1 The lowest grade for strength of concrete in reinforced concrete structures and in prestressed concrete C30and C40 respectively: 2 Maximum chlorion-content in concrete is 0.06%; 3 It is better to use non-alkali activated aggregate;when alkali activated aggregate is applied, max.alkali content in concrete is 3.0kg/m 4 The thickness of concrete cover shall be increased by 40%according to the stipulation of the Table 9.2.1 of the code;when effective protective measures are taken for concrete surface,the thick ness of concrete cover could be reduced appropriately. 5 Regular maintenance shall be performed during the cours of application. 3.4.4 In environmental categories II and IlI,the special effective measures shall be taken for con- crete structures with design working life up to 100 years: 3.4.5 In humid environment of severe cold and cold area,structural concrete shall meet relevant re- quirements for freezing-resistant,and the freezing-resistant grade of concrete shall conform to the re- quirements of relevant standards. 3.4.6 For concrete structurcs rquinng penetration-resistant,the penetration-resistant grade of 3.4.7 For structural members in environmental categories I,it is better to use ribbed steel bars oated with;and the special measurs shall be taken for prestressed steel reinforcements,anchorage devices and connectors. 3.4.8 The durability reguirements of concrete structures in environmental categorics IV and V shall confor to the stipulations of relevant standards. tures

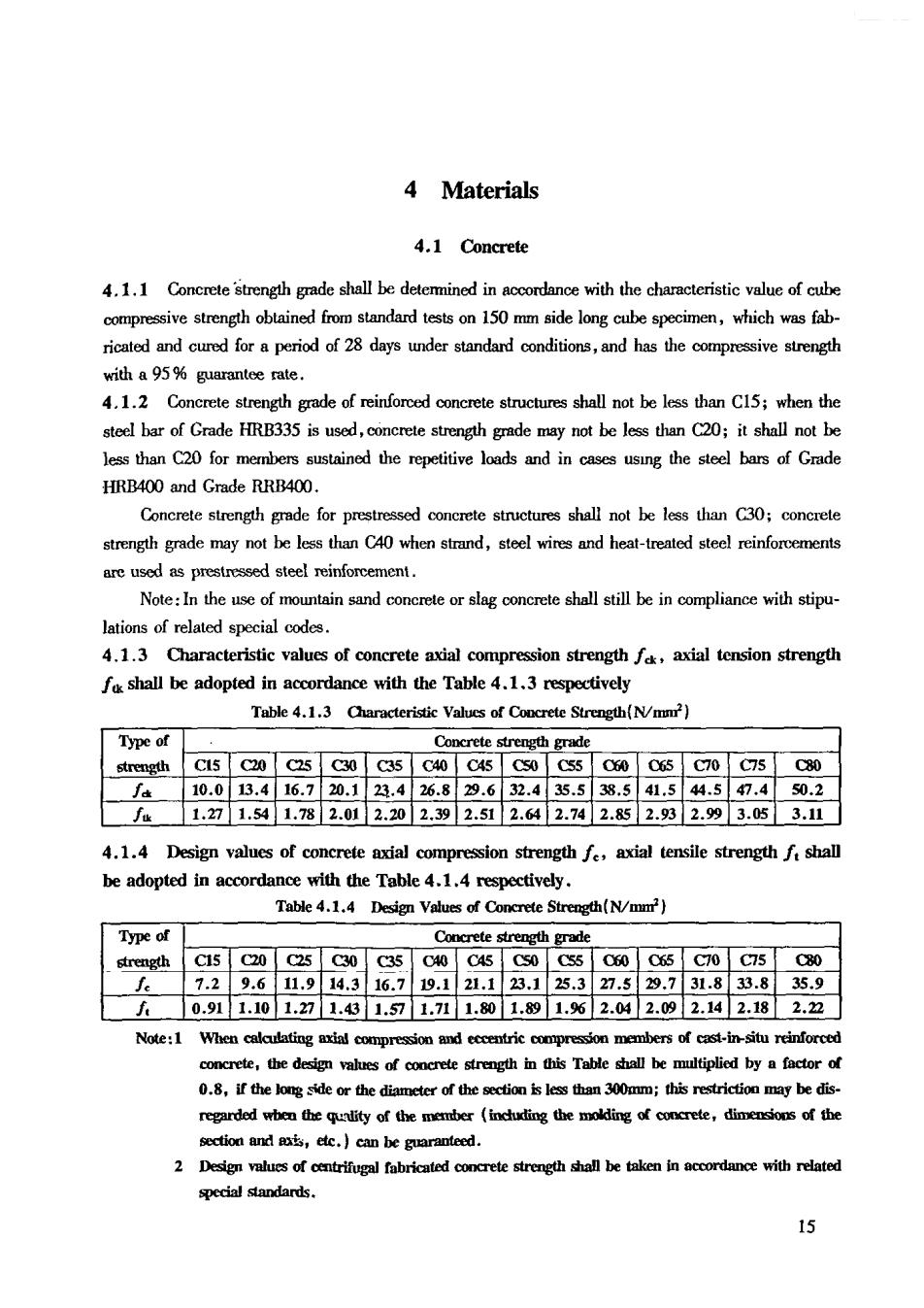

4 Materials 4.1 Concrete 4.1.1 Concrete 'strength grade shall be detemmined in accordance with the characteristic value of cube obained from standard long cube specimen,which was fab ricated and cured for a period of 28 days under standard conditions,and has the compressive strength with a95%guarantee rate. 4.1.2 