上游充通大¥ SHANGHAI JIAO TONG UNIVERSITY a Engineering Thermodynamics I Lecture 43-44 Cengel_Chapter 11 Refrigeration Cycles Spring,5/11/2018 Prof.,Dr.Yonghua HUANG 强 是 唱目e http://cc.sjtu.edu.cn/G2S/site/thermo.html SHANG ERSITY

Engineering Thermodynamics I Lecture 43‐44 Spring, 5/11/2018 Prof., Dr. Yonghua HUANG Cengel_ Chapter 11 Refrigeration Cycles http://cc.sjtu.edu.cn/G2S/site/thermo.html

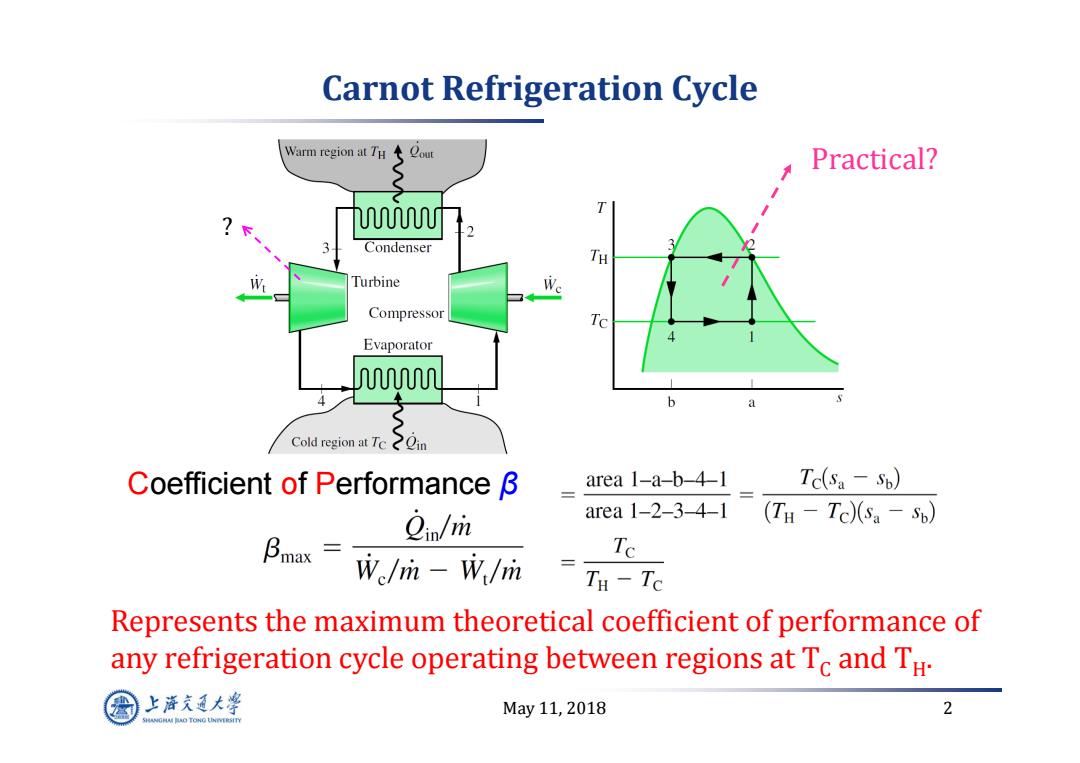

Carnot Refrigeration Cycle Warm region at TH Qout Practical? UUUT 3 Condenser TH Turbine Compressor Tc Evaporator mm b Cold region atTc之gin Coefficient of Performance B area 1-a-b-4-1 Tc(sa-Sp) 2in/m area 1-2-3-4-1 (TH -Tc)(Sa -Sp) Bmax Te We/m-W/mn TH-Tc Represents the maximum theoretical coefficient of performance of any refrigeration cycle operating between regions at Tc and TH. 上游充通大¥ May11,2018 2 HANGHAI HAO TONG LINIVERSITY

May 11, 2018 2 Carnot Refrigeration Cycle Practical? Coefficient of Performance β Represents the maximum theoretical coefficient of performance of any refrigeration cycle operating between regions at T C and T H. ?

