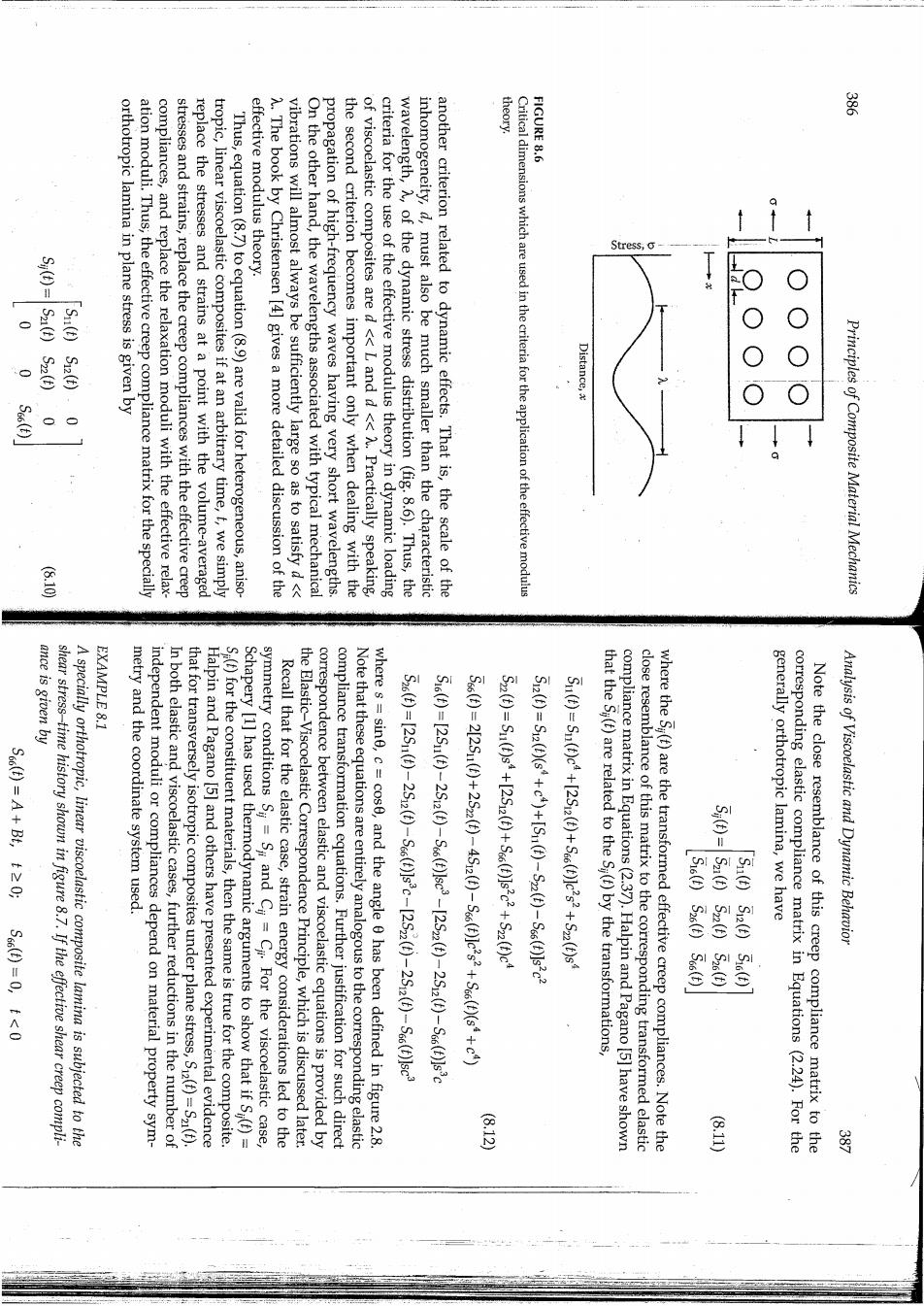

theory. FIGURE 8.6 Su(E)S12(f) orthotropic lamina in plane stress is given by S22(t) ation moduli.Thus,the effective creep compliance matrix for the specially compliances,and replace the relaxation moduli with the effective relax- stresses and strains,replace the creep compliances with the effective creep replace the stresses and strains at a point with the volume-averaged tropic,linear viscoelastic composites if at an arbitrary time,t,we simply Thus,equation(8.7)to equation(8.9)are valid for heterogeneous,aniso- effective modulus theory. A.The book by Christensen [4]gives a more detailed discussion of the vibrations will almost always be sufficiently large so as to satisfy d<< On the other hand,the wavelengths associated with typical mechanical propagation of high-frequency waves having very short wavelengths the second criterion becomes important only when dealing with the of viscoelastic composites are d <L and d<<A.Practically speaking, criteria for the use of the effective modulus theory in dynamic loading wavelength,A,of the dynamic stress distribution (fig.8.6).Thus,the inhomogeneity,d,must also be much smaller than the characteristic another criterion related to dynamic effects.That is,the scale of the Critical dimensions which are used in the criteria for the application of the effective modulus Stress, Distance, Principles of Composite Material Mechanics 610 ance is given by EXAMPLE 8.1 shear stress-time history shown in figure 8.7.If the effective shear creep compli- A specially orthotropic,linear viscoelastic composite lamina is subjected to the metry and the coordinate