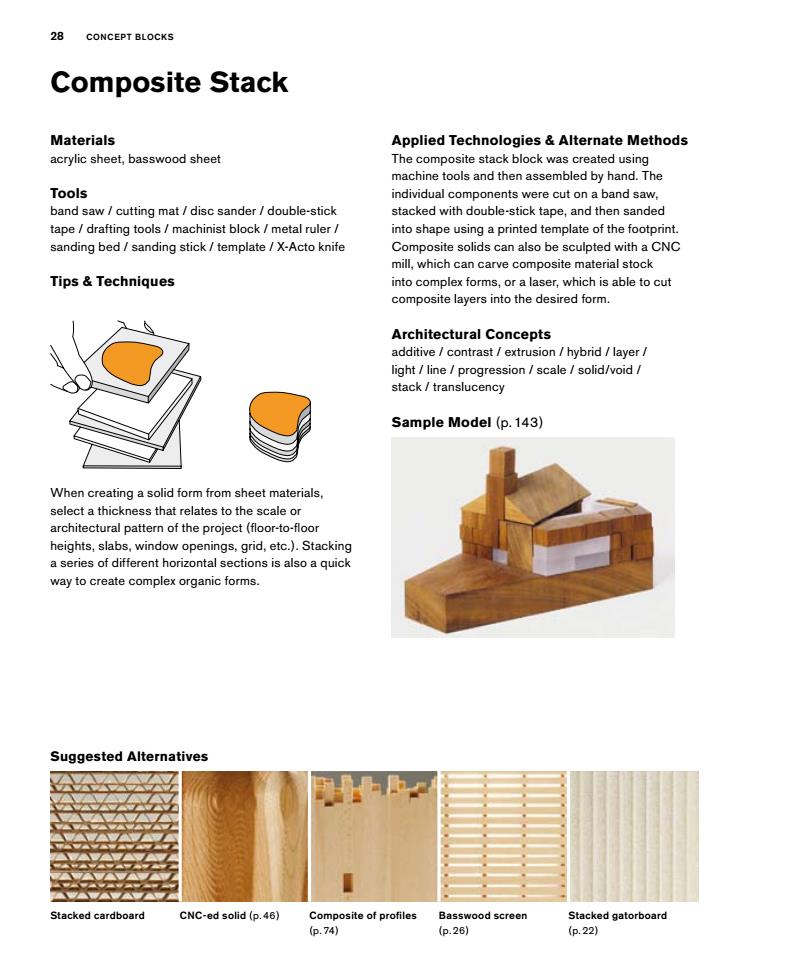

28 CONCEPT BLOCKS Composite Stack Materials Applied Technologies Alternate Methods acrylic sheet,basswood sheet The composite stack block was created using machine tools and then assembled by hand.The Tools individual components were cut on a band saw, band saw cutting mat disc sander double-stick stacked with double-stick tape,and then sanded tape/drafting tools machinist block/metal ruler into shape using a printed template of the footprint. sanding bed sanding stick/template /X-Acto knife Composite solids can also be sculpted with a CNC mill,which can carve composite material stock Tips Techniques into complex forms,or a laser,which is able to cut composite layers into the desired form. Architectural Concepts additive contrast extrusion hybrid layer/ light line progression scale solid/void stack/translucency Sample Model(p.143) When creating a solid form from sheet materials, select a thickness that relates to the scale or architectural pattern of the project(floor-to-floor heights,slabs,window openings,grid,etc.).Stacking a series of different horizontal sections is also a quick way to create complex organic forms. Suggested Alternatives Stacked cardboard CNC-ed solid(p.46) Composite of profiles Basswood screen Stacked gatorboard (p.74) (p.26) (p.22)

Applied Technologies & Alternate Methods The composite stack block was created using machine tools and then assembled by hand. The individual components were cut on a band saw, stacked with double-stick tape, and then sanded into shape using a printed template of the footprint. Composite solids can also be sculpted with a CNC mill, which can carve composite material stock into complex forms, or a laser, which is able to cut composite layers into the desired form. Architectural Concepts additive / contrast / extrusion / hybrid / layer / light / line / progression / scale / solid/void / stack / translucency Sample Model (p.143) Composite Stack Materials acrylic sheet, basswood sheet Tools band saw / cutting mat / disc sander / double-stick tape / drafting tools / machinist block / metal ruler / sanding bed / sanding stick / template / X-Acto knife Tips & Techniques When creating a solid form from sheet materials, select a thickness that relates to the scale or architectural pattern of the project (floor-to-floor heights, slabs, window openings, grid, etc.). Stacking a series of different horizontal sections is also a quick way to create complex organic forms. 28 Concept Blocks Stacked cardboard CNC-ed solid (p. 46) Composite of profiles (p.74) Basswood screen (p.26) Stacked gatorboard (p.22) Suggested Alternatives

