Fatigue Room Temperature Fatigue Performance Elevated Temperature Fatigue Performance of Selected Nickel Based Alloys of Alloy 625 3105 1200000 3Ined ■ 460C-40Ksi Conventional 1000000 2.510 GBE g 800000 2105 600000 1.5105 400000 1105 200000 510 0 010 Alloy 62560ks i Alloy 73840ksi V57A0ksi AR GBE MaterialS tres s Sample Condition

Fatigue 0 200000 400000 600000 800000 1000000 1200000 Alloy 625/60ksi Alloy 738/40ksi V57/40ksi Room Temperature F atigue Performance of S elected Nickel Bas ed Alloys Conventional GBE Cycles to Failure Material/S tres s Fatigue

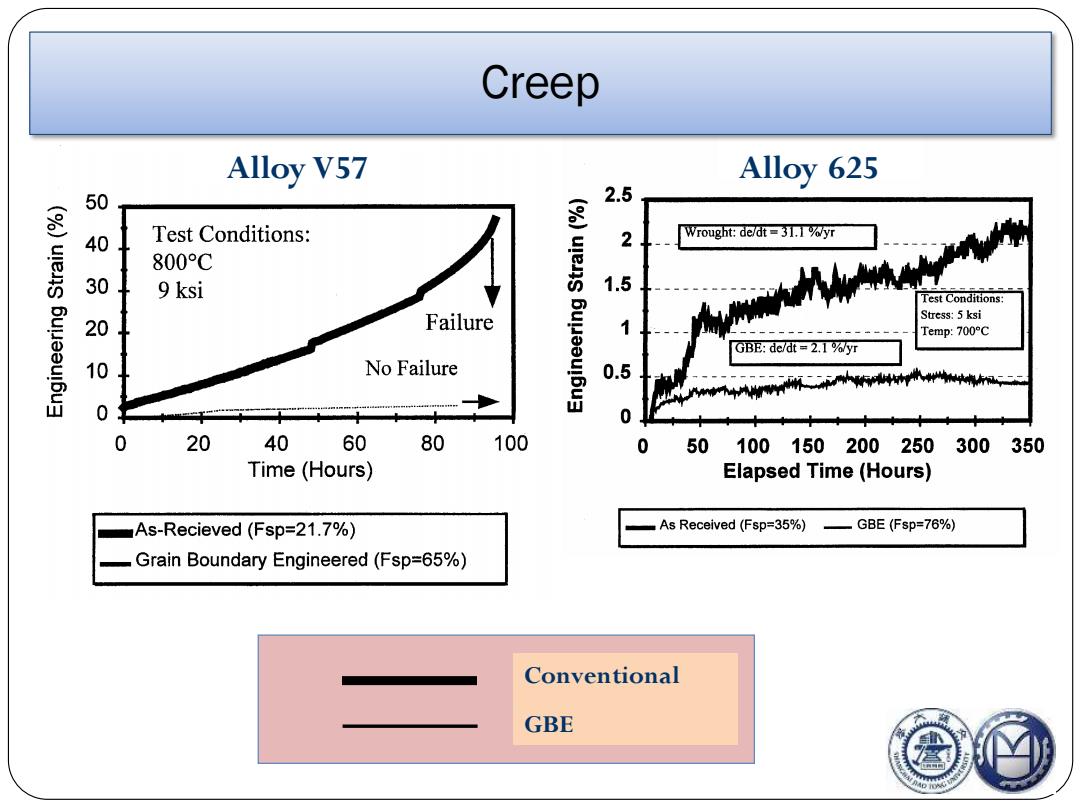

Creep Alloy V57 Alloy 625 2.5 5 Test Conditions: 2 Wrought:de/dt =31.1 %/yr 30 800C 9 ksi 1.5 Test Conditions: Failure Stress:5 ksi 1 Temp:700C 10 GBE:de/dt 2.1 %/yr No Failure 0.5 0 20 40 60 80 100 0 50 100150200250300350 Time (Hours) Elapsed Time (Hours) As-Recieved(Fsp=21.7%) As Received(Fsp=35%) 一GBE(Fsp=76%) Grain Boundary Engineered(Fsp=65%) Conventional GBE

