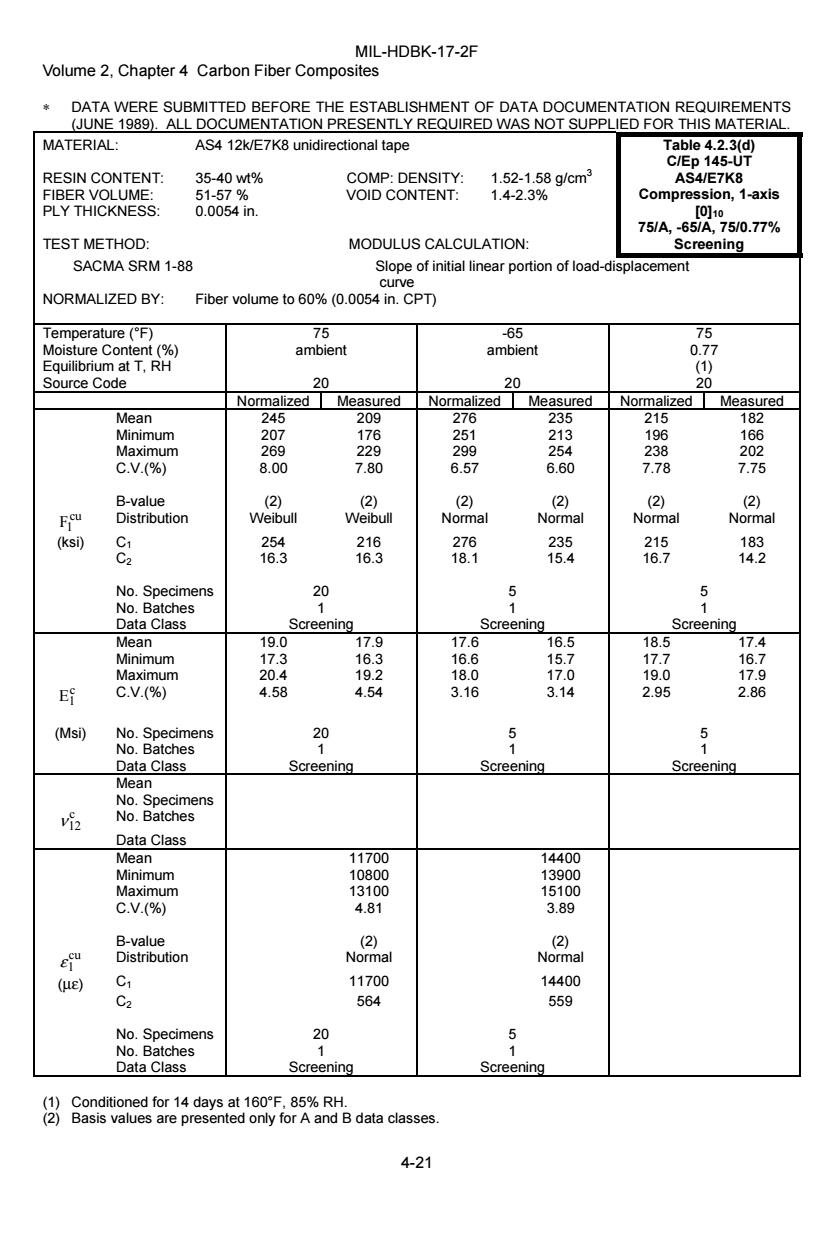

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(d) C/Ep 145-UT RESIN CONTENT: 35-40wt% COMP:DENSITY: 1.52-1.58g/cm3 AS4/E7K8 FIBER VOLUME: 51-57% VOID CONTENT: 1.4-2.3% Compression,1-axis PLY THICKNESS: 0.0054in. [0]10 75/A,-651A,75/0.77% TEST METHOD: MODULUS CALCULATION: Screening SACMA SRM 1-88 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60%(0.0054 in.CPT) Temperature (F) 75 -65 75 Moisture Content(%)】 ambient ambient 0.77 Equilibrium at T.RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 245 209 276 235 215 182 Minimum 207 176 251 213 196 166 Maximum 269 229 299 254 238 202 C.V.(%) 8.00 7.80 6.57 6.60 7.78 7.75 B-value (2) (2) (2) (2) (2) (2) Fcu Distribution Weibull Weibull Normal Normal Normal Normal (ksi) C1 254 216 276 235 215 183 C2 16.3 16.3 18.1 15.4 16.7 14.2 No.Specimens 20 5 5 No.Batches 1 1 Data Class Screening Screening Screening Mean 19.0 17.9 17.6 16.5 18.5 17.4 Minimum 17.3 16.3 16.6 15.7 17.7 16.7 Maximum 20.4 19.2 18.0 17.0 19.0 17.9 E C.V.(%) 4.58 4.54 3.16 3.14 2.95 2.86 (Msi) No.Specimens 20 ⑤ No.Batches 1 Data Class Screening Screening Screening Mean No.Specimens Vi2 No.Batches Data Class Mean 11700 14400 Minimum 10800 13900 Maximum 13100 15100 C.V.(%) 4.81 3.89 B-value (2) (2) ecu Distribution Normal Normal (LE) Ci 11700 14400 C2 564 559 No.Specimens 20 5 No.Batches 1 1 Data Class Screening Screening (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-21

