in chapter 6. 5.1 W developed over the years,and comprehensive literature surveys have are also used in the literature.Many analytical approaches have been terms"structure-property relationships"and"effective modulus theories" terms of constituent material properties is called"micromechanics."The ites literature,however,the analysis of effective composite properties in "minimechanics"[1].In the present context,and in much of the compos- of composites at the constituent material level should be referred to as to as "macromechanics,"it has been suggested that,perhaps,mechanics the behavior of composite material structures such as laminates is referred of mechanical behavior at the level of molecular or crystal structures.Since "micromechanics."To a materials scientist,the term may imply the study Before proceeding further,it is appropriate to discuss briefly the term of discontinuous fiber composites,including nanocomposites,is covered will be presented in chapter 4 and chapter 5,respectively.Micromechanics responding models for predicting strength and hygrothermal properties tents,and geometric arrangements of the fiber and matrix materials.Cor- in terms of the corresponding material properties,relative volume con- for predicting the effective moduli of continuous fiber-reinforced laminae detail.In this chapter,we will discuss various micromechanical models ever,and the roles of lamina constituent materials were not examined in stress-strain relationships involving the lamina effective moduli,how- concerned with the development and manipulation of macromechanical moduli of an equivalent homogeneous material.Chapter 2 was primarily aged stresses can be related to the volume-averaged strains by the effective volume element(RVE)in a heterogeneous