Concrete strength grade of reinfored concrete structures shall not be less than C15;when the steel bar of Grade HRB335 is used,cncrete strength grade may not be less than C20;it shall not be less than C20 for members sustained the repetitive loads and in cases using the steel bars of Grade HRB400 and Grade RRB400. Concrete strength grade for prestressed conrete structures shall not be less than C30;concrete strength grade may not be less than C40 when strand,steel wires and heat-treated steel reinforcements Note:In the use of mountain sand concrete or slag concrete shall still be in compliance with stipu- lations of related special codes 4.1.3 Characteristic valucs of concrete axial compression strengthf,axial tension strength fshall be adopted in accordance with the Table 4.1.3 respectively Table 4.1.3 Characteristic Valucs of Coocrete Strength(N/mm) Type of Concrete strength grad strength CI5 C20 C25 C30 C35 C40 C45 CSo CS5 C60 C65 C70 C75 C80 10.013.416.720.123.426.829.632.435.538.541.544.547.450.2 /1.271.541.782.012.202.392.512.642.742.852.32.993.05311 4.1.4 Design values of concrete axial compression strengthf axial tensile strengthfshall be adopted in accordance with the Table 4.1.4 respectively. Table 4.1.4 Design Values of Concrete Strength(N/mm) Type of trength 72 9.694.316.79.12.d.2s.327.59.731.83.8 35.9 0.911.101.271.431.571.711.801.8919%2.042.092.142.182.22 ersofc-initurenfor concrete,the design values of cocrete strength in this Table shall be multiplied byfactor of 0.8,if the ong side or the diameter of the section is less than 300mm;this restriction may be dis- section and etc.)can be guaranteed. 2 Design values of centrifugal fabricated coocrete strength shall be taken in accordance with related 15

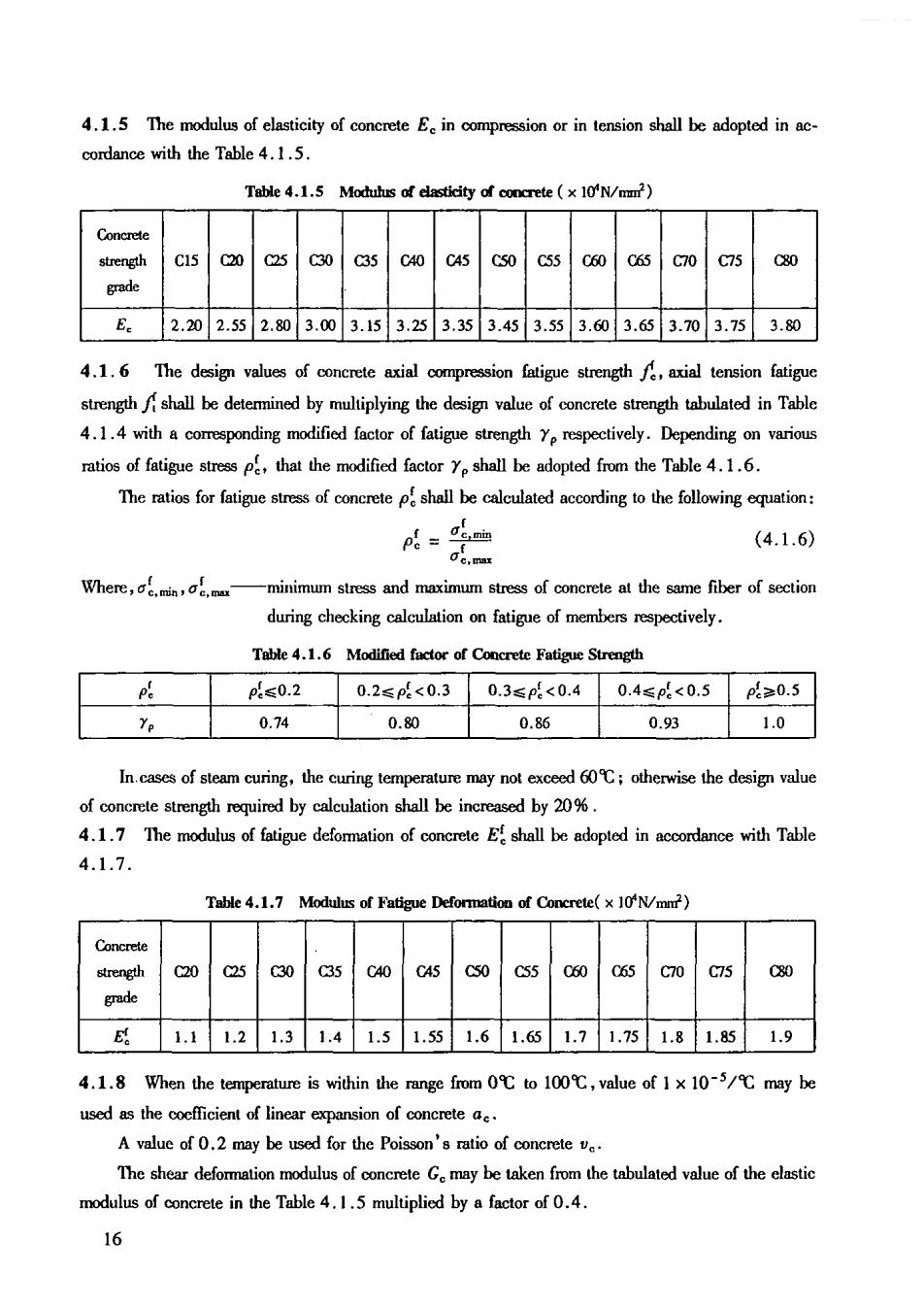