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-21 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(d) C/Ep 145-UT RESIN CONTENT: 35-40 wt% COMP: DENSITY: 1.52-1.58 g/cm3 AS4/E7K8 FIBER VOLUME: 51-57 % VOID CONTENT: 1.4-2.3% Compression, 1-axis PLY THICKNESS: 0.0054 in. [0]10 75/A, -65/A, 75/0.77% TEST METHOD: MODULUS CALCULATION: Screening SACMA SRM 1-88 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60% (0.0054 in. CPT) Temperature (°F) 75 -65 75 Moisture Content (%) ambient ambient 0.77 Equilibrium at T, RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 245 209 276 235 215 182 Minimum 207 176 251 213 196 166 Maximum 269 229 299 254 238 202 C.V.(%) 8.00 7.80 6.57 6.60 7.78 7.75 B-value (2) (2) (2) (2) (2) (2) Fcu 1 Distribution Weibull Weibull Normal Normal Normal Normal (ksi) C1 254 216 276 235 215 183 C2 16.3 16.3 18.1 15.4 16.7 14.2 No. Specimens 20 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening Mean 19.0 17.9 17.6 16.5 18.5 17.4 Minimum 17.3 16.3 16.6 15.7 17.7 16.7 Maximum 20.4 19.2 18.0 17.0 19.0 17.9 Ec 1 C.V.(%) 4.58 4.54 3.16 3.14 2.95 2.86 (Msi) No. Specimens 20 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening Mean No. Specimens ν 12 c No. Batches Data Class Mean 11700 14400 Minimum 10800 13900 Maximum 13100 15100 C.V.(%) 4.81 3.89 B-value (2) (2) ε 1 cu Distribution Normal Normal (µε) C1 11700 14400 C2 564 559 No. Specimens 20 5 No. Batches 1 1 Data Class Screening Screening (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(e) C/Ep 145-UT RESIN CONTENT: 35-40wt% COMP:DENSITY: 1.52-1.58g/cm3 AS4/E7K8 FIBER VOLUME: 51-57% VOID CONTENT: 1.4-2.3% Compression,1-axis PLY THICKNESS: 0.0054in. [0]10 18010.77% TEST METHOD: MODULUS CALCULATION: Screening SACMA SRM 1-88 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60%(0.0054 in.CPT) Temperature (F) 180 Moisture Content(%)】 0.77 Equilibrium at T.RH (1) Source Code 20 Normalized Measured Normalized Measured Normalized Measured Mean 150 127 Minimum 125 106 Maximum 176 150 C.V.