composite,the volume-aver- relationships for composite materials.Recall that for some representative to be essential to the development of practical engineering stress-strain In the previous chapter,the concept of an effective modulus was found Introduction Fiber-Reinforced Lamina Effective Moduli of a Continuous

here. work." 图 and Halpin [4]. ships between volume fractions and weight fractions will be presented on weight fractions.Measurements are discussed later,but the relation- constituent volume fractions,but actual measurements are often based uent materials.We will find that the micromechanics equations involve ization of the relative volume or weight contents of the various constit- One of the key elements in micromechanical analysis is the character- are both essential if we are to understand better "how composites cations,micromechanical analysis and experimental characterization design the material as well as the structure.Aside from design impli- can become part of a powerful design methodology that enables us to to be sufficiently accurate by comparison with experiment,however,it of direct measurement.Once a micromechanical model has been shown chanical model and other measured properties because of the difficulty such as fiber transverse moduli are usually inferred from the microme- validity of the models.Indeed,as we will see later,some properties corresponding composite properties are required in order to assess the erties are required as input to the models,and similar data on the characterization.Experimental data on the constituent material prop- in such an approach and that there is no substitute for experimental question.On the other hand,experience has shown that there are pitfalls binations without actually fabricating and testing the composites in "What if?"questions regarding the effects of various fiber/matrix com- Ideally,micromechanical models should enable us to answer quickly complete set of simple lamina design equations. used along with the mechanics of materials equations to formulate a solutions or experimental data,and some of these equations are often involves empirical solutions that are based on curve-fitting to elasticity ciently accurate that they are often used in design.A third category violate some of the laws of elasticity theory,some of the results are suffi- the simplifying assumptions used in the mechanics of materials approach because of the complex geometries and boundary conditions.Although approach often involves numerical solutions of the governing equations level,and fiber-packing geometry is taken into account.The elasticity involves the solution for actual stresses and strains at the micromechanical packing geometry is generally arbitrary.The theory of elasticity models stress and strain distributions at the micromechanical level,and fiber- simplifying assumptions make it unnecessary to specify the details of the rials or the elasticity theory.In the mechanics of materials approach Micromechanical analyses are based on either the mechanics of mate- been published by Chamis and Sendeckyj [2],Christensen [3],Hashin [1] Principles of Composite Material Mechanics 登 we get the "rule of mixtures": Pe =PrUr+PmUm equation(3.3)and equation(3.4)and solving for the composite density, tuting the product of density and volume for weight in each term of tively.Note that the weight of the voids has been neglected here.Substi- the weights of the ith constituent,fibers,matrix,and composite,respec- where w:=Wi/Wo wr=Wi/Wo wm =Wm/Wo and Wi Ws,Wm,and W.are 