上游充通大粤 SHANGHAI JIAO TONG UNIVERSITY Design for X Customer needs and product specifications are for the concept phase Detail design faces the difficulty linking needs and specifications to the specific design issues like: >Reliability Robustness >Serviceablility >Environmental impact Manufacturability Design for X:the X represents one of the above criteria

Design for X Customer needs and product specifications are for the concept phase Detail design faces the difficulty linking needs and specifications to the specific design issues like: Reliability Robustness Serviceablility Environmental impact Manufacturability Design for X: the X represents one of the above criteria

上游充通大¥ SHANGHAI JIAO TONG UNIVERSITY Design for Manufacturing Definition >Design for manufacturing (DFM)is a development practice emphasizing manufacturing issues throughout the product development process. >Successful DFM results in lower production cost without sacrificing product quality

Design for Manufacturing Definition : Design for manufacturing (DFM) is a development practice emphasizing manufacturing issues throughout the product development process. Successful DFM results in lower production cost without sacrificing product quality

上游充通大 SHANGHAI JIAO TONG UNIVERSITY Three Methods to Implement DFM 1.Organization:Cross-Functional Teams In addition to product designers,DFM still needs expertise from: Manufacturing engineers Cost accountants Production personnel 2.Design Rules:Specialized by Firm 3.CAD Tools:Boothroyd-Dewhurst Software >http://www.dfma.com

Three Methods to Implement DFM 1. Organization: Cross-Functional Teams In addition to product designers, DFM still needs expertise from: • Manufacturing engineers • Cost accountants • Production personnel 2. Design Rules: Specialized by Firm 3. CAD Tools: Boothroyd-Dewhurst Software http://www.dfma.com

上游充通大学 SHANGHAI JIAO TONG UNIVERSITY Five steps for DFM 1.Estimate the manufacturing costs 2.Reduce the costs of components 3.Reduce the costs of assembly 4.Reduce the costs of supporting production 5.Consider the impact of DFM decisions on other factors

Five steps for DFM 1. Estimate the manufacturing costs 2. Reduce the costs of components 3. Reduce the costs of assembly 4. Reduce the costs of supporting production 5. Consider the impact of DFM decisions on other factors

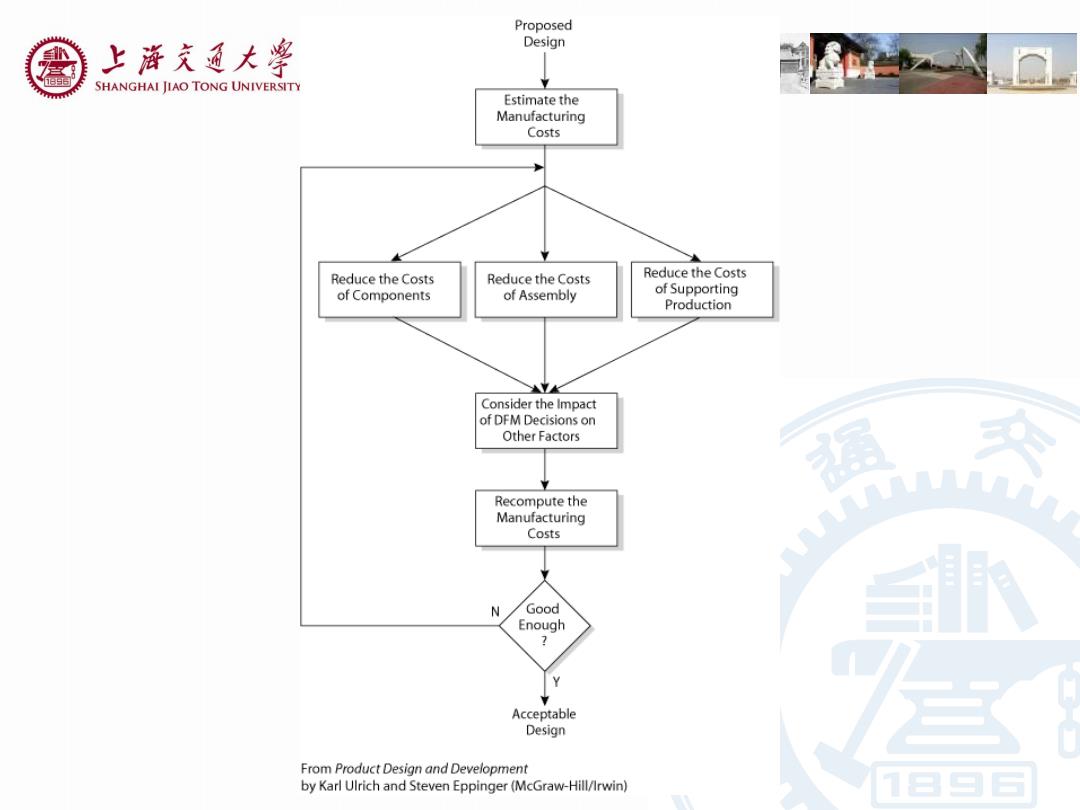

Proposed 上游充通大学 Design SHANGHAI JIAO TONG UNIVERSITY Estimate the Manufacturing Costs Reduce the Costs Reduce the Costs Reduce the Costs of Components of Assembly of Supporting Production Consider the lmpact of DFM Decisions on Other Factors Recompute the Manufacturing Costs N Good Enough 1 Y Acceptable Design From Product Design and Development by Karl Ulrich and Steven Eppinger(McGraw-Hill/Irwin)