Alloy V57 Alloy 625 Conventional GBE Creep

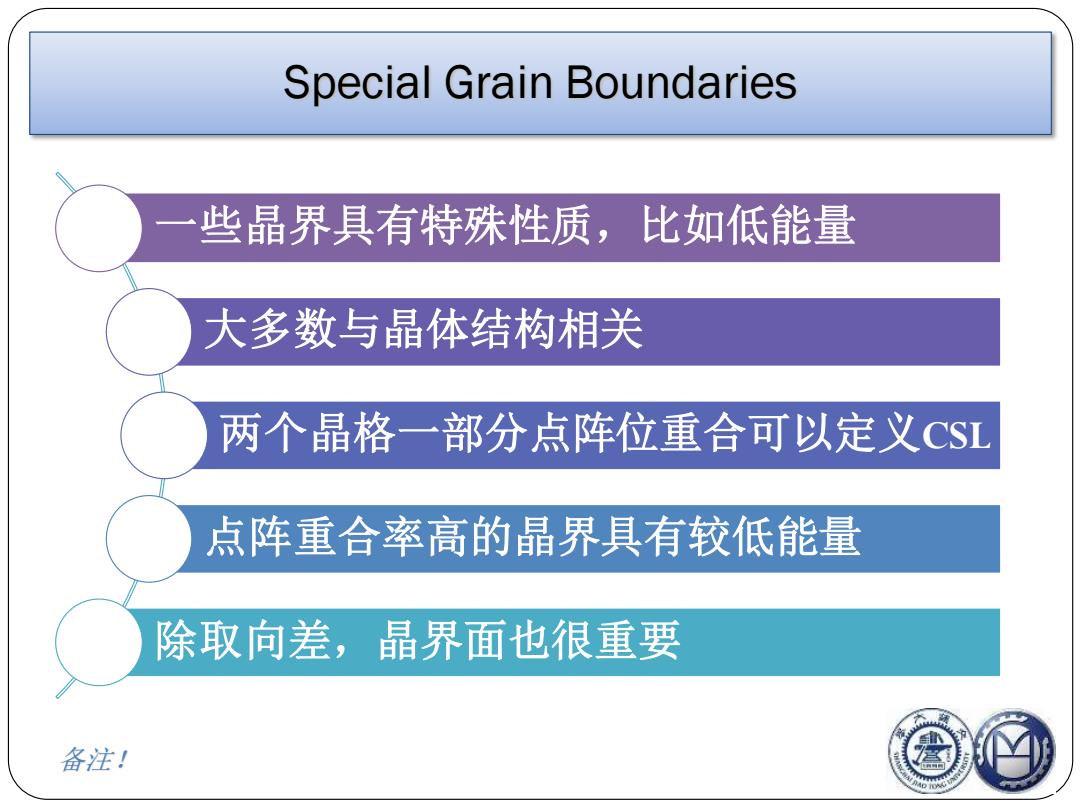

Special Grain Boundaries 些晶界具有特殊性质,比如低能量 大多数与晶体结构相关 两个晶格一部分点阵位重合可以定义CSL 点阵重合率高的晶界具有较低能量 除取向差,晶界面也很重要 备注!

Special Grain Boundaries 一些晶界具有特殊性质,比如低能量 大多数与晶体结构相关 两个晶格一部分点阵位重合可以定义CSL 点阵重合率高的晶界具有较低能量 除取向差,晶界面也很重要 备注!