8+8 voids,respectively.The corresponding equations for weight fractions are where vs vm,and vu are the volume fractions of the fiber,matrix,and Vr+Vm +Vo=1 In many cases this equation reduces to where v;=Vi/Ve=volume fraction of the ith constituent,Vi=volume of the ith constituent,V=total volume of the composite. volume fractions must be unity: For any number of constituent materials,n,the sum of the constituent Effective Moduli of a Continuous Fiber-Reinforced Lamina 8 罗 8 8 巴

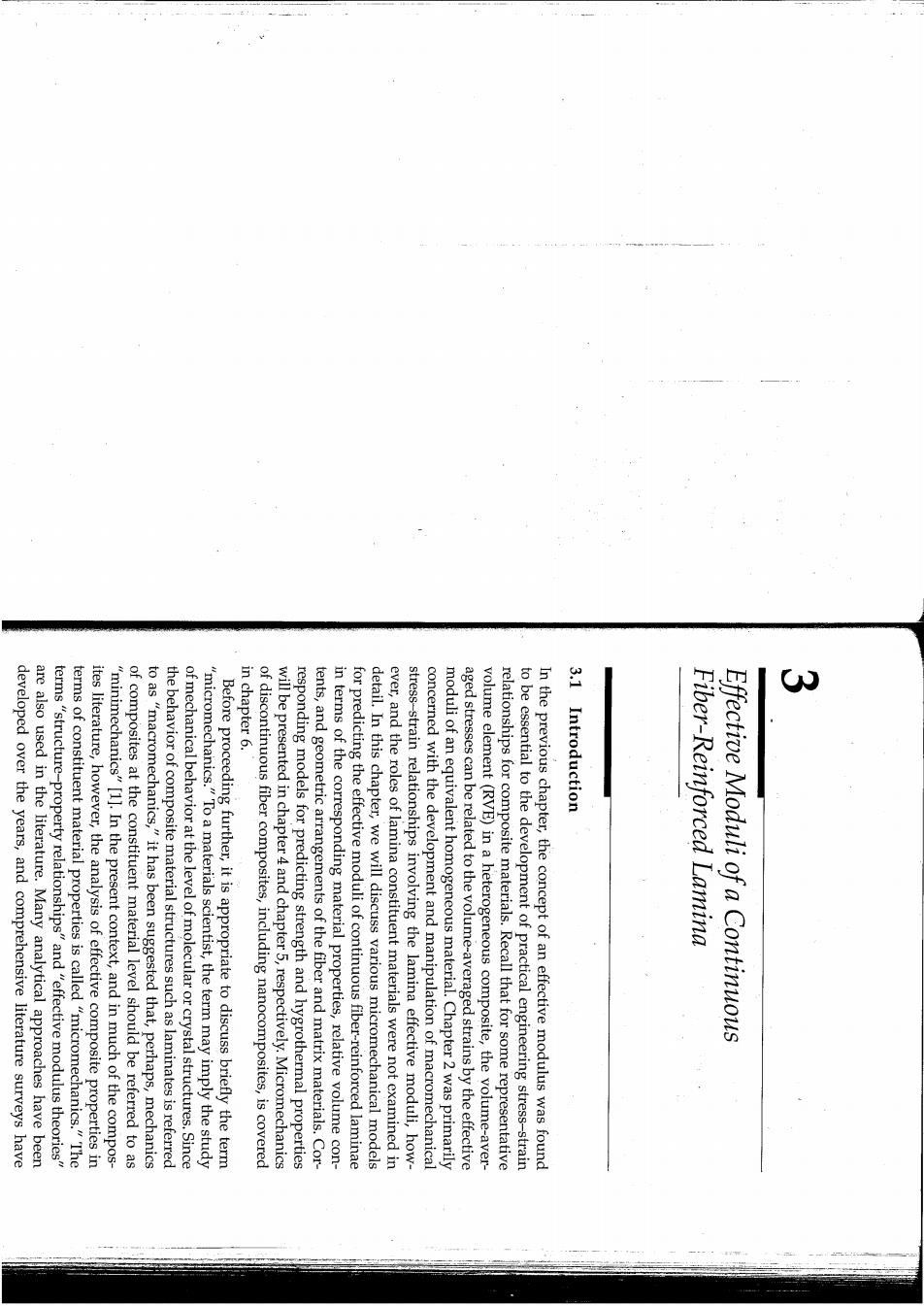

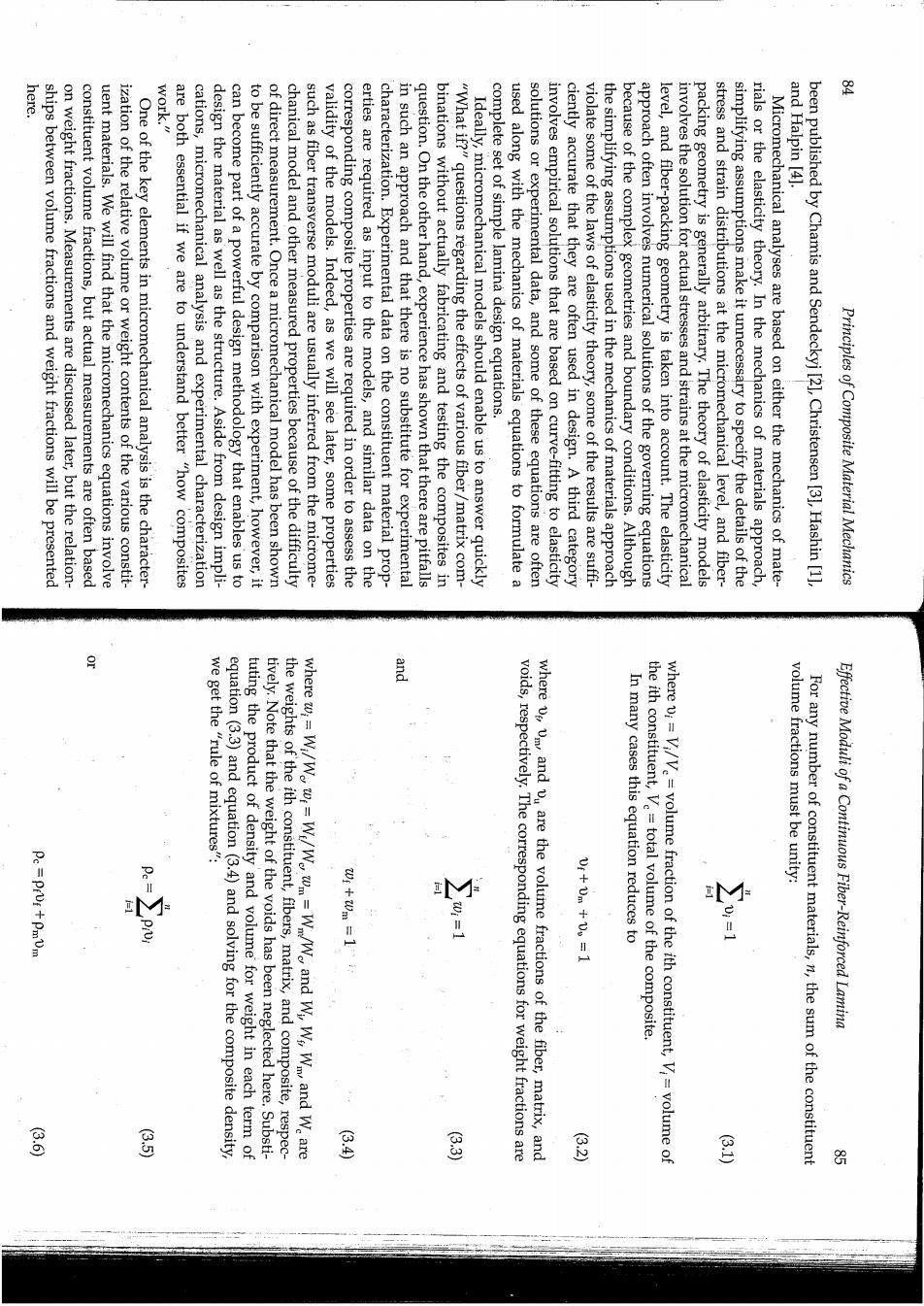

FIGURE 3.1 0F566. 置 Representative area elements for idealized square and triangular fibe fractions.Indeed,optical determination of area fractions is possible from the fiber length,then the area fractions must be equal to the volume as the square and triangular arrays shown in figure 3.1.If we assume representative area elements for idealized fiber-packing geometries such tions that may be expected in fiber composites,it is useful to consider the composite during the cure cycle can cause void contents of the order range 0.1 to 1%.Without vacuum bagging,however,volatiles trapped in can be rearranged as v.-1-(W/pi)+(W.-W)/pm calculated from measured weights and densities: and composite,respectively.Similarly,equation(3.1)and equation (3.2) where piPepm and pe are the densities of the ith constituent,fiber,matrix, er-packing geometries. that the fiber spacing,s,and the fiber diameter,d,do not change along In order to get some idea as to the range of constituent volume frac- Typical autoclave-cured composites may have void fractions in the Equation (3.2)can also be rearranged so that the void fraction can be Principles of Composite Material Mechanics 思 In this case, used to describe the relationshin