system used. independent moduli or compliances depend on material property sym- In both elastic and viscoelastic cases,further reductions in the number of that for transversely isotropic composites under plane stress,S2(f)=S2(t) Halpin and Pagano [5]and others have presented experimental evidence S()for the constituent materials,then the same is true for the composite. Schapery [1]has used thermodynamic arguments to show that if Si(f)= symmetry conditions S=Si and Cy=Ci For the viscoelastic case, Recall that for the elastic case,strain energy considerations led to the the Elastic-Viscoelastic Correspondence Principle,which is discussed later. correspondence between elastic and viscoelastic equations is provided by compliance transformation equations.Further justification for such direct Note that these equations are entirely analogous to the corresponding elastic where s=sine,c=cos6,and the angle 0 has been defined in figure 2.8. Sag-251g-255g-56ga-c-25:0-25:0-5%060 S0g-251g-255g-5%geeu-25:电-255g-s6cee l452g-B%c8e:s:+S%dS0-2125104+25:-Ss6 Sz(t)=Su()s4+[2S2()+So()s2c2+Sz()c Sr2()=Siz()(s+c)+[Su()-Sz()-S66(t)]s2c2 Su(t)=Su(t)c4+[2S2()+Sco()s2+Sz()s that the S;(t)are related to the Si(f)by the transformations, close resemblance of this matrix to the corresponding transformed elastic compliance matrix in Equations(2.37).Halpin and Pagano [5]have shown where the S(t)are the transformed effective creep compliances.Note the generally orthotropic lamina,we have S16(t)S26(t)S66(t) S22(t)S26(t) Su(t)S12(t)Sio(t) corresponding elastic compliance matrix in Equations (2.24).For the Note the close resemblance of this creep compliance matrix to the Analysis of Viscoelastic and Dynamic Behavior 8.12 s10

