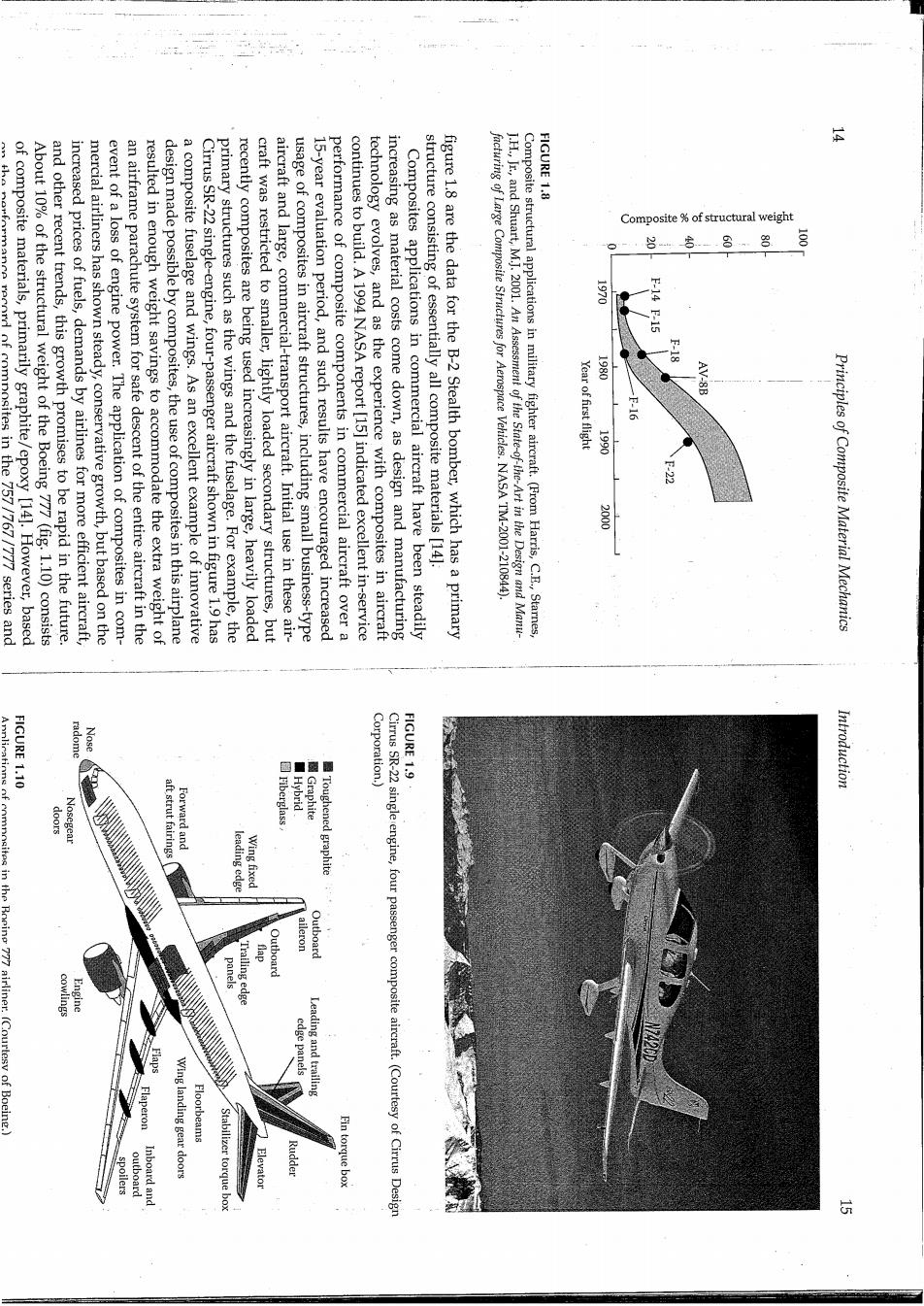

FIGURE 1.8 Composite of structural weight of composite materials,primarily graphite/epoxy [141.However,based nerformance record of composites in the 757/767/777 series and About 10%of the structural weight of the Boeing 777(fig.1.10)consists and other recent trends,this growth promises to be rapid in the future. increased prices of fuels,demands by airlines for more efficient aircraft, mercial airliners has shown steady,conservative growth,but based on the event of a loss of engine power.The application of composites in com- an airframe parachute system for safe descent of the entire aircraft in the resulted in enough weight savings to accommodate the extra weight of design made possible by composites,the use of composites in this airplane a composite fuselage and wings.As an excellent example of innovative Cirrus SR-22 single-engine,four-passenger aircraft shown in figure 1.9 has primary structures such as the wings and the fuselage.For example,the recently composites are being used increasingly in large,heavily loaded craft was restricted to smaller,lightly loaded secondary structures,but aircraft and large,commercial-transport aircraft.Initial use in these air- usage of composites in aircraft structures,including small business-type 15-year evaluation period,and such results have encouraged increased performance of composite components in commercial aircraft over a continues to build.A 1994 NASA report [15]indicated excellent in-service technology evolves,and as the experience with composites in aircraft increasing as material costs come down,as design and manufacturing Composites applications in commercial aircraft have been steadily structure consisting of essentially all composite materials [14]. figure 1.8 are the data for the B-2 Stealth bomber,which has a primary J.H.Jr,and Shuart,M.].2001.An Assessment of the State-of-the-Art in the Design and Manu- facturing of Large Composite Structures for Aerospace Vehicles.NASATM-2001-210844). Composite structural applications in military fighter aircraft.