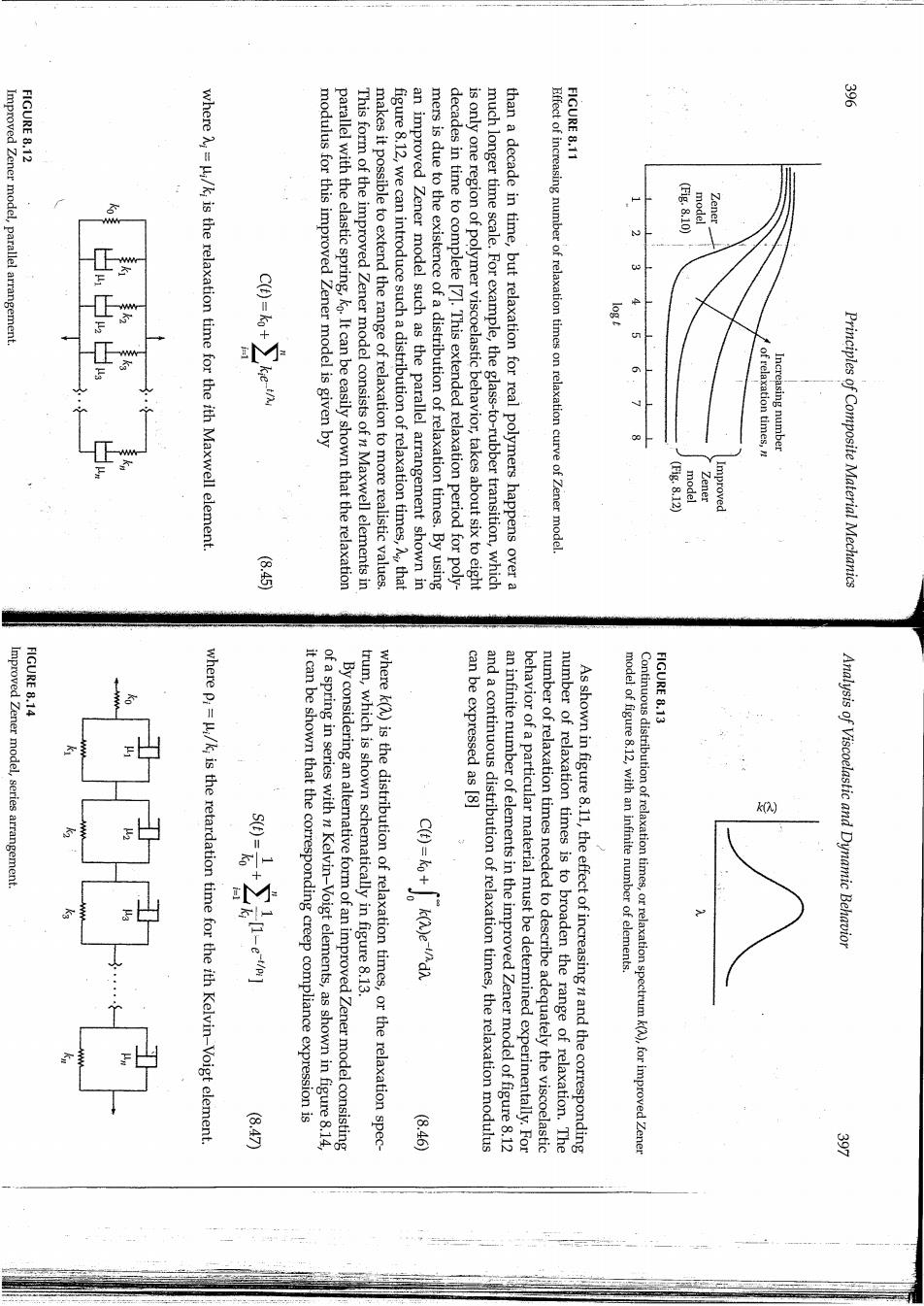

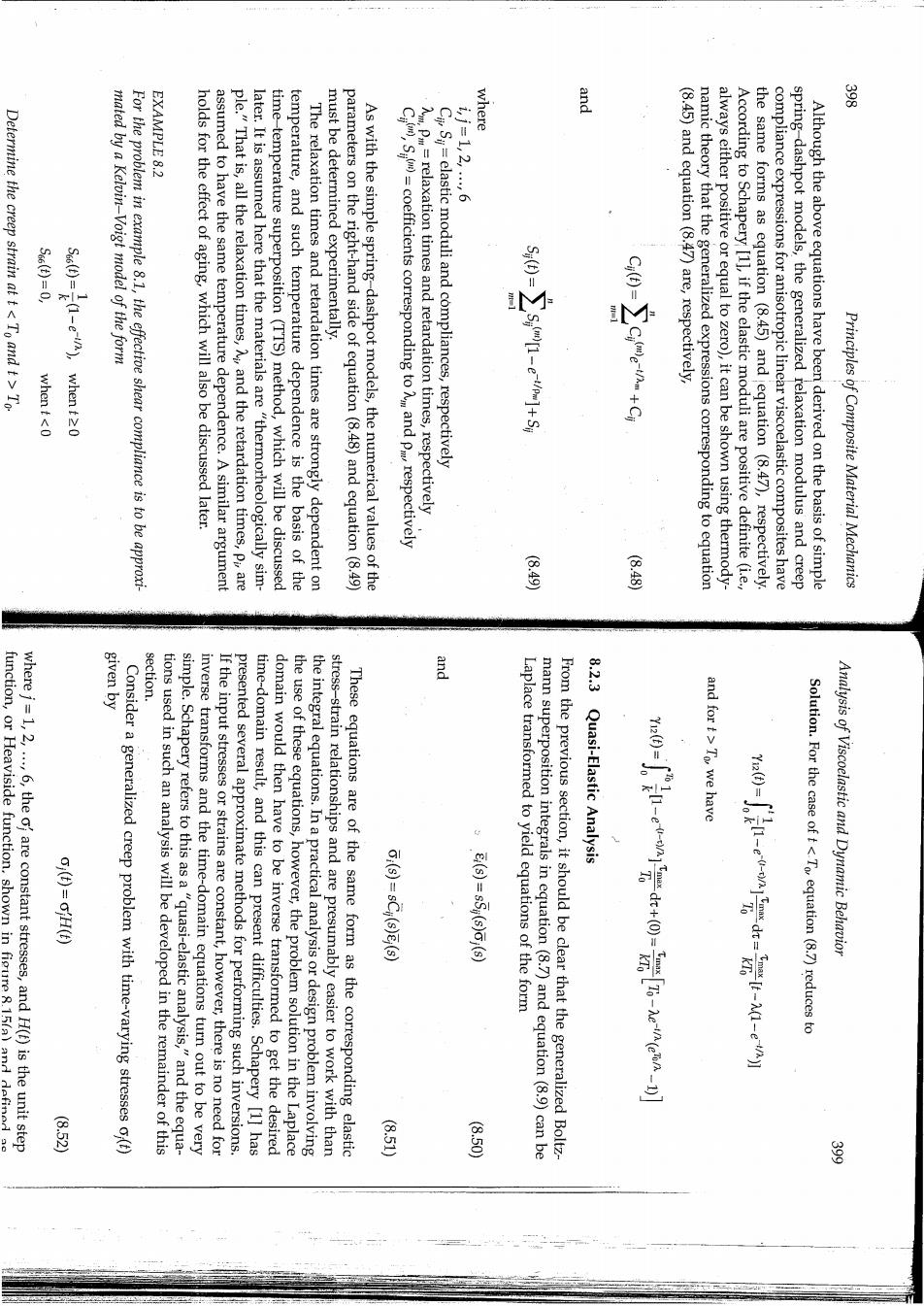

Improved Zener model,parallel arrangement FIGURE 8.12 FIGURE 8.11 黄肉 where =i/k is the relaxation time for the ith Maxwell element. modulus for this improved Zener model is given by parallel with the elastic spring,ko.It can be easily shown that the relaxation This form of the improved Zener model consists of n Maxwell elements in makes it possible to extend the range of relaxation to more realistic values. figure 8.12,we can introduce such a distribution of relaxation times,that an improved Zener model such as the parallel arrangement shown in mers is due to the existence of a distribution of relaxation times.By using decades in time to complete [7].This extended relaxation period for poly- is only one region of polymer viscoelastic behavior,takes about six to eight much longer time scale.For example,the glass-to-rubber transition,which than a decade in time,but relaxation for real polymers happens over a Effect of increasing number of relaxation times on relaxation curve of Zener model. 45:810 model Zener of relaxation times,n Increasing number 812 Improved Principles of Composite Material Mechanics (6.5) Improved Zener model,series arrangement. 8.·14 FIC ·13 FI where pi=i/k is the retardation time for the ith Kelvin-Voigt element. it can be shown that the corresponding creep compliance expression is of a spring in series with n Kelvin-Voigt elements,as shown in figure 8.14, By considering an alternative form of an improved Zener model consisting trum,which is shown schematically in figure 8.13. where k(A)is the distribution of relaxation times,or the relaxation spec- can be expressed as [8] and a continuous distribution of relaxation times,the relaxation modulus an infinite number of elements in the improved Zener model of figure 8.12 behavior of a particular material must be determined experimentally.For number of relaxation times needed to describe adequately the viscoelastic number of relaxation times is to broaden the range of relaxation.The As shown in figure 8.11,the effect of increasing n and the corresponding model of figure 8.12,with an infinite number of elements. Continuous distribution of relaxation times,or relaxation spectrumk(),for improved Zener k(A) Analysis of Viscoelastic and Dynamic Behavior 845 (6.46)