hetween the fiher area as shown in figure 3.3(b)and figure 3.3(c),then equation(3.10)can be we can approximate the Voronoi cell in figure 3.3(a)as an equivalent square closer to the center of that fiber than it is to the center of any other fiber.If [6].Each point within the space of a Voronoi cell for a particular fiber is cell(fig.3.3)and a statistical distribution describing the Voronoi cell size as the one shown in figure 3.2 can be quantified by the use of the Voronoi The random nature of the fiber-packing geometry in real composites such predictions to be exact. one piece of material to another,we should not expect our micromechanics of fibers.Since fiber-packing geometry is never entirely repeatable from be controlled for proper flow during molding)and the random orientation processing limitations(e.g.,the viscosity of the fiber/resin mixture must fiber composites,fiber volume fractions are usually much lower due to figure 3.2,and the fiber volume fractions range from 0.5 to 0.8.In short composites,the fibers are packed in a random fashion as shown in is generally not achievable in practice,however.In most continuous fiber The close packing of fibers required to produce these theoretical limits -0.000 and when s=d,the maximum fiber volume fraction is A similar calculation for the triangular array shows that Clearly,the maximum theoretical fiber volume fraction occurs when s=d. of the shaded square [5]: dividing the area of fiber enclosed in the shaded square by the total area micrographs.The fiber volume fraction for the square array is found by Effective Moduli ofa Continuous Fiber-Reinforced Lamina e13 8.12 c.10

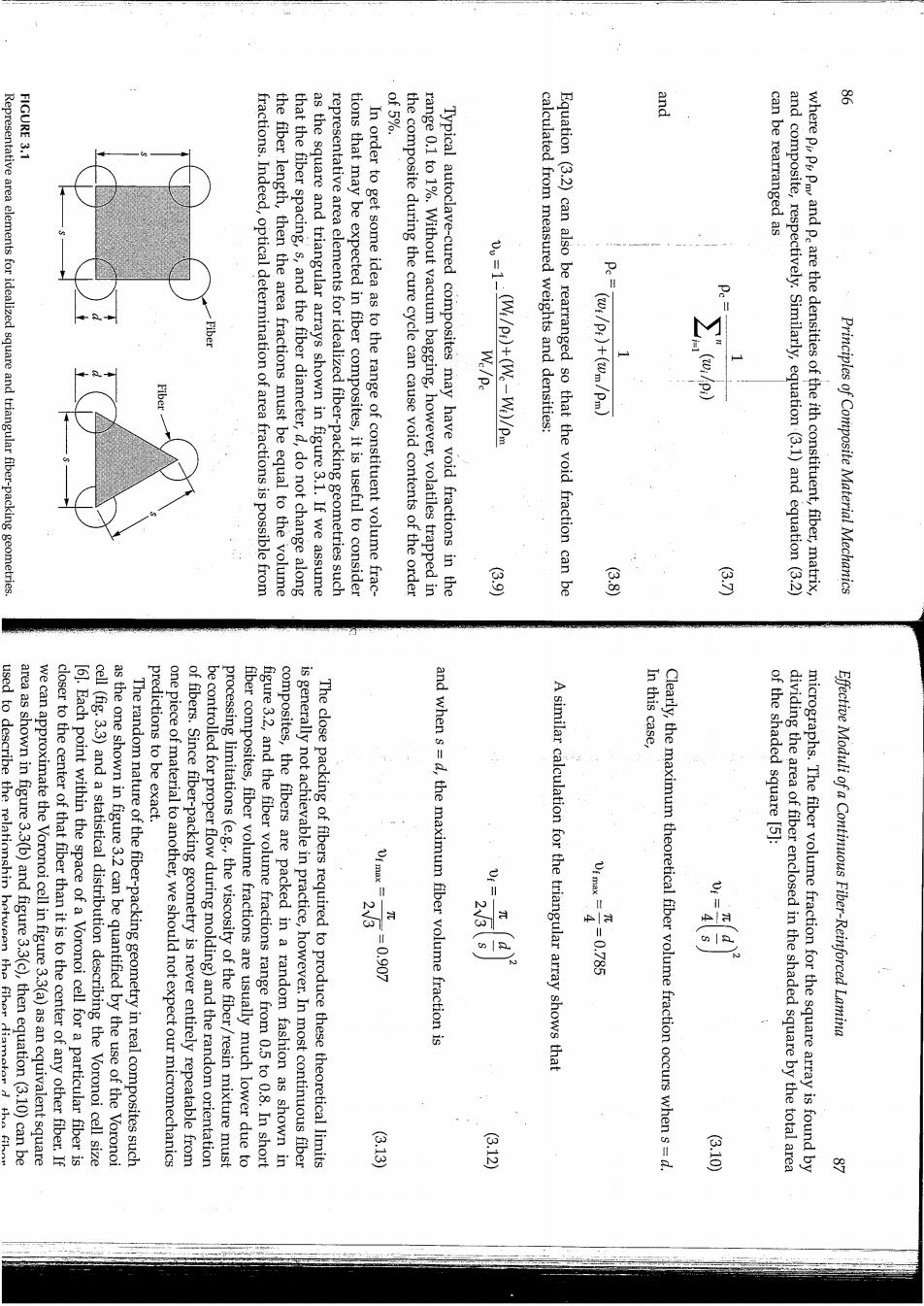

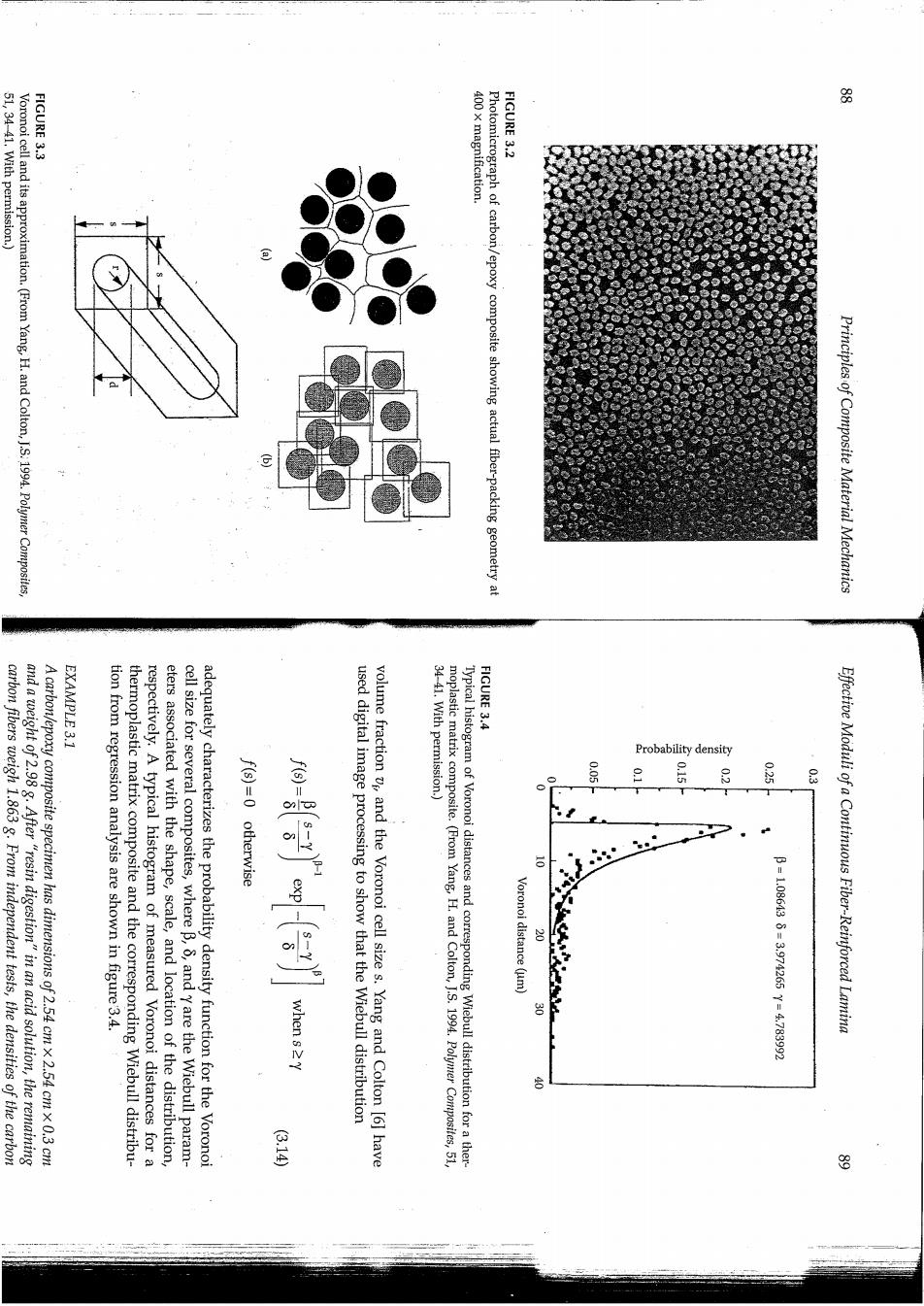