COMPOSITE STACK 29 Architecture is the masterly,correct,and magnificent play of masses brought together in light. LE CORBUSIER

composite stack 29 Architecture is the masterly, correct, and magnificent play of masses brought together in light. Le Corbusier

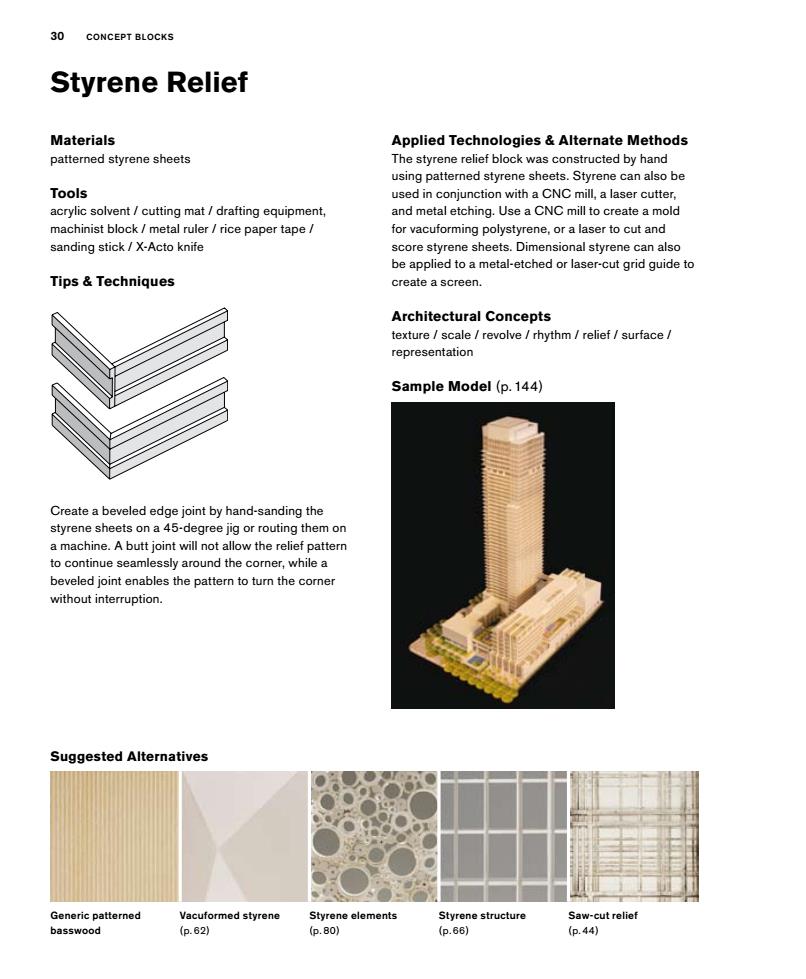

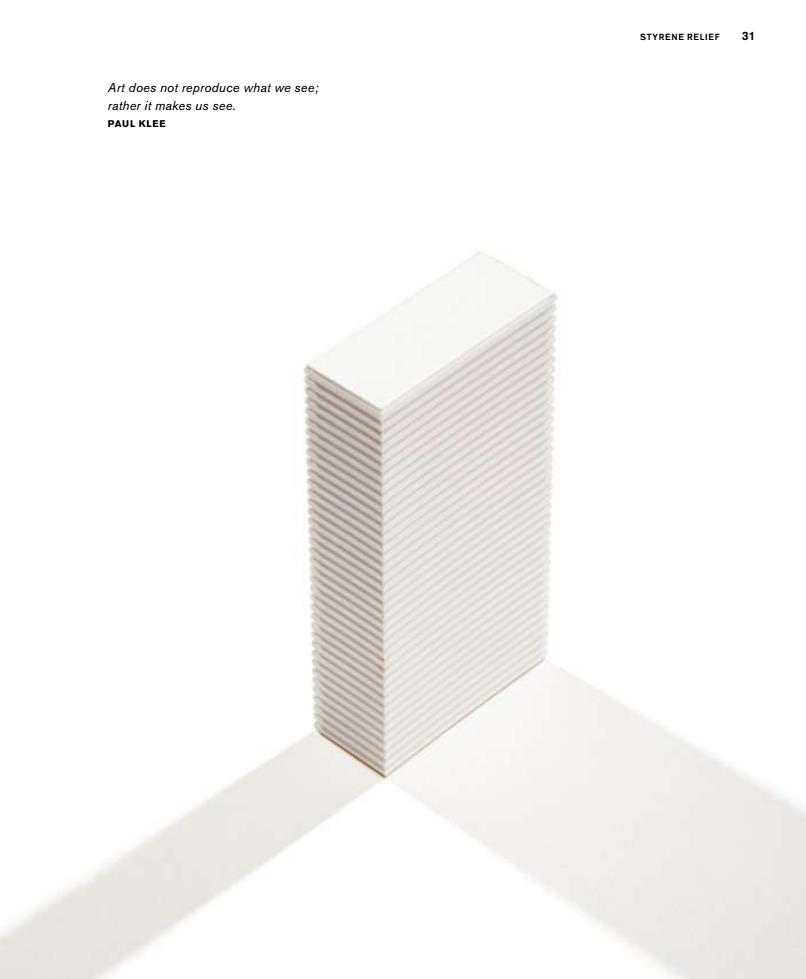

30 CONCEPT BLOCKS Styrene Relief Materials Applied Technologies Alternate Methods patterned styrene sheets The styrene relief block was constructed by hand using patterned styrene sheets.Styrene can also be Tools used in conjunction with a CNC mill,a laser cutter, acrylic solvent cutting mat/drafting equipment, and metal etching.Use a CNC mill to create a mold machinist block metal ruler rice paper tape/ for vacuforming polystyrene,or a laser to cut and sanding stick /X-Acto knife score styrene sheets.Dimensional styrene can also be applied to a metal-etched or laser-cut grid guide to Tips Techniques create a screen. Architectural Concepts texture scale revolve rhythm relief surface representation Sample Model(p.144) Create a beveled edge joint by hand-sanding the styrene sheets on a 45-degree jig or routing them on a machine.A butt joint will not allow the relief pattern to continue seamlessly around the corner,while a beveled joint enables the pattern to turn the corner without interruption. Suggested Alternatives Generic patterned Vacuformed styrene Styrene elements Styrene structure Saw-cut relief basswood (p.62) (p.80) (p.66) (p.44)

