Example 2-8 Take 2 min.to read example 2-8,consider the following problems. Why is average weekly demand,not average monthly demand,used to calculate reorder level?

Why is average weekly demand, not average monthly demand, used to calculate reorder level? Example 2-8 Take 2 min. to read example 2-8, consider the following problems

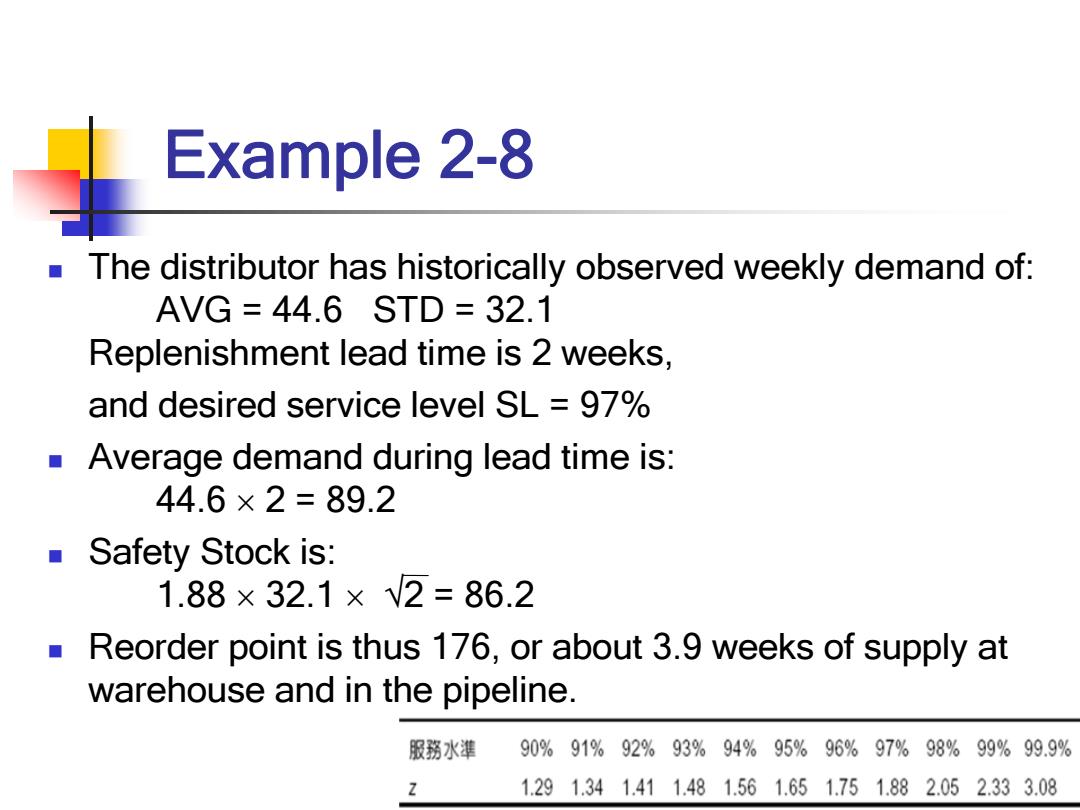

Example 2-8 The distributor has historically observed weekly demand of: AVG=44.6STD=32.1 Replenishment lead time is 2 weeks, and desired service level SL =97% Average demand during lead time is: 44.6×2=89.2 o Safety Stock is: 1.88×32.1×2=86.2 Reorder point is thus 176,or about 3.9 weeks of supply at warehouse and in the pipeline. 服務水準 90%91%92%93%94%95%96%97%98%99%99.9% Z 1.291.341.411.481.561.651.751.882.052.333.08

Example 2-8 The distributor has historically observed weekly demand of: AVG = 44.6 STD = 32.1 Replenishment lead time is 2 weeks, and desired service level SL = 97% Average demand during lead time is: 44.6 × 2 = 89.2 Safety Stock is: 1.88 × 32.1 × √2 = 86.2 Reorder point is thus 176, or about 3.9 weeks of supply at warehouse and in the pipeline

Example 2-8,Cont. Weekly inventory holding cost:0.87 ■Therefore,Q=679 Order-up-to level thus equals: Reorder Point Q=176+679=855 The average inventory level is: ■679/2+86.2=426 The distributor needs to keep about 10 (=426/44.58)weeks of inventory at the warehouse and in the pipeline