51,34-41.With permission.) FIGURE 3.3 400 x magnification FIGURE 3.2 Voronoi cell and its approximation.(From Yang,H.and Colton,J.S.1994.Polymer Composites Photomicrograph of carbon/epoxy composite showing actual fiber-packing geometry at Principles of Composite Material Mechanics EXAMPLE 3.1 FIGURE 3.4 Probability density carbon fibers weigh 1.863 g.From independent tests,the densities of the carbon and a weight of 2.98 g.After "resin digestion"in an acid solution,the remaining A carbon/epoxy composite specimen has dimensions of 2.54 cmx 2.54 cmx 0.3 cm tion from regression analysis are shown in figure 3.4. thermoplastic matrix composite and the corresponding Wiebull distribu- respectively.A typical histogram of measured Voronoi distances for a eters associated with the shape,scale,and location of the distribution, cell size for several composites,where B,5,and Y are the Wiebull param- adequately characterizes the probability density function for the Voronoi f(s)=0 otherwise when s 2Y used digital image processing to show that the Wiebull distribution volume fraction vp,and the Voronoi cell size s.Yang and Colton [6]have 34-41.With permission.) moplastic matrix composite.(From Yang,H.and Colton,J.S.1994.Polymer Composites,51 Typical histogram of Voronoi distances and corresponding Wiebull distribution for a ther 205 2 Voronoi distance (um) B10861393974265716783992 Effective Moduli of a Continuous Fiber-Reinforced Lamina 是 8

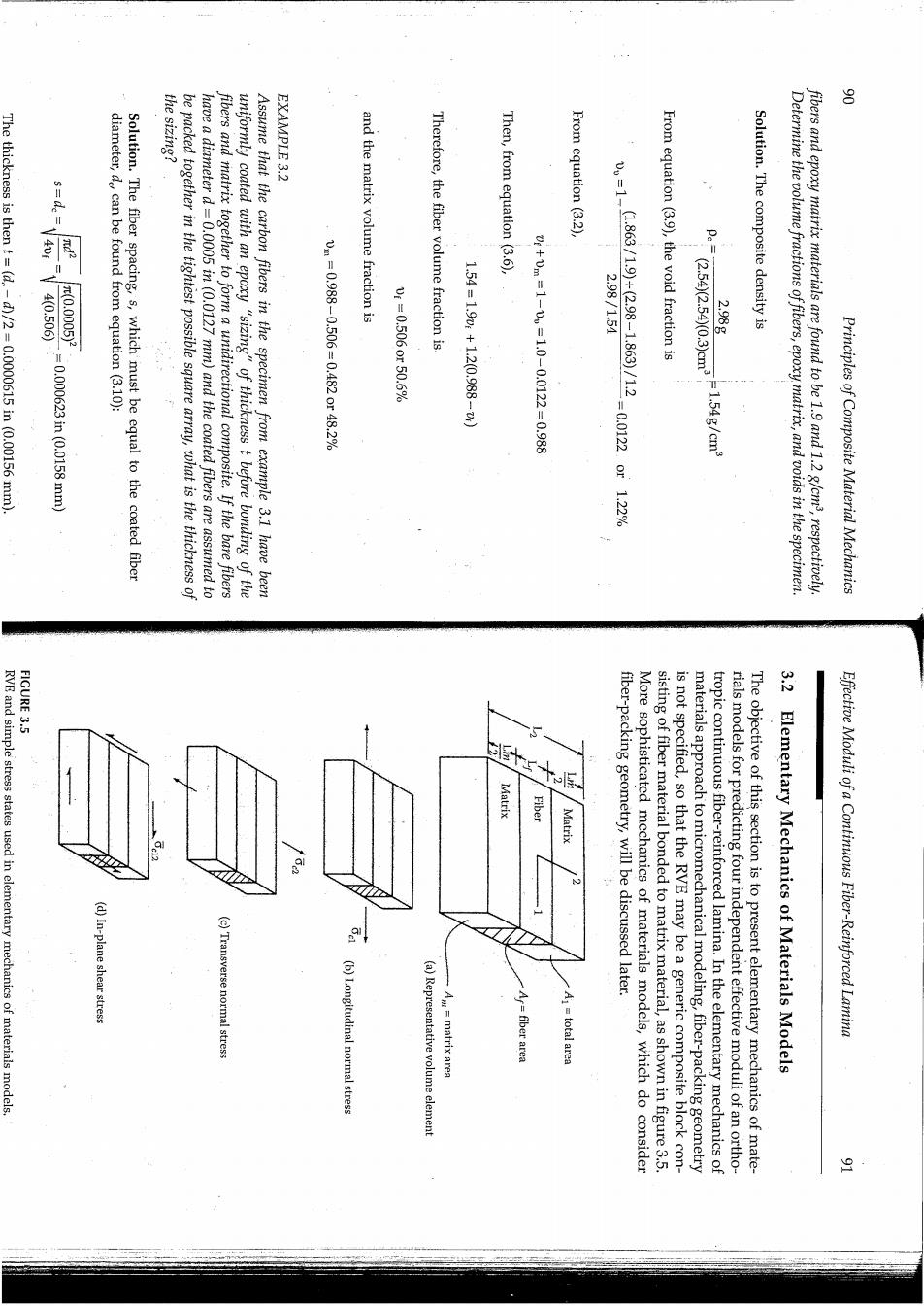

the sizing? EXAMPLE 3.2 The thickness is then t=(d.-d)/2=0.0000615 in(0.00156 mm) V40.506 (.0.00063in (00156 mm) diameter,do can be found from equation (3.10): Solution.The fiber spacing,s,which must be equal to the coated fiber be packed together in the tightest possible square array,what is the thickness of have a diameter