MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites 4.2.3 AS4 12k/E7K8 unidirectional tape* C/Ep 145-UT MATERIAL: AS4 12k/E7K8 unidirectional tape AS4/E7K8 Summary FORM: U.S.Polymeric AS4 12k/E7K8 unidirectional tape prepreg FIBER: Hercules AS4 12k MATRIX: U.S.Polymeric E7K8 Tg(dry): Tg(wet): Ta METHOD: PROCESSING:Autoclave cure:300-310F,120-130 min.,55 psi DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Date of fiber manufacture Date of testing Date of resin manufacture Date of data submittal 1/88 Date of form manufacture Date of analysis 1/93 Date of composite manufacture LAMINA PROPERTY SUMMARY 75F1A -65F/A 180F/A 75FN 180FW Tension,1-axis SSSS SS-S SSSS SSSS Tension.2-axis SS-- Tension,3-axis Compression,1-axis SS-S SS-S SS-- SS-- Compression,2-axis Compression,3-axis Shear,12-plane S--- S--- S--- S--- Shear,23-plane Shear,31-plane Classes of data in Strength/Modulus/Poisson's Ratio/Strain-to-Failure order:A A75,a A55,B=B30,b=B18,M Mean,I Interim,s=Screening,-=no data (See Table 1.4.2(c)) 4-16

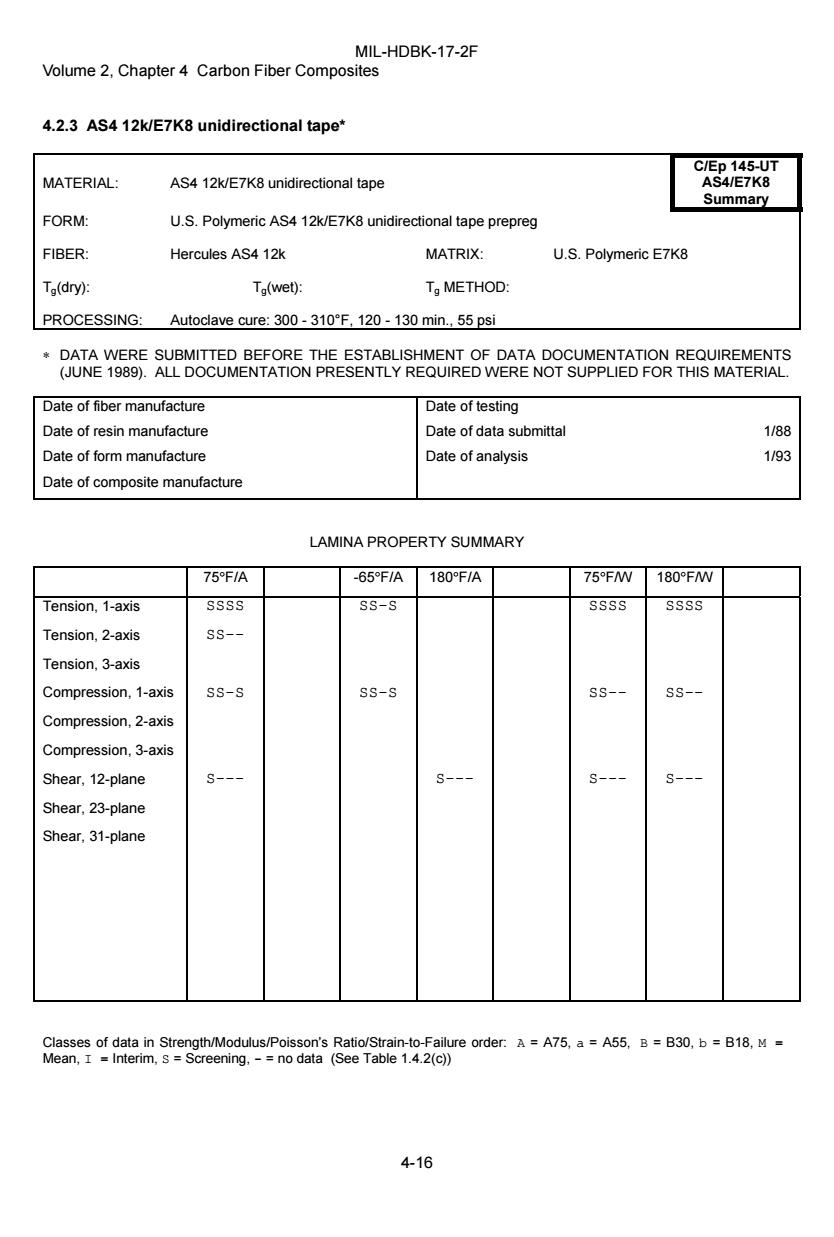

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-16 4.2.3 AS4 12k/E7K8 unidirectional tape* C/Ep 145-UT MATERIAL: AS4 12k/E7K8 unidirectional tape AS4/E7K8 Summary FORM: U.S. Polymeric AS4 12k/E7K8 unidirectional tape prepreg FIBER: Hercules AS4 12k MATRIX: U.S. Polymeric E7K8 Tg(dry): Tg(wet): Tg METHOD: PROCESSING: Autoclave cure: 300 - 310°F, 120 - 130 min., 55 psi ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Date of fiber manufacture Date of testing