Why not Supply Restriction? ·No health risk Restriction may cause sanitary problem with reduction on people hygiene May increase water duration in pipes,flush some particles,create vacuuming and potentially lead to bacteriological contamination May affect the overall economy of the city May damage International Image of the city MSC Seminar (January 30,2012) Tackling the Problem On the technical/engineering level -Improved monitoring and pumping system -Preparation before the crisis:top-up of reservoirs Leak detection to reduce water loss Technical communication and coordination with related partners when the crisis started A software to optimize the logistical operations, so as to forecast and control the salinity of potable water below a desirable level MSC Seminar (January 30,2012) 6

6 MSC Seminar (January 30, 2012) • No health risk • Restriction may cause sanitary problem with reduction on people hygiene • May increase water duration in pipes, flush some particles, create vacuuming and potentially lead to bacteriological contamination • May affect the overall economy of the city • May damage International Image of the city Why not Supply Restriction? MSC Seminar (January 30, 2012) Tackling the Problem • On the technical/engineering level – Improved monitoring and pumping system – Preparation before the crisis: top-up of reservoirs – Leak detection to reduce water loss • Technical communication and coordination with related partners when the crisis started • A software to optimize the logistical operations, so as to forecast and control the salinity of potable water below a desirable level

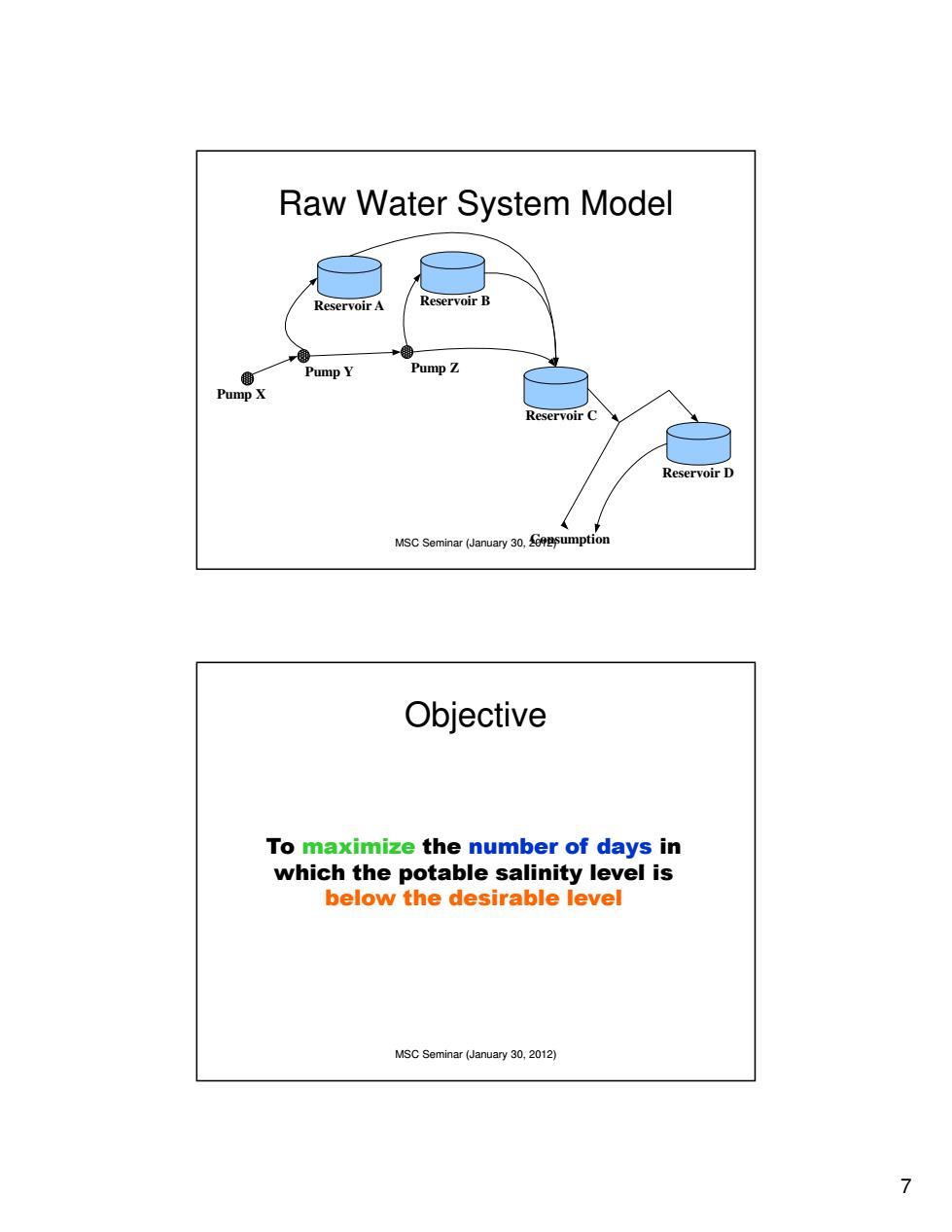

Raw Water System Model Reservoir A Reservoir B PumpY Pump Z PumpX Reservoir C Reservoir D MSC Seminar (January 30,sumption Objective To maximize the number of days in which the potable salinity level is below the desirable level MSC Seminar(January 30,2012) 7

7 MSC Seminar (January 30, 2012) Raw Water System Model Pump X Pump Y Pump Z Reservoir A Reservoir B Reservoir C Reservoir D Consumption MSC Seminar (January 30, 2012) Objective To maximize the number of days in which the potable salinity level is below the desirable level