d=0.0005 in (0.0127 mm)and the coated fibers are assumed to fibers and matrix together to form a unidirectional composite.If the bare fibers uniformly coated with an epoxy "sizing"of thickness t before bonding of the Assume that the carbon fibers in the specimen from example 3.1 have been and the matrix volume fraction is Therefore,the fiber volume fraction is Then,from equation (3.6), From equation(3.2) 10-0988-0.506-04320748.22% 15-0.5060750699 1.54-190541.20988-2V 5+00-1-00-1.0-00122-0288 u-1-0Ma/1gte%/0.809y12-00m0g1308 2.9871.54 From equation (3.9),the void fraction is P.(2.54)(2.54)0.3)cm Solution.The composite density is 2018 F1.548/cma Determine the volume fractions of fibers,epoxy matrix,and voids in the specimen. fibers and epoxy matrix materials are found to be 1.9 and 1.2 g/cm3,respectively. Principles of Composite Material Mechanics FIGURE 3.5 RVE and simple stress states used in elementary mechanics of materials models. Matrix Fiber Matrix (d)In-plane shear stress fiber-packing geometry,will be discussed later. (c)Transverse normal stress (b)Longitudinal normal stress (a)Representative volume element A=matrix area Ar=fber area A=total area More sophisticated mechanics of materials models,which do consider sisting of fiber material bonded to matrix material,as shown in figure 3.5 is not specified,so that the RVE may be a generic composite block con- materials approach to micromechanical modeling,fiber-packing geometry tropic continuous fiber-reinforced lamina.In the elementary mechanics of rials models for predicting four independent effective moduli of an ortho- The objective of this section is to present elementary mechanics of mate- Elementary Mechanics of Materials Models Effective Moduli of a Continuous Fiber-Reinforced Lamina