(%) 14.8 15.0 B-value (2) (2) Fcu Distribution Normal Normal (ksi) C1 150 127 C2 22.2 18.9 No.Specimens 5 No.Batches 1 Data Class Screening Mean 18.0 17.0 Minimum 17.4 16.4 Maximum 18.4 17.3 E C.V.(%) 2.46 2.41 (Msi) No.Specimens 5 No.Batches 1 Data Class Screening Mean No.Specimens 啦 No.Batches Data Class Mean Minimum Maximum C.V.(%) B-value ecu Distribution (LE) Ci C2 No.Specimens No.Batches Data Class (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-22

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-22 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(e) C/Ep 145-UT RESIN CONTENT: 35-40 wt% COMP: DENSITY: 1.52-1.58 g/cm3 AS4/E7K8 FIBER VOLUME: 51-57 % VOID CONTENT: 1.4-2.3% Compression, 1-axis PLY THICKNESS: 0.0054 in. [0]10 180/0.77% TEST METHOD: MODULUS CALCULATION: Screening SACMA SRM 1-88 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60% (0.0054 in. CPT) Temperature (°F) 180 Moisture Content (%) 0.77 Equilibrium at T, RH (1) Source Code 20 Normalized Measured Normalized Measured Normalized Measured Mean 150 127 Minimum 125 106 Maximum 176 150 C.V.(%) 14.8 15.0 B-value (2) (2) Fcu 1 Distribution Normal Normal (ksi) C1 150 127 C2 22.2 18.9 No. Specimens 5 No. Batches 1 Data Class Screening Mean 18.0 17.0 Minimum 17.4 16.4 Maximum 18.4 17.3 Ec 1 C.V.(%) 2.46 2.41 (Msi) No. Specimens 5 No. Batches 1 Data Class Screening Mean No. Specimens ν 12 c No. Batches Data Class Mean Minimum Maximum C.V.(%) B-value ε 1 cu Distribution (µε) C1 C2 No. Specimens No. Batches Data Class (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