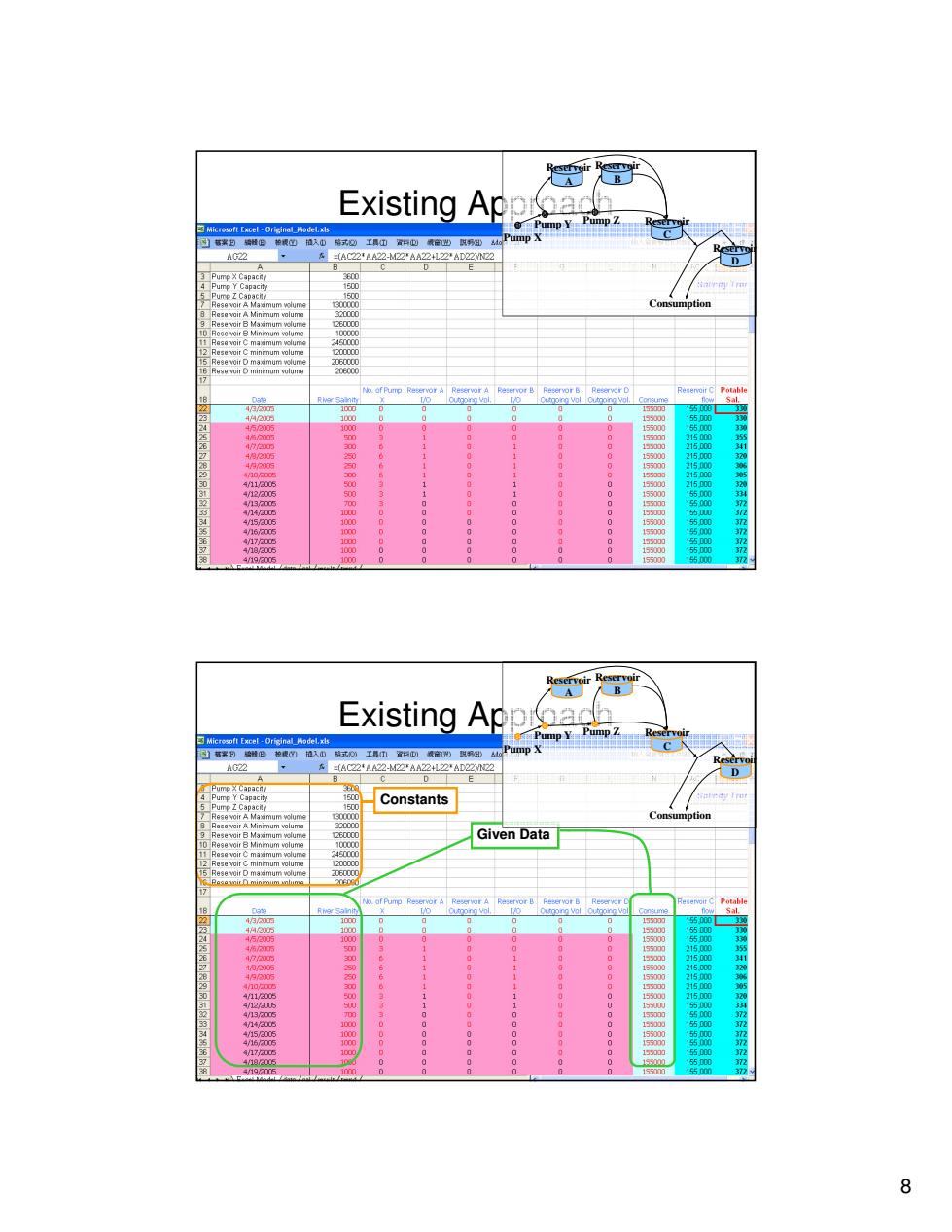

Existing Appac Microsoft Excel-Original_Model.xls Pump Y Pump子fd 福案由培情田轴根心植入山棉式边工具①置山载官出以易出从 AG22 =(AC22*AA22-M22AA22+122'AD22N2☑ D Pump X Capacity mp Consumption A Minimum yalume 2000 3 Reservoir B Maximum wolume 1260000 Reservoir B Minimum volume 206000 15500 82348878908234678 4500 15500 500 0 15500 215000 11 15500 21500 411 666333000000 110 0000 00000 1110000000 40400000000 9000000000000 2150 55 4/18/20 15500 372 419a005 1000 155000 5 372 Reservoir Existing Ap Microsoft Excel-Original Model.xls Pump AG22 =(AC22*A422-M22AA22+L22AD2222 D Constants Reservoir A Maximum wolume 130000 Reservair A Minimum volume 300 um Given Data 1200000 5 Reservoir D maximum wolume 20600 430国 1000 150 4420 1000 15500 23456789010345678 1 /11 415/2a00 66603300000 11000 00000 11000000 00000000000000 000000000000 15 0 5 8

8 MSC Seminar (January 30, 2012) Existing Approach Pump X Pump Y Pump Z Reservoir A Reservoir B Reservoir C Reservoir D Consumption MSC Seminar (January 30, 2012) Constants Given Data Existing Approach Pump X Pump Y Pump Z Reservoir A Reservoir B Reservoir C Reservoir D Consumption