Date of resin manufacture Date of data submittal 1/88 Date of form manufacture Date of analysis 1/93 Date of composite manufacture LAMINA PROPERTY SUMMARY 75°F/A -65°F/A 180°F/A 75°F/W 180°F/W Tension, 1-axis SSSS SS-S SSSS SSSS Tension, 2-axis SS-- Tension, 3-axis Compression, 1-axis SS-S SS-S SS-- SS-- Compression, 2-axis Compression, 3-axis Shear, 12-plane S--- S--- S--- S--- Shear, 23-plane Shear, 31-plane Classes of data in Strength/Modulus/Poisson’s Ratio/Strain-to-Failure order: A = A75, a = A55, B = B30, b = B18, M = Mean, I = Interim, S = Screening, - = no data (See Table 1.4.2(c))

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Nominal As Submitted Test Method Fiber Density (g/cm) 1.80 Resin Density (g/cm) 1.28 Composite Density (g/cm3) 1.59 1.52-1.59 Fiber Areal Weight (g1m3) 145 Fiber Volume (%) 59.6 53-60 Ply Thickness (in) 0.0054 0.0054-0.0057 LAMINATE PROPERTY SUMMARY Classes of data in Strength/Modulus/Poisson's Ratio/Strain-to-Failure order:A=A75,a A55,B=B30,b=B18,M Mean,I Interim,s Screening,-no data (See Table 1.4.2(c)) 4-17

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-17 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WERE NOT SUPPLIED FOR THIS MATERIAL. Nominal As Submitted Test Method Fiber Density (g/cm3 ) 1.80 Resin Density (g/cm3 ) 1.28 Composite Density (g/cm3 ) 1.59 1.52 - 1.59 Fiber Areal Weight (g/m2 ) 145 Fiber Volume (%) 59.6 53 - 60 Ply Thickness (in) 0.0054 0.0054 - 0.0057 LAMINATE PROPERTY SUMMARY Classes of data in Strength/Modulus/Poisson’s Ratio/Strain-to-Failure order: A = A75, a = A55, B = B30, b = B18, M = Mean, I = Interim, S = Screening, - = no data (See Table 1.4.2(c))