where and 395 EXAMPLE 8.2 Determine the creep strain at t<To and t>To 5.0-0 mated by a Kelvin-Voigt model of the form whent<0 For the problem in example 8.1,the effective shear compliance is to be approxi- holds for the effect of aging,which will also be discussed later. assumed to have the same temperature dependence.A similar argument ple."That is,all the relaxation times,and the retardation times,Pi are later.It is assumed here that the materials are "thermorheologically sim- time-temperature superposition (TTS)method,which will be discussed temperature,and such temperature dependence is the basis of the The relaxation times and retardation times are strongly dependent on must be determined experimentally. parameters on the right-hand side of equation(8.48)and equation(8.49) As with the simple spring-dashpot models,the numerical values of the C,S(=coefficients corresponding to and Prespectively A Pm=relaxation times and retardation times,respectively CS=elastic moduli and compliances,respectively 7-12.::6 容 (8.45)and equation (8.47)are,respectively, namic theory that the generalized expressions corresponding to equation always either positive or equal to zero),it can be shown using thermody- According to Schapery [1],if the elastic moduli are positive definite (i.e., the same forms as equation (8.45)and jequation (8.47),respectively. compliance expressions for anisotropic linear viscoelastic composites have spring-dashpot models,the generalized relaxation modulus and creep Although the above equations have been derived on the basis of simple Principles of Composite Material Mechanics 60 given by section. and function,or Heaviside function.shown in figure 8.15a)and defined wherej=1,2,...,6,the of are constant stresses,and H()is the unit step Consider a generalized creep problem with time-varying stresses o(t) tions used in such an analysis will be developed in the remainder of this simple.Schapery refers to this as a"quasi-elastic analysis,"and the equa- inverse transforms and the time-domain equations turn out to be very If the input stresses or strains are constant,however,there is no need for presented several approximate methods for performing such inversions. time-domain result,and this can present difficulties.Schapery [1]has domain would then have to be inverse transformed to get the desired the use of these equations,however,the problem solution in the Laplace the integral equations.In a practical analysis or design problem involving stress-strain relationships and are presumably easier to work with than These equations are of the same form as the corresponding elastic mann superposition integrals in equation(8.7)and equation(8.9)can be Laplace transformed to yield equations of the form From the previous section,it should be clear that the generalized Boltz- 8.2.3 Quasi-Elastic Analysis and for t>To we have Solution.For the case of t<To equation(8.7)reduces to Analysis of Viscoelastic and Dynamic Behavior 8.52 8.51 8.50 爱