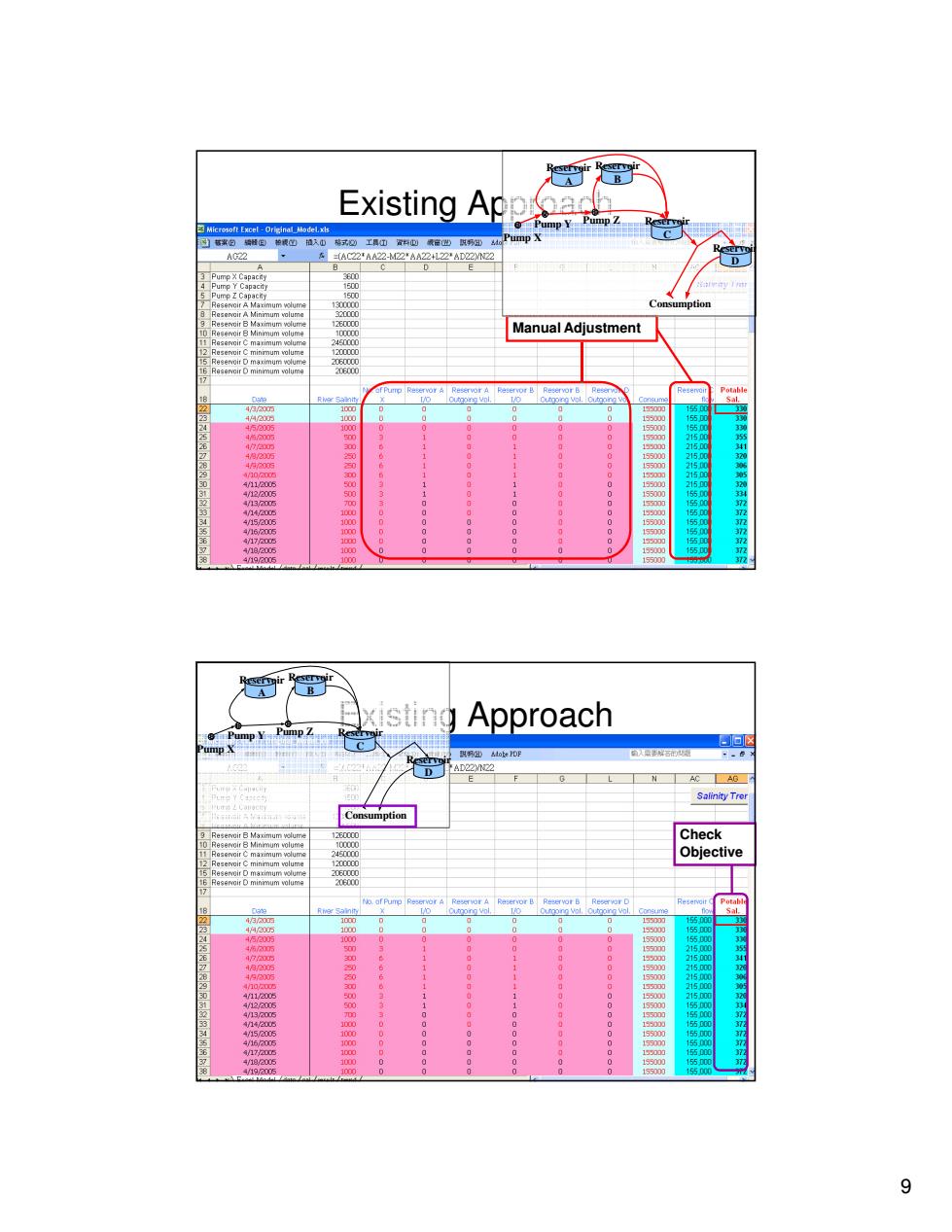

Existing Appa Microsoft Excel-Original_Model.xls ump Y 福案由培情田轴根心植入山棉式边工具①置山载官出以易出从 AG22 =(AC22*AA22-M22AA22+122'AD22N2☑ D Pump X Capacity mp Consumption A Minimum yalume 3 Reservoir B Maximum wolume 1260000 Reservoir B Minimum volume Manual Adjustment 206000 82348878908234678 4500 11 1550 230 411 412 11 1 6666330008 000 000000 11100000 00000000000000 0000000000000 4/18/20 5 372 4/19/a005 1000 15500 B xisting Approach 回☒ AC AG Salinity Trer Consumption mum Check Objective 1200000 5 Reservoir D maximum wolume 20EU000 6 Regervair D minimum volume 430 1000 55 4420 1000 15500 15500 2348678901034578 4/10 1 /11 000 /2005 110000 1 +666333000006 00000 11000000 90000000000000 9000000000000 0 9