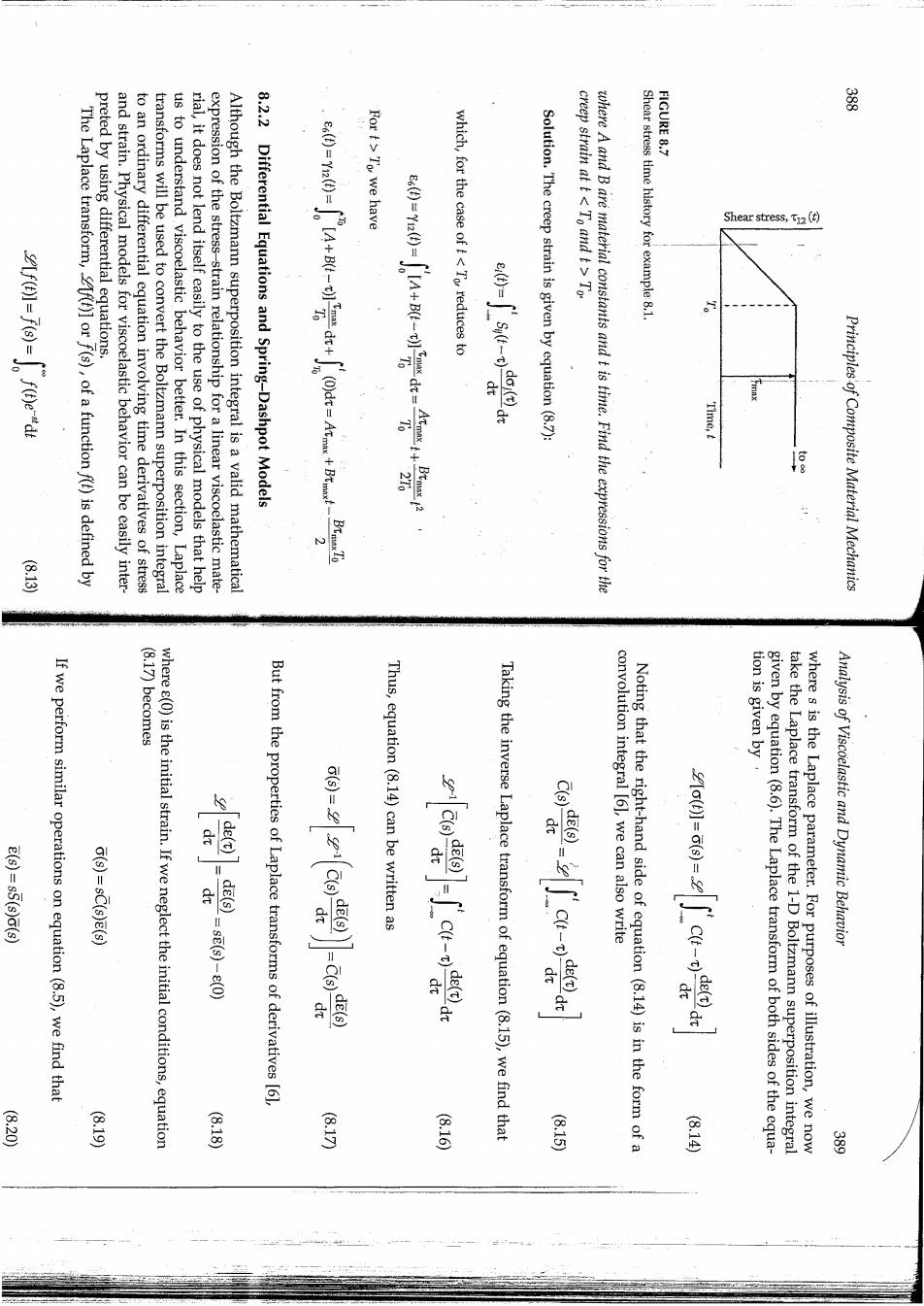

FIGURE 8.7 第 The Laplace transform,f(t)]or f(s),of a function f(t)is defined by preted by using differential equations. and strain.Physical models for viscoelastic behavior can be easily inter to an ordinary differential equation involving time derivatives of stress transforms will be used to convert the Boltzmann superposition integral us to understand viscoelastic behavior better.In this section,Laplace rial,it does not lend itself easily to the use of physical models that help expression of the stress-strain relationship for a linear viscoelastic mate- Although the Boltzmann superposition integral is a valid mathematical 8.2.2 Differential Equations and Spring-Dashpot Models For t>To,we have which,for the case of <To,reduces to Solution.The creep strain is given by equation(8.7): creep strain at t<To and t>To where A and B are material constants and t is time.Find the expressions for the Shear stress time history for example 8.1. Shear stress,() Time,t Principles of Composite Material Mechanics (8.17)becomes If we perform similar operations on equation(8.5),we find that where e(0)is the initial strain.If we neglect the initial conditions,equation But from the properties of Laplace transforms of derivatives [61, Thus,equation (8.14)can be written as Taking the inverse Laplace transform of equation(8.15),we find that convolution integral [61,we can also write tion is given by' Noting that the right-hand side of equation(8.14)is in the form of a given by equation(8.6).The Laplace transform of both sides of the equa- take the Laplace transform of the 1-D Boltzmann superposition integral where s is the Laplace parameter.For purposes of illustration,we now Analysis of Viscoelastic and Dynamic Behavior 8.20 (810 (6·18) 81M (816) (615 骂