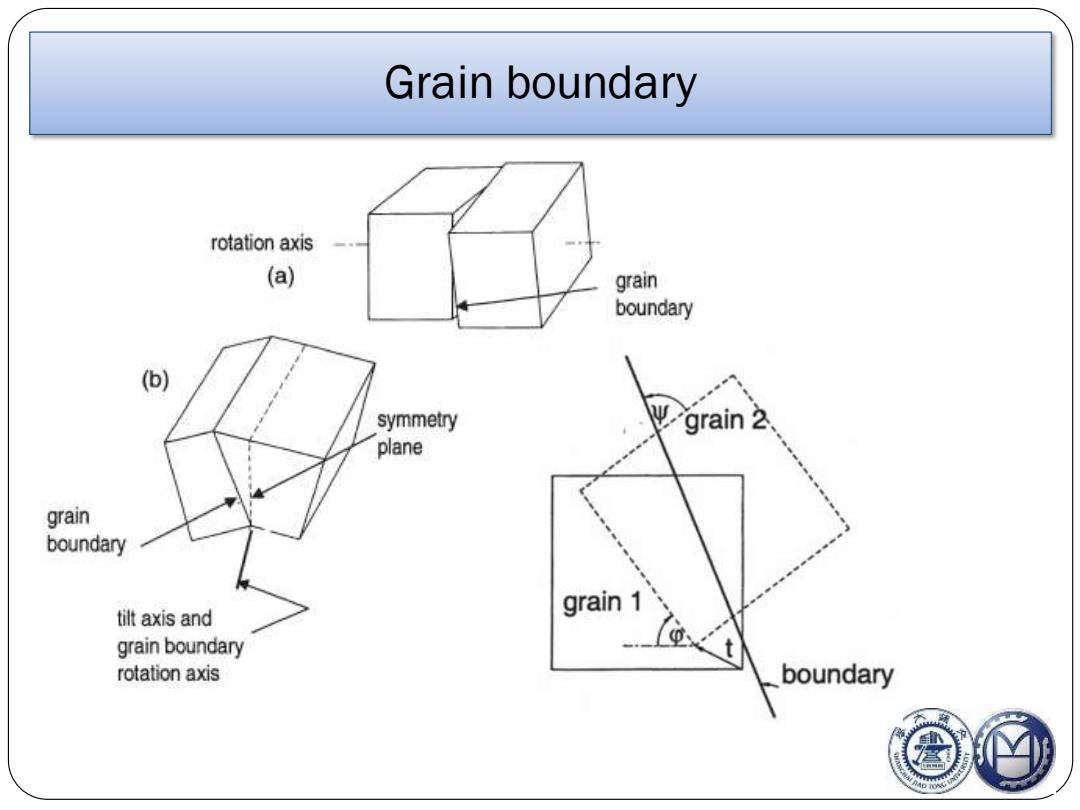

Grain boundary rotation axis (a) grain boundary (b) symmetry grain 2 plane grain boundary tilt axis and grain 1 grain boundary rotation axis boundary

Grain boundary

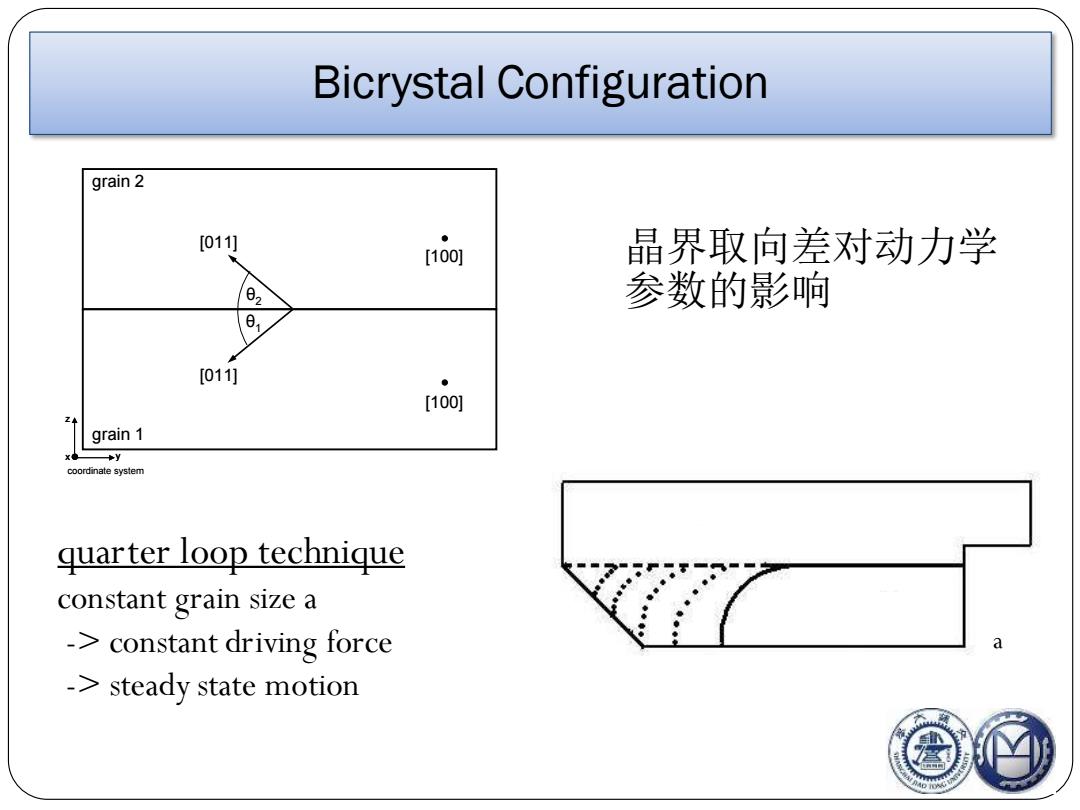

Bicrystal Configuration grain 2 [011] [100] 晶界取向差对动力学 02 参数的影响 日1 [011)] ● [100] grain 1 y coordinate system quarter loop technique constant grain size a >constant driving force >steady state motion

Bicrystal Configuration [011] [011] grain 1 grain 2 [100] [100] θ1 θ2 coordinate system x z y quarter loop technique constant grain size a -> constant driving force -> steady state motion a 晶界取向差对动力学 参数的影响