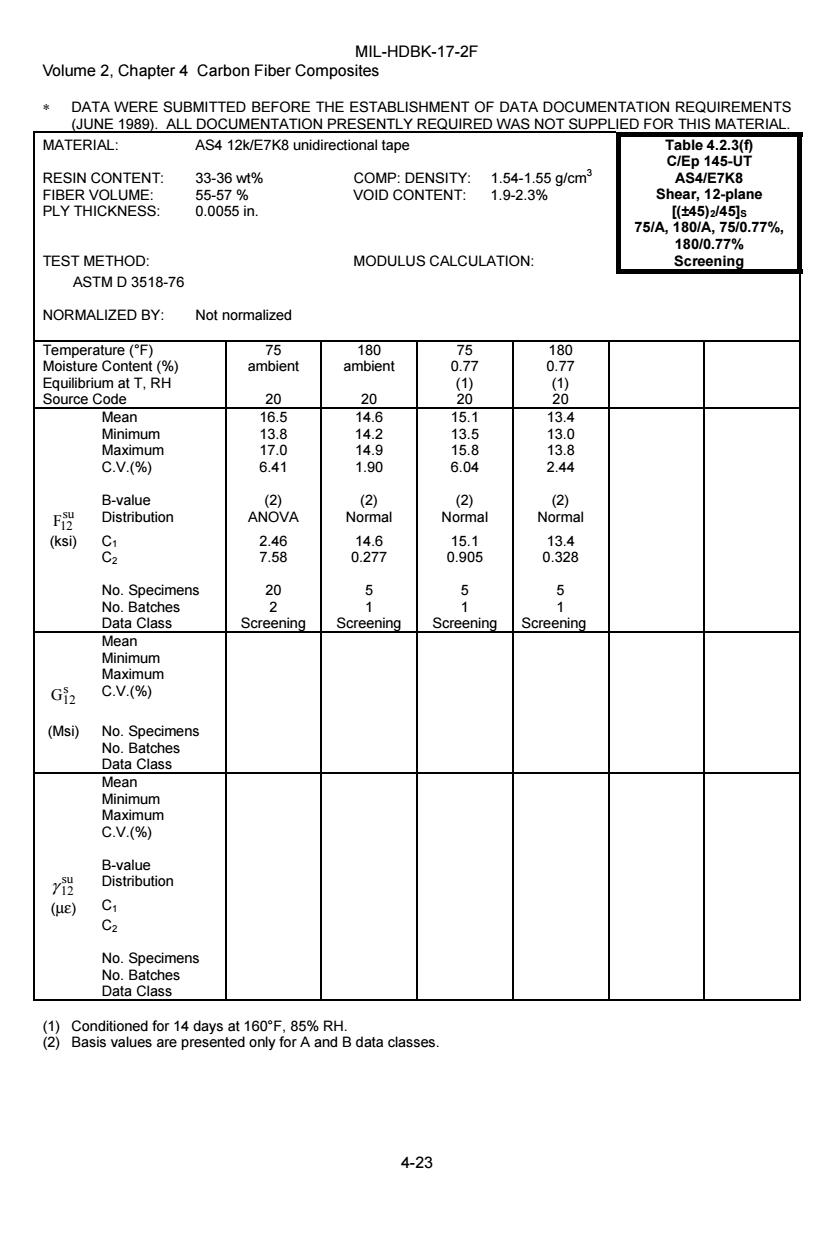

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(f) C/Ep 145-UT RESIN CONTENT: 33-36wt% COMP:DENSITY:1.54-1.55 g/cm3 AS4/E7K8 FIBER VOLUME: 55-57% VOID CONTENT:1.9-2.3% Shear,12-plane PLY THICKNESS: 0.0055in. [(±45)z/45]s 75/A,180/A,75/0.77%, 180/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3518-76 NORMALIZED BY: Not normalized Temperature(F) 75 180 75 180 Moisture Content(%) ambient ambient 0.77 0.77 Equilibrium at T,RH (1) (1) Source Code 20 20 20 20 Mean 16.5 14.6 15.1 13.4 Minimum 13.8 14.2 13.5 13.0 Maximum 17.0 14.9 15.8 13.8 C.V.(%) 6.41 1.90 6.04 2.44 B-value (2) (2) (2) (2) Distribution ANOVA Normal Normal Normal (ksi) C1 2.46 14.6 15.1 13.4 C2 7.58 0.277 0.905 0.328 No.Specimens 20 5 5 5 No.Batches 2 1 1 Data Class Screening Screening Screening Screening Mean Minimum Maximum Gi2 c.V.(%) (Msi) No.Specimens No.Batches Data Class Mean Minimum Maximum C.V.(%) B-value Distribution (uE) C1 C2 No.Specimens No.Batches Data Class (1) Conditioned for 14 days at 160F,85%RH. (2)Basis values are presented only for A and B data classes. 4-23

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-23 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(f) C/Ep 145-UT RESIN CONTENT: 33-36 wt% COMP: DENSITY: 1.54-1.55 g/cm3 AS4/E7K8 FIBER VOLUME: 55-57 % VOID CONTENT: 1.9-2.3% Shear, 12-plane PLY THICKNESS: 0.0055 in. [(±45)2/45]S 75/A, 180/A, 75/0.77%, 