(From Harris,C.E.Starnes 14 P-15 Year of first flight AV-8B 1P00 F22 2000 Principles of Composite Material Mechanics FIGURE 1.10 Corporation.) FIGURE 1.9 Introduction doors aft strut fairings Forward and Fiberglass Graphite Hybrid leading edge Wing fixed Toughened graphite in the Booino 777 airiner (Courtesv of Boeing. Outboard Outboard panels Trailing edge edge pane ading and trailing Wing landing gear doors Floorbeams Cirrus SR-22 single engine,four passenger composite aircraft.(Courtesy of Cirrus Design spoilers abilizer torque box

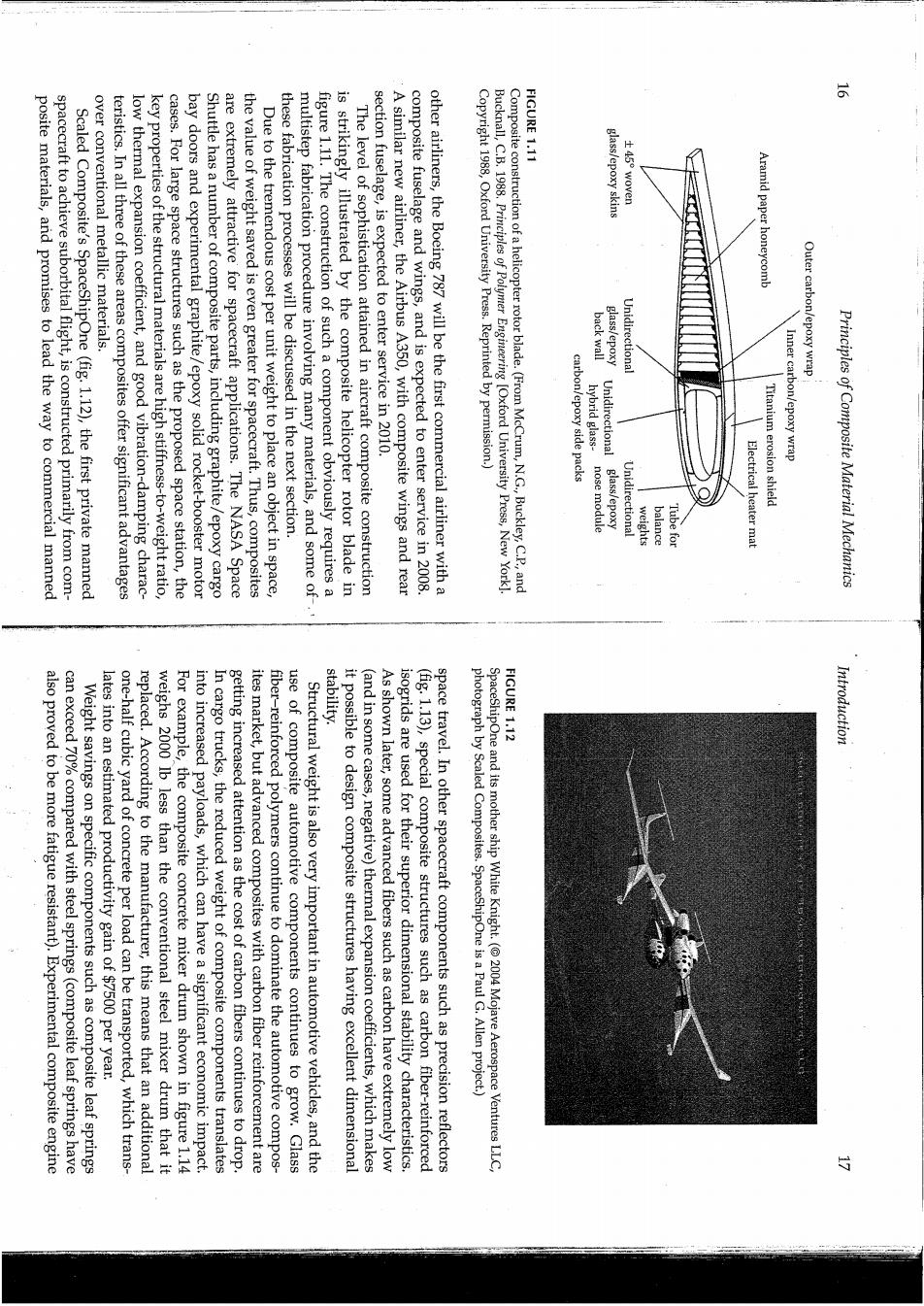

posite materials,anid promises to lead the way to commercial manned spacecraft to achieve suborbital flight,is constructed primarily from com- Scaled Composite's SpaceShipOne(fig.1.12),the first private manned over conventional metallic materials. FIGURE 1.11 t45 woven teristics.In all three of these areas composites offer significant advantages low thermal expansion coefficient,and good vibration-damping charac- key properties of the structural materials are high stiffness-to-weight ratio, cases.For large space structures such as the proposed space station,the bay doors and experimental graphite/epoxy solid rocket-booster motor Shuttle has a number of composite parts,including graphite/epoxy cargo are extremely attractive for spacecraft applications.The NASA Space the value of weight saved is even greater for spacecraft.Thus,composites Due to the tremendous cost per unit weight to place an object in space, these fabrication processes will be discussed in the next section. multistep fabrication procedure involving many materials,and some of- figure 1.11.The construction of such a component obviously requires a is strikingly illustrated by the composite helicopter rotor blade in The level of sophistication attained in aircraft composite construction section fuselage,is expected to enter service in 2010. A similar new airliner,the Airbus A350,with composite wings and rear composite fuselage and wings,and is expected to enter service in 2008 other airliners,the Boeing 787 will be the first commercial airliner with a Copyright 1988,Oxford University Press. Reprinted by permission.) Composite construction of a helicopter rotor blade.