Applied Technologies & Alternate Methods The styrene relief block was constructed by hand using patterned styrene sheets. Styrene can also be used in conjunction with a CNC mill, a laser cutter, and metal etching. Use a CNC mill to create a mold for vacuforming polystyrene, or a laser to cut and score styrene sheets. Dimensional styrene can also be applied to a metal-etched or laser-cut grid guide to create a screen. Architectural Concepts texture / scale / revolve / rhythm / relief / surface / representation Sample Model (p.144) Styrene Relief Materials patterned styrene sheets Tools acrylic solvent / cutting mat / drafting equipment, machinist block / metal ruler / rice paper tape / sanding stick / X-Acto knife Tips & Techniques Create a beveled edge joint by hand-sanding the styrene sheets on a 45-degree jig or routing them on a machine. A butt joint will not allow the relief pattern to continue seamlessly around the corner, while a beveled joint enables the pattern to turn the corner without interruption. 30 Concept Blocks Suggested Alternatives Generic patterned basswood Vacuformed styrene (p.62) Styrene elements (p.80) Styrene structure (p.66) Saw-cut relief (p.44)

STYRENE RELIEF 31 Art does not reproduce what we see; rather it makes us see. PAUL KLEE

styrene relief 31 Art does not reproduce what we see; rather it makes us see. Paul Klee