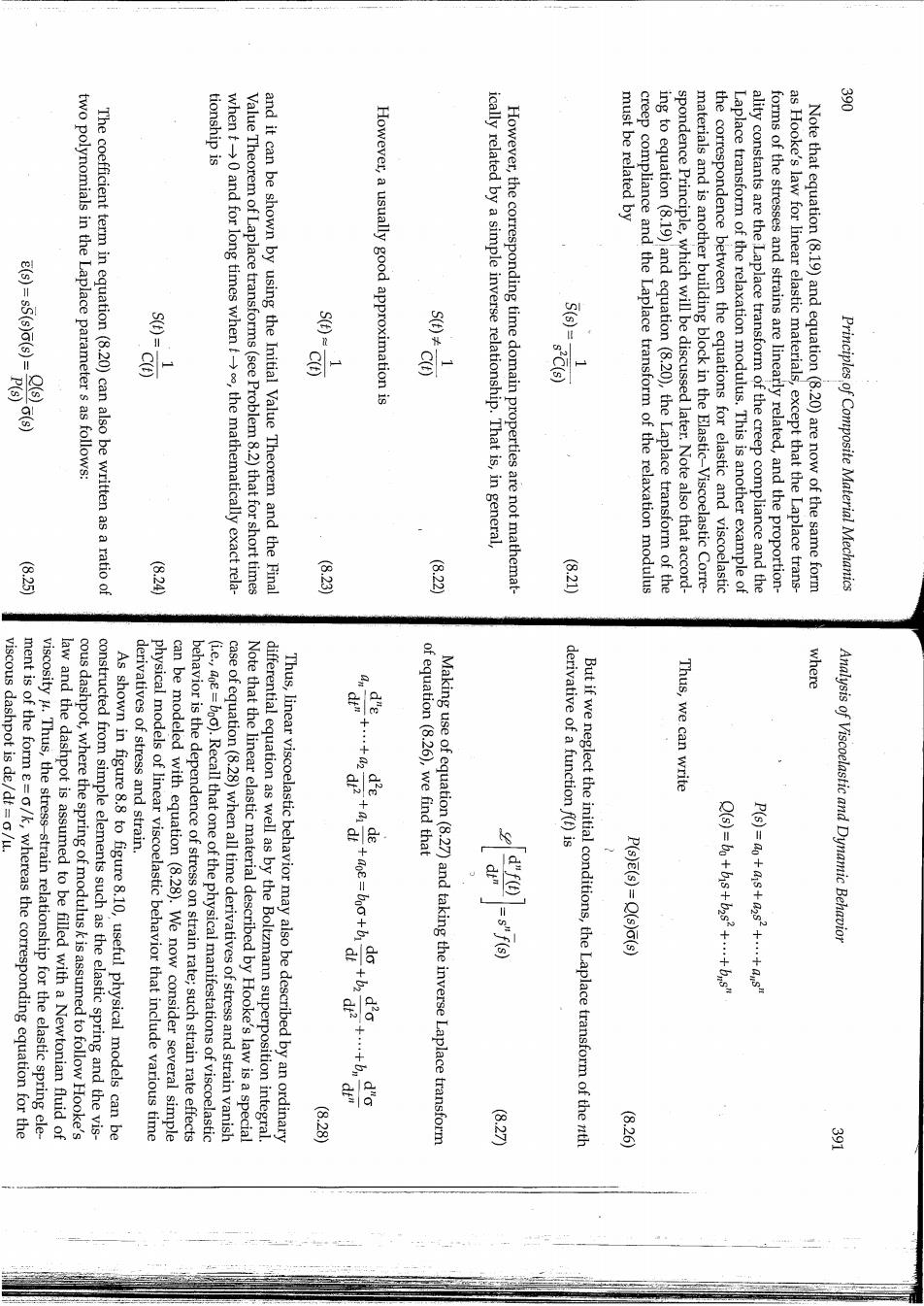

tionship is two polynomials in the Laplace parameter s as follows: must be related by The coefficient term in equation(8.20)can also be written as a ratio of when t>0 and for long times when to,the mathematically exact rela- Value Theorem of Laplace transforms(see Problem 8.2)that for short times and it can be shown by using the Initial Value Theorem and the Final However,a usually good approximation is ically related by a simple inverse relationship.That is,in general, However,the corresponding time domain properties are not mathemat- 5(6C() creep compliance and the Laplace transform of the relaxation modulus ing to equation(8.19)and equation(8.20),the Laplace transform of the spondence Principle,which will be discussed later.Note also that accord- materials and is another building block in the Elastic-Viscoelastic Corre- the correspondence between the equations for elastic and viscoelastic Laplace transform of the relaxation modulus.This is another example of ality constants are the Laplace transform of the creep compliance and the forms of the stresses and strains are linearly related,and the proportion- as Hooke's law for linear elastic materials,except that the Laplace trans- Note that equation(8.19)and equation(8.20)are now of the same form Principles of Composite Material Mechanics (8.2) 图 (622) ment is of the form g=o/k,whereas the corresponding equation