the condition that cross-sectional area of Throttle 10 is the largest (2)Rated flow rate:the flow rate which permits operation continuously under the rated pressure and the rated rotating speed. (3)Practical flow rate Q on the condition of different pressure;the different pressure is determined by the throttle.Read out the flow rate Q under the corresponding pressure. 4.Volumetric efficiency nv If the motor's rotational Speed in the hydraulic pump at zero pressure is basically the same as the rotational Speed in the rated working pressure (the value of rated rotational Speed and rotational Speed without load is equal),n=Q1/Q2 5.Overall efficiency of hydraulic pump n n=No/Ni or No=Ni*n=Ni*nm*nv The input power of hydraulic pump Ni Ni=M*N/974(kw) M-input torque on the condition of rated pressure n-rotational Speed of hydraulic pump on the condition of rated pressure The output power of hydraulic pump No No=P*Q/612(KW) P-The output pressure of hydraulic pump on the condition of rated pressure Q-The flow rate of hydraulic pump on the condition of rated pressure The overall efficiency of the hydraulic pump can be expressed as follows:

附件 24.4 10 outlet pressure, the pump leakage is zero .The flow rate under this condition is considered equal to the theoretical flow rate in industrial production. We should determine the Flow rate without load of pump under the condition that cross-sectional area of Throttle 10 is the largest. (2)Rated flow rate: the flow rate which permits operation continuously under the rated pressure and the rated rotating speed. (3)Practical flow rate Q on the condition of different pressure; the different pressure is determined by the throttle. Read out the flow rate Q under the corresponding pressure. 4. Volumetric efficiency ηv If the motor’s rotational Speed in the hydraulic pump at zero pressure is basically the same as the rotational Speed in the rated working pressure (the value of rated rotational Speed and rotational Speed without load is equal), η=Q1/Q2 5. Overall efficiency of hydraulic pump η η=No/Ni or No=Ni*η=Ni*ηm*ηv The input power of hydraulic pump Ni Ni=M*N/974(kw) M-input torque on the condition of rated pressure n- rotational Speed of hydraulic pump on the condition of rated pressure The output power of hydraulic pump No No=P*Q/612(KW) P-The output pressure of hydraulic pump on the condition of rated pressure Q- The flow rate of hydraulic pump on the condition of rated pressure The overall efficiency of the hydraulic pump can be expressed as follows: