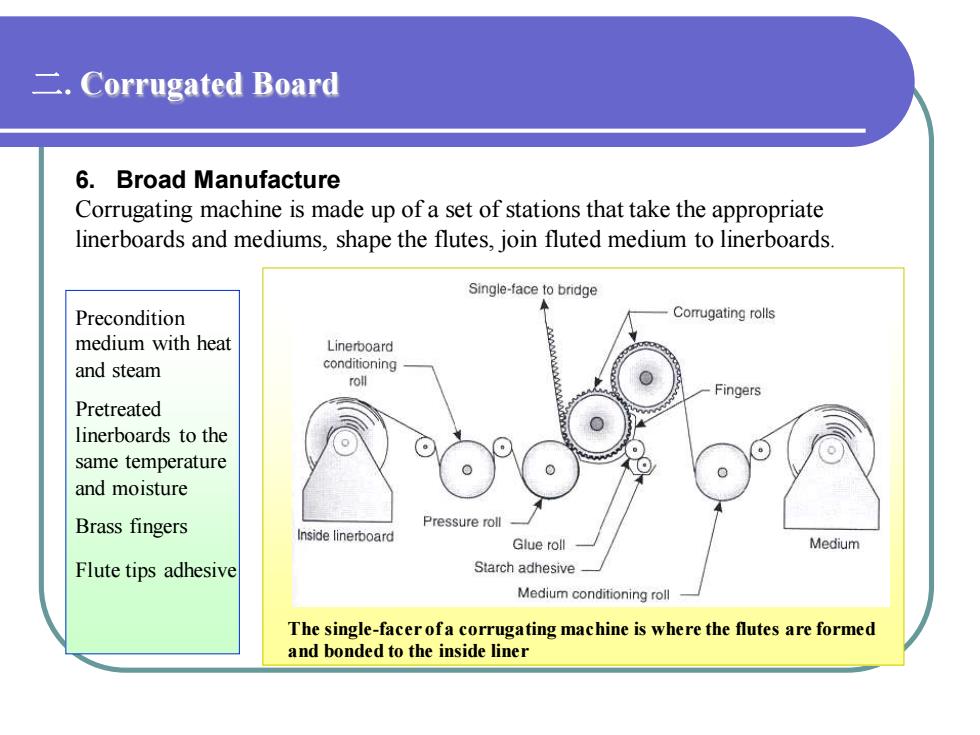

二. Corrugated Board 6. Broad Manufacture Corrugating machine is made up of a set of stations that take the appropriate linerboards and mediums, shape the flutes, join fluted medium to linerboards. Precondition medium with heat and steam Pretreated linerboards to the same temperature and moisture Brass fingers Flute tips adhesive The single-facer of a corrugating machine is where the flutes are formed and bonded to the inside liner

二. Corrugated Board 6. Broad Manufacture Corrugating machine is made up of a set of stations that take the appropriate linerboards and mediums, shape the flutes, join fluted medium to linerboards. Precondition medium with heat and steam Pretreated linerboards to the same temperature and moisture Brass fingers Flute tips adhesive The single-facer of a corrugating machine is where the flutes are formed and bonded to the inside liner

二. Corrugated Board Bridge -Draped in an overlapping wave pattern to the double-backer station Purpose-Isolating the two ends of the corrugating machine; balance; slow down The double-backer section of corrugating machine where a second linerboard is applied to the single-faced material coming from the single-facer unit

二. Corrugated Board Bridge -Draped in an overlapping wave pattern to the double-backer station Purpose-Isolating the two ends of the corrugating machine; balance; slow down The double-backer section of corrugating machine where a second linerboard is applied to the single-faced material coming from the single-facer unit

二. Corrugated Board ⚫ Manufacture: ⚫ Adhesive - On the other side of the medium to glue outer linerboard. ⚫ Final heating and cooling section - Between two long , flat belts. ⚫ Trimming edges- Slit board to required width and length and stack ⚫ Balanced construction- Outer and inner have identical grammage. ⚫ Upgrading only one liner may gain performance. ⚫ Unbalanced constructions - more problems with board wrappage. ⚫ Heavier liner is placed on the outside for better printing and on the inside for better compression strength

二. Corrugated Board ⚫ Manufacture: ⚫ Adhesive - On the other side of the medium to glue outer linerboard. ⚫ Final heating and cooling section - Between two long , flat belts. ⚫ Trimming edges- Slit board to required width and length and stack ⚫ Balanced construction- Outer and inner have identical grammage. ⚫ Upgrading only one liner may gain performance. ⚫ Unbalanced constructions - more problems with board wrappage. ⚫ Heavier liner is placed on the outside for better printing and on the inside for better compression strength