Agenda提纲 ▣Supply Chain 供应链 Advanced Planning/Scheduling (APS) 先进生产计划及调度 口Advanced Planning System Case Study先进生产计划 系统实例 6

6 6 ❑ Supply Chain 供应链 ❑ Advanced Planning/Scheduling (APS) 先进生产计划及调度 ❑ Advanced Planning System Case Study 先进生产计划 系统实例 Agenda 提纲

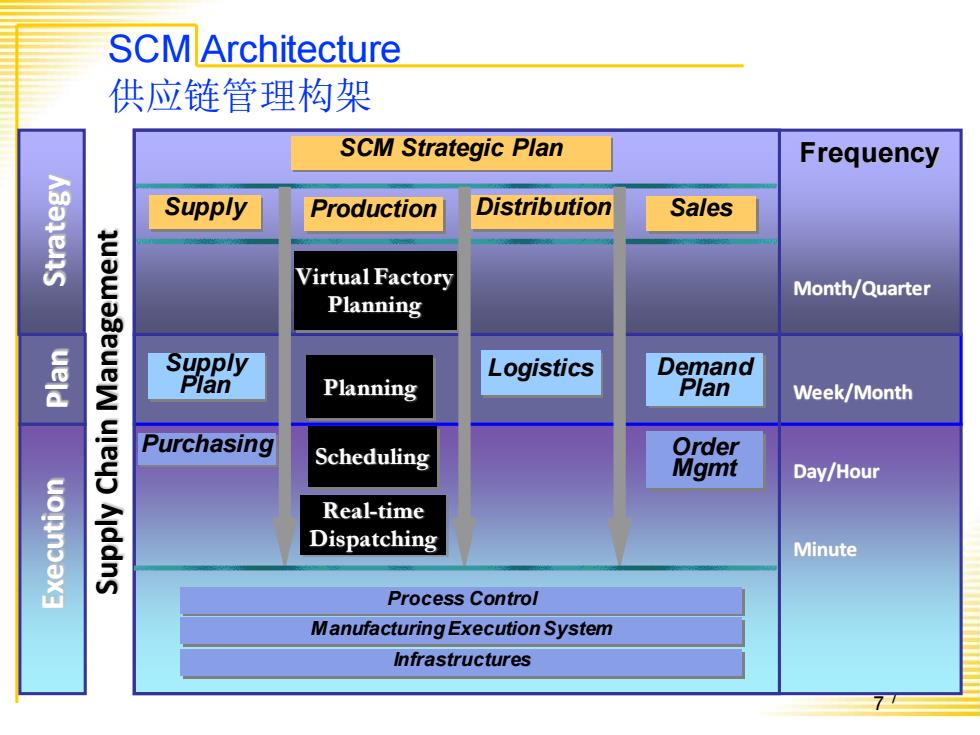

SCM Architecture 供应链管理构架 SCM Strategic Plan Frequency Supply Production Distribution Sales ueld quawaBeueW Virtual Factory Month/Quarter Planning Supply Logistics Demand Plan Planning Plan Week/Month uley) Purchasing Scheduling Order Mgmt Day/Hour Real-time Dispatching Minute Process Control Manufacturing Execution System Infrastructures

7 7 Purchasing Supply Plan Scheduling Logistics Planning Order Mgmt Demand Plan Supply Production Distribution Process Control Manufacturing Execution System Infrastructures SCM Strategic Plan Real-time Dispatching Virtual Factory Planning Sales Frequency Month/Quarter Week/Month Day/Hour Minute SCM Architecture 供应链管理构架 Strategy Plan Execution Supply Chain Management

Semiconductor Industry:Challenges 产业现状:挑战 口Marketing environment changes dramatically.半导体产业市场变化剧 烈。企业必须缩短市场反应时间,特别是生产计划的制定周期。 ▣ The cost of equipments is very high.半导体装备成本极高。主要设备 使用率的提高,能为公司节省巨额开支。 ▣ Semiconductor manufacturing is among the most complex production problems encountered today.半导体制造的复杂性和专业性,使其生 产管理成为最具挑战的课题。 ▣ Many enterprises lack expertise in IE/OR to apply APS.优秀的生产管 理系统需要先进工业工程(运筹)学成果支持。 In China中国国情: No domestic APS provider 无国内APS提供者。国外APS提供者产品价格高,服务尚未本地化 Production Management:guesswork,manual work 生产管理:主观臆断、手工计算 8 8

8 8 Semiconductor Industry: Challenges 产业现状:挑战 ❑ Marketing environment changes dramatically. 半导体产业市场变化剧 烈。企业必须缩短市场反应时间,特别是生产计划的制定周期。 ❑ The cost of equipments is very high. 半导体装备成本极高。主要设备 使用率的提高,能为公司节省巨额开支。 ❑ Semiconductor manufacturing is among the most complex production problems encountered today. 半导体制造的复杂性和专业性,使其生 产管理成为最具挑战的课题。 ❑ Many enterprises lack expertise in IE/OR to apply APS. 优秀的生产管 理系统需要先进工业工程(运筹)学成果支持。 In China 中国国情: ❑ No domestic APS provider 无国内APS提供者。国外APS提供者产品价格高,服务尚未本地化 ❑ Production Management: guesswork, manual work 生产管理:主观臆断、手工计算