for the viscous dashpot is de/dt=o/u. where viscosity #Thus,the stress-strain relationship for the elastic spring ele- law and the dashpot is assumed to be filled with a Newtonian fluid of cous dashpot,where the spring of modulus k is assumed to follow Hooke's constructed from simple elements such as the elastic spring and the vis- As shown in figure 8.8 to figure 8.10,useful physical models can be derivatives of stress and strain. physical models of linear viscoelastic behavior that include various time behavior is the dependence of stress on strain rate;such strain rate effects can be modeled with equation(8.28).We now consider several simple (ie.,aoe=boo).Recall that one of the physical manifestations of viscoelastic case of equation(8.28)when all time derivatives of stress and strain vanish Note that the linear elastic material described by Hooke's law is a special differential equation as well as by the Boltzmann superposition integral. Thus,linear viscoelastic behavior may also be described by an ordinary 但w+3P of equation(8.26),we find that 被0个 d2o Making use of equation(8.27)and taking the inverse Laplace transform derivative of a function f()is But if we neglect the initial conditions,the Laplace transform of the nth Thus,we can write P(s)=ao+as+azs2+...+ans" Analysis of Viscoelastic and Dynamic Behavior (828 图 826

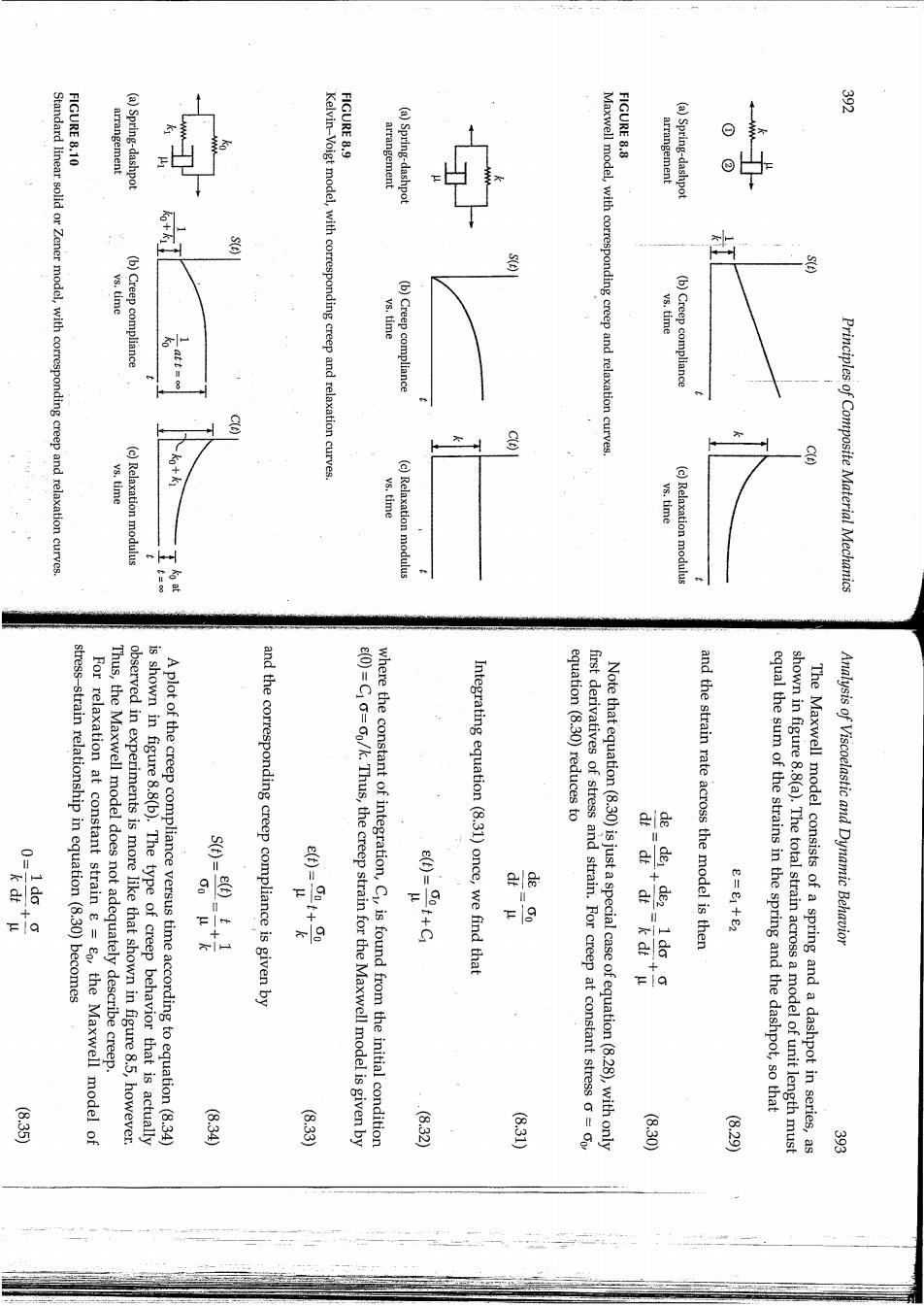

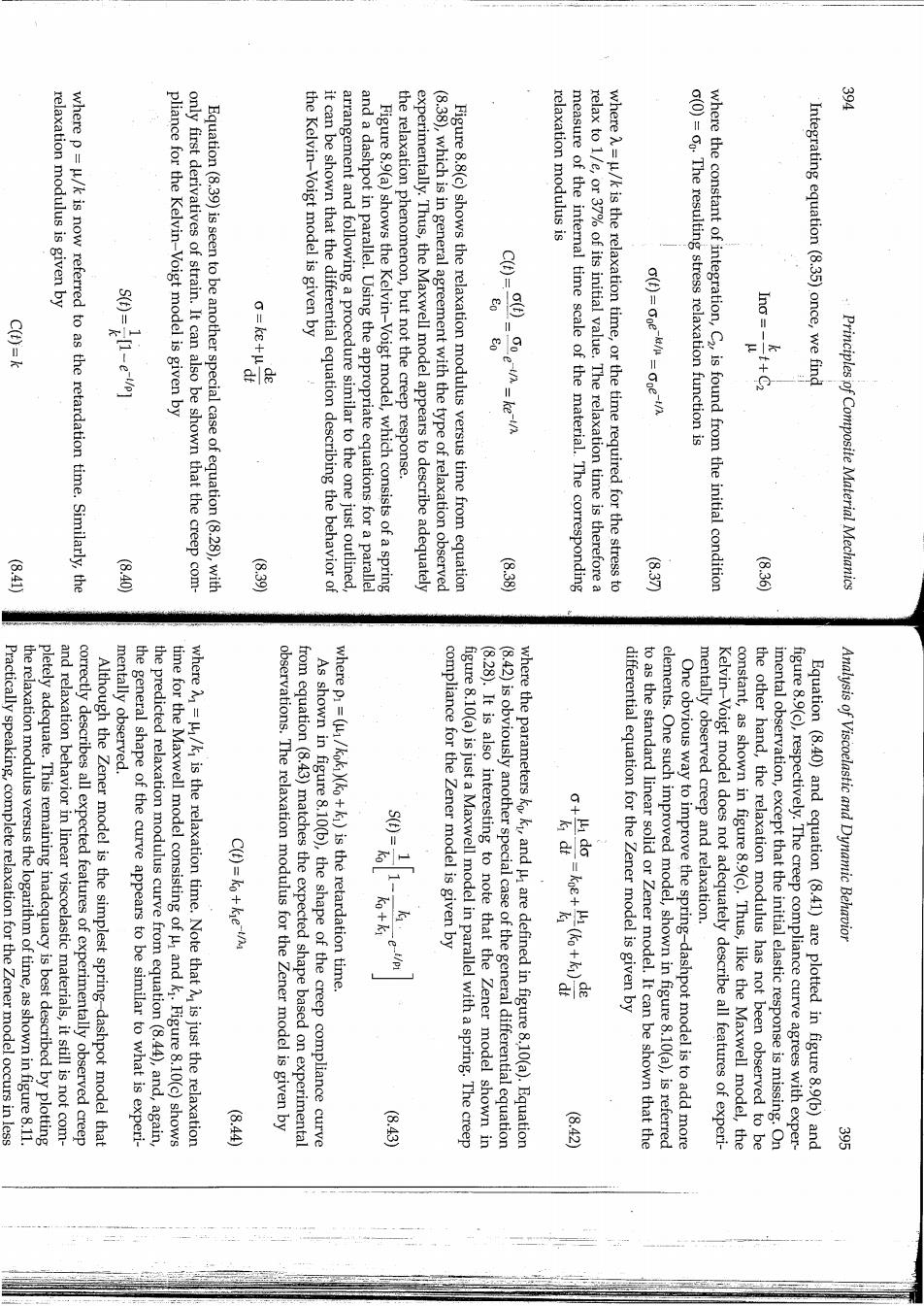