180/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3518-76 NORMALIZED BY: Not normalized Temperature (°F) 75 180 75 180 Moisture Content (%) ambient ambient 0.77 0.77 Equilibrium at T, RH (1) (1) Source Code 20 20 20 20 Mean 16.5 14.6 15.1 13.4 Minimum 13.8 14.2 13.5 13.0 Maximum 17.0 14.9 15.8 13.8 C.V.(%) 6.41 1.90 6.04 2.44 B-value (2) (2) (2) (2) Fsu 12 Distribution ANOVA Normal Normal Normal (ksi) C1 2.46 14.6 15.1 13.4 C2 7.58 0.277 0.905 0.328 No. Specimens 20 5 5 5 No. Batches 2 1 1 1 Data Class Screening Screening Screening Screening Mean Minimum Maximum Gs 12 C.V.(%) (Msi) No. Specimens No. Batches Data Class Mean Minimum Maximum C.V.(%) B-value γ 12 su Distribution (µε) C1 C2 No. Specimens No. Batches Data Class (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

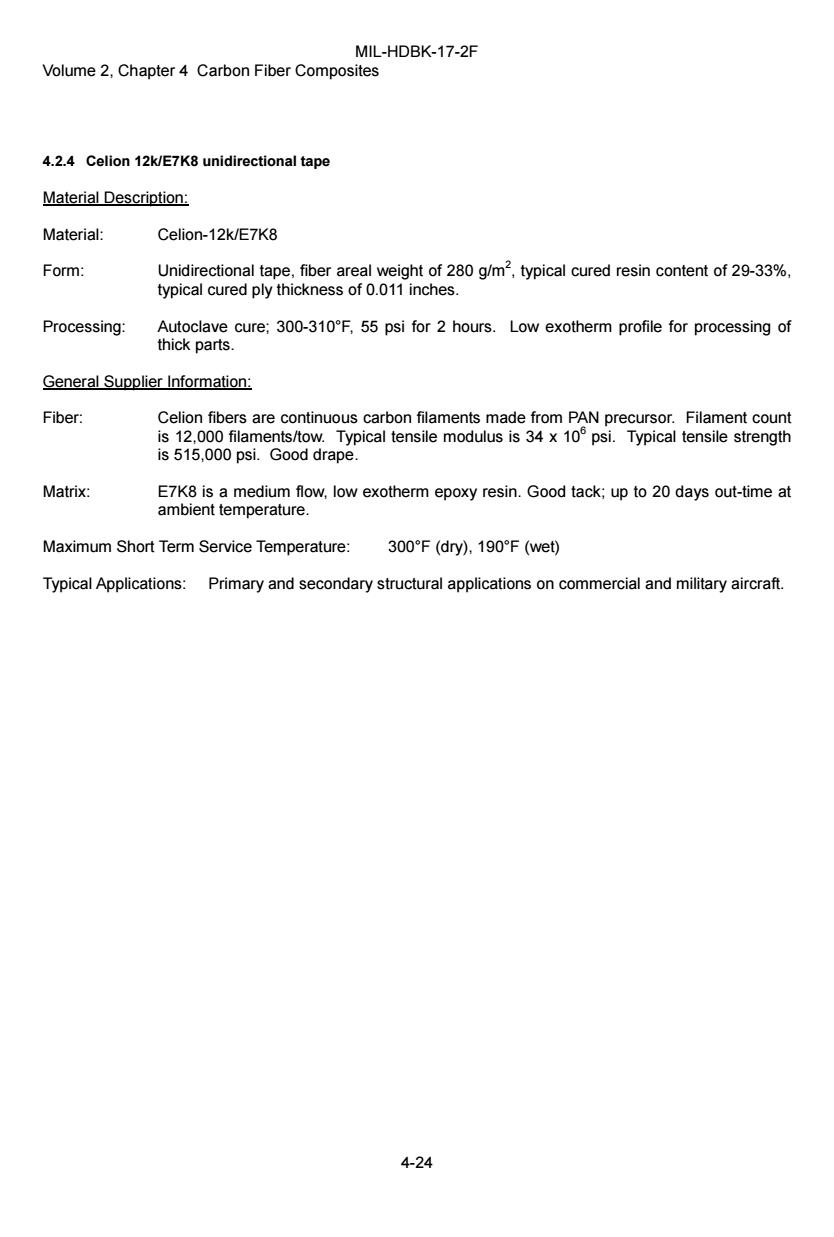

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites 4.2.4 Celion 12k/E7K8 unidirectional tape Material Description: Material: Celion-12k/E7K8 Form: Unidirectional tape,fiber areal weight of 280 g/m2,typical cured resin content of 29-33%, typical cured ply thickness of 0.011 inches. Processing: Autoclave cure:300-310F,55 psi for 2 hours.Low exotherm profile for processing of thick parts. General Supplier Information: Fiber: Celion fibers are continuous carbon filaments made from PAN precursor.Filament count is 12,000 filaments/tow.Typical tensile modulus is 34 x 10 psi.Typical tensile strength is 515,000 psi.Good drape. Matrix: E7K8 is a medium flow,low exotherm epoxy resin.Good tack;up to 20 days out-time at ambient temperature. Maximum Short Term Service Temperature: 300℉(dry),190°F(wet) Typical Applications:Primary and secondary structural applications on commercial and military aircraft. 4-24