4.1.5 The modulus of elasticity of concrete E in compression or in tension shall be adopted in ac- cordance with the Table 4.1.5. Table 4.1.5 Moduhrs of elasticity of concrete (x 10'N/mm) Concrete strength C035C40c45c50C55 c60c65c70C75 cxn grade E。2.202.52.803.03.153.253.353.453.53.603.653.703.753.80 4.1.6 The design values of concrete axial compression fatigue tension fatiguc strengthshall be determined by multiplying the design value of concrete strength tabulated in Table 4.1.4 with a comresponding modified factor of fatigue strength y respectively.Depending on various ratios of fatigue stress,that the modified factor shall be adopted from the Table 4.1.6. The ratios for fatigue stess of conrete shall be calculated according to the following qtion: (4.1.6) Where, -minimum stress and maximum stress of concrete at the same fiber of section during checking calculation on fatigue of members respectively Table 4.1.6 Modified factor of Concrete Fatigue Strength p6≤0.20.2≤p6<0.30.3≤p<0.40.4≤p<0.5pd≥0.5 0.74 0.80 0.86 0.93 1.0 In.cases of steam curing,the curing temperature may not exceed 60C;otherwise the design value 4.1.7 The modulus of fatigue deformation of concrete E shall be adopted in accordance with Table 4.1.7. Table 4.1.7 Modulus of Fatigue Deformation of Concrete(x1N/mm) Conerrte c5c30c35c40 C45 C50 C65 C70 C80 grade 1.11.21.31.41.51.51.61.61.71.751.81.851.9 4.l.8 When the temperature is within the range from0℃tol0o℃,value of1×10-5/℃may be used as the coefficient of linear expansion of concrete A value of 0.2 may be used for the Poisson's ratio of concrete ve. The shear deformation modulus of concrete Gmay be taken from the tabulated value of the elastic modulus of concrete in the Table 4.1.5 multiplied by a factor of 0.4. 16

