Strand of hot steel moves through a long automated series of horizontal and vertical rolls,which carefully shape it. Water sprays gradually cool the steel. The slabs are cut to length, and are transported for finishing and shaping at rolling mills

Strand of hot steel moves through a long automated series of horizontal and vertical rolls, which carefully shape it. Water sprays gradually cool the steel. The slabs are cut to length, and are transported for finishing and shaping at rolling mills

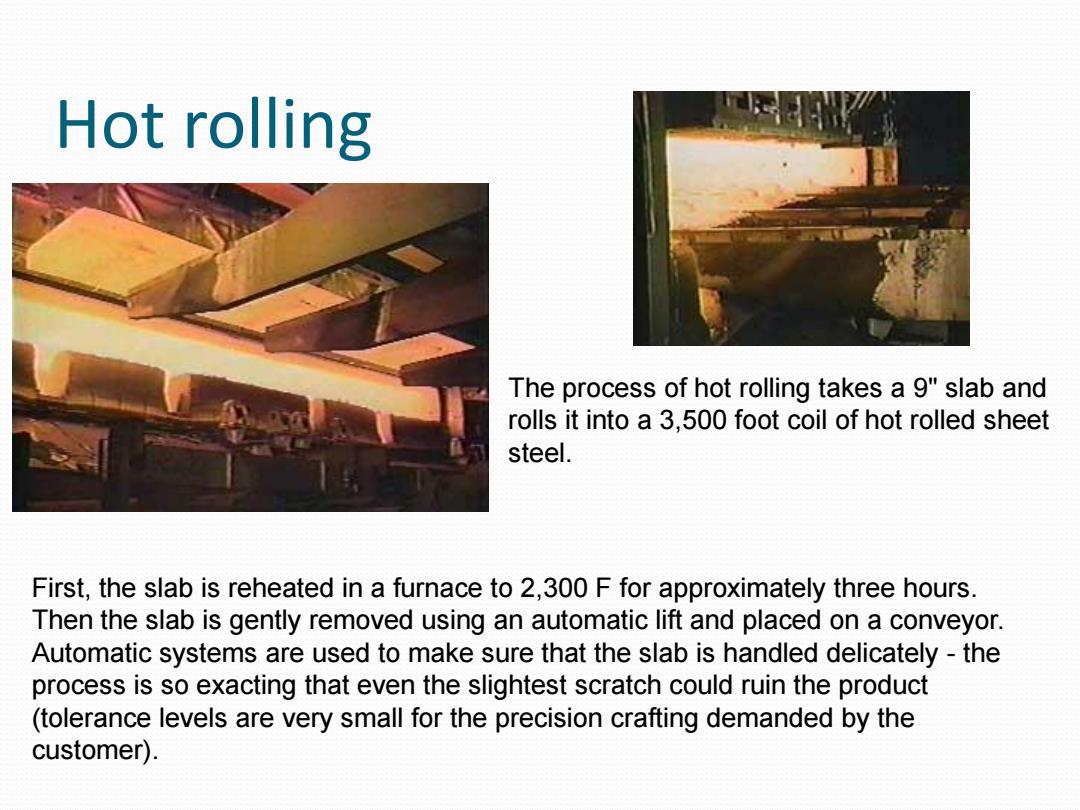

Hot rolling The process of hot rolling takes a 9"slab and rolls it into a 3,500 foot coil of hot rolled sheet steel. First,the slab is reheated in a furnace to 2,300 F for approximately three hours. Then the slab is gently removed using an automatic lift and placed on a conveyor. Automatic systems are used to make sure that the slab is handled delicately-the process is so exacting that even the slightest scratch could ruin the product (tolerance levels are very small for the precision crafting demanded by the customer)

Hot rolling The process of hot rolling takes a 9" slab and rolls it into a 3,500 foot coil of hot rolled sheet steel. First, the slab is reheated in a furnace to 2,300 F for approximately three hours. Then the slab is gently removed using an automatic lift and placed on a conveyor. Automatic systems are used to make sure that the slab is handled delicately - the process is so exacting that even the slightest scratch could ruin the product (tolerance levels are very small for the precision crafting demanded by the customer)