FIGURE 8.10 常 arrangement (a)Spring-dashpot FIGURE 8.9 Kelvin-Voigt model,with corresponding creep and relaxation curves arrangement (a)Spring-dashpot FIGURE 8.8 Standard linear solid or Zener model,with corresponding creep and relaxation curves. vs.time (b)Creep compliance ys.time (b)Creep compliance Maxwell model,with corresponding creep and relaxation curves. arrangement (a)Spring-dashpot vs.time (b)Creep compliance ys.time (c)Relaxation modulus + 8 ys,time (c)Relaxation modulus vs.time (c)Relaxation modulus Principles of Composite Material Mechanics 入 stress-strain relationship in equation(8.30)becomes For relaxation at constant strain g =8o,the Maxwell model of Thus,the Maxwell model does not adequately describe creep. observed in experiments is more like that shown in figure 8.5,however. is shown in figure 8.8(b).The type of creep behavior that is actually A plot of the creep compliance versus time according to equation(8.34) and the corresponding creep compliance is given by e(0)=Cio=0o/k.Thus,the creep strain for the Maxwell model is given by where the constant of integration,C1,is found from the initial condition O-8+O Integrating equation(8.31)once,we find that first derivatives of stress and strain.For creep at constant stress o=oo equation(8.30)reduces to Note that equation(8.30)is just a special case of equation(8.28),with only and the strain rate across the model is then 8-e+e2 Analysis of Viscoelastic and Dynamic Behavior 18 equal the sum of the strains in the spring and the dashpot,so that shown in figure 8.8(a).The total strain across a model of unit length must The Maxwell model consists of a spring and a dashpot in series,as 835 9.33 (8.32 (8.30 (639 常