4.2 Steel Reinforcements 4.2.1 Steel and structures shall be inac cordance with the following stipulations respectively: 1 The steel bars of Grade HRB400 and Grade HRB335 can be used for ordinary steel reinforce ment,the steel bars of Grade HPB235 and Grade RRB400 may also be used; 2 The prestressing strands and steel wires can be used for prestressed steel reinforcement,the heat-treated steel bars may also be used. inforcements in reinforced coocrete structures and in nrestreased concrete structures respectively. fied in curent nation sandard"Ho-rolled and ribbed see bar usd in reinfod"GB 1499; the steel bar of Grade HPB235 denotes the 235 steel bar pecified in cument national sandard"Hot- plain rod tee bar ued"GB 13013;and the of st bar of Grde RRB400 denotes the KIA00 steel bar specifiod in curent national standand"Waste-heat treated see bar used in reinforced concrete"CB 13014: wires specified in current national standard"Steel wires used in prestressed concrete"GB/T523. 4 When adopting the cold-drawn steel bar or other steel bars,which have not been listed in this Clause but theirtrenghendrateadcdongtionincooptianoewihrnepeirenents,shalcontfomtotipulaticmnscfspe cial stendards 4.2.2 The guarantee rate for the characteristic value of strength for steel bars shall not be less than 95%. Characteristic values of strength for hot-rolled steel bars are determined on the basis of yield strength where characteristic value is denoted byf Characteristic values of strength for prestressed steel wires,strands and heat-treated steel b bars are determined by ultimate tensile strength where characteristic value is denoted byf The characteristic values of strength of ordinary steel bars and prestressed steel reinforce ments shall be adopted from the Table 4.2.2-1 and the Table 4.2.2-2 respectively. The nominal,the calculated sectional area and the theoretical weight of stee bars,strands and steel wires with various diameters shall be adopted from Appendix B. Table 4.2.-1 Vahes of for Ordinary Sted Bars(N/m Types d(mm) 拉 HPB235(Q235)1 8-20 235 Hot rolled HRB35(20MnS 6.0 335 steel bar 6 RRB40O(K20MiS】 8-40 400 Note:l The diameter of bard denotes ominal diameter When steel bars with diameter greater thn 40 are used,the retiable engineering experiences shall be available. 12