(From McCrum,N.G.,Buckley,C.P.,and Bucknall,C.B.1988.Principles of Polymer Engineering [Oxford University Press,New York]. glass/epoxy skins Aramid paper honeycomb back wall glass/epoxy Unidirectional Outer carbon/epoxy wrap carbon/epoxy side packs hybrid glass- Unidirectional Inner carbon/epoxy wrap nose module glass/epoxy Unidirectional Titanium erosion shield weights balance Tube for Electrical heater mat Principles of Composite Material Mechanics FIGURE 1.12 Introduction also proved to be more fatigue resistant).Experimental composite engine can exceed 70%compared with steel springs(composite leaf springs have Weight savings on specific components such as composite leaf springs lates into an estimated productivity gain of $7500 per year. one-half cubic yard of concrete per load can be transported,which trans- replaced.According to the manufacturer,this means that an additional weighs 2000 Ib less than the conventional steel mixer drum that it For example,the composite concrete mixer drum shown in figure 1.14 into increased payloads,which can have a significant economic impact. In cargo trucks,the reduced weight of composite components translates getting increased attention as the cost of carbon fibers continues to drop. ites market,but advanced composites with carbon fiber reinforcement are fiber-reinforced polymers continue to dominate the automotive compos- use of composite automotive components continues to grow.Glass Structural weight is also very important in automotive vehicles,and the it possible to design composite structures having excellent dimensional (and in some cases,negative)thermal expansion coefficients,which makes As shown later,some advanced fibers such as carbon have extremely low isogrids are used for their superior dimensional stability characteristics. (fig.1.13),special composite structures such as carbon fiber-reinforced space travel.In other spacecraft components such as precision reflectors photograph by Scaled Composites.SpaceShipOne is a Paul G.Allen project.) SpaceShipOne and its mother ship White Knight.(2004 Mojave Aerospace Ventures LLC