relaxation modulus is given by where p =u/k is now referred to as the retardation time.Similarly,the pliance for the Kelvin-Voigt model is given by only first derivatives of strain.It can also be shown that the creep com- Equation(8.39)is seen to be another special case of equation(8.28),with the Kelvin-Voigt model is given by it can be shown that the differential equation describing the behavior of arrangement and following a procedure similar to the one just outlined, and a dashpot in parallel.Using the appropriate equations for a parallel Figure 8.9(a)shows the Kelvin-Voigt model,which consists of a spring the relaxation phenomenon,but not the creep response. experimentally.Thus,the Maxwell model appears to describe adequately (8.38),which is in general agreement with the type of relaxation observed Figure 8.8(c)shows the relaxation modulus versus time from equation relaxation modulus is C(t)= measure of the internal time scale of the material.The corresponding relax to 1/e,or 37%of its initial value.The relaxation time is therefore a where A=u/k is the relaxation time,or the time required for the stress to (t)=Goe-k/a =Goet/ o(0)=0o.The resulting stress relaxation function is where the constant of integration,C2,is found from the initial condition Integrating equation (8.35)once,we find Principles of Composite Material Mechanics 墨 640) 8.39 3.37 (8.36 Practically speaking,complete relaxation for the Zener model occurs in less the relaxation modulus versus the logarithm of time,as shown in figure 8.11 pletely adequate.This remaining inadequacy is best described by plotting and relaxation behavior in linear viscoelastic materials,it still is not com- correctly describes all expected features of experimentally observed creep mentally observed. Although the Zener model is the simplest