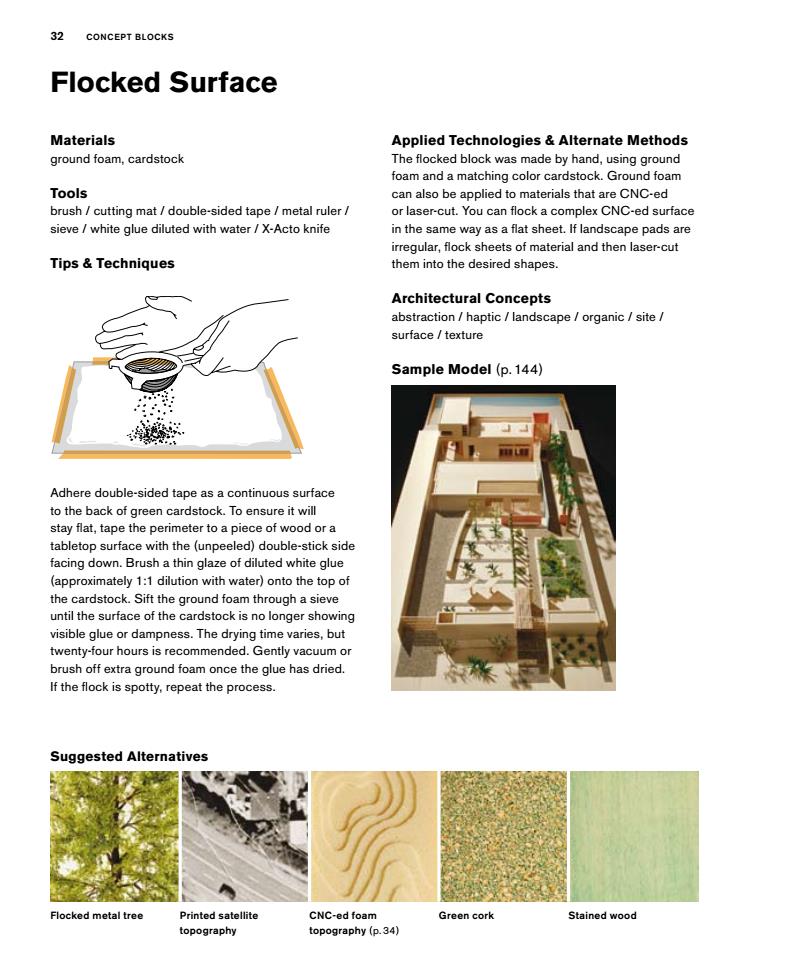

32 CONCEPT BLOCKS Flocked Surface Materials Applied Technologies Alternate Methods ground foam,cardstock The flocked block was made by hand,using ground foam and a matching color cardstock.Ground foam Tools can also be applied to materials that are CNC-ed brush cutting mat double-sided tape metal ruler/ or laser-cut.You can flock a complex CNC-ed surface sieve white glue diluted with water/X-Acto knife in the same way as a flat sheet.If landscape pads are irregular,flock sheets of material and then laser-cut Tips Techniques them into the desired shapes. Architectural Concepts abstraction/haptic /landscape/organic/site surface texture Sample Model (p.144) Adhere double-sided tape as a continuous surface to the back of green cardstock.To ensure it will stay flat,tape the perimeter to a piece of wood or a tabletop surface with the (unpeeled)double-stick side facing down.Brush a thin glaze of diluted white glue (approximately 1:1 dilution with water)onto the top of the cardstock.Sift the ground foam through a sieve until the surface of the cardstock is no longer showing visible glue or dampness.The drying time varies,but twenty-four hours is recommended.Gently vacuum or brush off extra ground foam once the glue has dried. If the flock is spotty,repeat the process. Suggested Alternatives Flocked metal tree Printed satellite CNC-ed foam Green cork Stained wood topography topography(p.34)

Applied Technologies & Alternate Methods The flocked block was made by hand, using ground foam and a matching color cardstock. Ground foam can also be applied to materials that are CNC-ed or laser-cut. You can flock a complex CNC-ed surface in the same way as a flat sheet. If landscape pads are irregular, flock sheets of material and then laser-cut them into the desired shapes. Architectural Concepts abstraction / haptic / landscape / organic / site / surface / texture Sample Model (p.144) Flocked Surface Materials ground foam, cardstock Tools brush / cutting mat / double-sided tape / metal ruler / sieve / white glue diluted with water / X-Acto knife Tips & Techniques Adhere double-sided tape as a continuous surface to the back of green cardstock. To ensure it will stay flat, tape the perimeter to a piece of wood or a tabletop surface with the (unpeeled) double-stick side facing down. Brush a thin glaze of diluted white glue (approximately 1:1 dilution with water) onto the top of the cardstock. Sift the ground foam through a sieve until the surface of the cardstock is no longer showing visible glue or dampness. The drying time varies, but twenty-four hours is recommended. Gently vacuum or brush off extra ground foam once the glue has dried. If the flock is spotty, repeat the process. 32 Concept Blocks Flocked metal tree Printed satellite topography CNC-ed foam topography (p.34) Green cork Stained wood Suggested Alternatives