上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 组织工程支架(scaffold)材料 ©天然高分子材料 蛋白质类:College、Gelatin 多糖类:Chitosan、Hyaluronic Acid ● 合成降解聚合物 聚丙烯酸及其衍生物、聚乙二醇及其共聚物、 聚乙烯醇、聚交酯 ·生物陶瓷 磷酸鈣陶瓷、聚磷酸鈣、 羥基磷灰石、珊瑚(碳酸钙) ·生物复合材料

组织工程支架 (scaffold)材料 天然高分子材料 蛋白质类:College 、Gelatin 多糖类:Chitosan 、Hyaluronic Acid • 合成降解聚合物 聚丙烯酸及其衍生物、聚乙二醇及其共聚物、 聚乙烯醇、聚交酯 • 生物陶瓷 磷酸鈣陶瓷、聚磷酸鈣、 羥基磷灰石、珊瑚(碳酸钙) • 生物复合材料

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 冷冻干燥 i88n 1e40 6n手卡时m 1841 1线《e4辅手6 0dsn (a) 参数:溶液浓度、冷冻温度、冷冻时间和冷冻速率等 Lie Ma,et al.Collagen/chitosan porous scaffolds with improved biostability for skin tissue engineering.Biomaterials 2003;24:4833-41

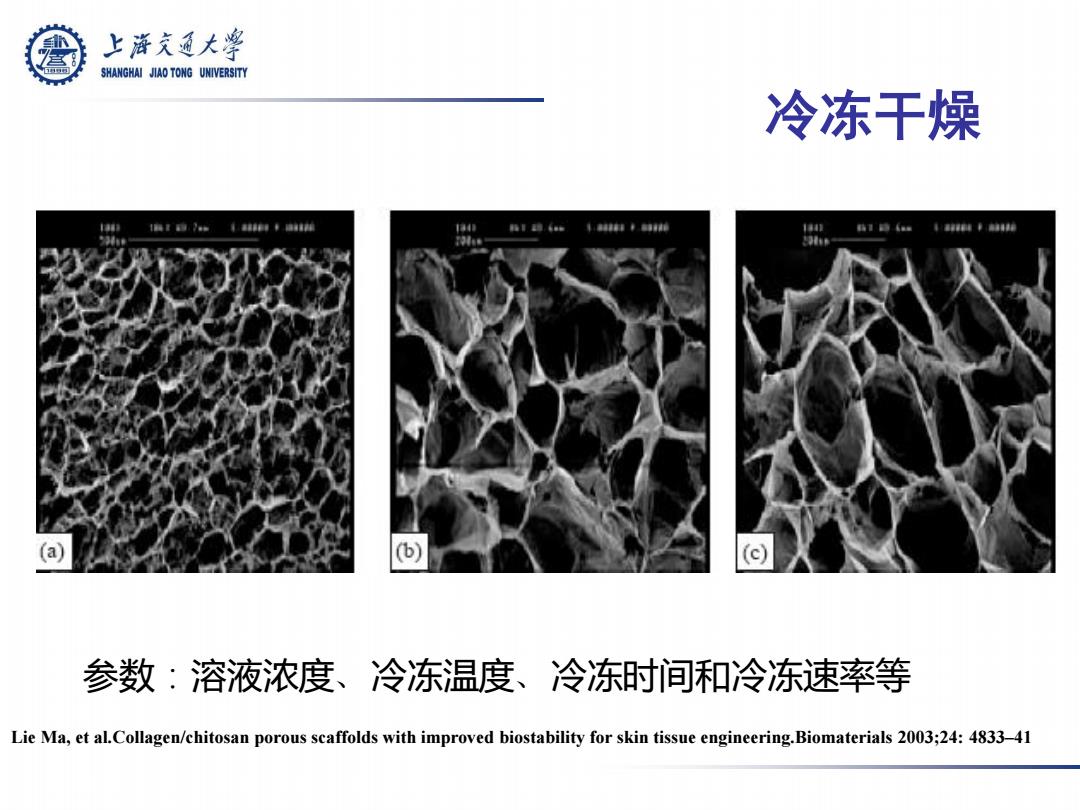

冷冻干燥 Lie Ma, et al.Collagen/chitosan porous scaffolds with improved biostability for skin tissue engineering.Biomaterials 2003;24: 4833–41 参数:溶液浓度、冷冻温度、冷冻时间和冷冻速率等

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 冷冻一凝胶 溶液 冷冻 回 温度低于 溶液凝结点 凝胶 Morphology of the chitosan and alginate scaffolds Ming-Hua Ho,et al.Preparation of porous scaffolds by using freeze-extraction and freeze-gelation methods. Biomaterials 2004;25:129-38

冷冻-凝胶 Ming-Hua Ho,et al. Preparation of porous scaffolds by using freeze-extraction and freeze-gelation methods. Biomaterials 2004;25:129–38 溶液 冷冻 凝胶 温度低于 溶液凝结点 Morphology of the chitosan and alginate scaffolds

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 致孔剂致孔 Ice particulates 形成气体的盐致孔 Polymer solution ④水溶性致孔剂致孔 Aluminium mold Mixing ©冰晶致孔 Freezing Liquid nitrogen Freeze-drying Polymer sponge Morphology of cross-sections of PLLA sponges Guoping Chen,et al.Development of biodegradable porous scaffolds for tissue engineering.Materials Science and Engineering,2001;C 17:63-9

致孔剂致孔 形成气体的盐致孔 水溶性致孔剂致孔 冰晶致孔 Guoping Chen,et al. Development of biodegradable porous scaffolds for tissue engineering. Materials Science and Engineering,2001; C 17:63–9 Morphology of cross-sections of PLLA sponges

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY 热致相分离(TIPS) 均向聚合物溶液:高温→低温 淬火热力学状态 18.28Bk 参数:聚合物浓度、溶剂/非溶剂组成、 淬火过程及添加剂 kU250E33290798 SE angeadwa.I 0m200k250E33292/9 Fig.SEM images of the cross section of morphous PLGA foams as a function of coarsening time.The metastable foams were prepared by coarsening 9%(w/v) unstable region region polymer solution at 43C for 0 min(a),2 min(b),10 min(c),and then quenching by liquid nitrogen. Concentration,Φ

热致相分离(TIPS) 均向聚合物溶液:高温低温 淬火热力学状态 参数:聚合物浓度、溶剂/非溶剂组成、 淬火过程及添加剂 Fig. SEM images of the cross section of morphous PLGA foams as a function of coarsening time. The foams were prepared by coarsening 9% (w/v) polymer solution at 43C for 0 min (a), 2 min (b), 10 min (c), and then quenching by liquid nitrogen