Example 2-8, Cont. Weekly inventory holding cost: 0.87 Therefore, Q=679 Order-up-to level thus equals: Reorder Point + Q = 176+679 = 855 The average inventory level is: 679/2+86.2=426 The distributor needs to keep about 10 (=426/44.58)weeks of inventory at the warehouse and in the pipeline

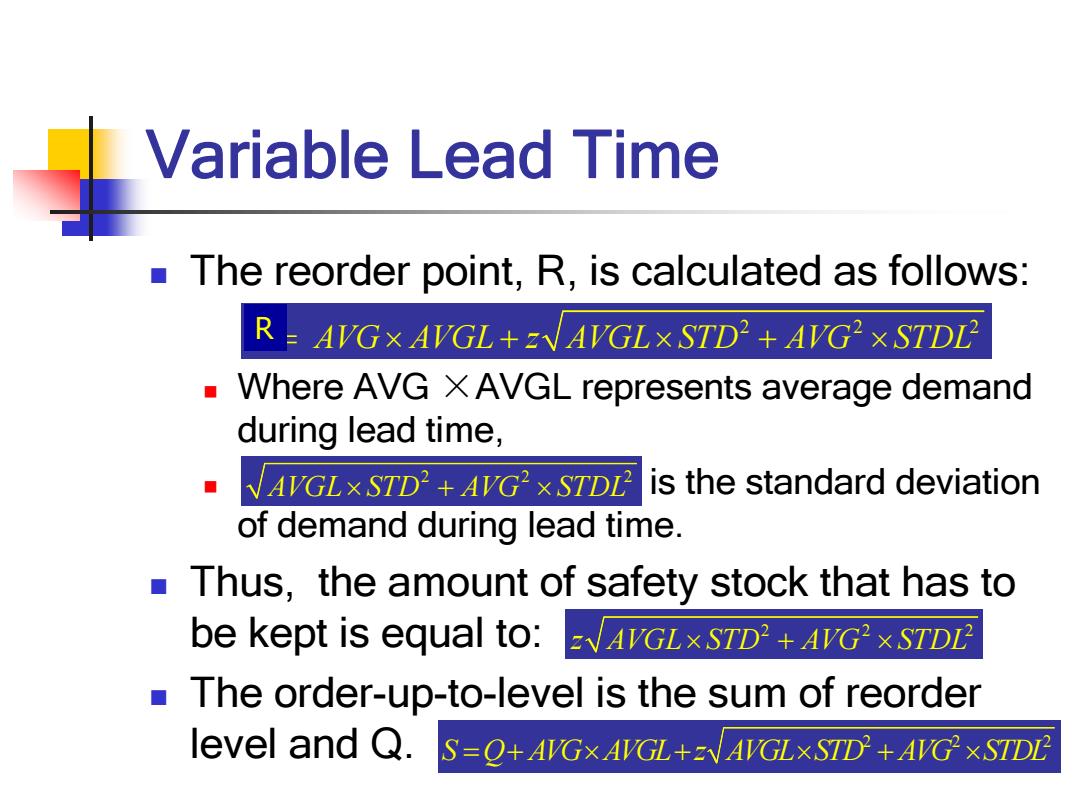

Variable Lead Time In many cases,the assumption that the lead time to the warehouse is fixed and known in advance does not hold. In many practical situations the lead time must be assumed to be normally distributed with Average lead time,AVGL Standard deviation,STDL

Variable Lead Time In many cases, the assumption that the lead time to the warehouse is fixed and known in advance does not hold. In many practical situations the lead time must be assumed to be normally distributed with Average lead time, AVGL Standard deviation, STDL

Variable Lead Time The reorder point,R,is calculated as follows: R=AVGx AVGL+√AGL×STD2+AVG XSTDL Where AVG XAVGL represents average demand during lead time, A GLX STD+AGx STD is the standard deviation of demand during lead time. Thus,the amount of safety stock that has to be kept is equal to:√AVGLxS7D2+4AvG2xS7D形 The order-up-to-level is the sum of reorder level and Q.S-0+AGxAG+AGLXSTD+AGXSTDE

Variable Lead Time The reorder point, R, is calculated as follows: Where AVG ×AVGL represents average demand during lead time, is the standard deviation of demand during lead time. Thus, the amount of safety stock that has to be kept is equal to: The order-up-to-level is the sum of reorder level and Q. 22 2 AVGL STD AVG STDL ×+ × 22 2 z AVGL STD AVG STDL ×+ × 222 S Q AVG AVGL z AVGL STD AVG STDL =+ × + × + × 22 2 s R =× + ×+ × AVG AVGL z AVGL STD AVG STDL