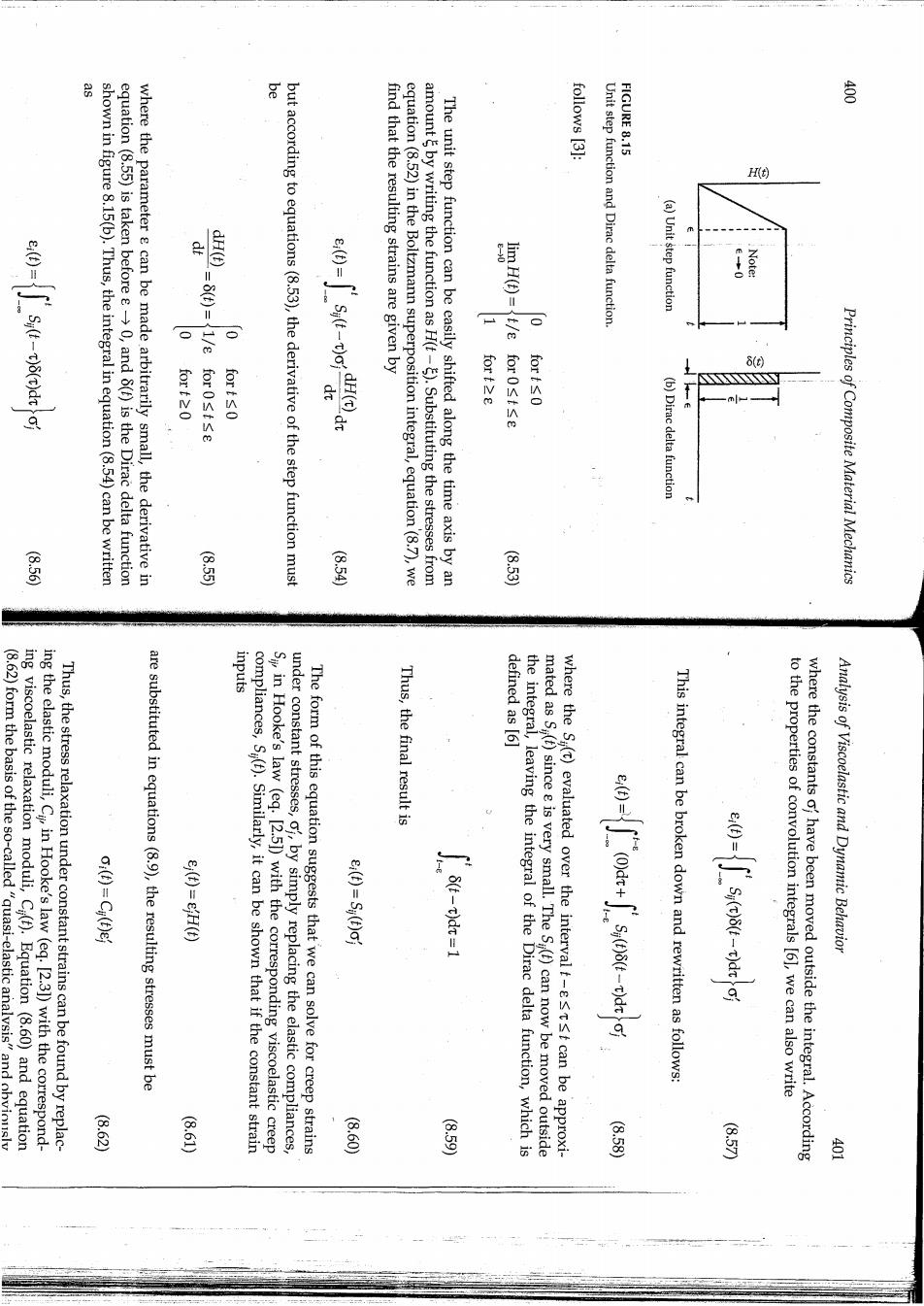

常 follows [3]: FIGURE 8.15 营 H(t shown in figure 8.15(b).Thus,the integral in equation(8.54)can be written equation(8.55)is taken before g->0,and 8(f)is the Dirac delta function where the parameter g can be made arbitrarily small,the derivative in 10-8O1y60n05t56 but according to equations(8.53),the derivative of the step function must find that the resulting strains are given by 60:070 equation(8.52)in the Boltzmann superposition integral,equation(8.7),we amount by writing the function as H(t-E).Substituting the stresses from The unit step function can be easily shifted along the time axis by an forte H()t/e for0stse Unit step function and Dirac delta function (a)Unit step function 10 6() (b)Dirac delta function 1 Principles of Composite Material Mechanics S.56 S.55 S.54) 8.53 inputs defined as [6] (8.62)form the basis of the so-called "quasi-elastic analysis"and obviouslv ing the elastic moduli,C in Hooke's law (eq.[2.31)with the correspond- ing viscoelastic relaxation moduli,C(t).Equation (8.60)and equation Thus,the stress relaxation under constant strains can be found by replac- are substituted in equations(8.9),the resulting stresses must be compliances,S(f).Similarly,it can be shown that if the constant strain S in Hooke's law (eq.[2.5])with the corresponding viscoelastic creep under constant stresses,of,by simply replacing the elastic compliances, The form of this equation suggests that we can solve for creep strains Thus,the final result is 9⊙o@ e(t)=jH(t) the integral,leaving the integral of the Dirac delta function,which is mated as S(t)since e is very small.The S(t)can now be moved outside where the Si(t)evaluated over the interval t-gstst can be approxi- This integral can be broken down and rewritten as follows: to the properties of convolution integrals [61,we can also write where the constants of have been moved outside the integral.According Analysis of Viscoelastic and Dynamic Behavior (6.62 86 6.60 859) S.58) 85M

later. 常 found to be EXAMPLE 8.3 2-7.0gMa 1.20.5pMPa From example 2.3,stresses along the principal material directions were E(t)=Su()1+S12()02 along the principal material directions are given by predict the creep strains.From equations(8.60),we find that the creep strains of the vessel are all constant,and we can use a quasi-elastic analysis to Solution.Since the internal pressure,p,is constant,the stresses in the wall principal material directions in the wall of the vessel. that the internal pressure,p,is constant,determine the creep strains'along the one-term series representations of the form shown in