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(a) C/Ep 145-UT RESIN CONTENT: 32-37wt% COMP:DENSITY: 1.53-1.59g/cm3 AS4/E7K8 FIBER VOLUME: 53-60% VOID CONTENT: 0.64-2.2% Tension,1-axis PLY THICKNESS: 0.0054in. [0]10 75/A,-651A,75/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTMD 3039-76 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60%(0.0054 in.CPT) Temperature (F) 75 -65 75 Moisture Content(%)】 ambient ambient 0.77 Equilibrium at T.RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 303 293 291 273 304 294 Minimum 253 252 255 239 286 276 Maximum 345 347 327 306 317 306 c.V.(%) 8.26 8.94 8.93 8.90 4.16 4.22 B-value (2) (2) (2) (2) (2) (2) Fu Distribution ANOVA ANOVA Normal Normal Normal Normal (ksi) C1 26.7 32.4 291 273 304 294 C2 4.40 7.49 26.0 24.4 12.7 12.2 No.Specimens 20 5 5 No.Batches 2 1 Data Class Screening Screening Screening Mean 19.3 18.7 20.1 18.8 19.6 18.9 Minimum 18.5 17.4 19.7 18.4 19.0 18.4 Maximum 21.3 21.4 20.6 19.3 20.1 19.4 E时 C.V.(%) 3.79 6.10 1.67 1.79 2.04 1.96 (Msi) No.Specimens 20 ⑤ No.Batches Data Class Screening Screening Screening Mean 0.320 0.288 No.Specimens 啦 No.Batches Data Class Screening Screening Mean 13900 13500 14600 Minimum 12500 12000 13700 Maximum 16000 14800 15000 C.V.(%) 11.0 8.24 3.83 B-value (2) (2) (2) e Distribution Normal Normal Normal (LE) C1 13900 13500 14600 C2 1530 1110 561 No.Specimens 5 5 5 No.Batches 1 1 1 Data Class Screening Screening Screening (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-18

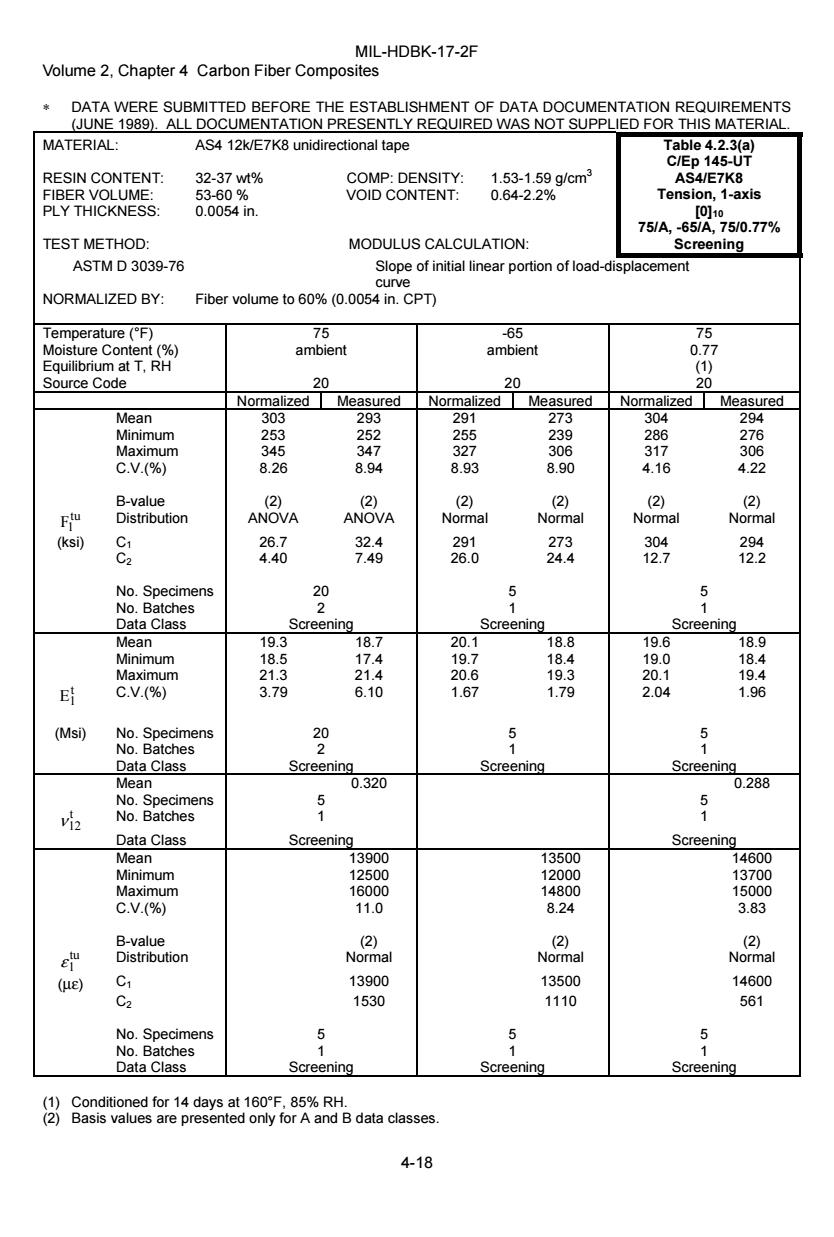

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-18 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(a) C/Ep 145-UT RESIN CONTENT: 32-37 wt% COMP: DENSITY: 1.53-1.59 g/cm3 AS4/E7K8 FIBER VOLUME: 53-60 % VOID CONTENT: 0.64-2.2% Tension, 1-axis PLY THICKNESS: 0.0054 in. [0]10 75/A, -65/A, 75/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60% (0.0054 in. CPT) Temperature (°F) 75 -65 75 Moisture Content (%) ambient ambient 0.77 Equilibrium at T, RH (1) Source Code 20 20 20 Normalized Measured Normalized Measured Normalized Measured Mean 303 293 291 273 304 294 Minimum 253 252 255 239 286 276 Maximum 345 347 327 306 317 306 C.V.(%) 8.26 8.94 8.93 8.90 4.16 4.22 B-value (2) (2) (2) (2) (2) (2) Ftu 1 Distribution ANOVA ANOVA Normal Normal Normal Normal (ksi) C1 26.7 32.4 291 273 304 294 C2 4.40 7.49 26.0 24.4 12.7 12.2 No. Specimens 20 5 5 No. Batches 2 1 1 Data Class Screening Screening Screening Mean 19.3 18.7 20.1 18.8 19.6 18.9 Minimum 18.5 17.4 19.7 18.4 19.0 18.4 Maximum 21.3 21.4 20.6 19.3 20.1 19.4 Et 1 C.V.(%) 3.79 6.10 1.67 1.79 2.04 1.96 (Msi) No. Specimens 20 5 5 No. Batches 2 1 1 Data Class Screening Screening Screening Mean 0.320 0.288 No. Specimens 5 5 ν 12 t No. Batches 1 1 Data Class Screening Screening Mean 13900 13500 14600 Minimum 12500 12000 13700 Maximum 16000 14800 15000 C.V.