第二相颗粒 弥散 析出 Dispersion Precipitation 不可溶 基体中相变形成 。非共格 ·共格/非共格 例如铜中氧化铝颗 例如Al-Cu合金中 粒 的析出相

第二相颗粒 弥散 Dispersion • 不可溶 • 非共格 • 例如铜中氧化铝颗 粒 析出 Precipitation • 基体中相变形成 • 共格/非共格 • 例如Al-Cu合金中 的析出相

第二相颗粒结构 完全共格 存在应变的共格 (a) (b) 半共格 非共格 (c) (d)

完全共格 存在应变的共格 半共格 非共格 第二相颗粒结构

Summary Dislocations can interact with the stress fields of precipitates. Moving dislocations can: 1.glide through coherent precipitates->shearing the precipitate. 2.bow around incoherent precipitates,leaving loops as they bypass two precipitates which act like pinning centres for the dislocations leading to an increase in the dislocation density). Both these processes need an application of higher stresses (assuming an harder precipitate)lead to the strengthening of the material. ▣ Semi-coherent precipitates have interfacial misfit dislocations which partially relieve the coherency strains.(These dislocations are structural dislocations). 轨

Summary 4 q Dislocations can interact with the stress fields of precipitates. q Moving dislocations can: 1. glide through coherent precipitates → shearing the precipitate. 2. bow around incoherent precipitates, leaving loops as they bypass two precipitates which act like pinning centres for the dislocations (→ leading to an increase in the dislocation density). q Both these processes need an application of higher stresses (assuming an harder precipitate) → lead to the strengthening of the material. q Semi-coherent precipitates have interfacial misfit dislocations which partially relieve the coherency strains. (These dislocations are structural dislocations)

Summary:Precipitate Hardening effect The hardening effect of precipitates can arise in many ways as below: Coherency Strengthening:due to elastic coherency strains surrounding the particle Modulus Hardening:due to difference in elastic moduli of the matrix and particle Lattice Resistance:the dislocation may face an increased lattice friction stress in the precipitate. Chemical Strengthening:arises from additional interface created on shearing Stacking-fault Strengthening:due to difference between stacking-fault energy between particle and matrix when these are both FCC or HCP(when dislocations are split into partials) Order Strengthening:due to additional work required to create an APB in case of dislocations passing through precipitates which have an ordered lattice

Summary: Precipitate Hardening effect 5 The hardening effect of precipitates can arise in many ways as below: q Coherency Strengthening: due to elastic coherency strains surrounding the particle q Modulus Hardening: due to difference in elastic moduli of the matrix and particle q Lattice Resistance: the dislocation may face an increased lattice friction stress in the precipitate. q Chemical Strengthening: arises from additional interface created on shearing q Stacking-fault Strengthening: due to difference between stacking-fault energy between particle and matrix when these are both FCC or HCP (when dislocations are split into partials) q Order Strengthening: due to additional work required to create an APB in case of dislocations passing through precipitates which have an ordered lattice

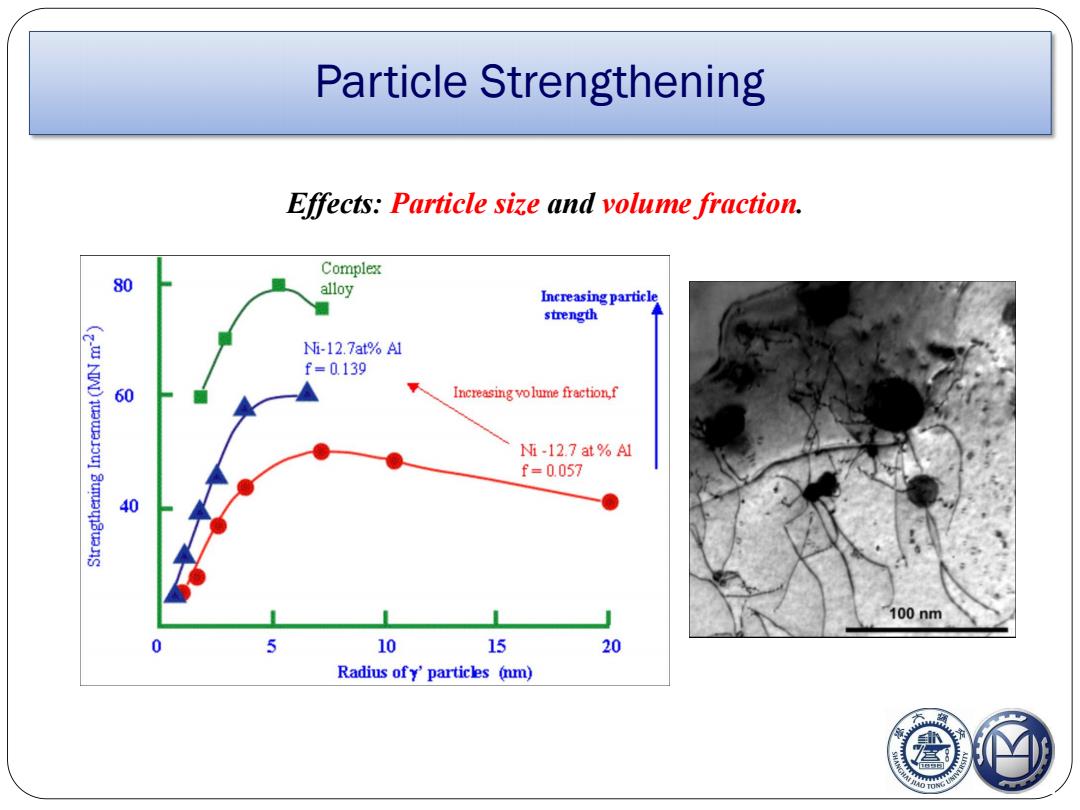

Particle Strengthening Effects:Particle size and volume fraction Complex 80 alloy Increasing particle strength Ni-12.7at%Al f=0139 60 Increasing volume fraction,f i-12.7at%A1 f=0.057 40 100nm 0 10 15 20 Radius ofy'particles (nm)

Particle Strengthening Ef ects: Particle size and volume fraction