spring-dashpot model that the general shape of the curve appears to be similar to what is experi- the predicted relaxation modulus curve from equation(8.44),and,again time for the Maxwell model consisting of and k.Figure 8.10(c)shows where =/k is the relaxation time.Note that is just the relaxation observations.The relaxation modulus for the Zener model is given by from equation(8.43)matches the expected shape based on experimental As shown in figure 8.10(b),the shape of the creep compliance curve where p=(/kok)(ko+k)is the retardation time. compliance for the Zener model is given by figure 8.10(a)is just a Maxwell model in parallel with a spring.The creep (8.28).It is also interesting to note that the Zener model shown in (8.42)is obviously another special case of the general differential equation where the parameters koki,and are defined in figure 8.10(a).Equation differential equation for the Zener model is given by to as the standard linear solid or Zener model.It can be shown that the elements.One such improved model,shown in figure 8.10(a),is referred One obvious way to improve the spring-dashpot model is to add more mentally observed creep and relaxation. Kelvin-Voigt model does not adequately describe all features of experi- constant,as shown in figure 8.9(c).Thus,like the Maxwell model,the the other hand,the relaxation modulus has not been observed to be imental observation,except that the initial elastic response is missing.On figure 8.9(c),respectively.The creep compliance curve agrees with exper- Equation (8.40)and equation (8.41)are plotted in figure 8.9(b)and Analysis of Viscoelastic and Dynamic Behavior 墨 .3) 3) 芳