(%) 11.0 8.24 3.83 B-value (2) (2) (2) ε 1 tu Distribution Normal Normal Normal (µε) C1 13900 13500 14600 C2 1530 1110 561 No. Specimens 5 5 5 No. Batches 1 1 1 Data Class Screening Screening Screening (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(b) C/Ep 145-UT RESIN CONTENT: 32-37wt% COMP:DENSITY: 1.53-1.59g/cm3 AS4/E7K8 FIBER VOLUME: 53-60% VOID CONTENT: 0.64-2.2% Tension,1-axis PLY THICKNESS: 0.0054in. [0]10 180/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60%(0.0054 in.CPT) Temperature (F) 180 Moisture Content(%) 0.77 Equilibrium at T.RH (1) Source Code 20 Normalized Measured Normalized Measured Normalized Measured Mean 310 296 Minimum 284 274 Maximum 326 306 C.V.(%) 5.87 4.76 B-value (2) (2) Fu Distribution Normal Normal (ksi) C1 310 296 C2 18.2 13.9 No.Specimens 5 No.Batches 1 Data Class Screening Mean 20.1 19.2 Minimum 19.1 18.5 Maximum 21.8 20.4 E时 C.V.(%) 5.65 4.01 (Msi) No.Specimens 5 No.Batches Data Class Screening Mean 0.288 No.Specimens 啦 No.Batches Data Class Screening Mean 14600 Minimum 13900 Maximum 15400 C.V.(%) 4.21 B-value (2) e Distribution Normal (LE) Ci 14600 C2 616 No.Specimens 5 No.Batches 1 Data Class Screening (1) Conditioned for 14 days at 160F,85%RH. (2) Basis values are presented only for A and B data classes. 4-19

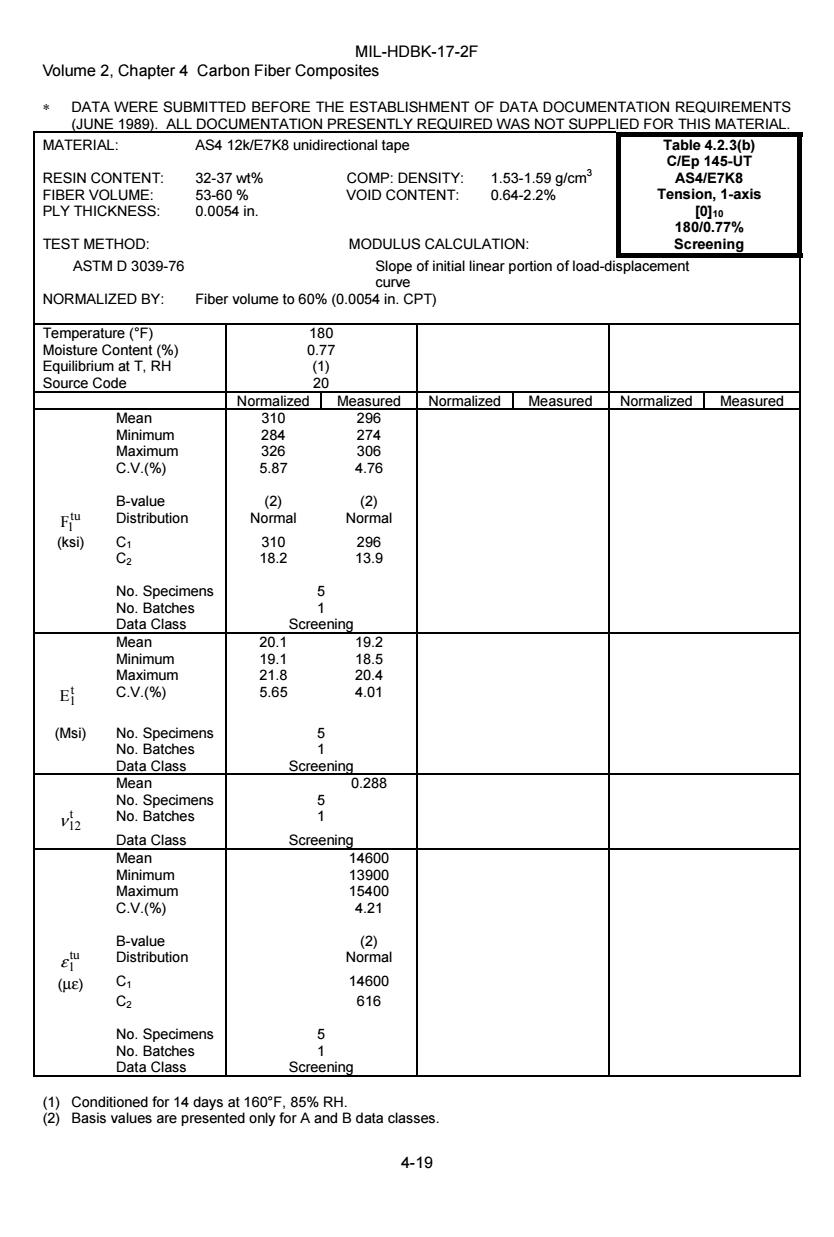

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-19 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(b) C/Ep 145-UT RESIN CONTENT: 32-37 wt% COMP: DENSITY: 1.53-1.59 g/cm3 AS4/E7K8 FIBER VOLUME: 53-60 % VOID CONTENT: 0.64-2.2% Tension, 1-axis PLY THICKNESS: 0.0054 in. [0]10 