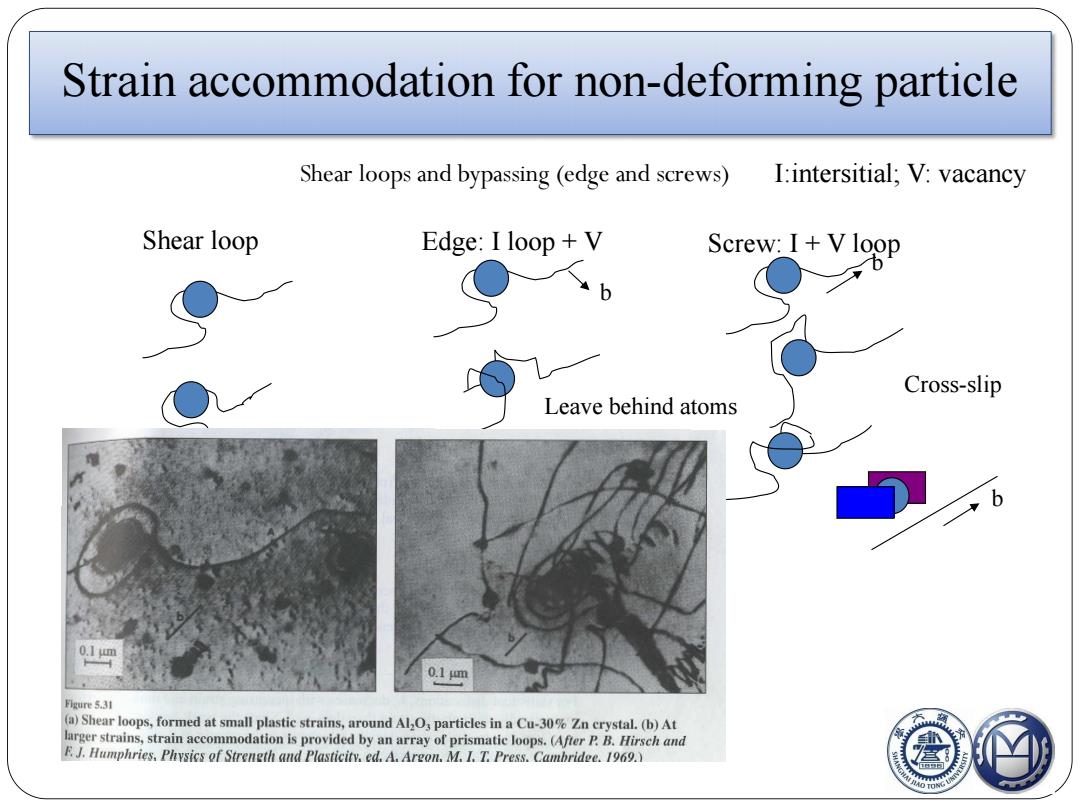

Strain accommodation for non-deforming particle Shear loops and bypassing(edge and screws) I:intersitial;V:vacancy Shear loop Edge:I loop +V Screw:I+V loop Cross-slip Leave behind atoms 0.1m 0.1um Figure 5.31 (a)Shear loops,formed at small plastic strains,around Al2O,particles in a Cu-30%Zn crystal.(b)At larger strains,strain accommodation is provided by an array of prismatic loops.(After P.B.Hirsch and E.J.Humphries,Physics of Strength and Plasticity.ed.A.Argon.M.I.T.Press.Cambridee.1969. 圈

Strain accommodation for non-deforming particle 17 Shear loop vacancies interstitial Edge: I loop + V Screw: I + V loop b b b Cross-slip Leave behind atoms Shear loops and bypassing (edge and screws) I:intersitial; V: vacancy

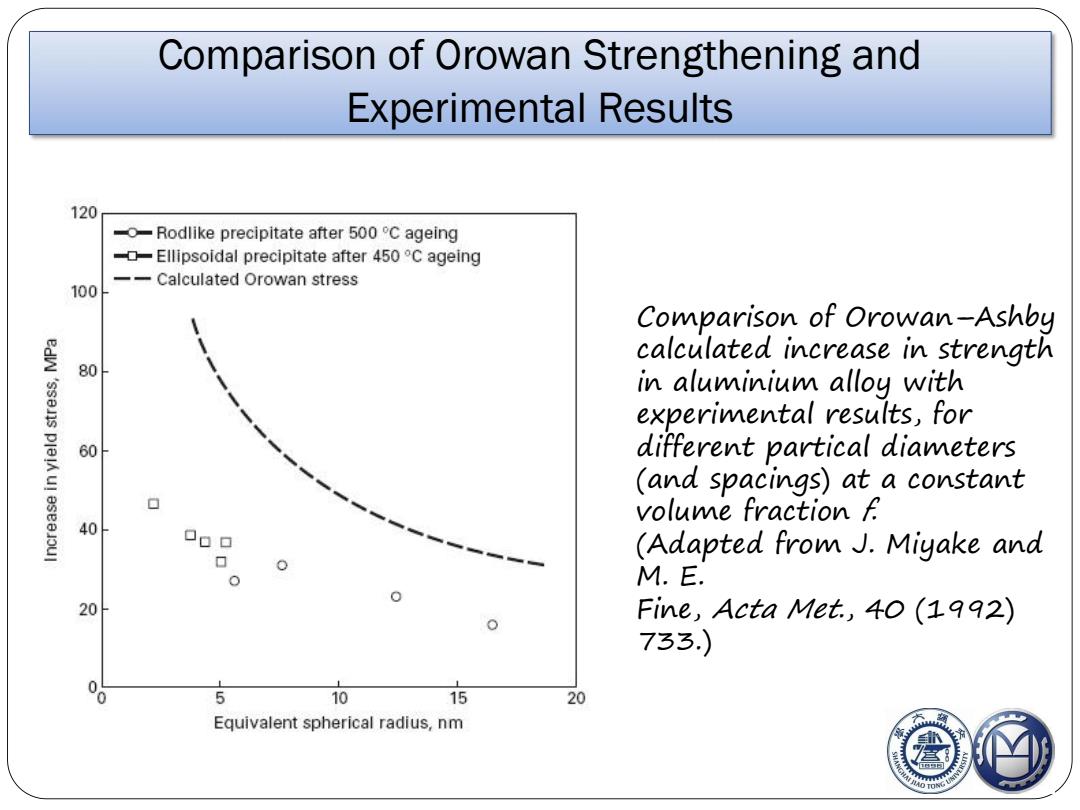

Comparison of Orowan Strengthening and Experimental Results 120 --Rodlike precipitate after 500 C ageing --Ellipsoidal precipitate after 450C ageing --Calculated Orowan stress 100 Comparison of Orowan-Ashby calculated increase in strength 80 in aluminium alloy with experimental results,for 60 different partical diameters (and spacings)at a constant volume fraction f 40 (Adapted from J.Miyake and M.E. 0 20 0 Fine,Acta Met.,40 (1992) 733.) 5 10 15 20 Equivalent spherical radius,nm

Comparison of Orowan Strengthening and Experimental Results 18 Comparison of Orowan–Ashby calculated increase in strength in aluminium alloy with experimental results, for different partical diameters (and spacings) at a constant volume fraction f. (Adapted from J. Miyake and M. E. Fine, Acta Met., 40 (1992) 733.)