equations(8.49).Assuming viscoelastic composite having creep compliances that can be modeled by using The filament wound pressure vessel described in example 2.3 is constructed of a different elastic moduli at each time step. elastic problems,and the time dependence is accounted for by using approach,where finite element models are employed to solve a series of applications involve finite element implementations of the quasi-elastic of creep in prestressed polymer composite lubricators [12].Many of these analysis of creep in prestressed composite connectors [111,and modeling mer composites [9],prediction of creep in rotating viscoelastic disks [101, practical applications such as micromechanical modeling of creep in poly- The quasi-elastic approach has been successfully used in a number of coelastic systems,and this correspondence will be discussed in more detail between the equations for linear elastic systems and those for linear vis- inputs.Such equations give additional hints of a direct correspondence (8.60)and equation (8.:62)are only valid for constant or near-constant relationships.It should be emphasized again,however,that equation eliminate the need for Laplace transform analysis in the stress-strain Principles of Composite Material Mechanics 就斯尊5-2。:10。wh where 8.2.4 It is now convenient to define a new variable=t-t,so that sinusoidally varying strains are given by Substituting equation(8.63)in equation(8.7),we find that the resulting superscript denoting a sinusoidally varying quantity An=complex stress amplitudes i=imaginary operator,is(-1)1/2 批=121。:10 can be written as @Using the contracted notation and complex exponentials,such stresses Consider the case where the stresses vary sinusoidally with frequency general procedure here follows that presented by Fung [3]. easier to analyze sinusoidal vibrations of viscoelastic composites.The strains that vary sinusoidally with time.The results will make it much analogous simplification will be demonstrated for the case of stresses or equations that resemble the linear elastic Hooke's law.In this section,an the Boltzmann superposition integrals are reduced to simple algebraic In the previous section,it was shown that when the inputs are constant, Sinusoidal Oscillations and Complex Modulus Notation -ego79541026-10g152a+552050+t5 2( in the above expressions for the strains,we find that Substituting these stresses and the creep compliances from equations(8.49) Analysis of Viscoelastic and Dynamic Behavior A.65 (S.64) 6.63