180/0.77% TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Fiber volume to 60% (0.0054 in. CPT) Temperature (°F) 180 Moisture Content (%) 0.77 Equilibrium at T, RH (1) Source Code 20 Normalized Measured Normalized Measured Normalized Measured Mean 310 296 Minimum 284 274 Maximum 326 306 C.V.(%) 5.87 4.76 B-value (2) (2) Ftu 1 Distribution Normal Normal (ksi) C1 310 296 C2 18.2 13.9 No. Specimens 5 No. Batches 1 Data Class Screening Mean 20.1 19.2 Minimum 19.1 18.5 Maximum 21.8 20.4 Et 1 C.V.(%) 5.65 4.01 (Msi) No. Specimens 5 No. Batches 1 Data Class Screening Mean 0.288 No. Specimens 5 ν 12 t No. Batches 1 Data Class Screening Mean 14600 Minimum 13900 Maximum 15400 C.V.(%) 4.21 B-value (2) ε 1 tu Distribution Normal (µε) C1 14600 C2 616 No. Specimens 5 No. Batches 1 Data Class Screening (1) Conditioned for 14 days at 160°F, 85% RH. (2) Basis values are presented only for A and B data classes

MIL-HDBK-17-2F Volume 2,Chapter 4 Carbon Fiber Composites DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989).ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(c) C/Ep 145-UT RESIN CONTENT: 32-38wt% COMP:DENSITY:1.54-1.59 g/cm3 AS4/E7K8 FIBER VOLUME: 53-60% VOID CONTENT:0.64-0.75% Tension,2-axis PLY THICKNESS: 0.0057in. [90]20 75/A TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Not normalized Temperature (F) 75 Moisture Content(%)】 ambient Equilibrium at T.RH Source Code 20 Mean 5.47 Minimum 4.10 Maximum 7.01 C.V.(%) 13.2 B-value (1) Fu Distribution Weibull (ksi) C1 5.79 C2 8.04 No.Specimens 20 No.Batches 1 Data Class Screening Mean 1.23 Minimum 1.16 Maximum 1.32 E吃 C.V.