The tool tends to be deflected to a greater extent by the cutting forces and to vibrate. Vibration may affect not only the dimensions of the machined surface,but its roughness and the life of the cutting tools

The tool tends to be deflected to a greater extent by the cutting forces and to vibrate. Vibration may affect not only the dimensions of the machined surface, but its roughness and the life of the cutting tools

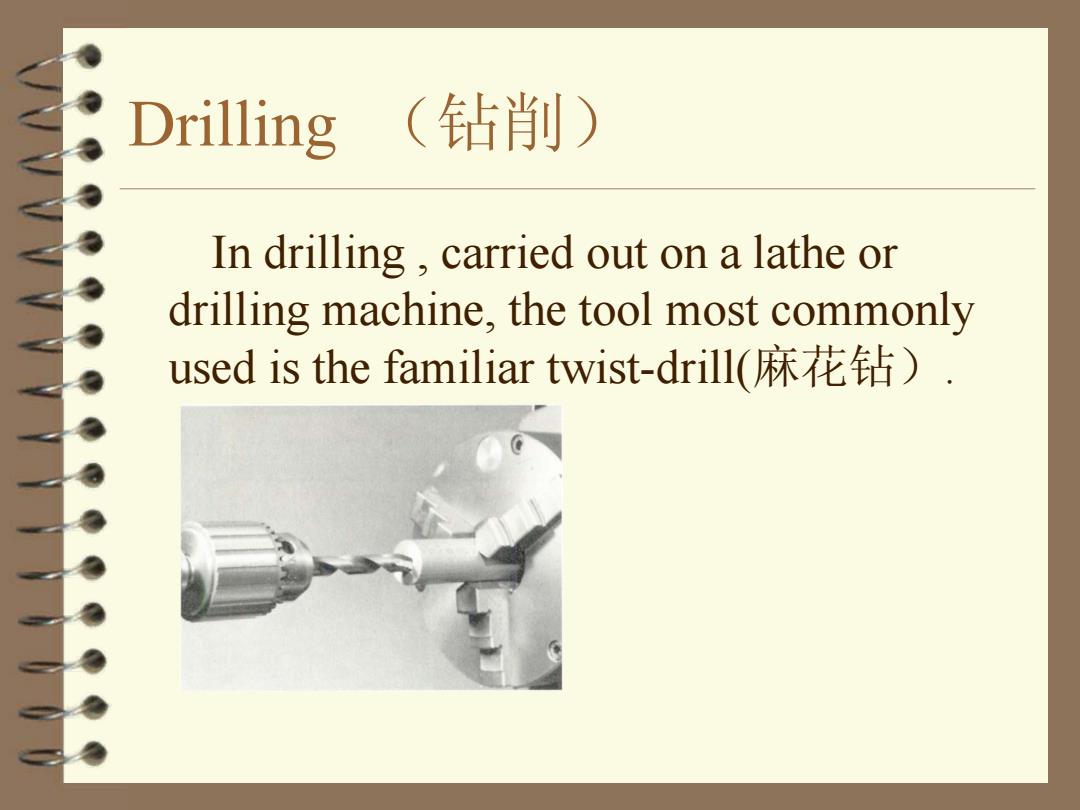

Drilling :(钻削) In drilling,carried out on a lathe or drilling machine,the tool most commonly used is the familiar twist-drill(庥花钻)

Drilling (钻削) In drilling , carried out on a lathe or drilling machine, the tool most commonly used is the familiar twist-drill(麻花钻)

Drills are slender,highly stressed(受力 很大的)tools,.he flutes(排屑槽)of which have to be carefully designed to permit chip flow while maintaining adequate strength

Drills are slender, highly stressed (受力 很大的) tools, the flutes(排屑槽) of which have to be carefully designed to permit chip flow while maintaining adequate strength

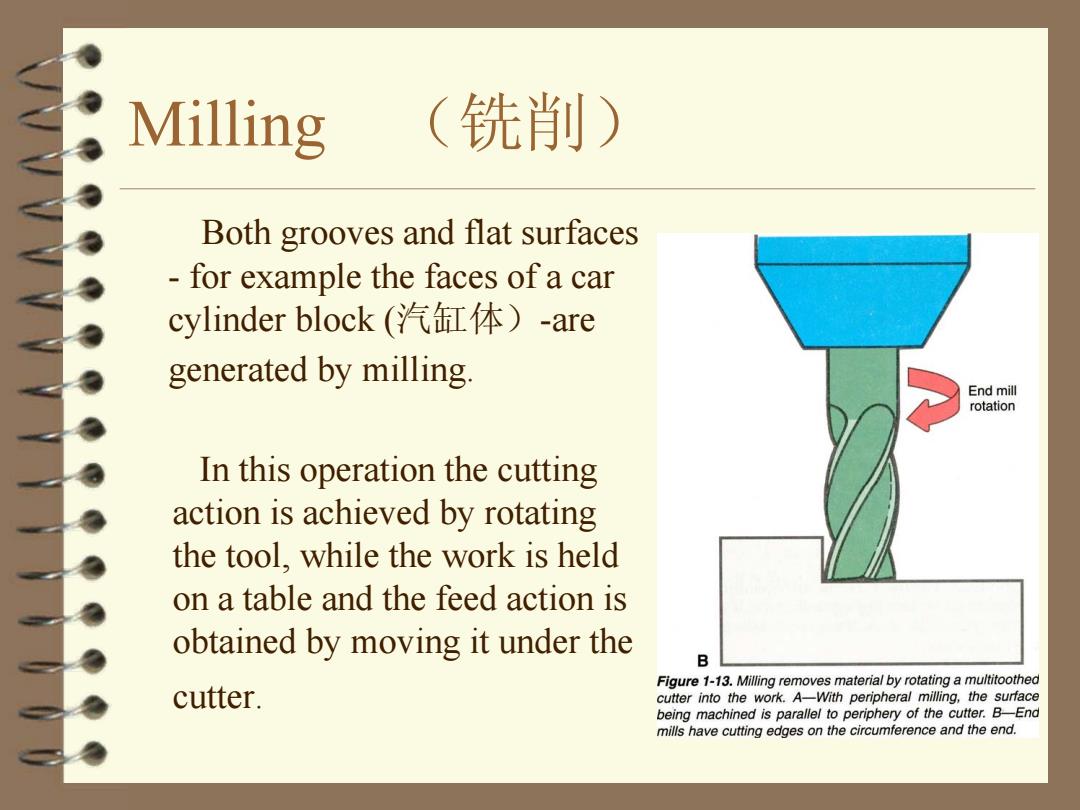

Milling (铣削) Both grooves and flat surfaces for example the faces of a car cylinder block(汽缸体)-are generated by milling End mill rotation In this operation the cutting action is achieved by rotating the tool,while the work is held on a table and the feed action is obtained by moving it under the B Figure 1-13.Milling removes material by rotating a multitoothed cutter. cutter into the work.A-With peripheral milling,the surface being machined is parallel to periphery of the cutter.B-End mills have cutting edges on the circumference and the end

Milling (铣削) Both grooves and flat surfaces - for example the faces of a car cylinder block (汽缸体)-are generated by milling. In this operation the cutting action is achieved by rotating the tool, while the work is held on a table and the feed action is obtained by moving it under the cutter