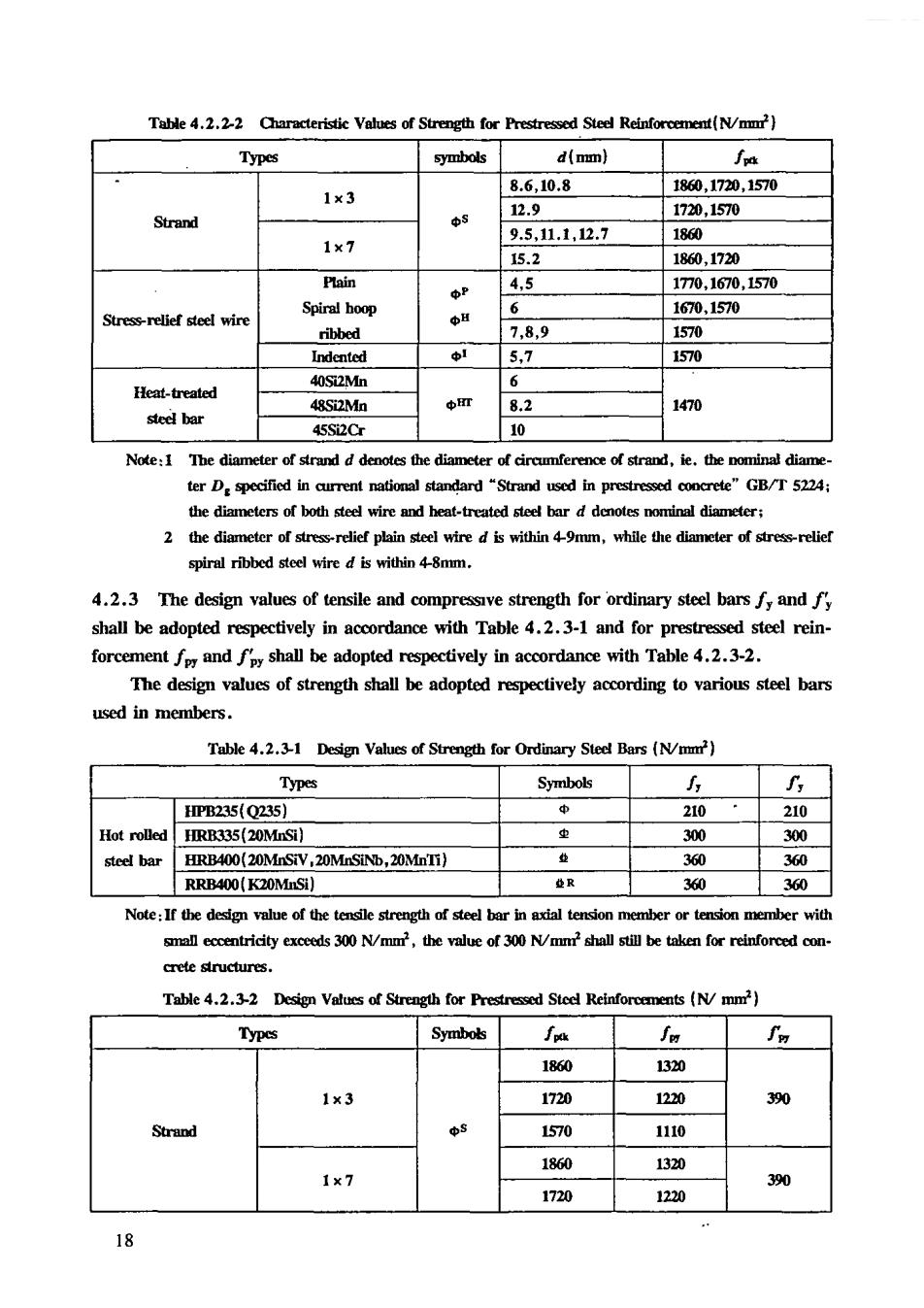

Table 4.2.2-2 Characteristic Values of Strength for Prestressed Steel Reinforcement(N/) Types symbols d(mm) foa 1×3 8.6,10.8 1860,1720,1570 12.9 1720,1570 Strand 9.5.11.1.12.7 1860 1×7 152 1601720 P 170.1670.570 Stress-relief steel wire Spiral hoop 1670.1570 ribbed 色为 7,8,9 1570 Indented l 5.7 1570 40Si2Mn 6 Heat-treated 4SzM恤 中 8.2 1470 stedl bar 45Si2Cr 10 Noe:1 The the diameter of.diame ter D specificd in current national standard"Strand used in prestressed"GB/T5224 the diameters of both steel wire ad heat-treated steel bar d denotes nominal diameter; 2 the diameter of stressrelief plain steel wire d is within 4-9mm,while the diameter of stress-relief spiral ribbed steel wire d is within 4-8mm 4.2.3 The design values of tensile and compressive strength for ordinary steel bars fy and fy shall be adopted respectively in accordance with Table 4.2.3-1 and for prestressed steel rein forcementf andfy shall be adopted respectively in accordance with Table 4.2.3-2. The design values of strength shall be adopted respectively according to various steel bars used in members. Table 4.2.3-1 Design Valucs of Strength for Ordinary Sted Bars (N/mm) Symbols B235(Q235) 中 210 210 Hot rolled HRB335(20MnSi) 300 200 steel bar HRB400(20MnSiV,20MnSiNb,20MnTi) 30 RRB400(K20MnSi) 丝R 360 360 Note.If the value of the tensile strength af steel har in axial tension member or tension crete siructures. Table 4.2.3-2 Design Vatues of Strength for Prestressed Steel Reinforcements (N/mm) Symbols frex f时 ∫ 1860 1320 1×3 1720 1220 晚 Strand 1570 1110 1860 1320 1×7 1720 1220 8