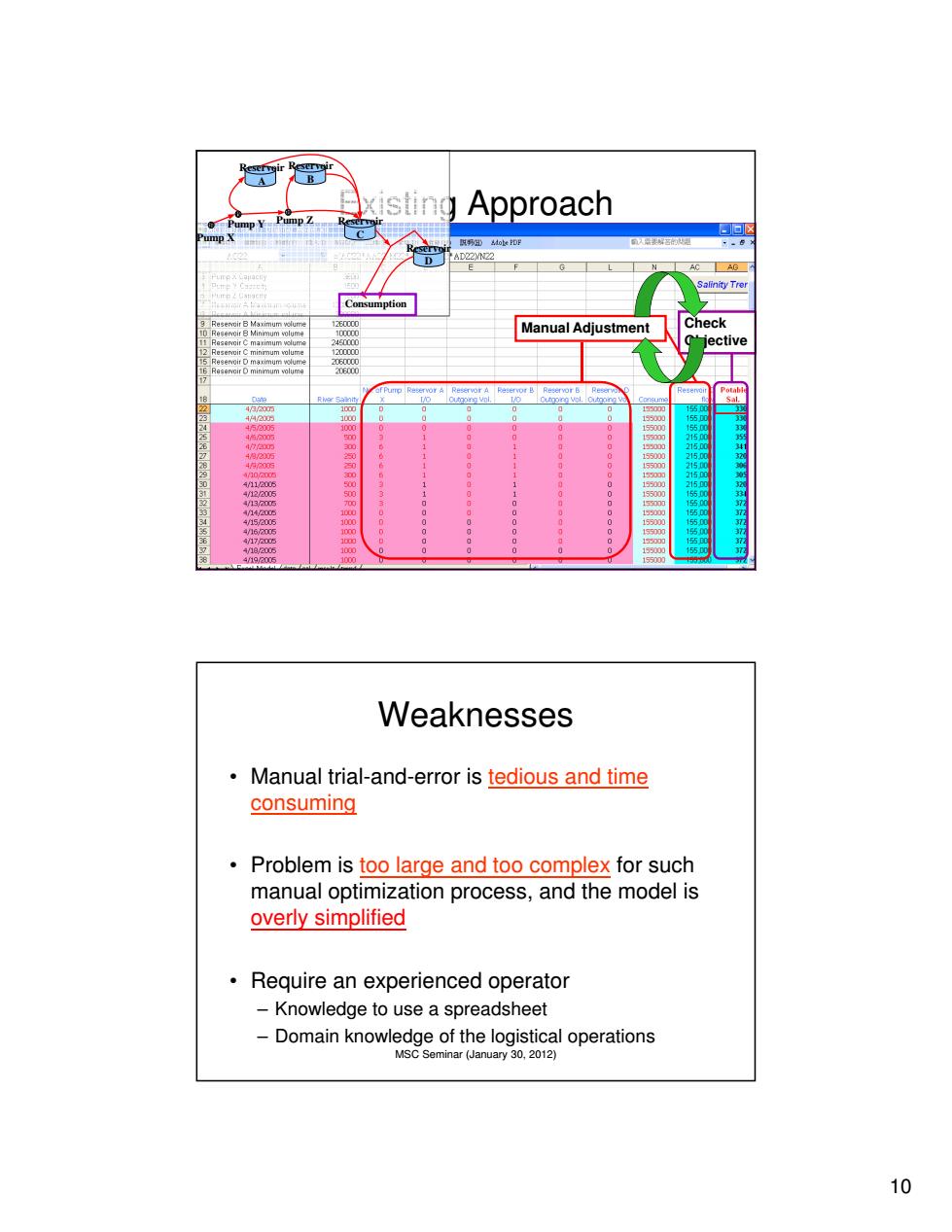

9 MSC Seminar (January 30, 2012) Manual Adjustment Existing Approach Pump X Pump Y Pump Z Reservoir A Reservoir B Reservoir C Reservoir D Consumption MSC Seminar (January 30, 2012) Existing Approach Check Objective Pump X Pump Y Pump Z Reservoir A Reservoir B Reservoir C Reservoir D Consumption

xisting Approach 照易知oe扣明 - D G AC AG Salinity Trer Consumption Reservoir B Maximum wolume 12E0000 Check Reservoir B Minimum volume Manual Adjustment ective olume 206000 45/005 100 0 0 2150 4887890023467 2150 4/112005 1 4/12,2005 0 3300 00000 0000000000000 900000000000 1550 00o 000 55 419a005 1000 15500 Weaknesses Manual trial-and-error is tedious and time consuming Problem is too large and too complex for such manual optimization process,and the model is overly simplified Require an experienced operator -Knowledge to use a spreadsheet Domain knowledge of the logistical operations MSC Seminar (January 30,2012) 10

10 MSC Seminar (January 30, 2012) Check Objective Manual Adjustment Existing Approach Pump X Pump Y Pump Z Reservoir A Reservoir B Reservoir C Reservoir D Consumption MSC Seminar (January 30, 2012) Weaknesses • Manual trial-and-error is tedious and time consuming • Problem is too large and too complex for such manual optimization process, and the model is overly simplified • Require an experienced operator – Knowledge to use a spreadsheet – Domain knowledge of the logistical operations