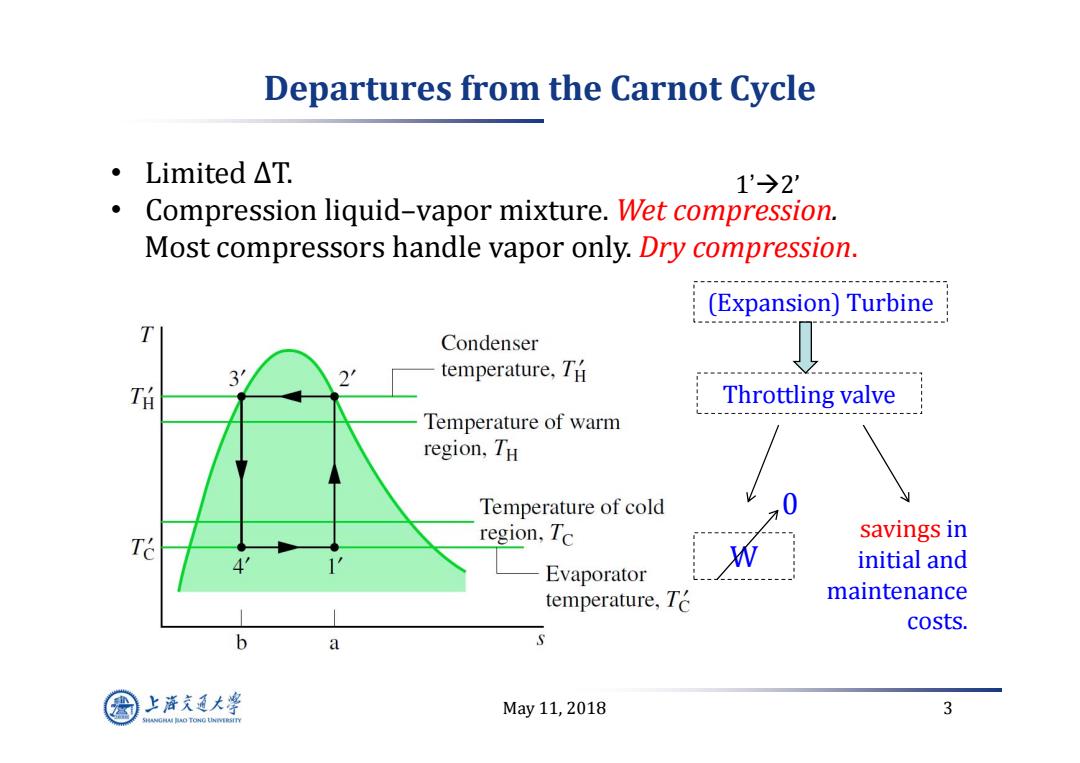

Departures from the Carnot Cycle ·Limited△T. 1'→2' Compression liquid-vapor mixture.Wet compression. Most compressors handle vapor only.Dry compression. (Expansion)Turbine T Condenser 2' temperature,TH TH Throttling valve Temperature of warm region,TH Temperature of cold 0 T region,Tc savings in W initial and Evaporator temperature,Te maintenance costs. b a 上游充通大¥ May11,2018 3 SHANGHA BAO TONG LINIERSITY

May 11, 2018 3 Departures from the Carnot Cycle • Limited ∆T. • Compression liquid–vapor mixture. Wet compression. Most compressors handle vapor only. Dry compression. savings in initial and maintenance costs. (Expansion) Turbine Throttling valve W 0 1’2’

Vapor-compression refrigeration cycle ●Evaporator: Ci=hha m Qin-refrigeration capacity.(kW). Alternative unit:ton of refrigeration,211 kJ/min. i We Compressor =h2-hi m------小 unuut Condenser ●Condenser VExpansion Compressor =h2-h3! valve i_m Evaporator m ●Throttling process Saturated or superheated vapor 2m 上海文①大学 May11,2018 4 SHANGHAI BAO TONG LINIVERSITY

May 11, 2018 4 Vapor ‐compression refrigeration cycle

Working substance:p-h diagram 4000 3000 2000 R134a Tcond:A0-55C ressure 198 ratio 600 500 2.0-3.0 LLL100LOC00bo06066600 300 200 0900 Enthalpy [kJ/kg] x=0.10 00 030 040 050 060 0,70 0.80 40 =0.20 040 0.50 50 2--100 120 140 160T 130 200220 300 150-250W △h≈120~150k/kg 20020 T△h≈2535k/kg 三im,△h WFm,△h/ comp,e/ ←≈65% 3.5-6.0kg/hr no.is 50-80W 上游充通大率 3.0-5.0 compe May11,2018 5 SHANGHA BAO TONG LINIERSITY

May 11, 2018 5 comp,e evap,r COP W Q MSRS 150‐250 W Enthalpy [kJ/kg] Pressure ratio 2.0 ‐3.0 h 120~150 kJ/kg Qevap ,r m r h Tevap: 10 ‐25 C Tcond: 40 ‐55 C h 25~35 kJ/kg r comp,e o,is m h W 65% 3.5‐6.0 kg/hr 50 ‐80 W 3.0 ‐5.0 R134a Working substance: p‐h diagram