(8.9),we find that the sinusoidally varying stresses are Alternatively,if we substitute sinusoidally varying strains in equation Fourier transform of the creep compliance S(). ance,S'(),is equal to a factor of io times S(),and S()is the ing creep compliance.According to equation(8.69),the complex compli- compliance is not simply equal to the Fourier transform of the correspond- Fourier transforms.It is important to note,however,that the complex compliances are related to frequency-domain complex compliances by pliances in the linear elastic material.In addition,the time-domain creep the same way that static stresses and strains are related by elastic com- are related to the sinusoidally varying strains by complex compliances in Thus,in linear viscoelastic materials,the sinusoidally varying stresses so that equation(8.68)becomes ¥⑧⑧ simply define the frequency-domain complex compliances as follows: In order to get this equation to resemble Hooke's law more closely,we Thus,the stress-strain relationship reduces to compliances,[()1,or S(),which is written as The integral in equation(8.66)is just the Fourier transform of the creep be changed to -so that integral,and since S(f)=0 for t<0,the lower limit on the integral can The terms not involving functions of may be moved outside the Principles of Composite Material Mechanics 多70 8.70 (669 6·68 4.675 (6.66) diagram are and nential representations of the rotating stress and strain vectors in the the horizontal or the vertical projection of the vectors.The complex expo- with angular velocity o,and the physical oscillation is generated by either in figure 8.16.The stress and strain vectors are both assumed to be rotating these equations may be given with the aid of the rotating vector diagram dissipation,or damping.A physical interpretation of the 1-D forms of energy storage,whereas the imaginary part is associated with energy Thus,the real part of the complex modulus is associated with elastic 8m()=phase lag between o(t)and En(t) Chi ()=loss modulus Cm ()=storage modulus (no summation on m and n in eq.[8.75]),where 10)11B)+-e)1.B+当!B"0B。6r0 in terms of its real and imaginary parts as follows: tation.Since the complex modulus is a complex variable,we can write it viscoelasticity theory,but it also has a straightforward physical interpre- The complex modulus notation not only has a mathematical basis in ulus matrix must be related by [S()]=[C()]-1. respectively,where the complex compliance matrix and the complex mod- written in matrix form as (())=[C()((t)] moduli,C ()Alternatively,equation (8.70)and equation (8.71)may be and the C()are the Fourier transforms of the corresponding relaxation where the complex moduli are defined by Analysis of Viscoelastic and Dynamic Behavior B56 875 S.70 853 8.72 常