Machine Tools Continued Manufacturing&Systems

Manufacturing& Systems Machine Tools Continued

Traditional metal cutting operations Turning (车削) >Facing (车端面) > Boring (镗削) > Drilling (钻削) Milling > (铣削) Broaching (拉削)

Traditional metal cutting operations Turning (车削) Facing (车端面) Boring (镗削) Drilling (钻削) Milling (铣削) Broaching (拉削)

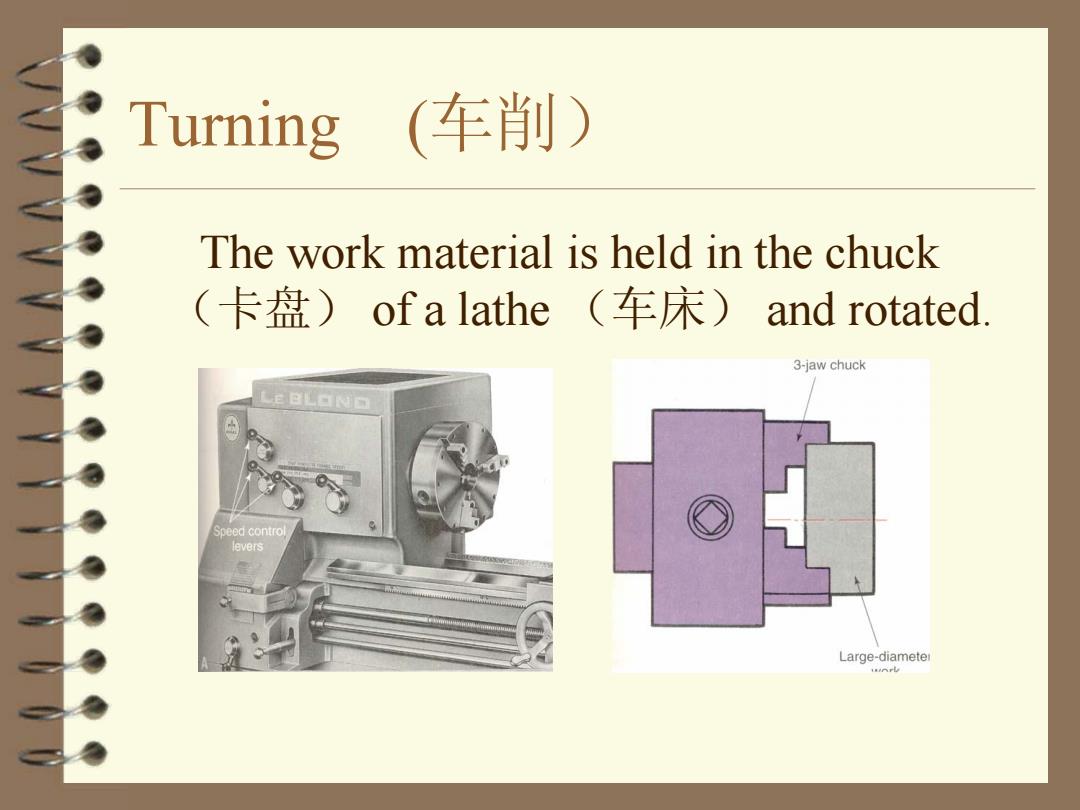

Turning (车削) The work material is held in the chuck (卡盘)of a lathe(车床)and rotated 3-jaw chuck EEL口m Speed control levers Large-diameter wnrl

Turning (车削) The work material is held in the chuck (卡盘) of a lathe (车床) and rotated

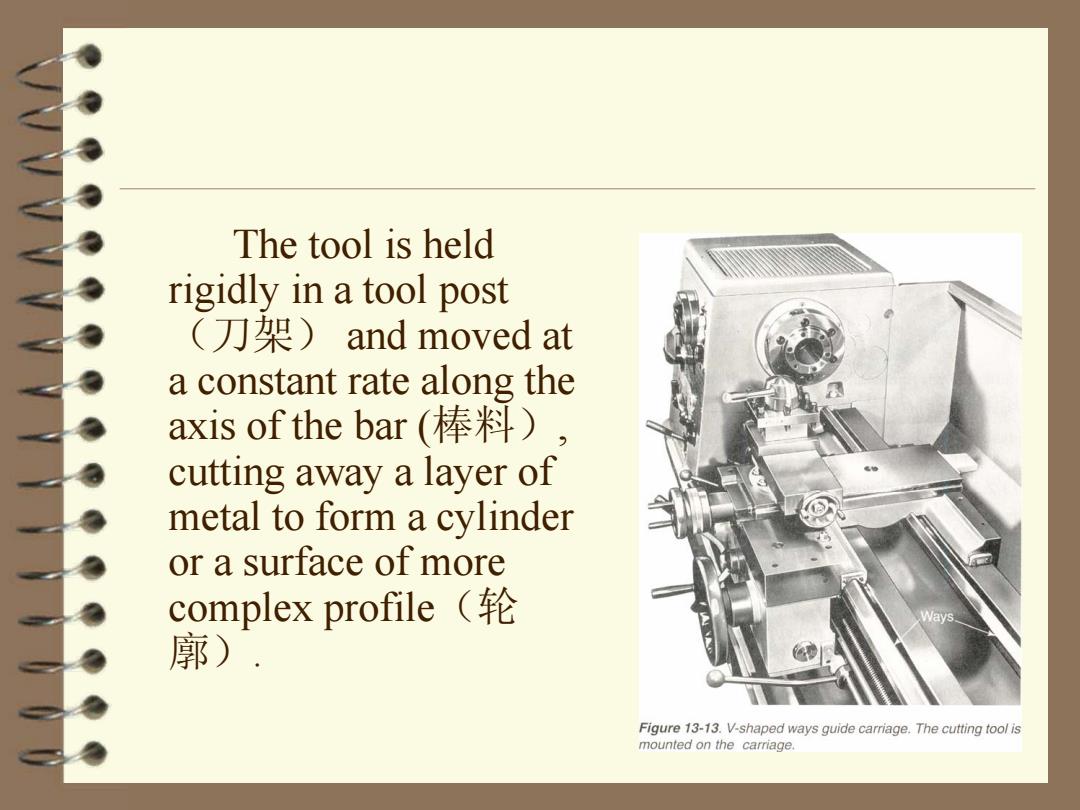

The tool is held rigidly in a tool post (刀架)and moved at a constant rate along the axis of the bar(棒料) cutting away a layer of metal to form a cylinder or a surface of more complex profile(轮 廓). Figure 13-13.V-shaped ways guide carriage.The cutting tool is mounted on the carriage

The tool is held rigidly in a tool post (刀架) and moved at a constant rate along the axis of the bar (棒料), cutting away a layer of metal to form a cylinder or a surface of more complex profile(轮 廓)

The cutting speed (V)is the rate at which the uncut surface of the work passes the cutting edge of the tool-usually expressed in units of m/min. The feed (f)is the distance moved by the tool in an axial direction at each revolution of the work

The cutting speed (V) is the rate at which the uncut surface of the work passes the cutting edge of the tool-usually expressed in units of m/min. The feed (f) is the distance moved by the tool in an axial direction at each revolution of the work