(%) 3.76 (Msi) No.Specimens 20 No.Batches 1 Data Class Screening Mean No.Specimens No.Batches Data Class Mean Minimum Maximum C.V.(%) B-value e Distribution (LE) C1 C2 No.Specimens No.Batches Data Class (1)Basis values are presented only for A and B data classes. 4-20

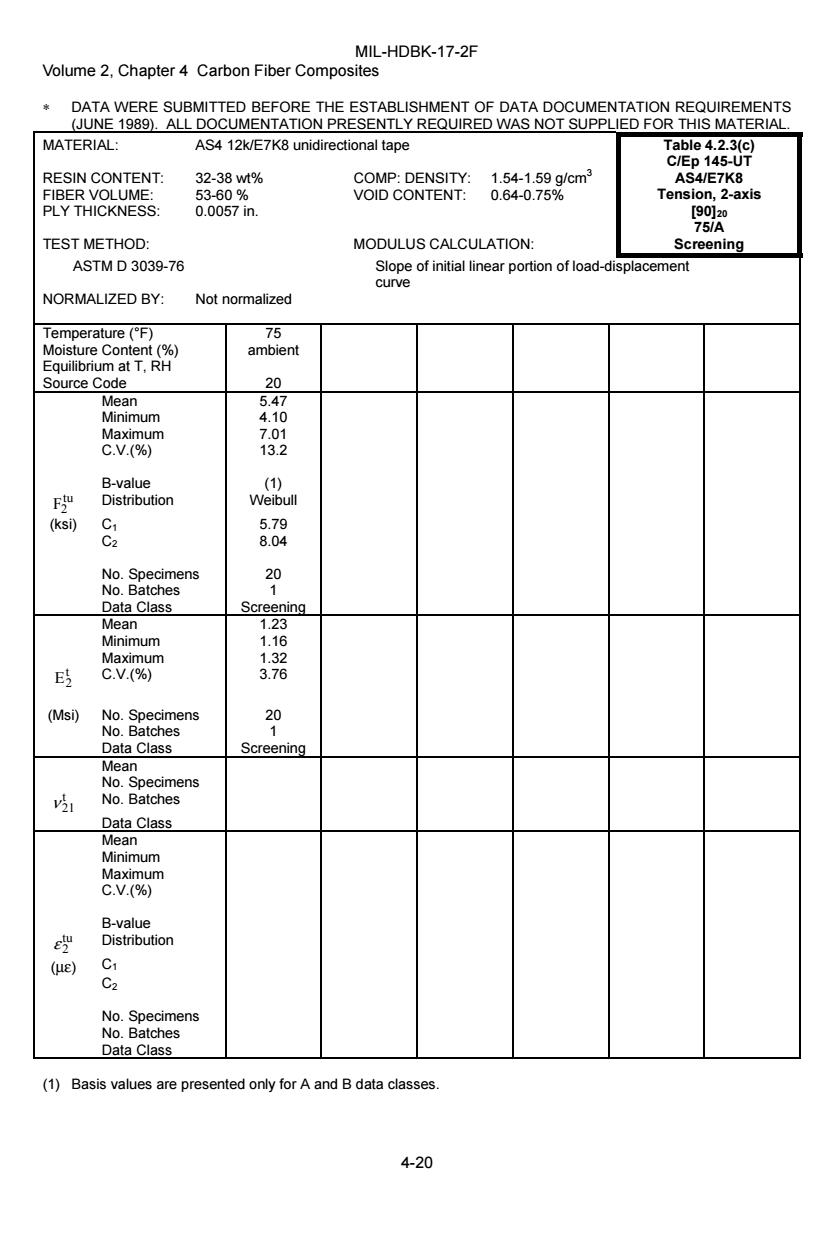

MIL-HDBK-17-2F Volume 2, Chapter 4 Carbon Fiber Composites 4-20 ∗ DATA WERE SUBMITTED BEFORE THE ESTABLISHMENT OF DATA DOCUMENTATION REQUIREMENTS (JUNE 1989). ALL DOCUMENTATION PRESENTLY REQUIRED WAS NOT SUPPLIED FOR THIS MATERIAL. MATERIAL: AS4 12k/E7K8 unidirectional tape Table 4.2.3(c) C/Ep 145-UT RESIN CONTENT: 32-38 wt% COMP: DENSITY: 1.54-1.59 g/cm3 AS4/E7K8 FIBER VOLUME: 53-60 % VOID CONTENT: 0.64-0.75% Tension, 2-axis PLY THICKNESS: 0.0057 in. [90]20 75/A TEST METHOD: MODULUS CALCULATION: Screening ASTM D 3039-76 Slope of initial linear portion of load-displacement curve NORMALIZED BY: Not normalized Temperature (°F) 75 Moisture Content (%) ambient Equilibrium at T, RH Source Code 20 Mean 5.47 Minimum 4.10 Maximum 7.01 C.V.(%) 13.2 B-value (1) Ftu 2 Distribution Weibull (ksi) C1 5.79 C2 8.04 No. Specimens 20 No. Batches 1 Data Class Screening Mean 1.23 Minimum 1.16 Maximum 1.32 Et 2 C.V.(%) 3.76 (Msi) No. Specimens 20 No. Batches 1 Data Class Screening Mean No. Specimens ν 21 t No. Batches Data Class Mean Minimum Maximum C.V.(%) B-value ε 2 tu Distribution (µε) C1 C2 No. Specimens No. Batches Data Class (1) Basis values are presented only for A and B data classes