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-24 4.2.4 Celion 12k/E7K8 unidirectional tape Material Description: Material: Celion-12k/E7K8 Form: Unidirectional tape, fiber areal weight of 280 g/m2 , typical cured resin content of 29-33%, typical cured ply thickness of 0.011 inches. Processing: Autoclave cure; 300-310°F, 55 psi for 2 hours. Low exotherm profile for processing of thick parts. General Supplier Information: Fiber: Celion fibers are continuous carbon filaments made from PAN precursor. Filament count is 12,000 filaments/tow. Typical tensile modulus is 34 x 106 psi. Typical tensile strength is 515,000 psi. Good drape. Matrix: E7K8 is a medium flow, low exotherm epoxy resin. Good tack; up to 20 days out-time at ambient temperature. Maximum Short Term Service Temperature: 300°F (dry), 190°F (wet) Typical Applications: Primary and secondary structural applications on commercial and military aircraft

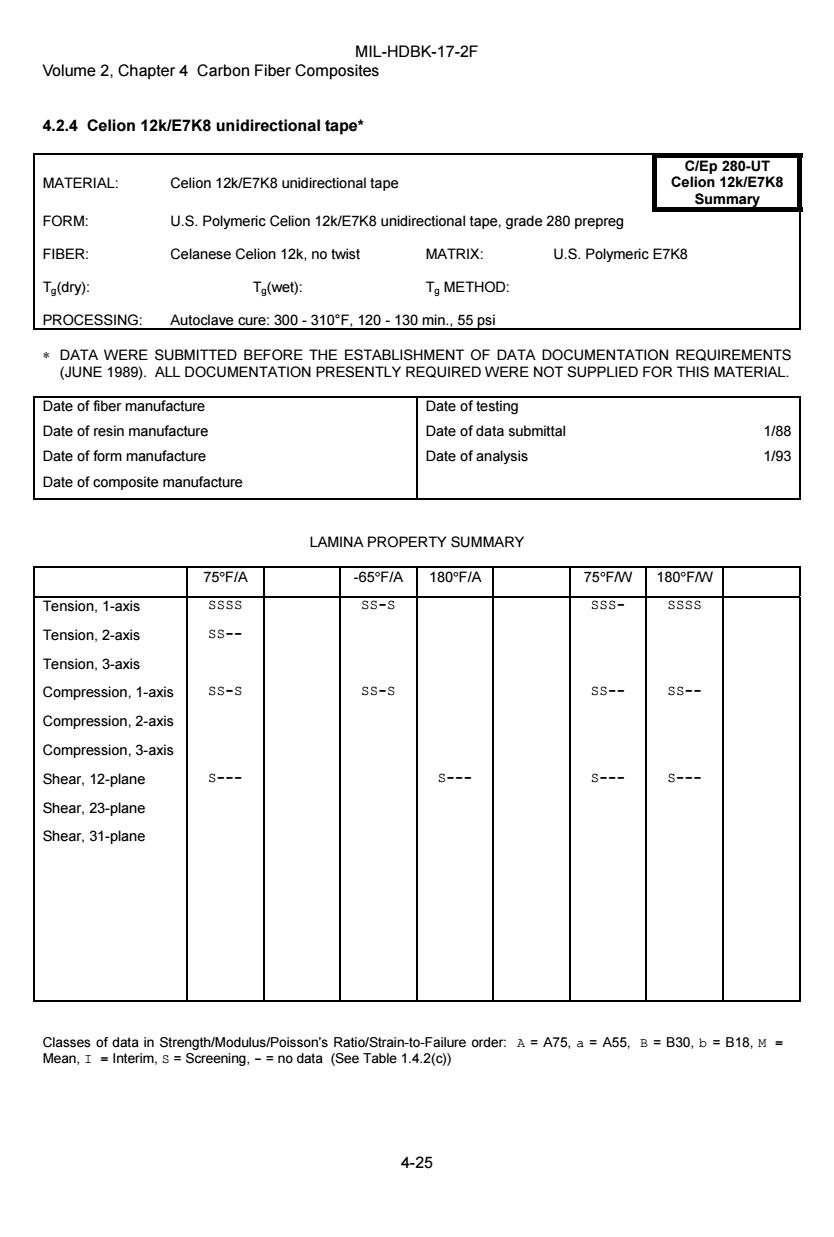

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites 4.2.4 Celion 12k/E7K8 unidirectional tape* C/Ep 280-UT MATERIAL: Celion 12k/E7K8 unidirectional tape Celion 12k/E7K8 Summary FORM: U.S.Polymeric Celion 12k/E7K8 unidirectional tape,grade 280 prepreg FIBER: Celanese Celion 12k,no twist MATRIX: U.S.Polymeric E7K8 Tg(dry): Tg(wet): Ta METHOD: PROCESSING:Autoclave cure:300-310F,120-130 min.,55 psi DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Date of fiber manufacture Date of testing Date of resin manufacture Date of data submittal 1/88 Date of form manufacture Date of analysis 1/93 Date of composite manufacture LAMINA PROPERTY SUMMARY 75F1A -65F/A 180F/A 75F/W 180FW Tension,1-axis SSSS SS-S SSS- SSSS Tension,2-axis s$-- Tension,3-axis Compression,1-axis SS-S SS-S SS-- SS-- Compression,2-axis Compression,3-axis Shear,12-plane S--- S--- $--- S-- Shear,23-plane Shear,31-plane Classes of data in Strength/Modulus/Poisson's Ratio/Strain-to-Failure order:A A75,a A55,B=B30,b=B18,M Mean,I Interim,s=Screening,-=no data (See Table 1.4.2(c)) 4-25

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-25 4.2.4 Celion 12k/E7K8 unidirectional tape* C/Ep 280-UT MATERIAL: Celion 12k/E7K8 unidirectional tape Celion 12k/E7K8 Summary FORM: U.S. Polymeric Celion 12k/E7K8 unidirectional tape, grade 280 prepreg FIBER: Celanese Celion 12k, no twist MATRIX: U.S. Polymeric E7K8 Tg(dry): Tg(wet): Tg METHOD: PROCESSING: Autoclave cure: 300 - 310°F, 120 - 130 min., 55 psi ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Date of fiber manufacture Date of testing Date of resin manufacture Date of data submittal 1/88 Date of form manufacture Date of analysis 1/93 Date of composite manufacture LAMINA PROPERTY SUMMARY 75°F/A -65°F/A 180°F/A 75°F/W 180°F/W Tension, 1-axis SSSS SS-S SSS- SSSS Tension, 2-axis SS-- Tension, 3-axis Compression, 1-axis SS-S SS-S SS-- SS-- Compression, 2-axis Compression, 3-axis Shear, 12-plane S--- S--- S--- S--- Shear, 23-plane Shear, 31-plane Classes of data in Strength/Modulus/Poisson’s Ratio/Strain-to-Failure order: A = A75, a = A55, B = B30, b = B18, M = Mean, I = Interim, S = Screening, - = no data (See Table 1.4.2(c))